Starter generator

A technology for starters and generators, which is applied to engine components, engine ignition, machines/engines, etc. It can solve problems such as difficult to improve rotor detection accuracy, and difficult to improve the relative positional relationship accuracy of rotation angle sensors, so as to achieve manufacturing and realization Facilitation and space utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

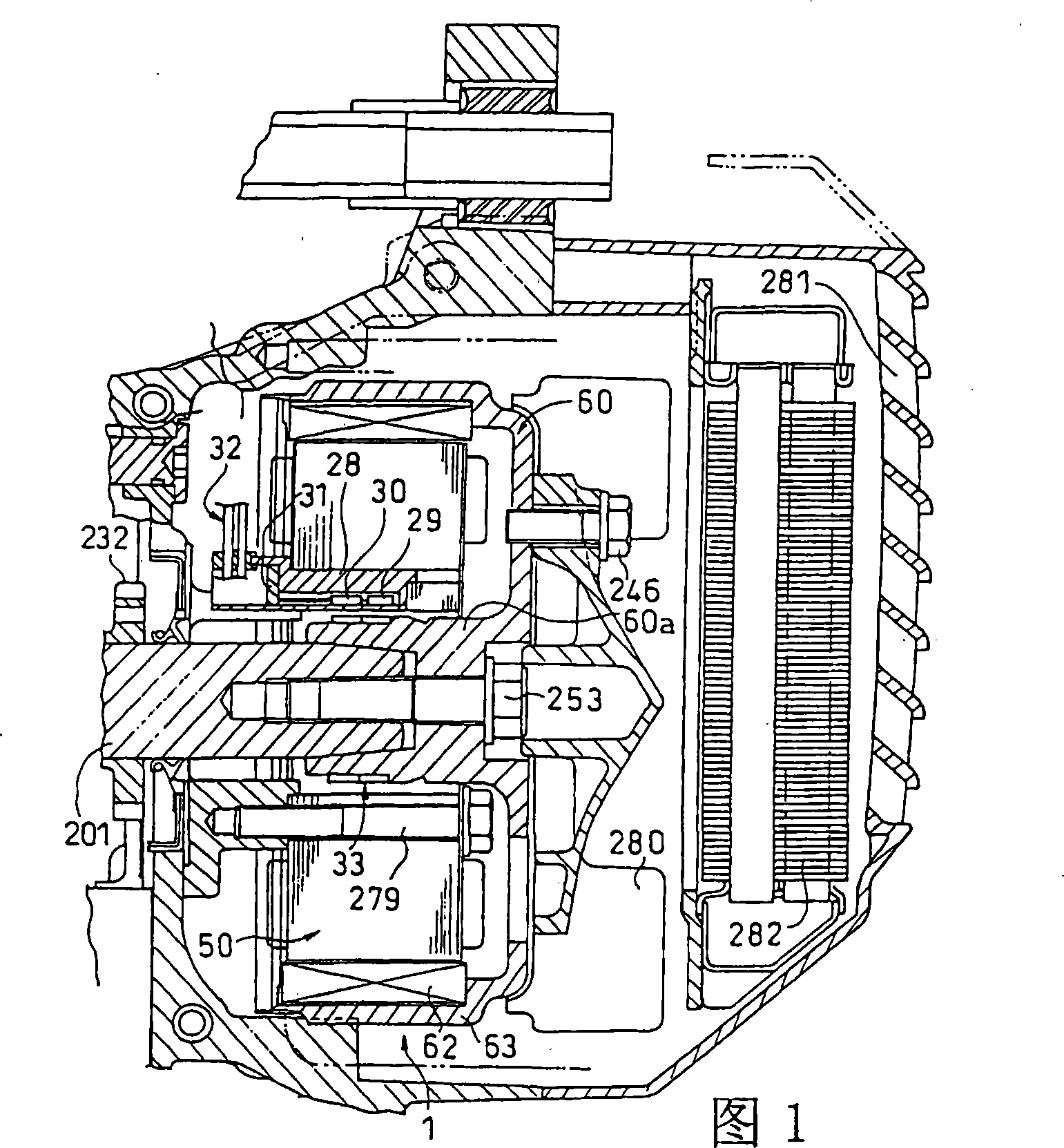

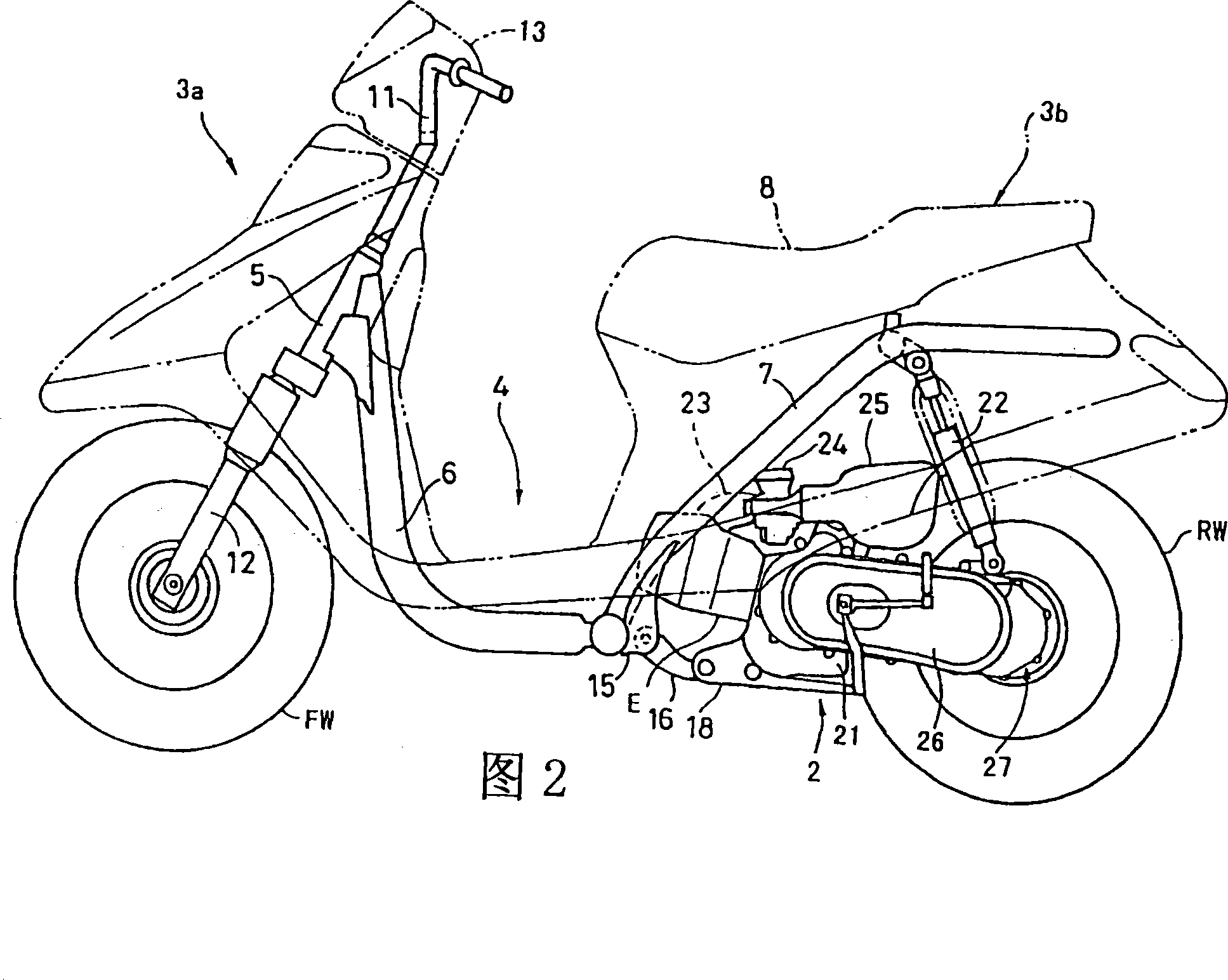

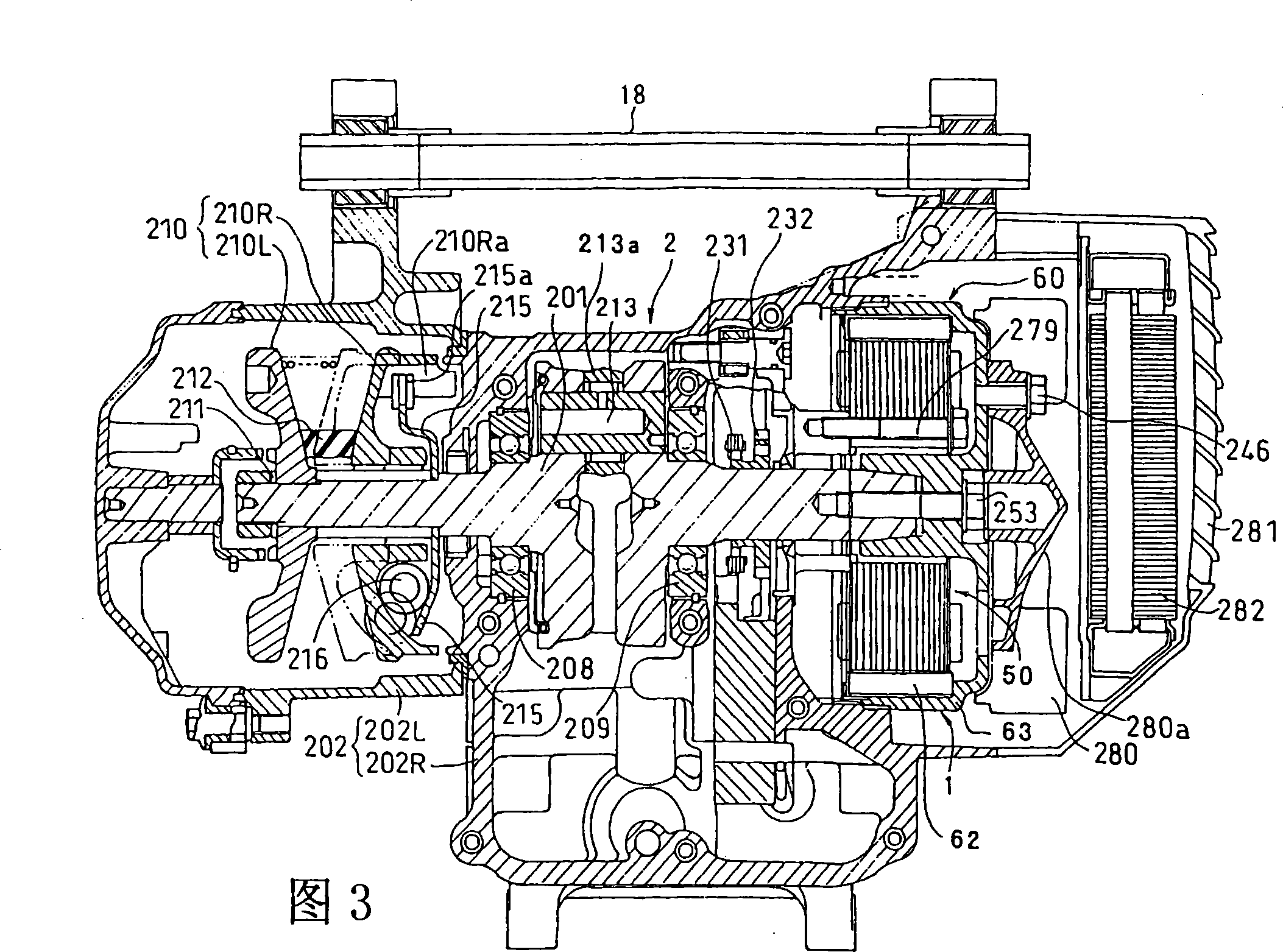

[0041] An embodiment of the present invention will be described below with reference to the drawings. Fig. 2 is a side perspective view of a scooter-type motorcycle equipped with a starter-generator according to an embodiment of the present invention. In this figure, the vehicle body front part 3a and the vehicle body rear part 3b are connected by the low floor part 4, and the vehicle body frame constituting the vehicle body frame mainly includes a downpipe 6 and a main pipe 7. A seat 8 is arranged above a fuel tank and a storage box (both not shown) supported by the main pipe 7 .

[0042] A handle 11 extending upward and a front fork 12 extending downward are rotatably supported on a steering head 5 at the front of the vehicle body, and a front wheel FW is pivotally supported on the lower end of the front fork 12 . The upper part of the handle 11 is covered with a handle cover 13 containing the instrument panel. A support 15 is provided at the lower end of the upright porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com