Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308results about How to "Increase slot fill rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

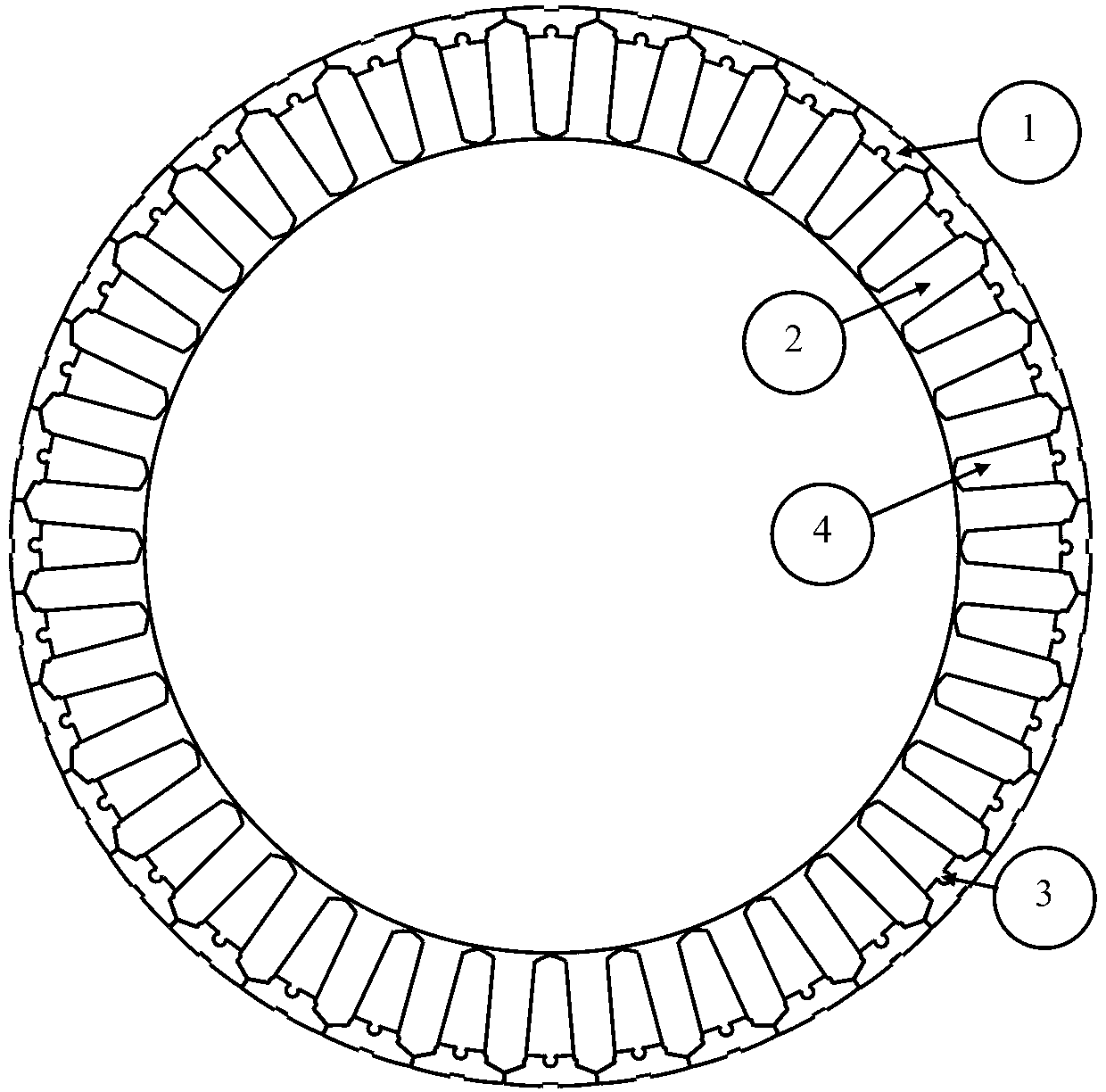

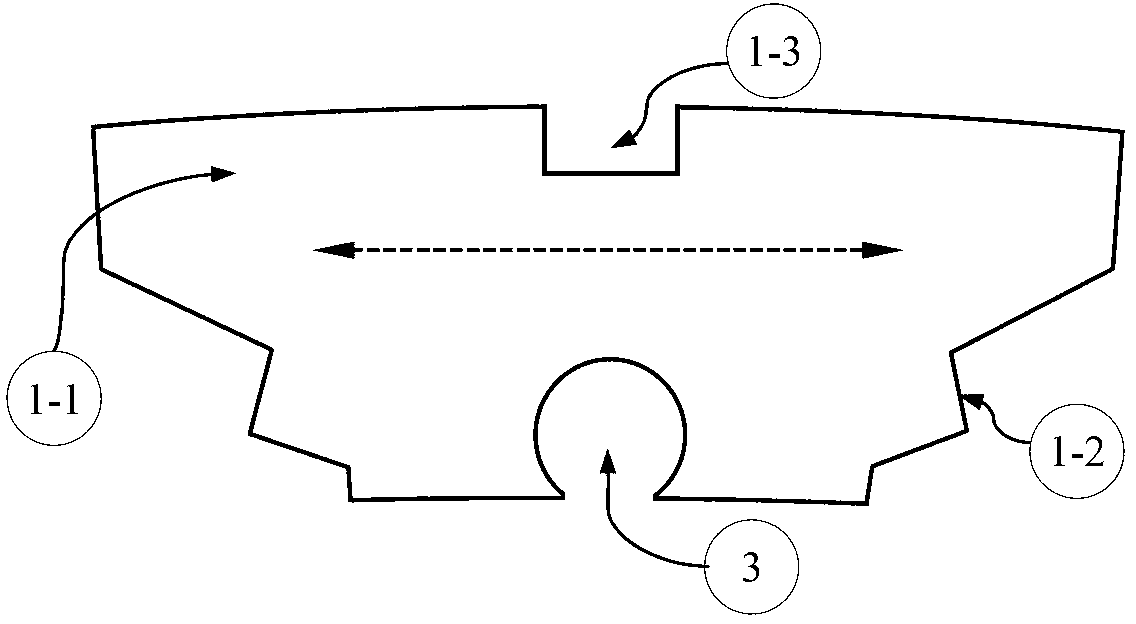

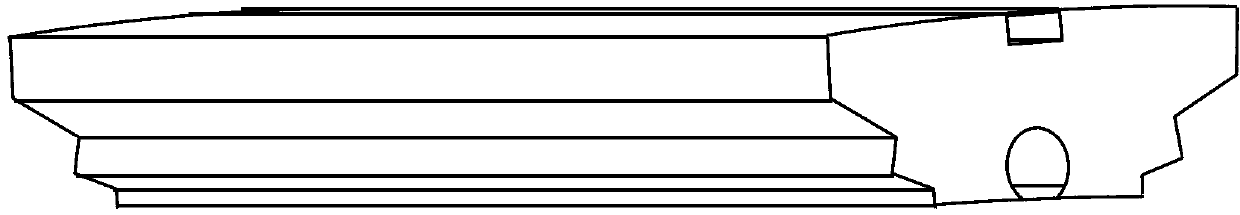

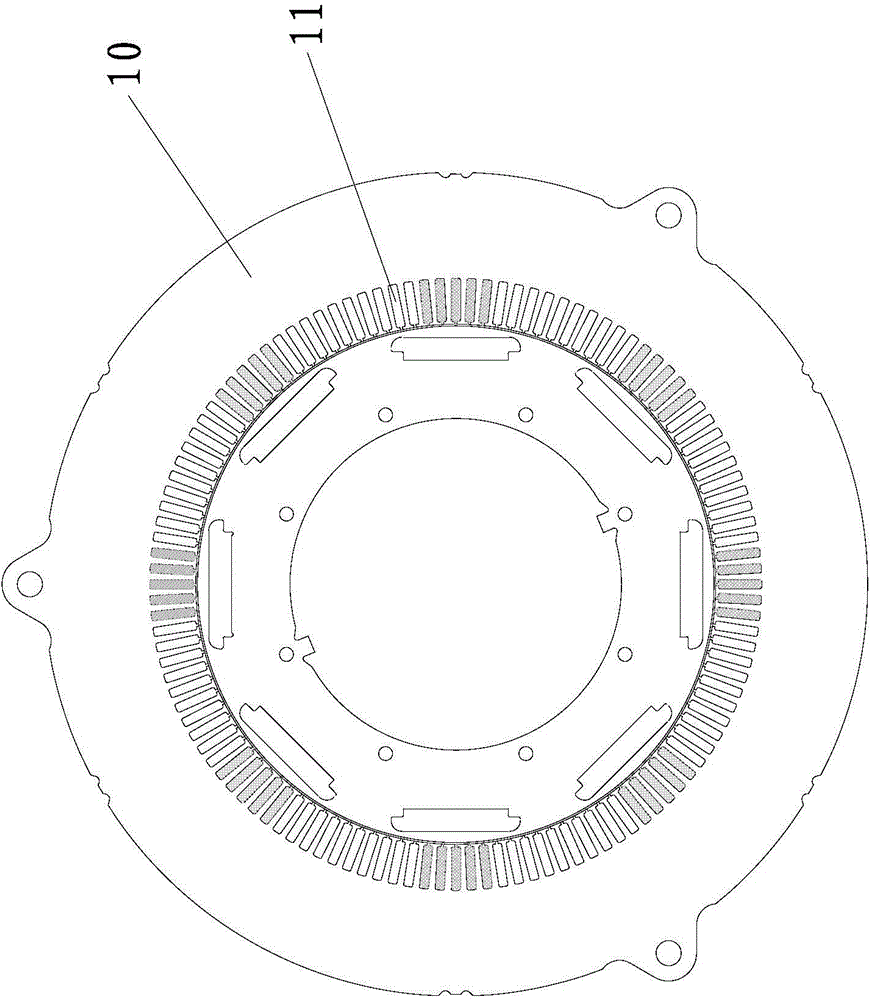

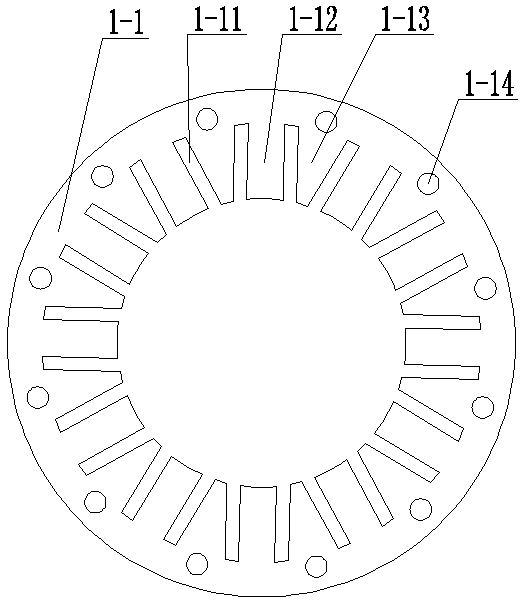

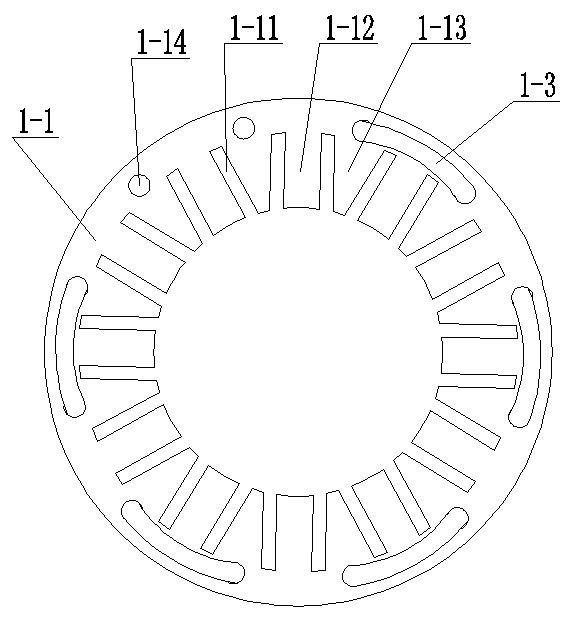

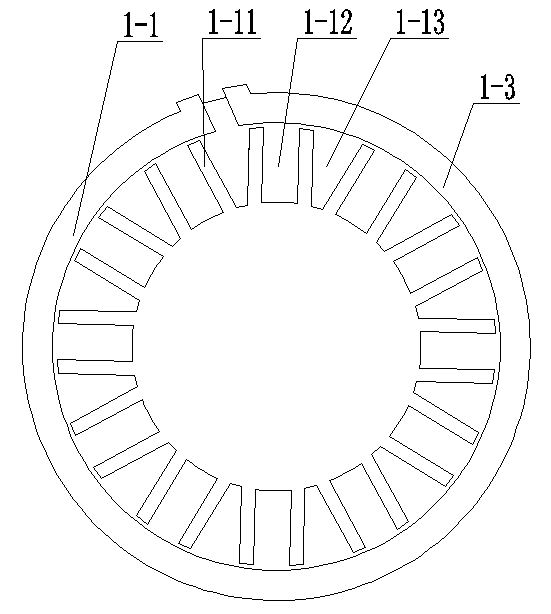

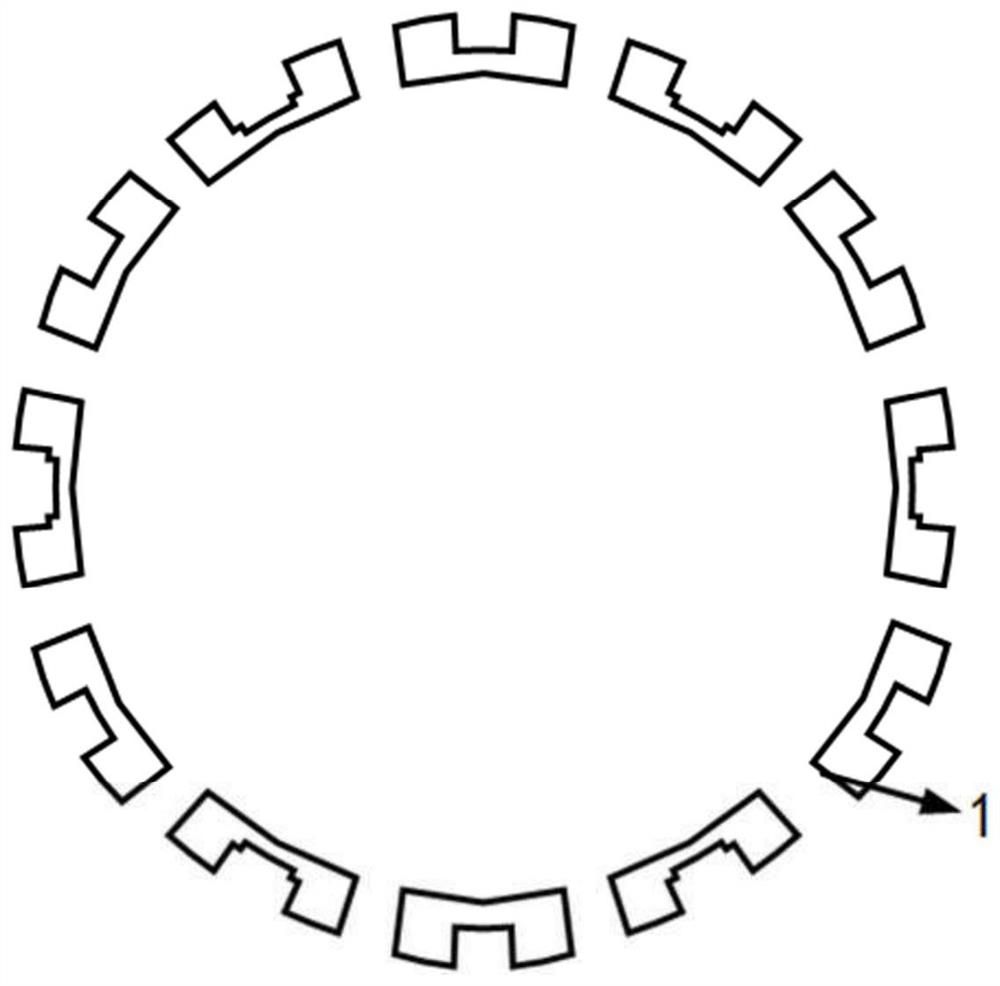

Structure of motor stator core and cooling method for motor stator based on structure of motor stator core

ActiveCN103280903ALow ferromagnetic lossImprove efficiencyWindings insulation shape/form/constructionMagnetic circuit stationary partsWater coolingOil cooling

The invention relates to a structure of a motor stator core and a cooling method for a motor stator based on the structure of the motor stator core. The structure is characterized in that the stator core is formed by splicing and combining stator yoke units and stator tooth units, wherein the quantities of the stator yoke units and the stator tooth units are the same, and are equal to the slot number Z1 of a stator; the stator yoke units and the stator tooth units are formed by laminating oriented silicon steel sheets; a stator yoke unit is connected between every two adjacent tooth units; the tooth units and the stator yoke units are in joggle joint; the silicon steel sheets of the stator yoke units are oriented circumferentially; and the silicon steel sheets of the stator tooth units are oriented radially. The cooling method is selected from one of air cooling, water cooling and oil cooling. The structure has the advantage that the motor has the characteristics of low ferromagnetic loss, high efficiency, low torque pulsation, low slot effect, low running noise, low wind resistance, high slot fullness rate of a stator winding, high utilization ratio of a silicon steel sheet material, suitability of the stator for automatic mass production and the like.

Owner:曹宇轩

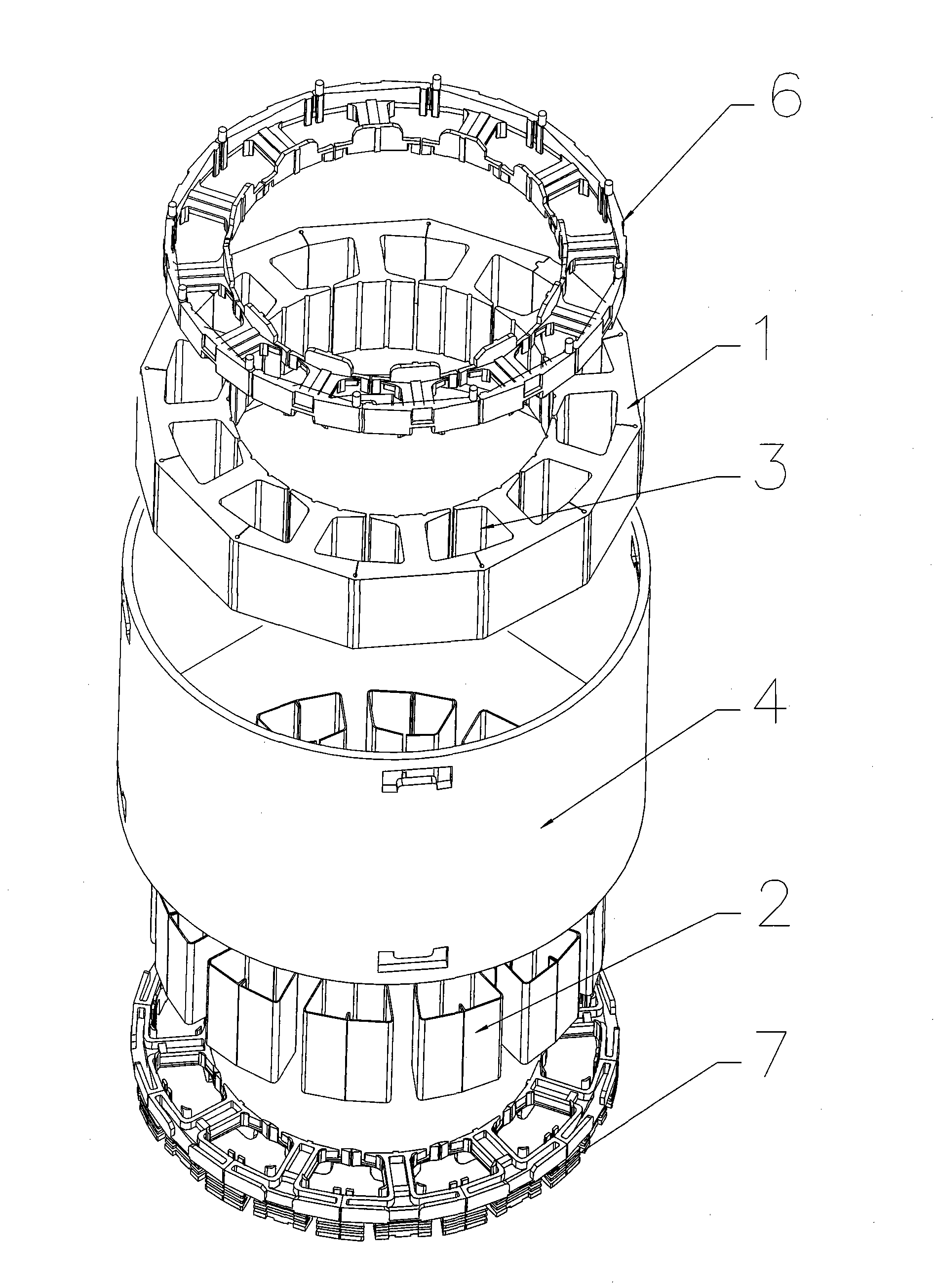

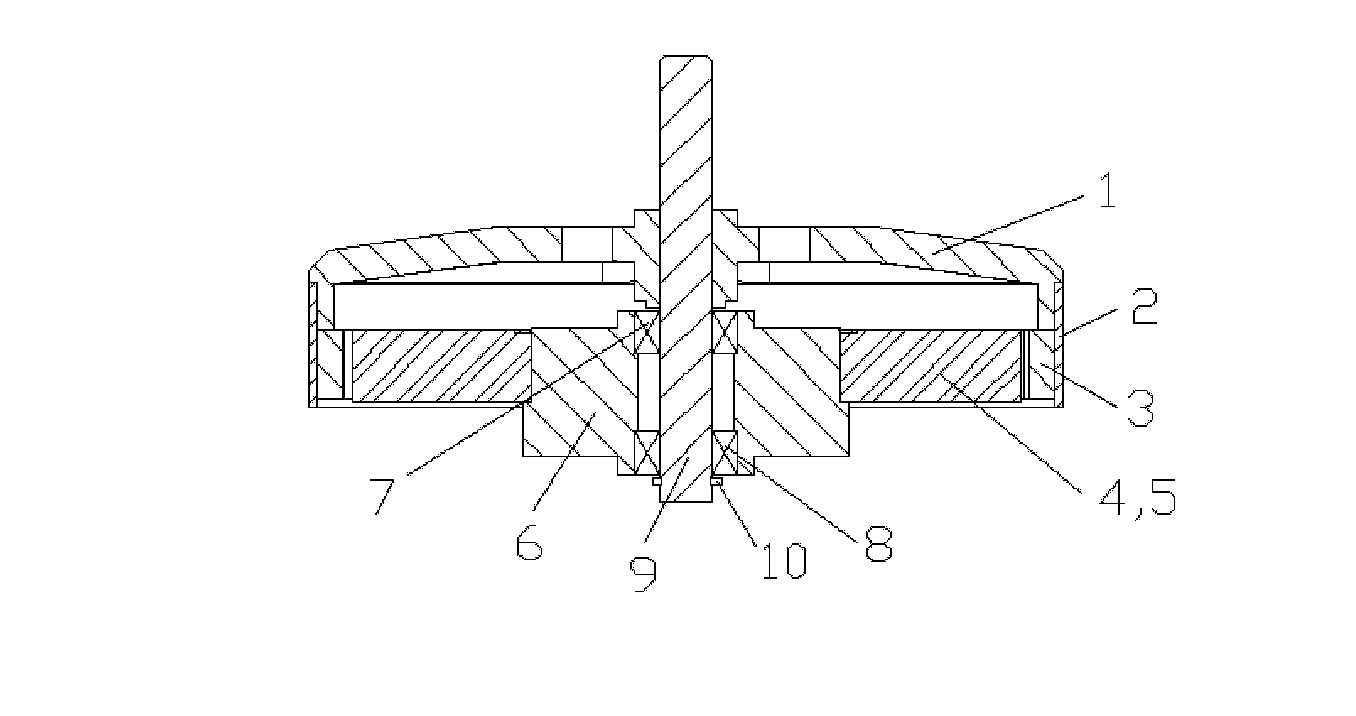

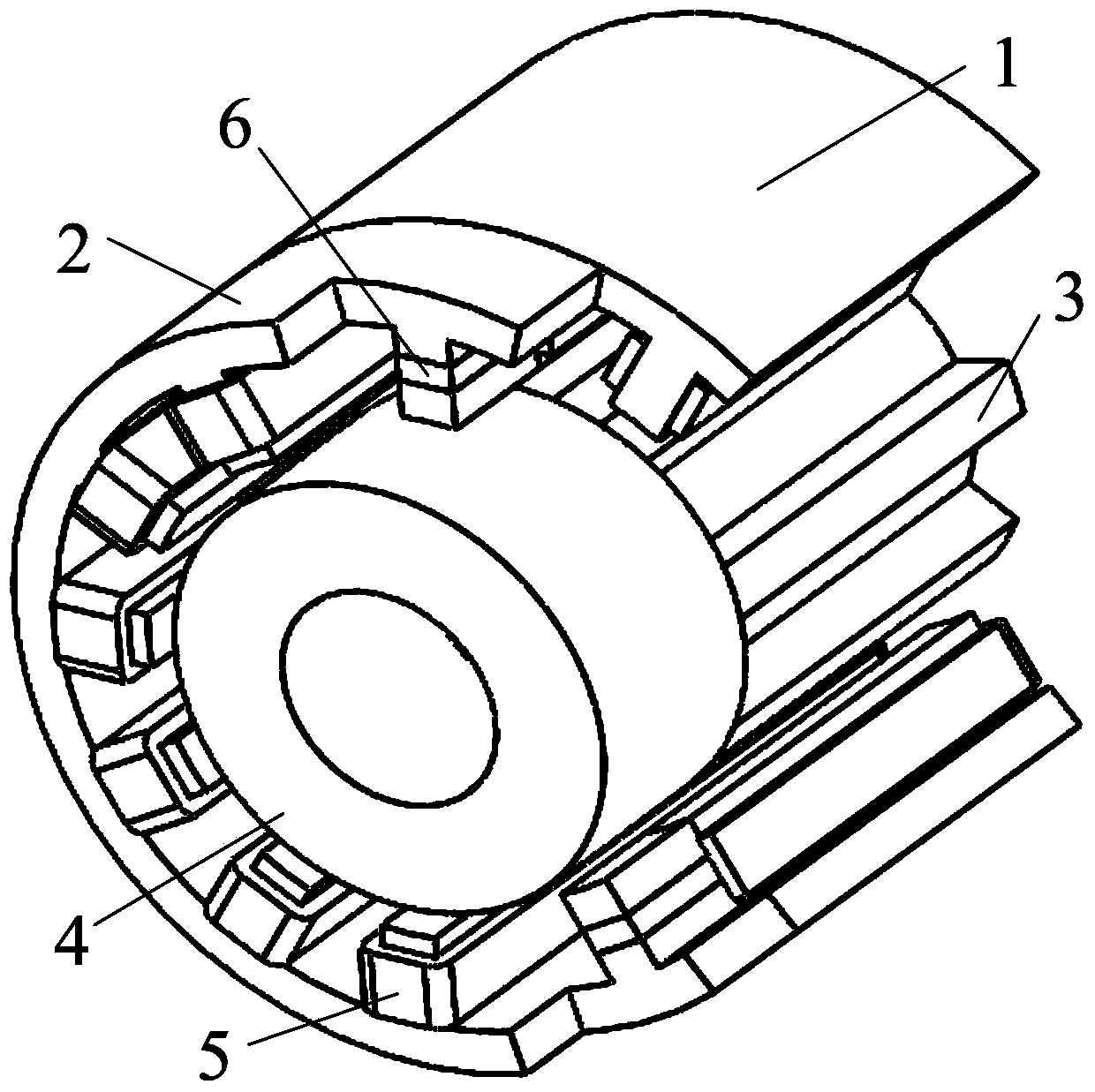

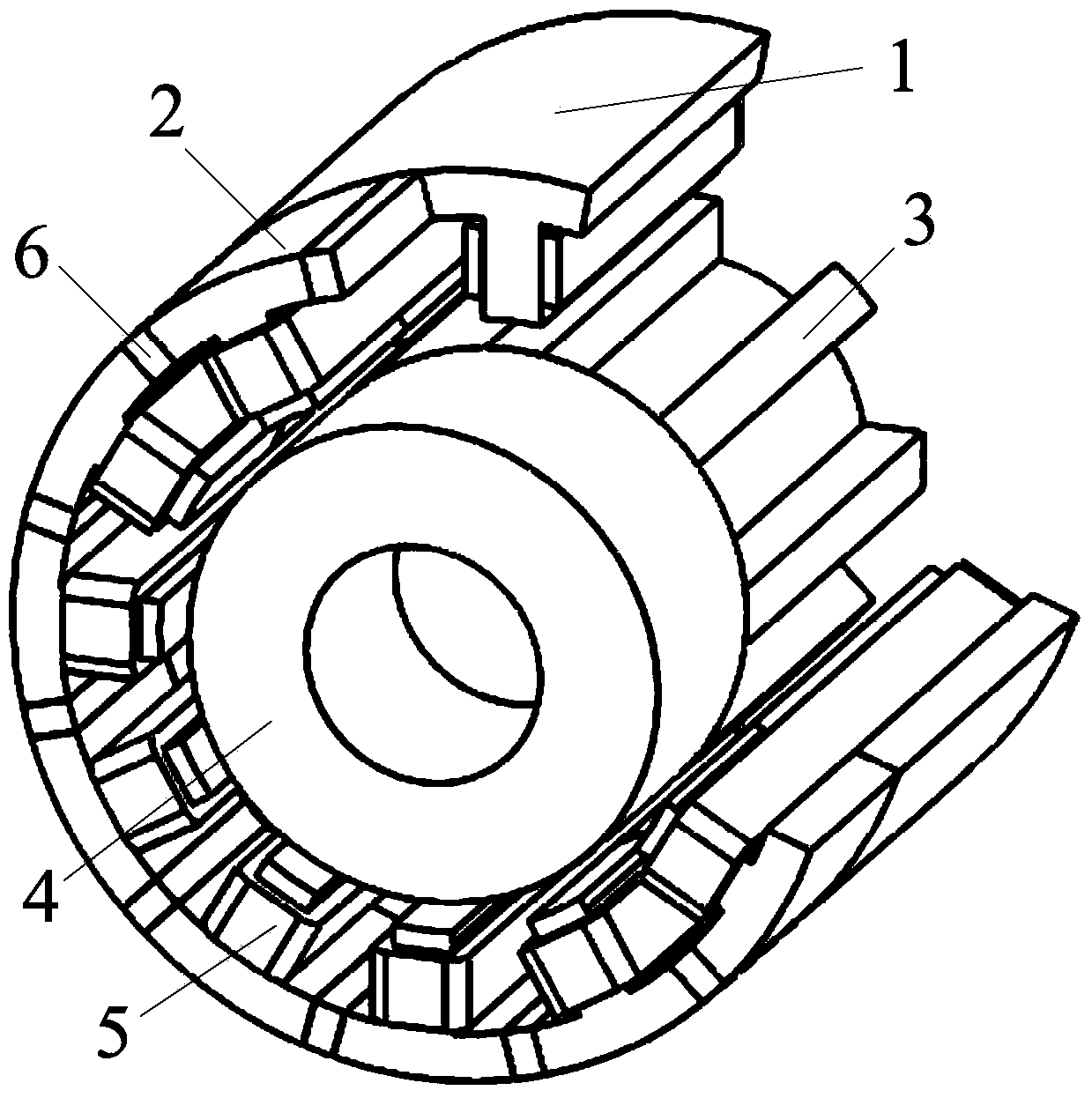

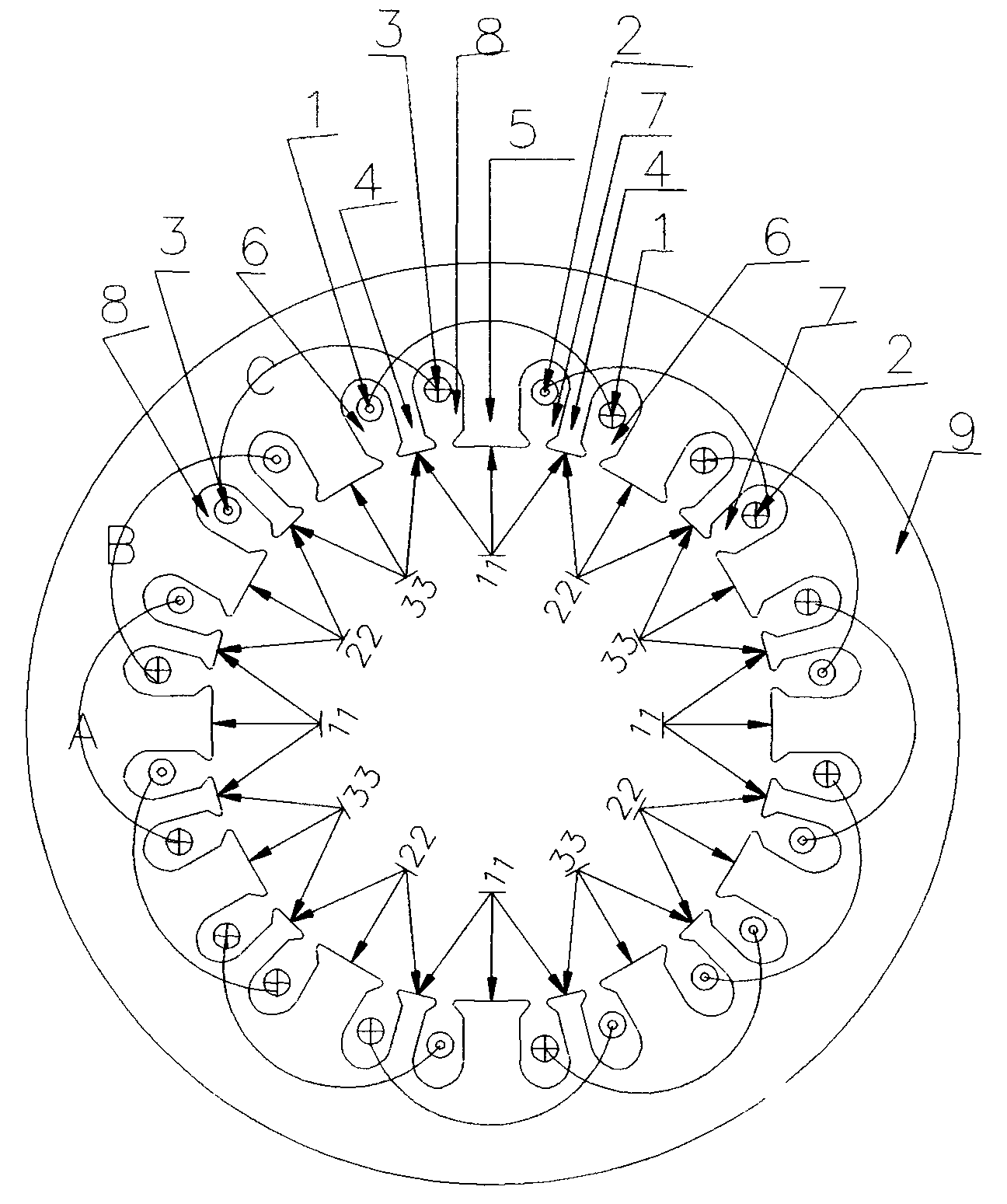

Three-degree-of-freedom magnetic suspension switch reluctance motor

ActiveCN103490572AEasy to integrateReduce manufacturing costMechanical energy handlingMagnetic bearingThree degrees of freedom

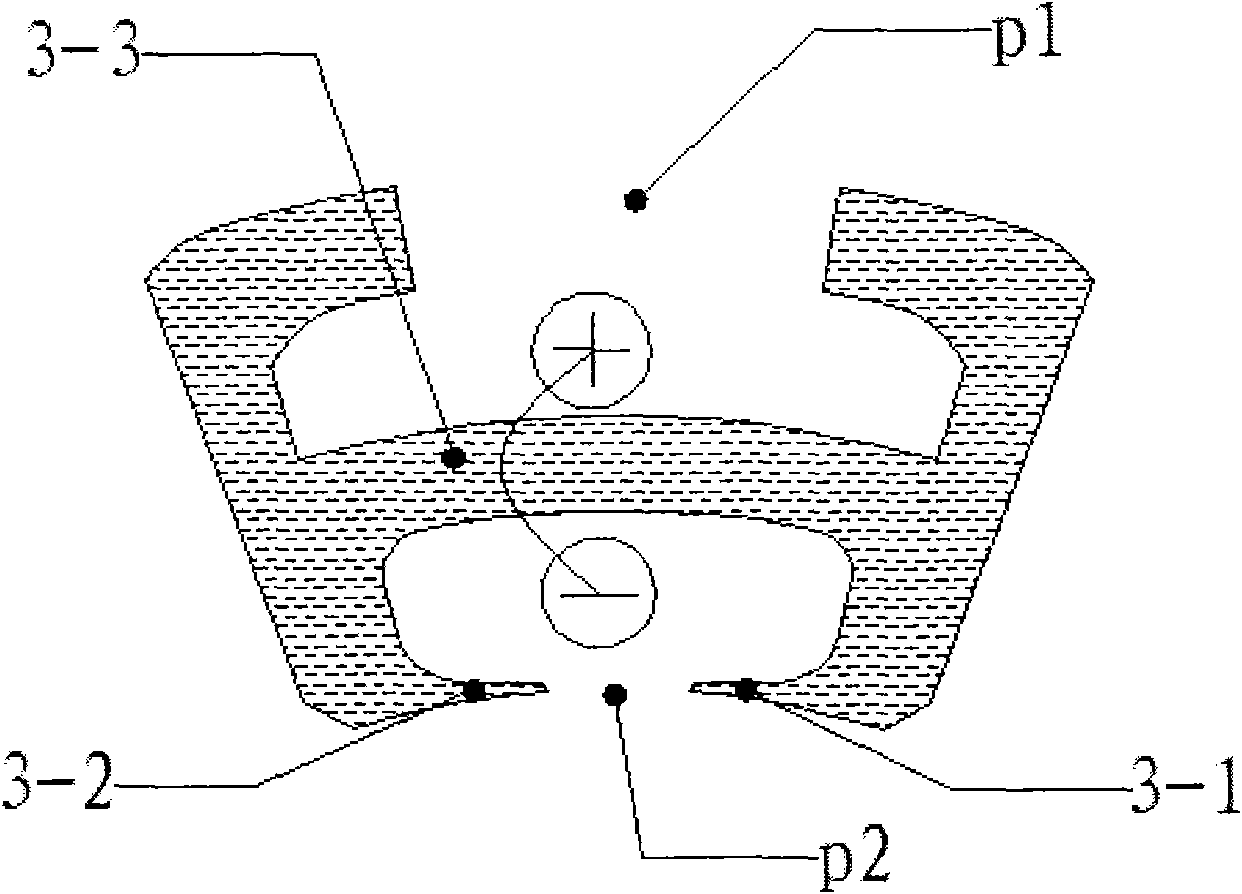

The invention relates to a three-degree-of-freedom magnetic suspension switch reluctance motor, and belongs to the field of magnetic suspension switch reluctance motors and magnetic suspension bearings. A motor stator is composed of a radial magnetic filed motor stator body and two magnetic bearing stator bodies. The radial magnetic filed motor stator body and the two magnetic bearing stator bodies are of a salient pole structure, a motor winding winds each stator tooth of the radial magnetic filed motor stator body, and a magnetic bearing winding winds each stator tooth of each magnetic bearing stator body. A rotor is composed of a salient pole rotor body and two cylindrical rotor bodies in an axial superposition mode, the salient pole rotor body is located between the two cylindrical rotor bodies and is used for generating torque, and the cylindrical rotor bodies are used for generating radial and axial suspension force. The three-degree-of-freedom magnetic suspension switch reluctance motor integrates a bearingless switch reluctance motor and an axial magnetic suspension bearing, and is high in integrity. Only one set of windings is arranged on the radial magnetic bearing stator teeth, the stator bodies are of the salient pole structure, and therefore a plurality of structure modes can be selected. The minimum inductance area is used for suspension control, suspension current has little influence on torque current, and the inter-phase coupling effect is little.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mixed excitation short-magnetic-circuit variable-reluctance motor

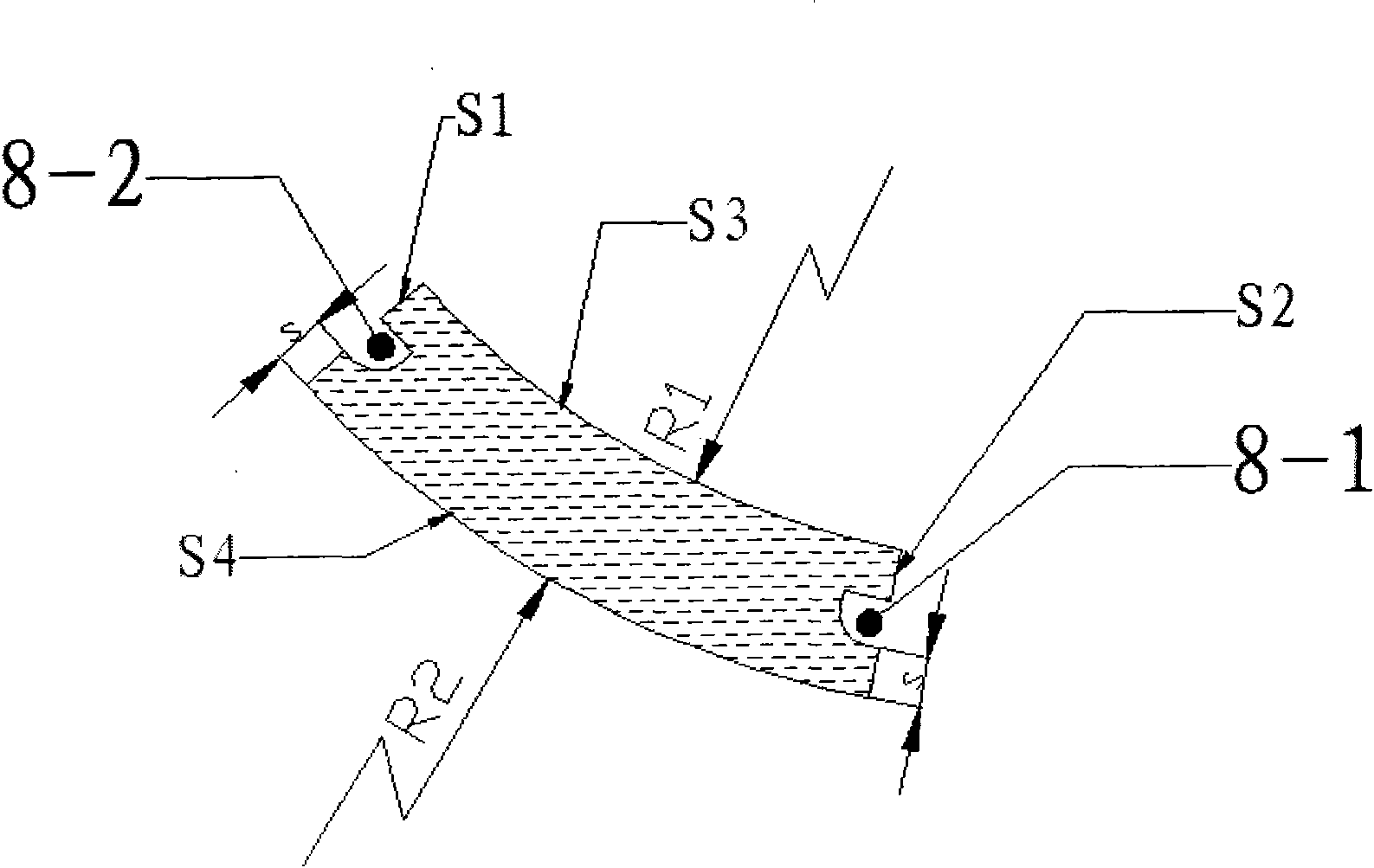

InactiveCN102315746AEasy to installFlexibleMagnetic circuit rotating partsMagnetic circuit stationary partsNoise levelElectrical polarity

The invention discloses a mixed excitation short-magnetic-circuit variable-reluctance motor 1 as well as a stator structure and a rotor structure thereof. An inner circular face t of a base part 2 of the mixed excitation short-magnetic-circuit variable-reluctance motor is provided with modules 2-1 which protrude inwards in a preset interval angle; the stator part comprises a plurality of H-shaped stator sections 3 and first permanent magnets 4 (1) arranged at all the H-shaped stator sections p1, and the polarities of the permanent magnets of the stator sections are opposite; an exciting winding coil is embedded into two stator slots of each H-shaped stator section 3; and the rotor part comprises a rotor body 5 and a plurality of annular body rotor sections 8 arranged on the rotor body and / or second permanent magnets 4 (2), wherein the second permanent magnets are arranged on the s3 surfaces of the annular body rotor sections, and open grooves 8-1 and 8-2 are arranged on the lateral surfaces of the annular body rotor sections. According to the invention, the rotating force of the variable-reluctance motor can be increased, the energy density is improved, the torque ripple and the vibration and noise level are reduced, the performance is stable, and the size is smaller under the requirement of same output torque.

Owner:SOUTH CHINA UNIV OF TECH

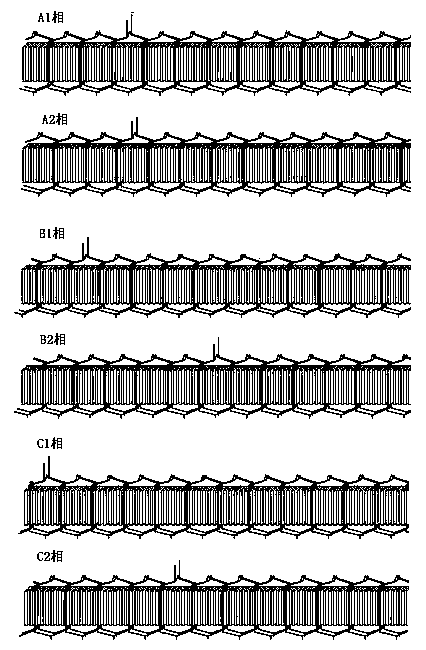

Three-phase motor stator and electric vehicle drive motor

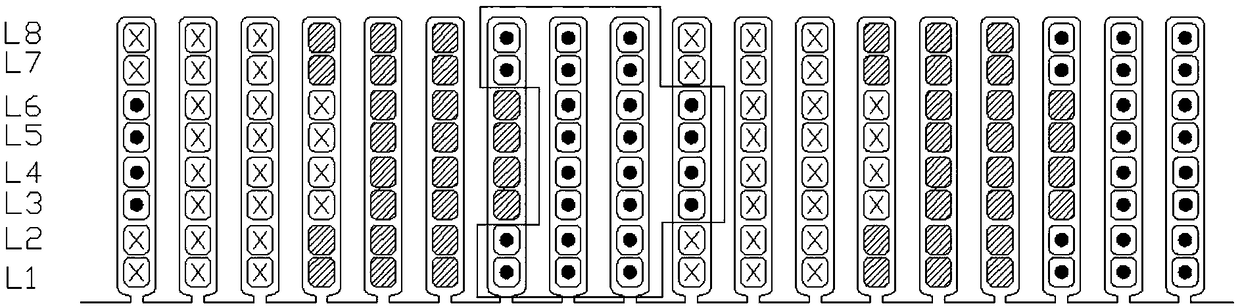

ActiveCN109038878AIncrease the number of turnsReduce AC copper consumptionWindings insulation shape/form/constructionElectric machinesNew energyStator coil

The embodiment of the invention provides a three-phase motor stator and an electric vehicle drive motor, belonging to the field of new energy vehicle motors. The three-phase motor stator comprise a stator iron core, A plurality of stator slots are formed in the stator core, wherein the stator windings are arranged in the plurality of stator slots in six layers, the number of slots per pole per phase is 3, and each phase stator coil in the three-phase stator coil is divided into three groups, and each group of stator coils occupies two adjacent stator slots side by side, wherein one stator slotis displaced between two adjacent groups of stator coils. As a result, the harmonics of the motor are effectively reduced, the AC copper consumption caused by skin effect and proximity effect is reduced, the voltage and current of the high-voltage system are matched, and the purposes of high torque, low torque ripple, low vibration noise, good heat dissipation performance and high electrical reliability are achieved.

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

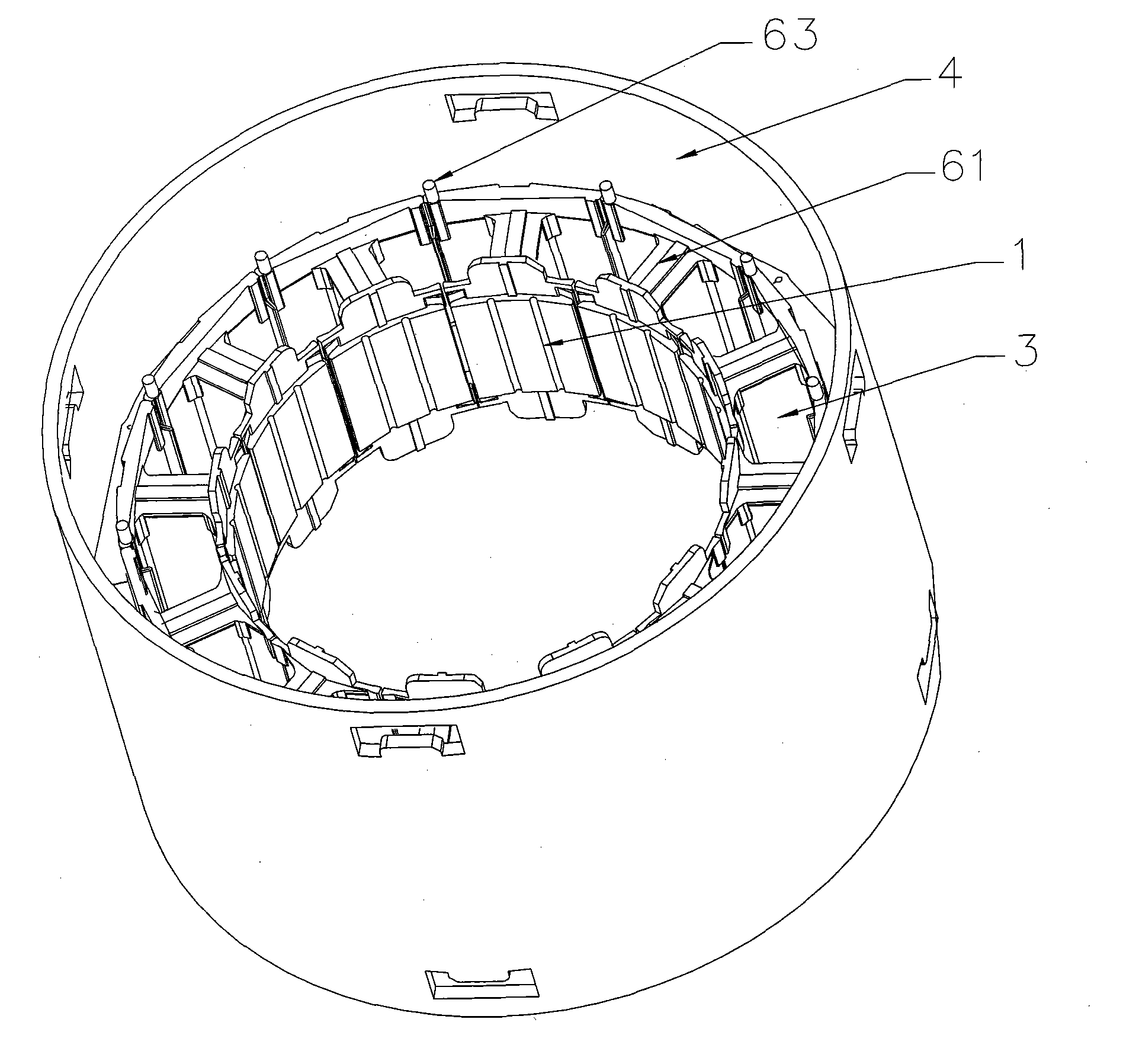

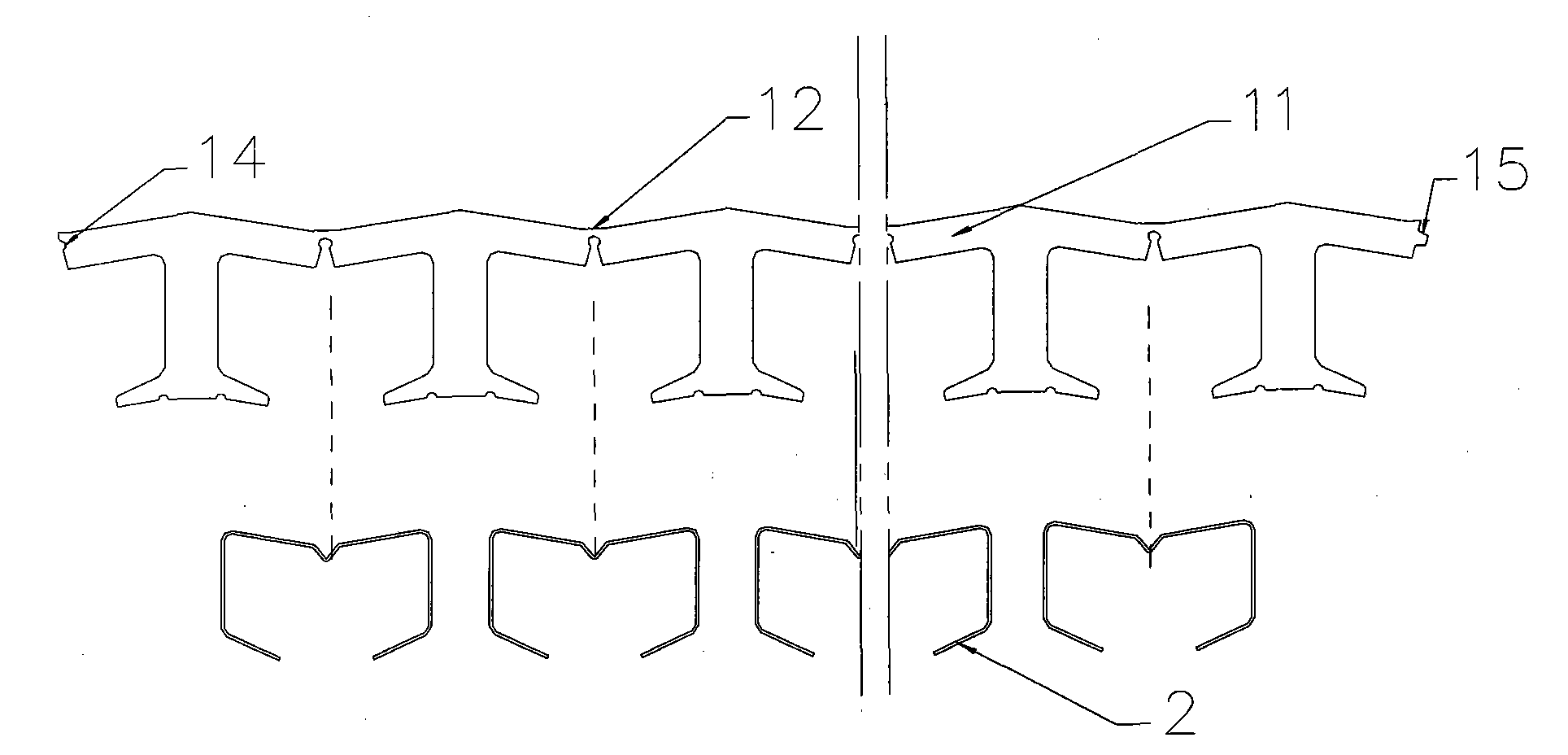

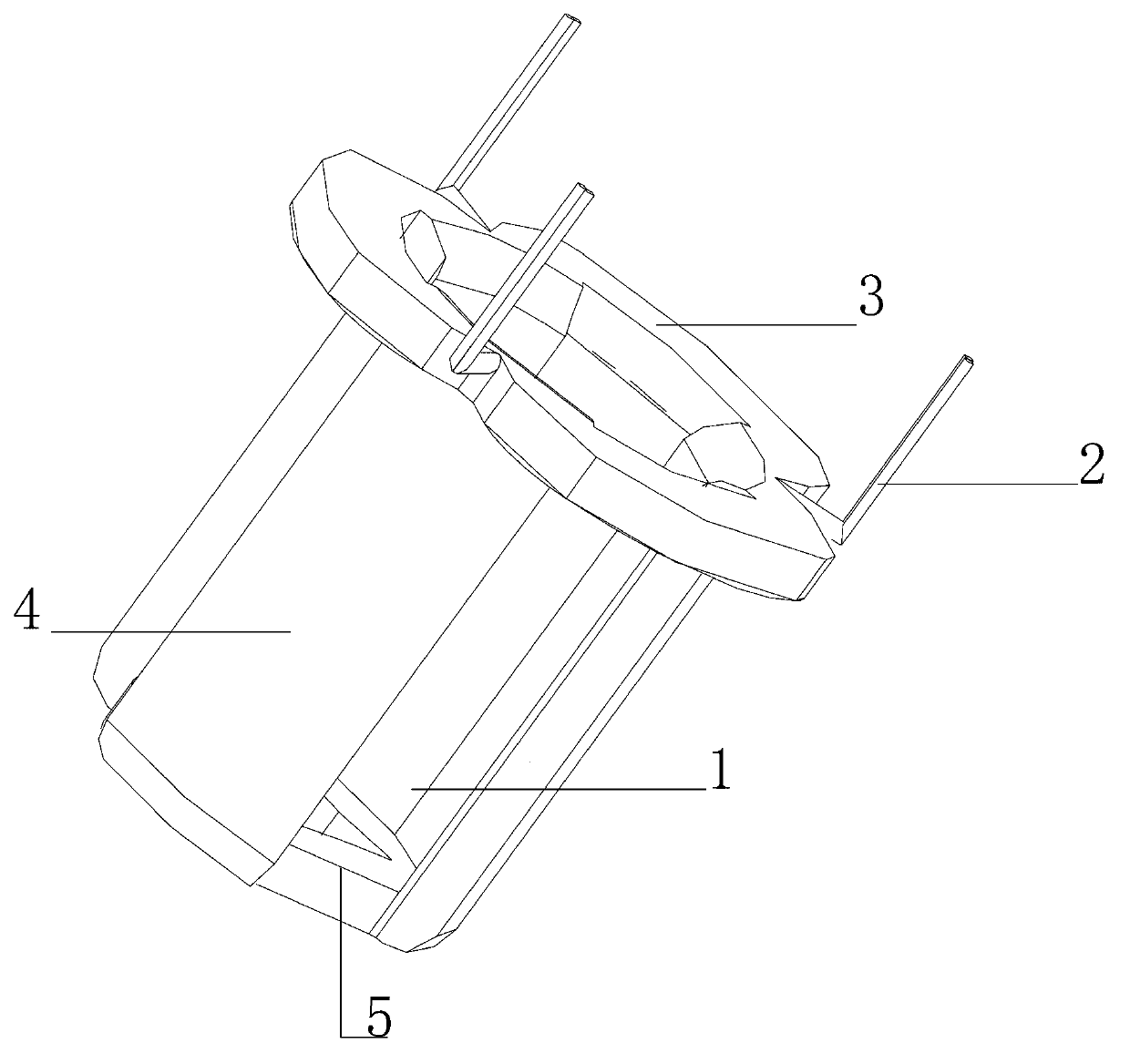

Drum motor stator structure

ActiveCN102111021AMeet expansion needsImprove work efficiencyMagnetic circuit stationary partsInterference fitStator coil

The invention discloses a drum motor stator structure. The drum motor stator structure comprises a stator core, end insulation, stator slot paper and stator coil windings, wherein the stator slot paper is arranged in a stator slot of the stator core; the end insulation is arranged on the two end surfaces of the stator core; the stator coil windings are wound on the end insulation; a drum shell is arranged on the outer edge of the stator core; the stator core adopts a stripped stator core; the stripped stator core is bent to be annular and is arranged in the drum shell; and the outer wall of the annular stripped stator core and the inner wall of the drum shell are in interference fit. In the drum motor stator structure, the stripped stator core structure is adopted; and in the state of naturally unfolding the stripped stator core structure, the volumes of the coil windings in the stator slot are increased, the slot fullness rate is improved, the work efficiency of the motor is greatly improved, and the motor performance is very high.

Owner:ZHONGSHAN BROAD OCEAN

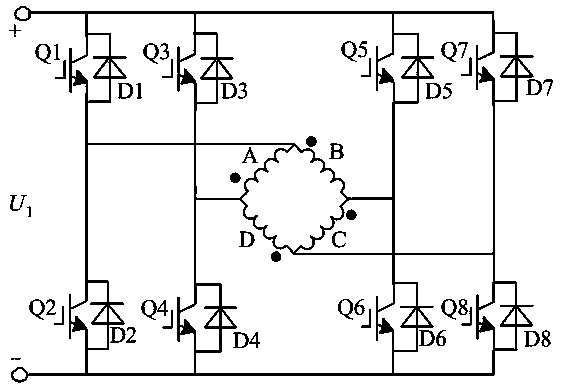

High-reliability four-phase alternating current starting motor

ActiveCN103701286AImprove reliabilityLow failure rateSynchronous generatorsSynchronous motorsStarter generatorElectric machine

The invention provides a high-reliability four-phase alternating current starting motor, which comprises end covers, a stator, a bearing, a magnetic yoke, an exciting winding, a position sensor and a rotor formed by a shaft and pawl poles; the rotor pawl poles are fixed on the pawl shaft; the number of the pawl poles is 4n-2 or 4n-4, wherein n in a natural number; the exciting winding inside the pawl poles is fixed on the end cover at one end of the motor by the magnetic yoke; the stator is positioned outside the rotor and has the pole number of 4n; centralized windings are arranged on stator poles; n stator coils in close phases are serially connected to form one phase; the four phases of stator windings are annularly connected end to end and are respectively connected onto middle points of four-phase bridge arms. The four-phase starting motor can be used both as a starter and a power generator; the reliability is high as the four-phase centralized stator windings are adopted; well voltage adjusting performance is realized by adopting a brushless electro-exciting structure and the high-reliability four-phase alternating current starting motor is suitable for being used on a vehicle idle speed halt system.

Owner:CHONGQING YIHU ENGINE MACHINERY

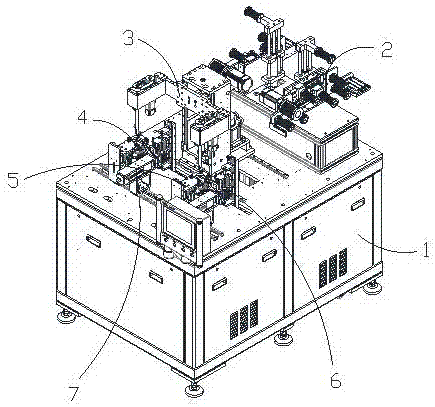

Vertical winding machine and winding method thereof

InactiveCN107546934AAvoid tanglesImprove stabilityManufacturing dynamo-electric machinesWinding machineWire tension

The invention discloses a vertical winding machine and a winding method of the vertical winding machine, which mainly include a frame and a tension control mechanism installed on the frame for controlling the tension of the enameled wire, and for embedding the enameled wire into the stator wire groove. The vertical winding mechanism, the product rotation mechanism used to fix the stator and drive the stator to rotate, the clamping and arranging mechanism used to limit the position of the enameled wire in the stator wire slot, and the cross-slot mechanism used to hook the enameled wire when the enameled wire crosses the slot And control components for controlling all power sources on the inner winding machine. The multi-strand wire vertical inner winding machine provided by the invention can automatically wind the inner winding stator in the whole process, and the winding is uniform, and the enameled wire will not be scratched during the winding process.

Owner:东莞拓蓝自动化科技有限公司

Brushless DC (Direct Current) motor for unmanned air vehicles

InactiveCN102130565AMany slotsImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsMass ratioElectric machine

The invention relates to a brushless DC (Direct Current) motor for unmanned air vehicles, belonging to the technical field of unmanned air vehicle powerplants. The brushless DC motor comprises an external rotor composed of a rotor end cover, a rotor yoke and a permanent magnet, a stator composed of a winding, a stator iron core and a stator yoke, an upper bearing, a lower bearing, a rotation shaft and a stopper ring, wherein the outer diameter of the rotor yoke is the same as that of the rotor end cover, the rotor yoke is fixed at the lower end of the rotor end cover, the permanent magnet is fixed on the inner wall of the rotor yoke, and the number of magnetic poles of the permanent magnet is 24; the stator iron core comprises 18 slots, the stator yoke is sleeved on the inner wall of the stator iron core, and the winding is coiled on the outside of the stator iron core; the upper bearing and the lower bearing are respectively fixed on two ends of the rotation shaft; the stator is connected with the rotor through the rotation shaft, the stator is embedded inside the rotor end cover, and the stopper ring is sleeved on the rotation shaft. In the invention, by directly driving airscrews, the brushless DC motor is beneficial to elimination of efficiency loss of a driving system, and improvement of lift force / power consumption ratio and lift force / mass ratio of air vehicles.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

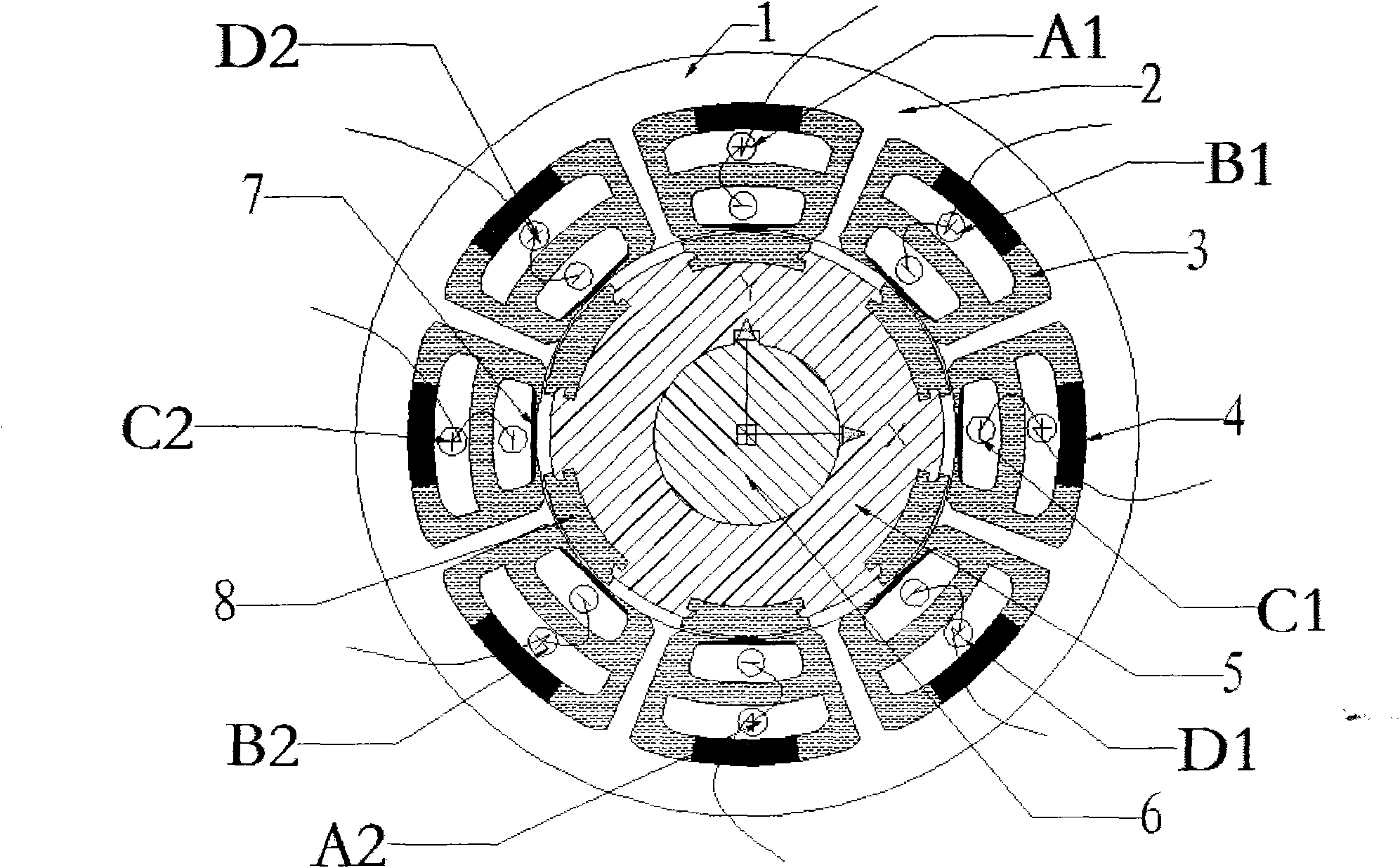

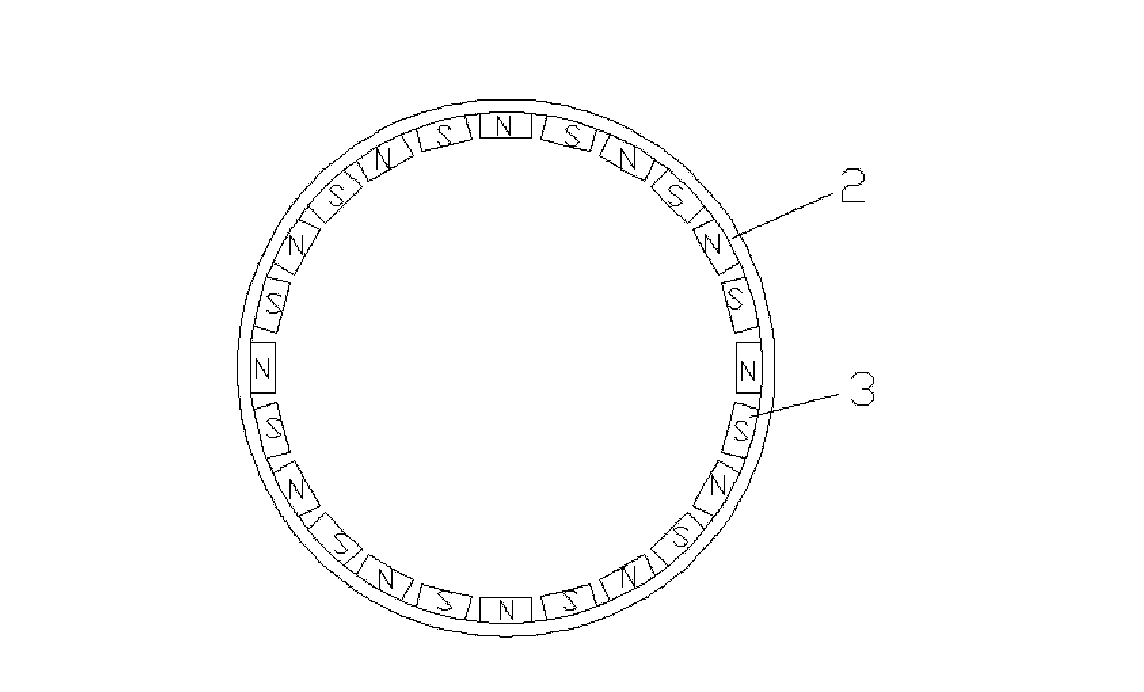

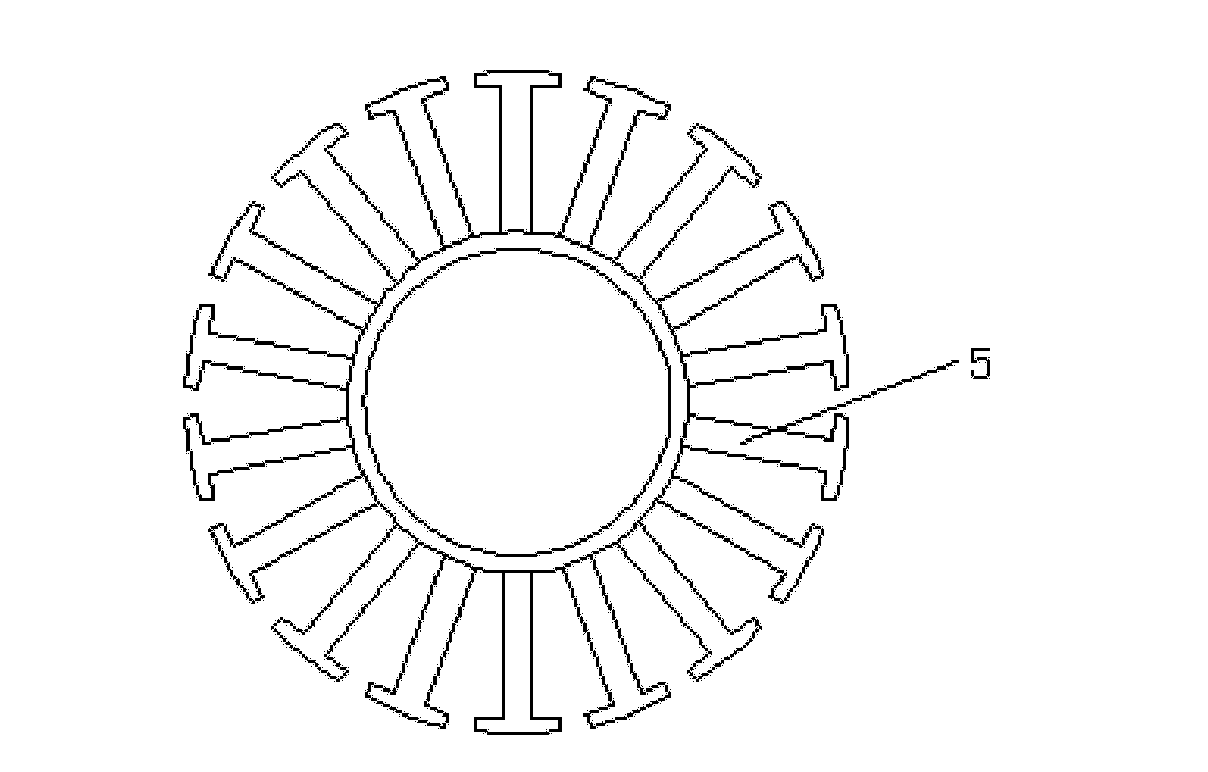

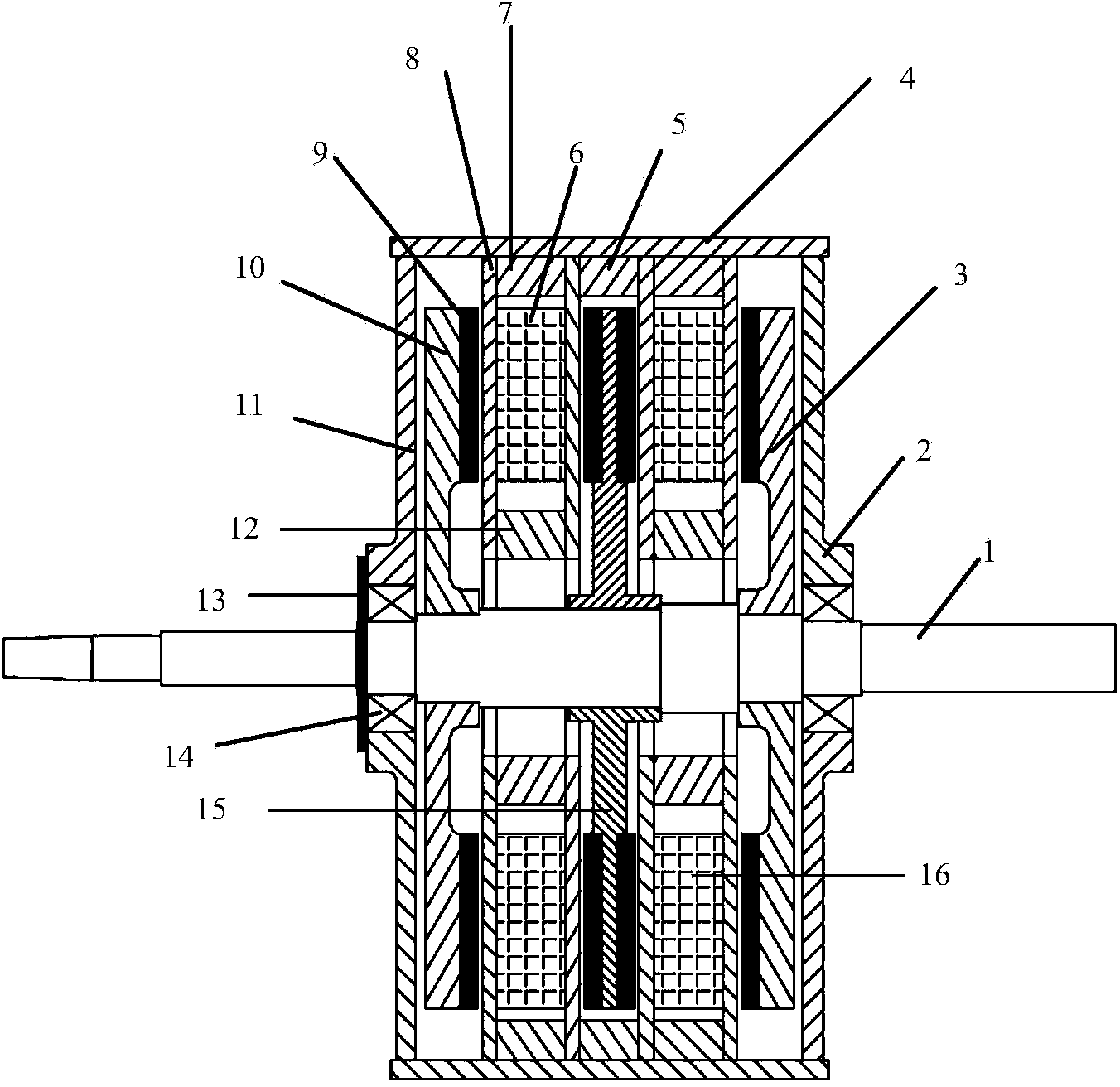

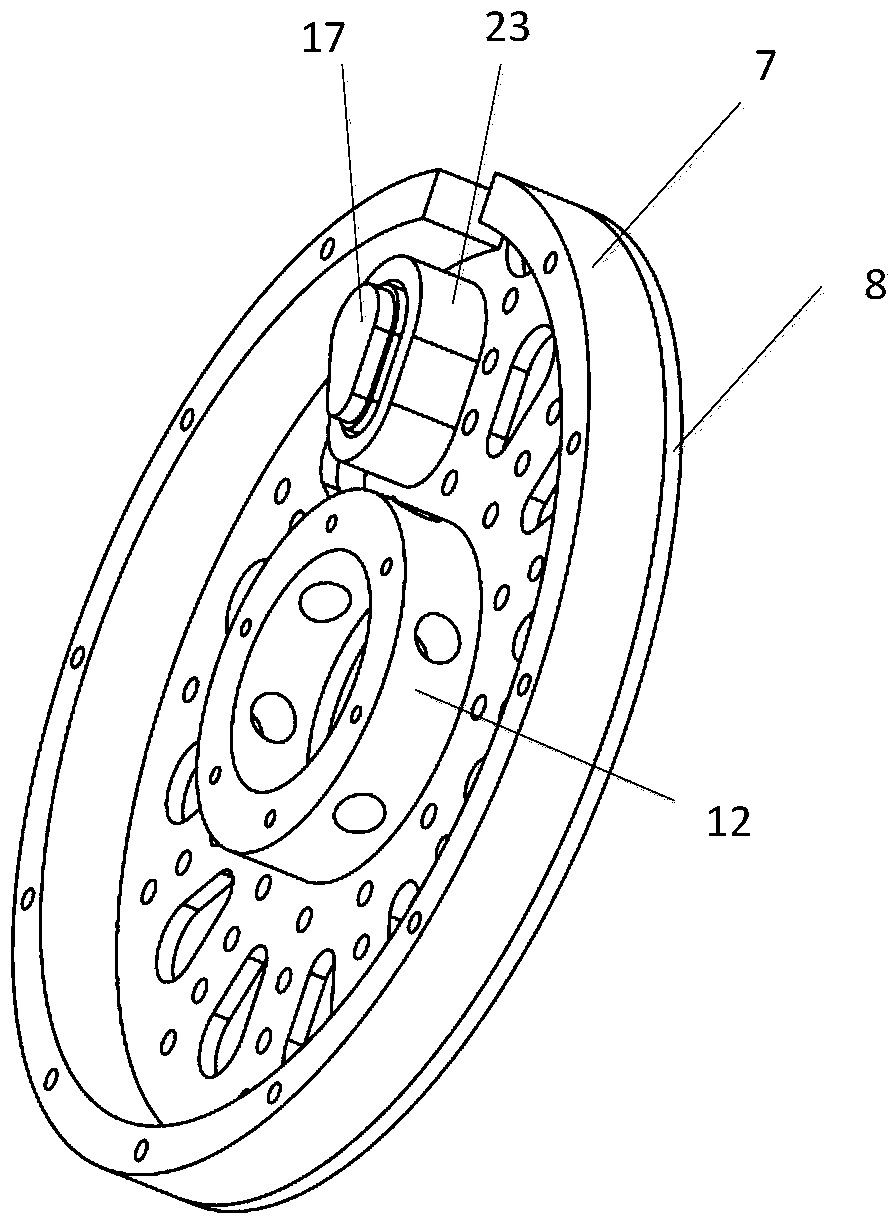

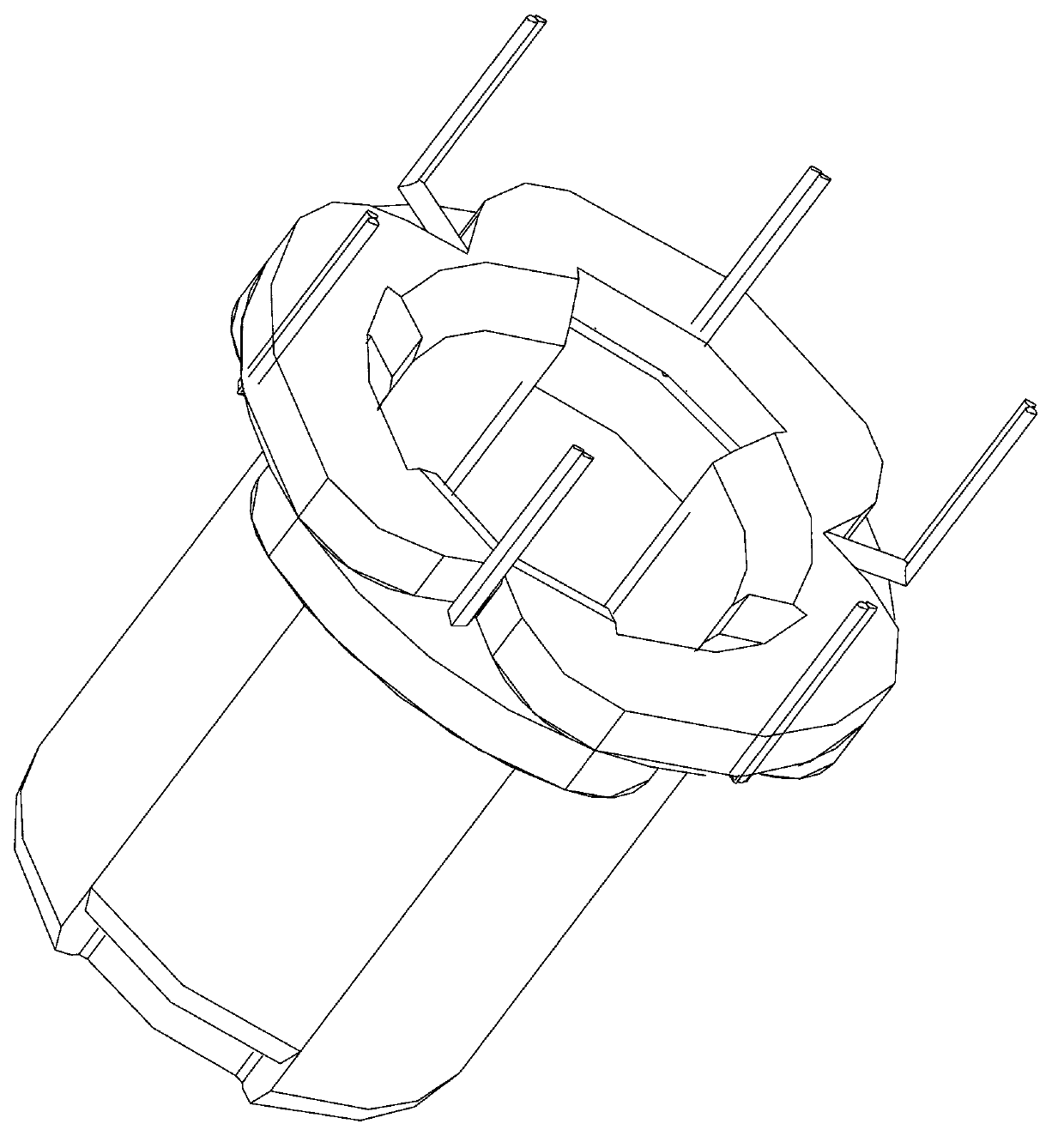

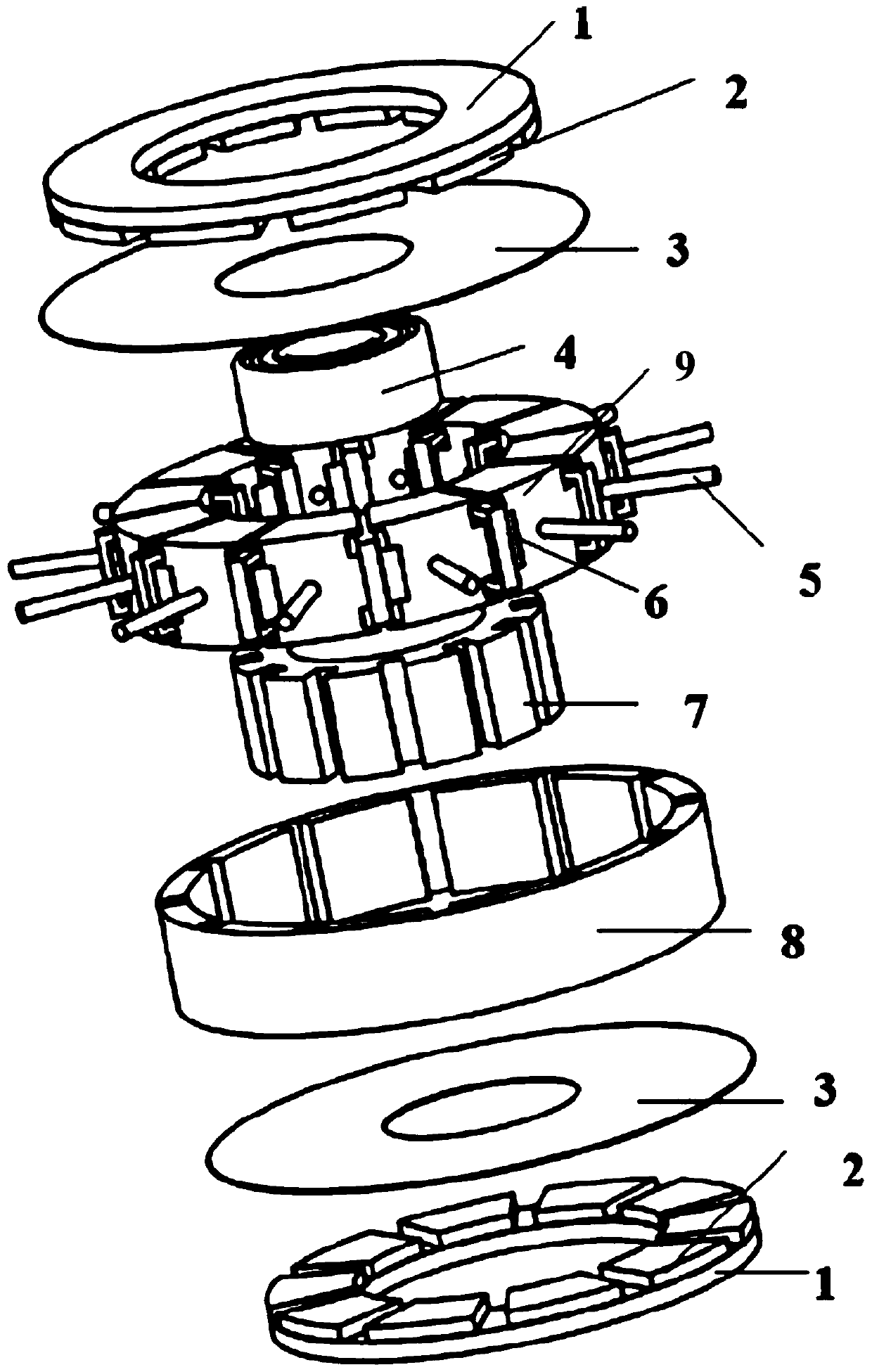

Permanent-magnet biased hybrid magnetic bearing switch reluctance motor

ActiveCN104038002AIncrease slot fill rateFlexible controlMagnetic holding devicesWindings conductor shape/form/constructionMagnetic bearingElectromotive force

The invention provides a permanent-magnet biased hybrid magnetic bearing switch reluctance motor. A torque stator and a suspension force stator of the motor are axially superposed, and a torque rotor and a suspension force rotor of the motor are axially superposed; each of the torque stator and the suspension force stator both is of a salient pole structure and provided with twelve teeth; the torque rotor is of the salient pole structure and provided with eight teeth, while the suspension force rotor is of a cylindrical structure; windings, twelve in total, are wound around a stator tooth formed by the torque stator and the suspension force stator; an annularly magnetized permanent magnet is placed on each of twelve stator yokes, or a radially magnetized permanent magnet is placed on each of twelve suspension force stator teeth. The motor is characterized in that decoupling of torque and suspension force is realized structurally and convenient control is achieved, permanent magnets are used for providing biased magnetic flux and large radial bearing capacity is realized, and the influence of motional electromotive force on current chopping control is eliminated, and good current control effect and good high speed adaptability are achieved.

Owner:NANJING UNIV OF POSTS & TELECOMM

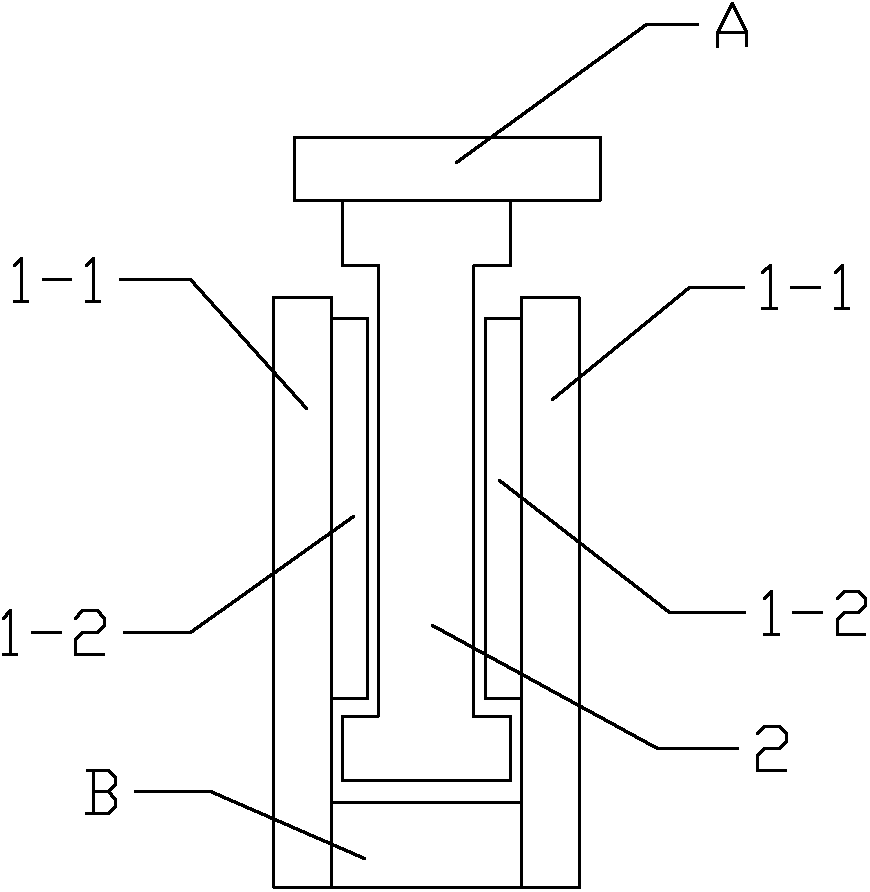

Yoke-free closed slot type multi-plate permanent magnet motor

InactiveCN104113171AIncreased torque densityImprove efficiencyDynamo-electric machinesLow speedElectric machine

The invention discloses a yoke-free closed slot type multi-plate permanent magnet motor comprising a motor housing, a plurality of rotors, and a plurality of stators. The motor housing consists of a rotating shaft, a bearing, a front end cover, a rear end cover and a casing; the plurality of rotors are fixed with the rotating shaft; and the stators are arranged among the adjacent rotors. Each stator has a yoke-free closed slot structure formed by two stator outer teeth, a stator inner tooth between the two stator outer teeth, a stator inner plug, a stator outer plug, and a winding. Each rotor with a combined oblique pole structure includes a plurality of rotor plates that are distributed coaxially at intervals along the axial direction and fan-shaped permanent magnets contacted to the rotor plates. According to the invention, the provided yoke-free closed slot type multi-plate permanent magnet motor has advantages of improved slot full rate, iron core material saving, torque quality improvement, torque density enhancement, and improvement of whole operation efficiencies of the low speed and light load.

Owner:HUAZHONG UNIV OF SCI & TECH

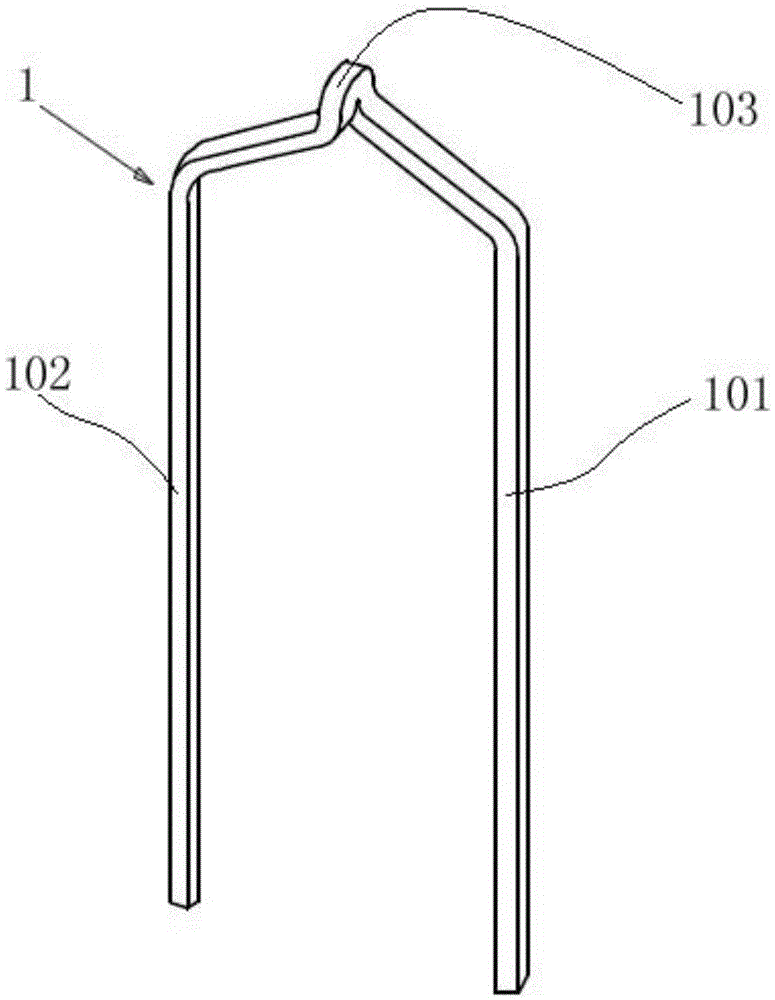

Motor stator and winding method thereof

ActiveCN104882975AIncrease slot fill rateEasy to installMagnetic circuit stationary partsWindings conductor shape/form/constructionCopper wireStator coil

The invention provides a motor stator and a winding method thereof. The motor stator comprises an iron core and a stator winding. Stator slots are formed in the iron core at equal intervals. Each phase of the stator winding contains a stator coil group based on winding in a wave winding mode or lap winding mode and a connecting coil group enabling two of more than two groups of stator coil groups to be connected in series; and two winding leading-out wire groups are formed naturally at the two ends of the stator coil groups after series connection. Each stator coil group, each connecting coil group, and each winding leading-out wire group contains four flat type copper wires respectively. In addition, the invention also provides a winding method of the motor stator. On the basis of the wave winding or lap winding way, the corresponding stator windings of all phases are wound and the stator coil groups of all phases of the stator winding are connected in series. Under the circumstances that the motor stator volume is not changed, the motor power is substantially improved; and the power is high and the size is small relatively.

Owner:QUANZHOU KPL ELECTRIC APPLIANCE FOR VEHICLE

Coil winding, combined winding and permanent magnet motor without groove and framework

InactiveCN103280905ASimple preparation processIncrease slot fill rateWindings conductor shape/form/constructionBarrel ShapedPermanent magnet motor

The invention discloses a coil winding, a combined winding and a permanent magnet motor without a groove and a framework. The coil winding is formed by uniformly distributing 3*N groups of coils along the circumference and is a round barrel-shaped winding with an edge and no cover; and the combined winding is formed by two II type coil windings in a mutual nesting way or one I type coil winding and one II type coil winding in a mutual nesting way. According to the coil winding, the combined winding and the permanent magnet motor without the groove and the framework, the structure is ingenious, the appearance is attractive, and high tankful rate of the motor can be realized.

Owner:CHANGSHA METRIC ELECTRIC TECH CO LTD

Axial magnetic flux concentrated winding type hybrid excitation motor

ActiveCN110460175AReduce electricity lossReduced risk of demagnetizationMagnetic circuit rotating partsSynchronous machine detailsElectric machineMagnetic poles

The invention diskloses an axial magnetic flux concentrated winding type hybrid excitation motor. The motor includes a stator disk and two rotor disks, wherein the stator disk includes a stator core,an armature winding, an exciting winding and a magnetic ring, the rotor disks respectively include a rotor back yoke, a magnetic pole block and a permanent magnet, left and right sides of the stator core of the stator disk are provided with stator slots, the armature winding is installed on a magnetic yoke of the stator core, two rotor disks are arranged on both sides of the stator disk, the number of rotor poles matches the number of the stator slots to form a concentrated winding motor structure, the permanent magnets and the magnetic pole blocks are alternately installed on the rotor disks,the two rotor disks are staggered and installed on both sides of the stator disk, the magnetic pole blocks extend outward in the radial direction and form an additional air gap of an excitation fieldin the axial direction with the magnetic ring on the stator core. The motor is advantaged in that the motor has high power density and wide magnetic field adjustment range, and has important application prospects in electric vehicle driving systems, hybrid power generation systems and aviation electric propulsion systems.

Owner:NANJING UNIV OF SCI & TECH

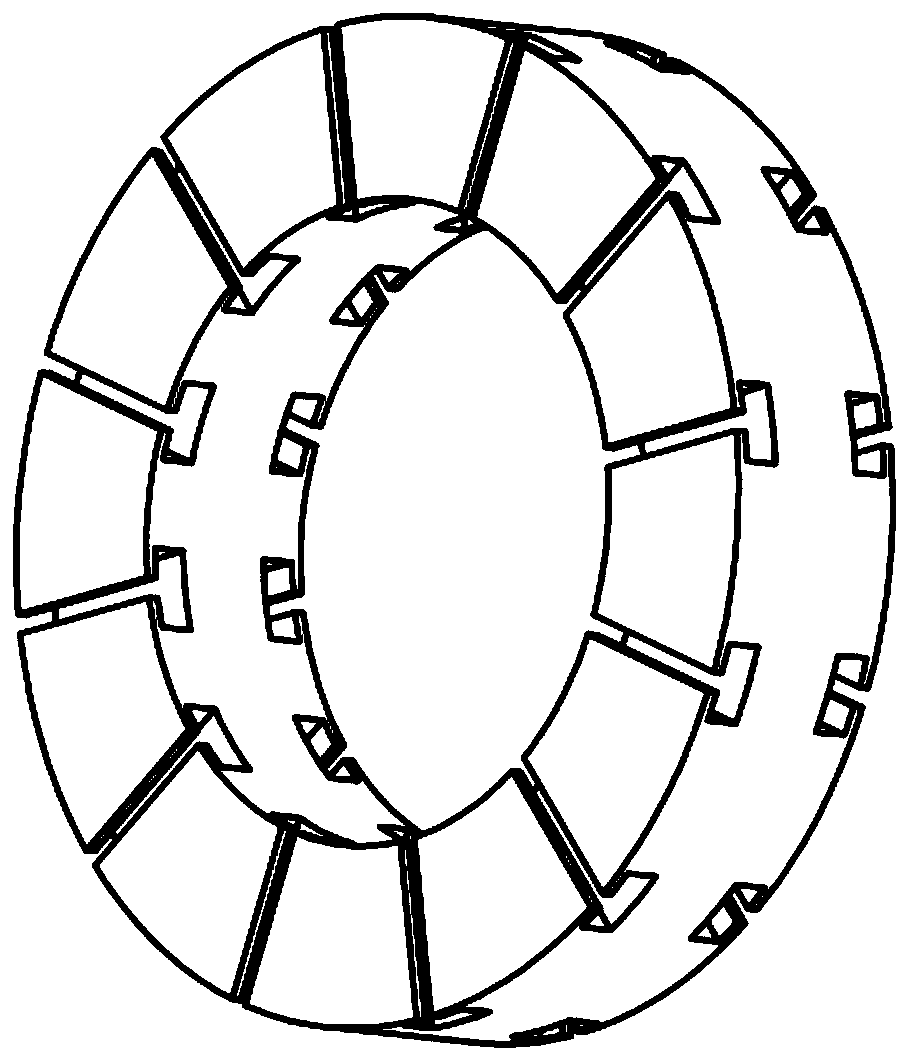

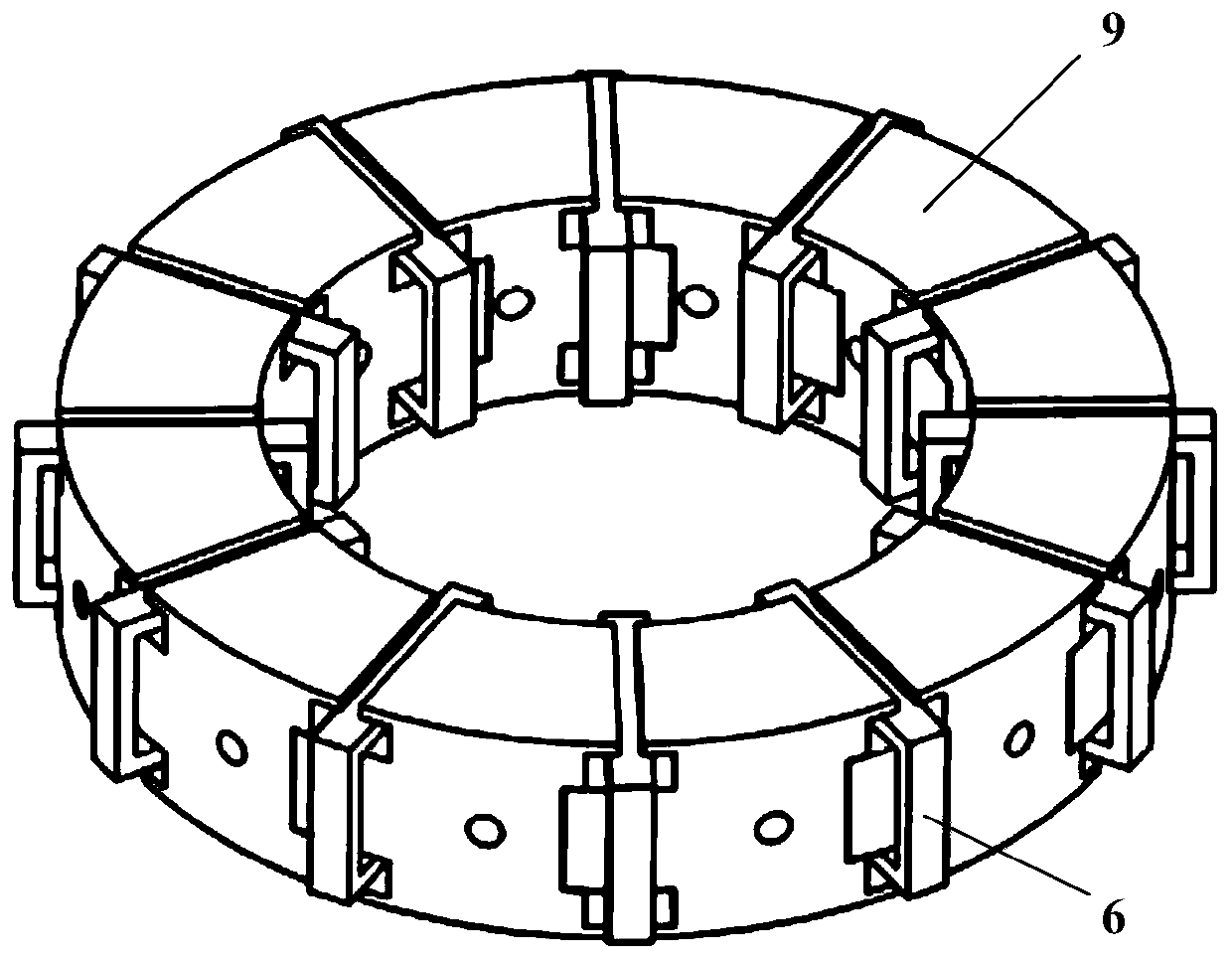

Modular axial flux permanent magnet motor

InactiveCN110611379AReduce stressHigh mechanical strengthWindingsMagnetic circuit rotating partsFlywheel energy storageCooling effect

The invention discloses a modular axial flux permanent magnet motor. The motor comprises a stator, double rotors and a bearing. The stator comprises a stator iron core, a stator winding, stator iron core fixing pins and a stator sealing plate. The stator iron core adopts a modular structure, the stator winding is wound on a yoke part of the stator iron core, and the stator iron core fixing pins radially penetrate through the stator iron core and are fixed on a fixed ring. The stator sealing plate is used for sealing stator cooling oil to improve the cooling effect. The rotors comprise rotor back yokes and rotor permanent magnets which are symmetrically installed on two sides of the stator, the rotor permanent magnets are fixed to the rotor back yokes, and inner circumferences of the rotorback yokes are fixed to the bearing. Equal air gaps are kept between the double rotors and the stator to generate a magnetic field. The modular axial flux permanent magnet motor has the advantages ofhigh air gap flux density, high stator structural strength, high torque density and good cooling effect and is suitable for being applied to electric propulsion, wind power generation and high-speed flywheel energy storage occasions.

Owner:NANJING UNIV OF SCI & TECH

Permanent magnet synchronous motor with high-power density

InactiveCN101882850AIncrease in sizeImprove space utilizationSynchronous machine detailsMagnetic circuit stationary partsSynchronous motorPermanent magnet synchronous motor

The invention relates to a permanent magnet synchronous motor with high-power density, which belongs to the technical field of motors and solves the problem that the motor volume is large or the motor efficiency is decreased as pipelines are arranged in the motor to cool the motor with a liquid cooling method in the traditional multi-phase permanent magnet synchronous motor. The synchronous motor comprises a stator and a rotor. A gas gap is formed between the stator and the rotor, and the stator comprises an armature iron core and an armature winding. The gas gap side surface of the armature iron core is in a tooth groove structure. The interval arrangement of parallel teeth and trapezoidal teeth are formed on the gas gap side surface of the armature iron core by a plurality of parallel grooves. The gas gap side edges of the trapezoidal teeth are short edges, and the middle of the tooth root of each trapezoidal tooth is provided with an axial circular through hole. The armature winding is sheathed on the parallel teeth, and is formed by connecting single-layer coils in series or parallel, wherein the coil is square. The invention is suitable for permanent magnetic synchronous motors.

Owner:HARBIN INST OF TECH

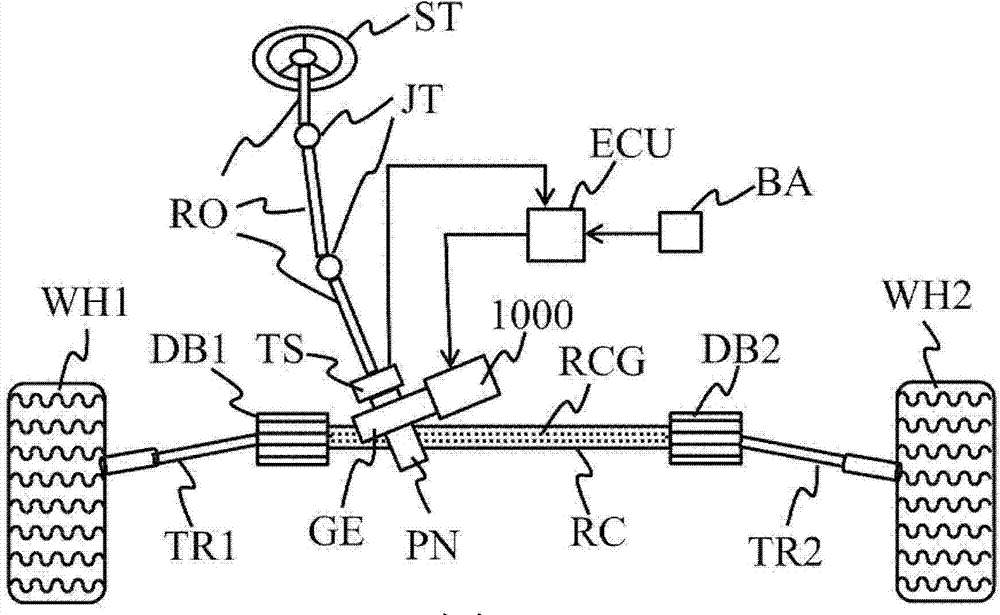

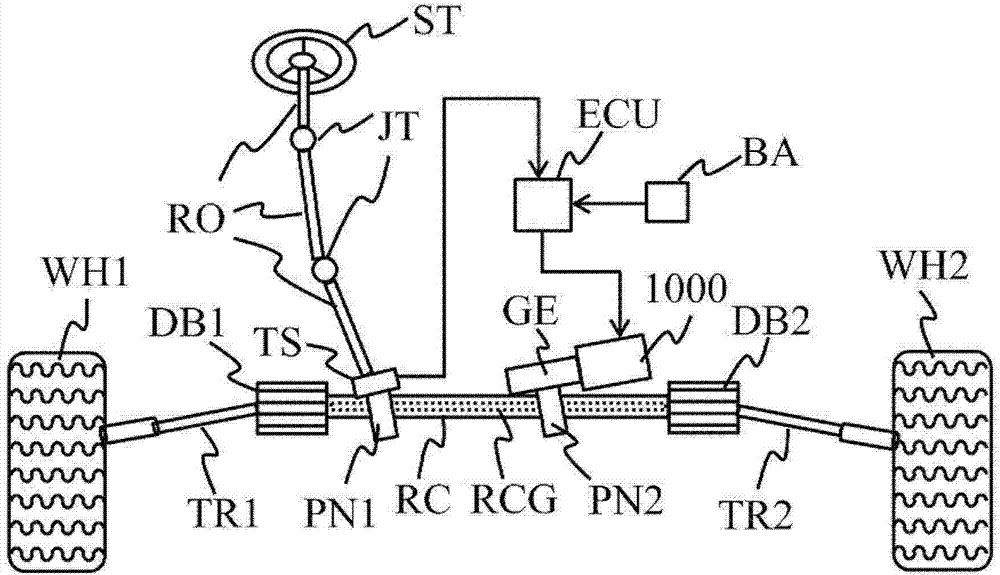

Rotating electrical machine and electric power steering system using the same

InactiveCN103701289AReduce torque rippleIncrease torqueMagnetic circuit rotating partsElectric machinesElectric power steeringLow voltage

The invention relates to a permanent magnet motor which aims to increase slot filling factor and design freedom in a motor for low voltage and large torque. A rotating electrical machine of the invention is characterized in that: in a concentrated winding motor having the combination of the number of poles and the number of slots of 10:12 or 14:12, the numbers of coil turns of adjacent same-phase coils are different.

Owner:HITACHI AUTOMOTIVE SYST LTD

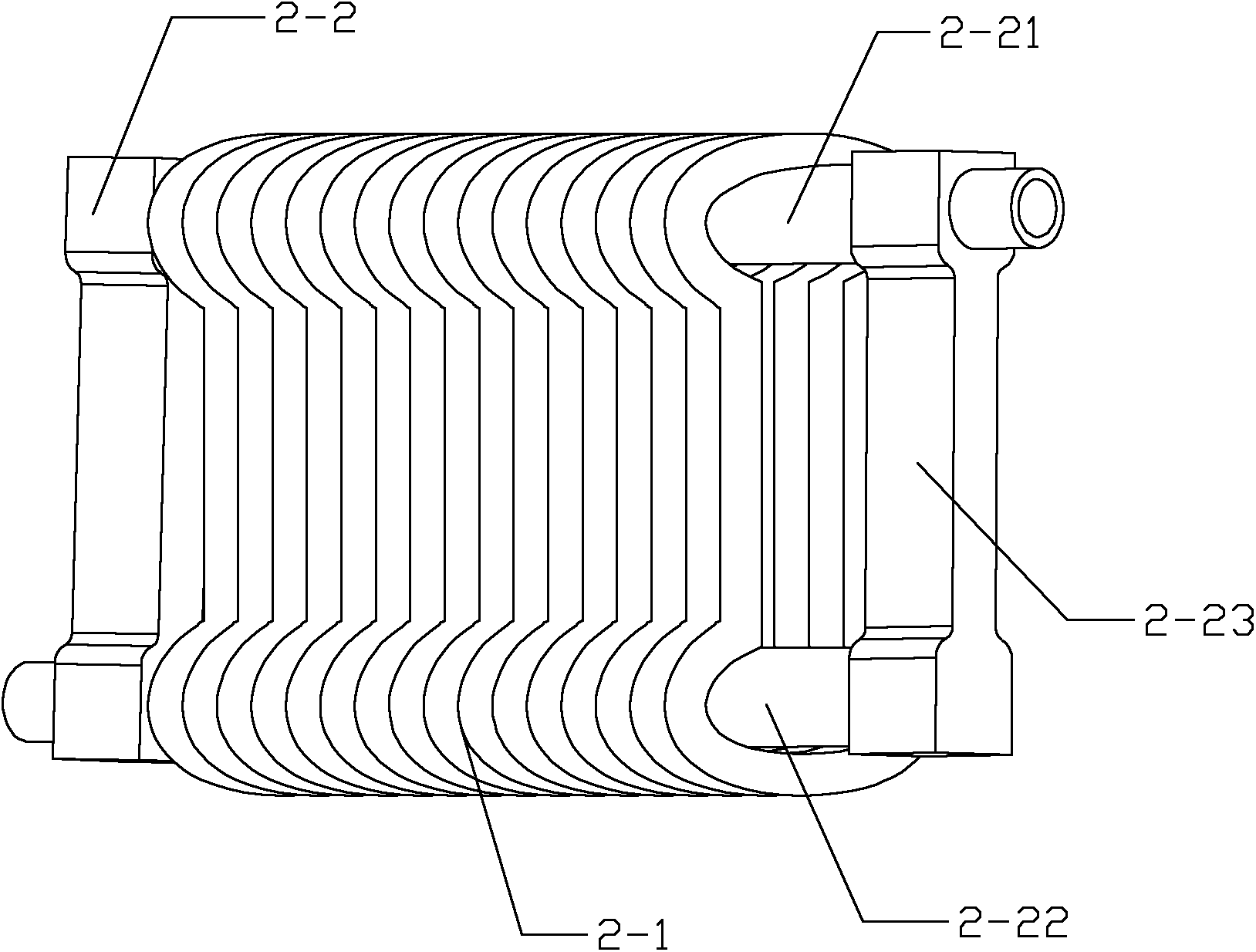

Coreless permanent magnet linear motor with cooling structure, manufacturing mould for winding coil thereof and machining process for winding coil

ActiveCN102255469ASimple structureEasy to manufactureMagnetic circuit rotating partsManufacturing dynamo-electric machinesPermanent magnet linear motorControl theory

The invention relates to a coreless permanent magnet linear motor with a cooling structure, a manufacturing mould for a winding coil thereof and a machining process for the winding coil and belongs to the technical field of linear motors. The coreless permanent magnet linear motor with the cooling structure is used for solving the radiation problem of a coreless permanent magnet linear motor. Stators of the coreless permanent magnet linear motor with the cooling structure are mirror-symmetrically arranged at the two sides of a rotor, wherein the rotor comprises an armature winding and a cooling pipeline; the cooling pipeline is composed of an upper pipeline, a lower pipeline and two connectors; the upper pipeline passes through an arc-shaped through hole which is formed on the upper end part of the armature winding; and the lower pipeline passes through an arc-shaped through hole which is formed on the lower end part of the armature winding. The manufacturing mould for the winding coil of the coreless permanent magnet linear motor with the cooling structure is composed of two winding shape-fixing components, a coil dislocation moving component and two base plates. The machining process for the winding coil by using the manufacturing mould for the winding coil is used for realizing the dislocation of upper and lower coil edges of the winding coil and preventing a winding from falling into pieces. The machining process provided by the invention is suitable for the coreless permanent magnet linear motor.

Owner:HARBIN INST OF TECH

Fault-tolerant type single-winding bearing-less permanent magnet motor

InactiveCN103929035ACompact structureShort endsMagnetic holding devicesSynchronous machines with stationary armatures and rotating magnetsShortest distancePermanent magnet motor

The invention discloses a fault-tolerant type single-winding bearing-less permanent magnet motor. A stator magnet yoke is in a cylinder shape and is placed on the outermost portion of the permanent magnet motor. A rotating shaft and the stator magnet yoke are coaxial, the rotating shaft is placed in the middle in the stator magnet yoke, a rotor iron core coaxial with the rotating shaft is fixed on the outer periphery surface of the rotating shaft, and a plurality of permanent magnets which are evenly distributed on the outer surface of the rotor iron core in a Halbach array structure to form a cylinder shape are fixed on the outer periphery surface of the rotating shaft. Six armature teeth and six fault-tolerant teeth which are arranged in an alternating mode in the periphery direction are fixed evenly on the inner periphery face of the stator magnet yoke. Each armature tooth is provided with a set of an armature winding which generates torque and radial suspension force at the same time in a winding mode. Each set of armature winding is of a concentrating short-distance winding structure. Each phase control current is formed by overlapping of a torque winding control current component and a suspension force winding control current component. According to the fault-tolerant type single-winding bearing-less permanent magnet motor, only one set of armature winding is needed, the structure is simple, motor weight is lowered, and the suspension operation capacity with fault of the motor is improved.

Owner:JIANGSU UNIV

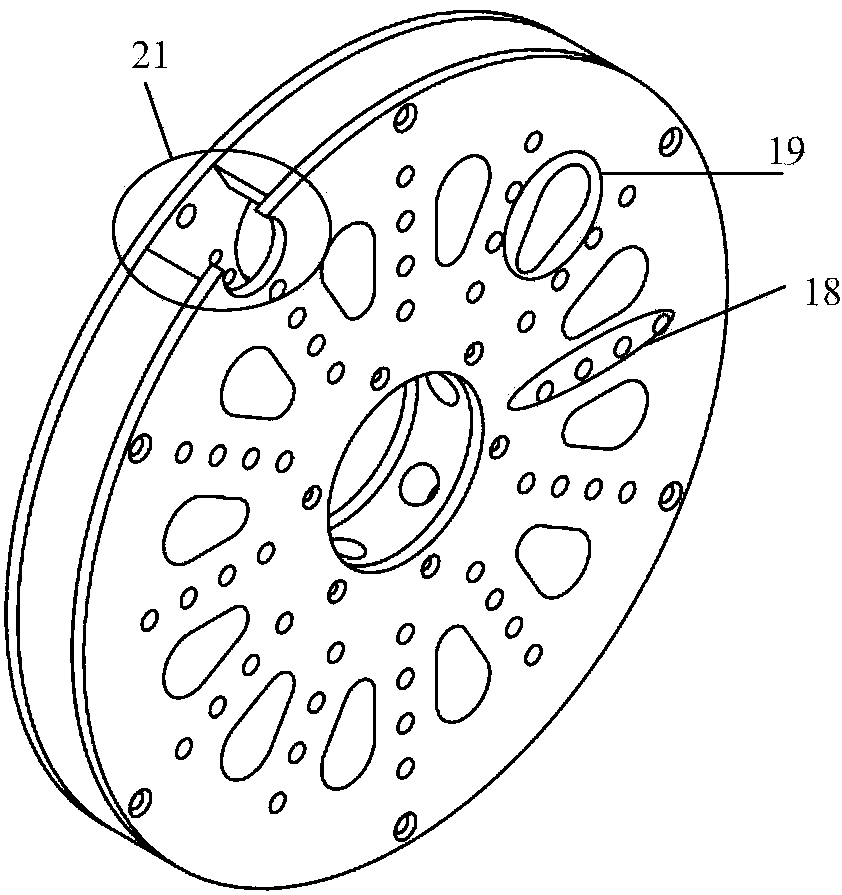

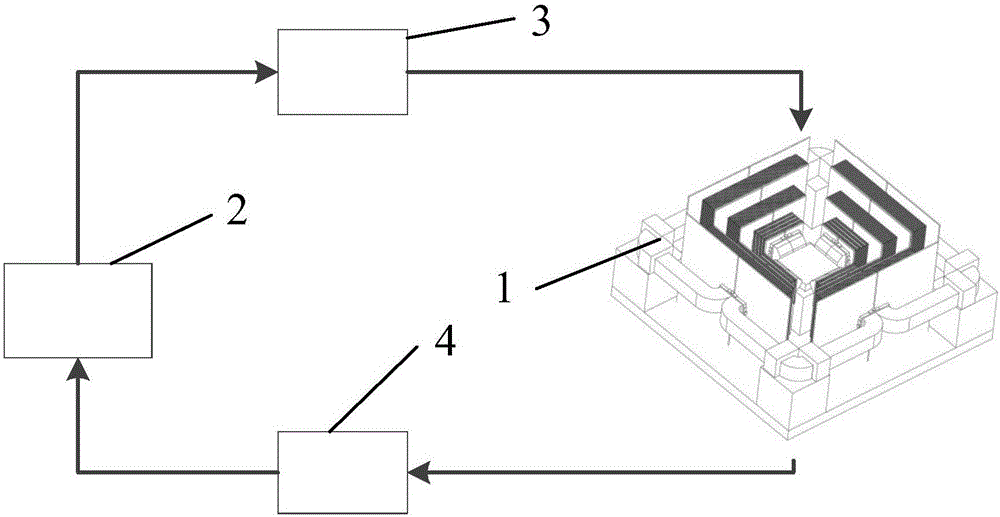

Wideband rotating magnetic characteristic measuring system and method based on flexible excitation coil

ActiveCN106842083AHigh Saturation Magnetic DensityHigh initial permeabilityMagnetic property measurementsDigital signal processingConductor Coil

The invention discloses a wideband rotating magnetic characteristic measuring system and method based on a flexible excitation coil. The measuring system comprises a detection device, a digital signal processing unit, a power amplifier, and a differential amplification circuit. The digital signal processing unit is connected with the power amplifier and the differential amplification circuit. The detection device is connected with the power amplifier and the differential amplification circuit. The detection device comprises a three-stage frustum-shaped excitation winding, a sample holder, a horizontal structure magnetic ring, a center pillar, a buckle, a corner pillar and a base. The excitation winding of the measuring system is designed as a multi-stage frustum-shaped structure to realize a wideband magnetic characteristic test. The measuring method comprises first giving an excitation signal with a low frequency, gradually increasing the frequency of the excitation signal until the sample is saturated; replacing the excitation winding connection mode after the sample is completely measured in the excitation winding connection method, and repeating the measurement process until the highest detection band.

Owner:HEBEI UNIV OF TECH

Switch reluctance motor without bearings

InactiveCN103259464AGood suspensionIncrease profitMagnetic holding devicesReluctance motorControl theory

The invention discloses a switch reluctance motor without bearings. The number of teeth of a suspension stator of the reluctance motor is four, the number of teeth of a torque stator is four times of a phase number m, the number of teeth of a rotor is integral times of four, four suspension stator teeth stretch out of a stator yoke of the rotor, then the phase number m teeth of the torque stator stretch out of each tooth of the suspension stator again, a torque winding winds on each tooth of the torque stator, a suspension winding winds on each tooth of the suspension stator, currents of the torque windings and the suspension windings are controlled respectively, and suspension force and torque are produced at the same time. According to the switch reluctance motor without the bearings, only one winding is arranged on the teeth of the torque stator and the teeth of the suspension stator respectively, relative to a traditional duplex winding switch reluctance motor without the bearings, the torque is not contacted with the suspension windings, a groove full rate is high, a utilization rate of the windings is high, the suspension force and torque force are completely decoupled structurally, a control method is simple, suspension performance of the motor is good, systematic cost is low, and high-speed adaptability is strong.

Owner:NANJING UNIV OF POSTS & TELECOMM

High-power density permanent magnet servo motor and stator structure therefor

InactiveCN105680581AEnsure inner circle is smoothReduce cogging torqueMagnetic circuit rotating partsMagnetic circuit stationary partsRotor magnetsHigh pressure

The invention relates to a stator structure of a high power density motor, comprising a stator tooth core, a stator yoke core and a winding, the stator tooth core is wound with the winding, and is connected with the stator yoke iron The cores are spliced and connected, and filled with a filler in a vacuum and high pressure environment; after splicing, the head end of the stator tooth core forms a ring with a gap. The present invention also relates to a high power density servo motor, comprising the above-mentioned stator structure, a rotor and its rotor magnetic steel, the magnetic steel is attached to the outer surface of the rotor iron core, and the outer surface of the magnetic steel adopts an eccentric structure; the rotor Located inside the stator structure and coaxial with the stator; the air gap between the stator structure and the rotor is a non-uniform air gap. The invention can not only ensure the inner circle of the stator iron core is smooth, reduce the cogging torque of the motor, but also improve the slot full rate of the motor.

Owner:SHANGHAI ELECTRICGROUP CORP

Stator core, stator, motor and air conditioner

InactiveCN106100169AIncrease the winding spaceIncrease slot fill rateMagnetic circuit stationary partsMechanical engineeringUtilization rate

The invention provides a stator core, a stator, a motor and an air conditioner. The stator core comprises a plurality of coiling iron cores sequentially connected, and first connecting structures which arranged between adjacent coiling iron cores, and through which the adjacent coiling iron cores are pivotally connected together. The coiling iron cores on two ends are directly connected together or connected through a second connecting structure. The problem that in the prior art, the stator core is low in coiling efficiency, poor in production size precision and quality, low in iron core raw material utilization rate and incapable of being used to produce motors with high coil space factor can be solved.

Owner:ZHUHAI KAIBANG MOTOR MFR +4

Motor and sine stator

InactiveCN104079085AImprove efficiencyEliminate the effects ofMagnetic circuit stationary partsWire rodElectrical resistance and conductance

The invention relates to a single phase or three phases including an alternating current synchronous motor stator, an alternating current asynchronous motor stator and the like, in particular to a motor and a sine stator. A plurality of teeth 5 and a plurality of teeth 4 are circumferentially arranged at intervals, the width of bodies of the teeth 5 is larger than that of bodies of the teeth 4 by two or more times, the motor sine stator is formed by arranging the teeth 5 serving as the main parts and the left and right teeth 4 serving as the auxiliary parts, three-tooth pole cambered surface air gaps are distributed according to the sine law, but the total cross section of an iron core is kept unchangeable, the polar distance becomes short, the end of a stator coil becomes short, the resistance of the coil is small, the loss is reduced, motor output and efficiency are increased, wire rods are saved, and wire inserting and connecting are easy to conduct in a labor saving mode. Thus, the effect of five harmonics, seven harmonics and other harmonic magnetic potentials on the motor is further reduced, the performance and the torque of the motor are improved, and the motor sine stator has good energy saving and emission reducing effects.

Owner:顾明

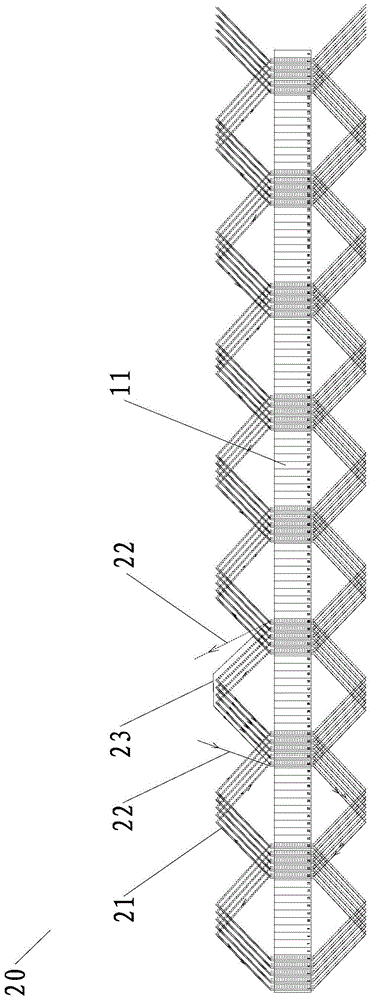

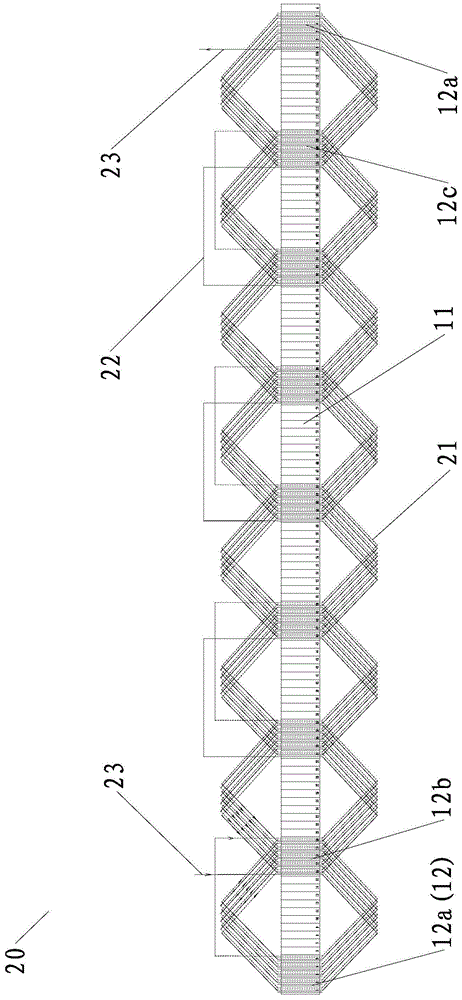

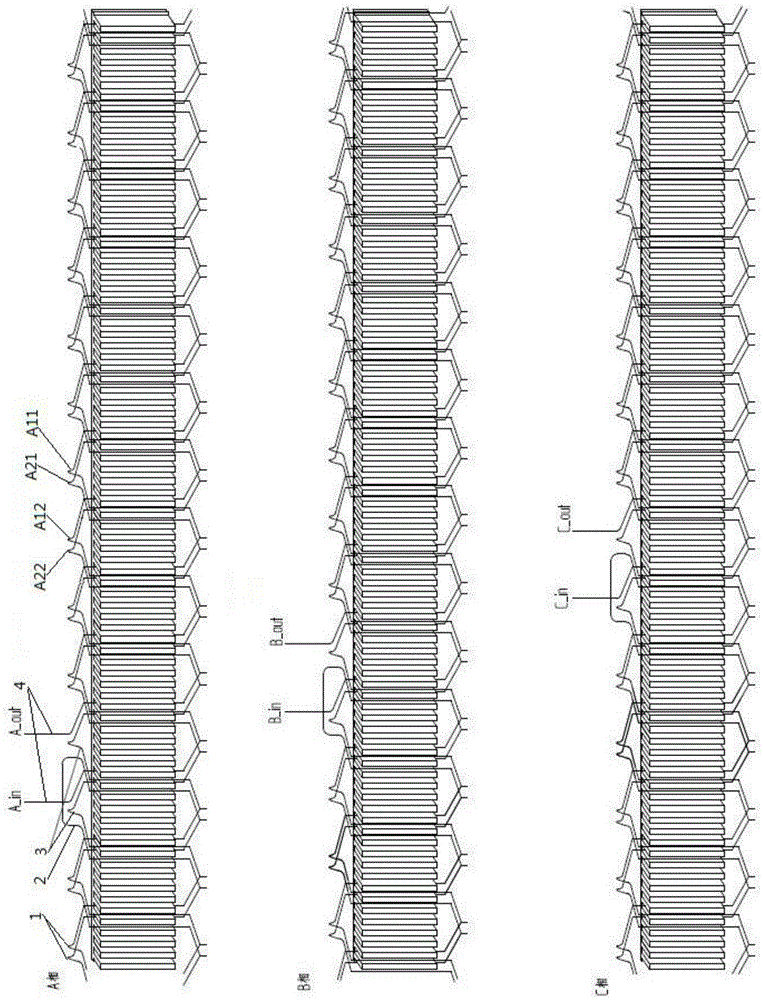

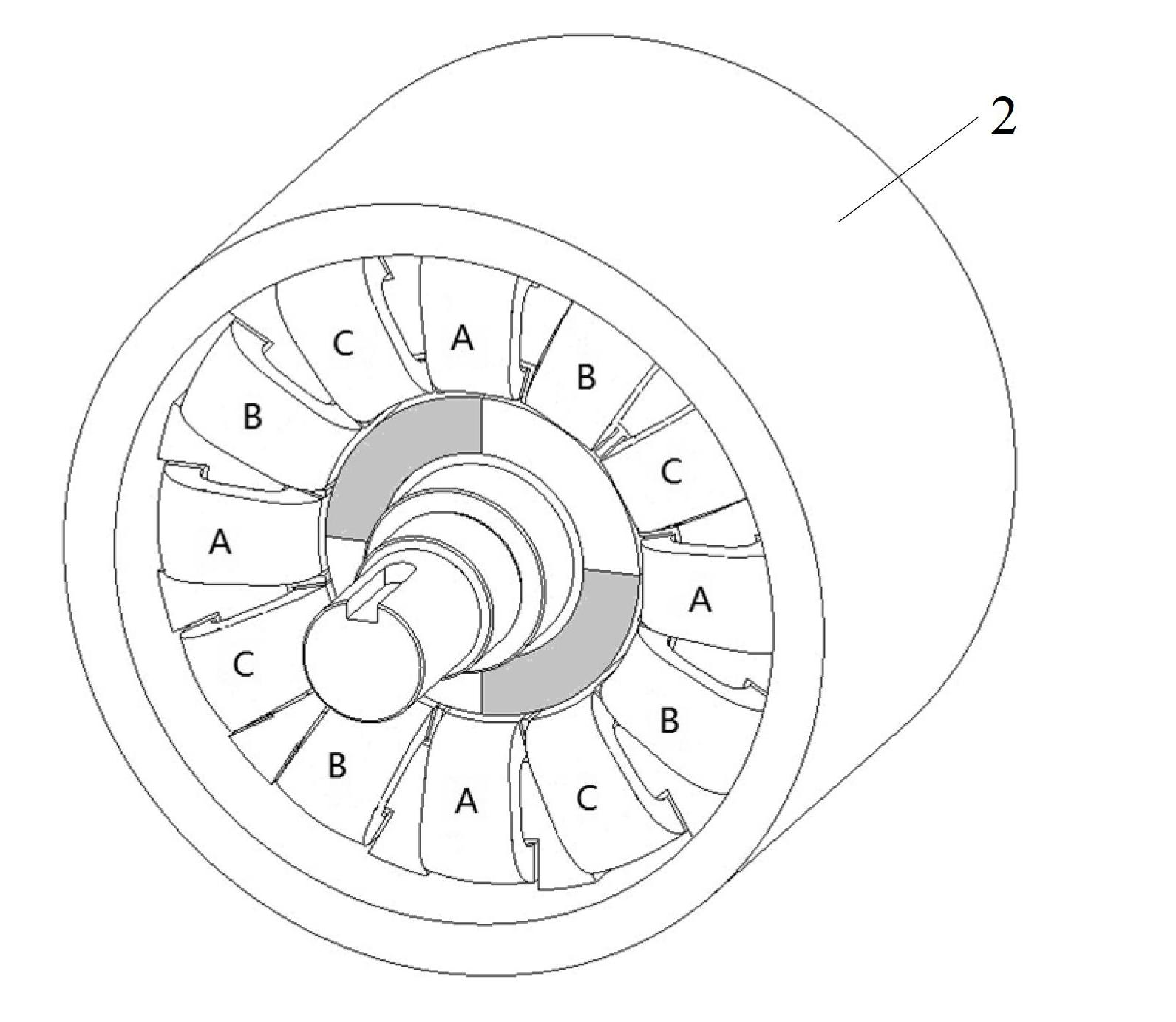

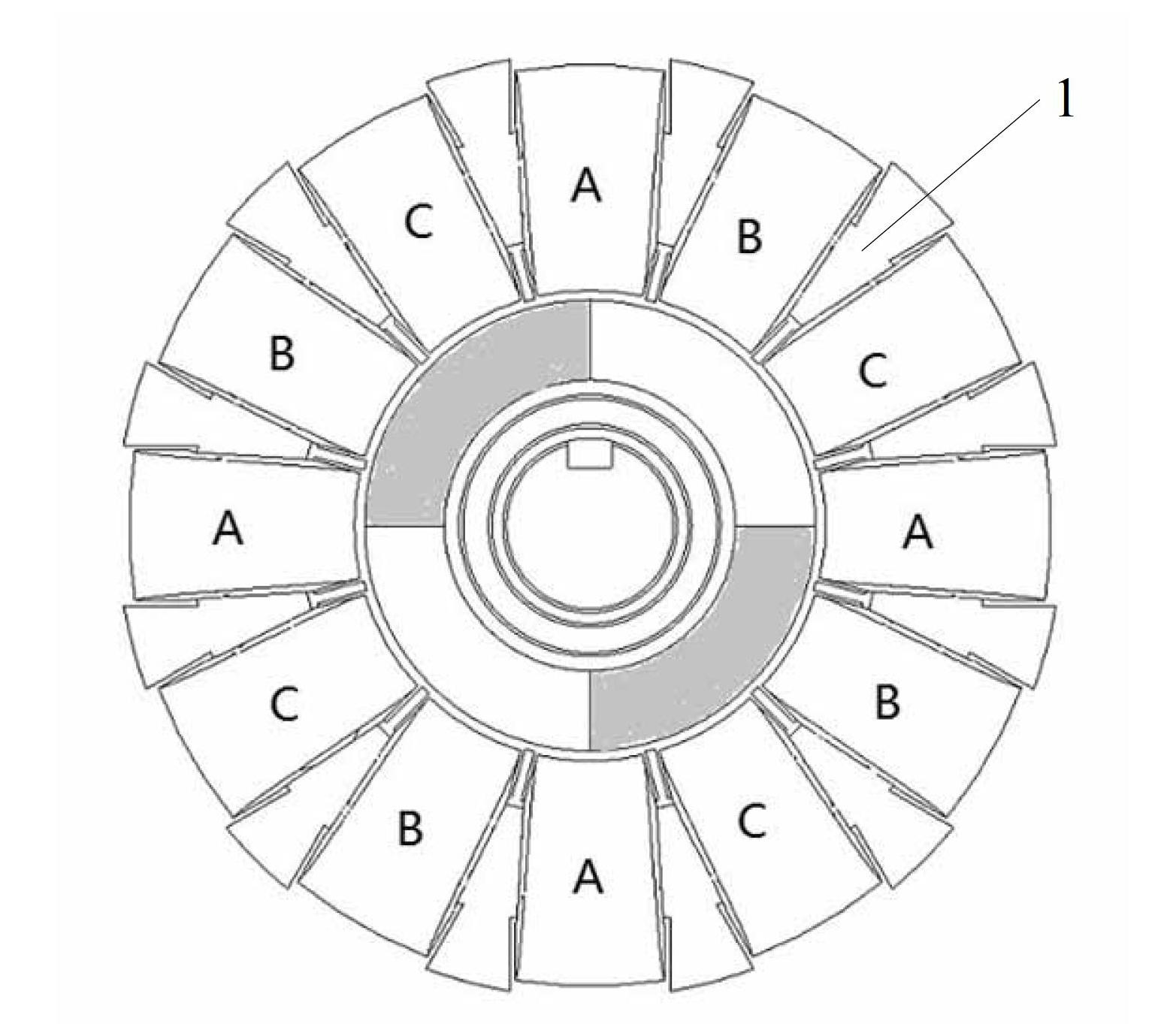

Automobile generator stator assembly employing three-phase multi-slot flat copper wire

ActiveCN105634169AIncrease slot fill rateReduce copper consumptionWindings conductor shape/form/constructionCopper lossCopper wire

The invention relates to an automobile generator stator assembly employing a three-phase multi-slot flat copper wire. The automobile generator stator assembly comprises a stator core and three phase windings A, B and C, wherein the automobile generator stator assembly is characterized in that inner and outer two layers of winding positions are arranged in each winding slot of the stator core; the three phase windings A, B and C are alternately arranged in the stator core; each phase winding comprises two split-phase windings which are adjacent in circumferential direction; each split-phase winding comprises a layered winding I and a layered winding II, which are adjacent in radial direction in the same slot and are opposite in direction and are arranged in a wave form; the layered windings I of the two split-phase windings are parallel in winding direction; and the layered windings II of the two split-phase windings are parallel in winding direction. The wire inserting design of the structure significantly improves the copper wire spacer factor of the stator assembly; the usage amount of the copper wire at the end part of the stator assembly is reduced; the material cost is reduced; meanwhile, the volume of a generator is reduced; the power density of the generator is improved; the copper loss is reduced; and the generator efficiency is improved.

Owner:JINZHOU HALLA ELECTRICAL EQUIP

Stator assembly of automotive engine or driving motor

ActiveCN103795170AIncrease slot fill rateIncreased power volume densityManufacturing dynamo-electric machinesWindings conductor shape/form/constructionCross connectionCopper wire

The invention relates to a stator assembly of an automotive engine or a driving motor. The stator assembly comprises a stator iron core and multiple phases of windings, and is characterized in that each phase of winding is composed of multiple sets of rectangular copper wire base winding elements, a rectangular copper wire cross connection element and a rectangular copper wire outlet element, wherein the multiple sets of rectangular copper wire base winding elements are connected end to end and sequentially inserted into winding grooves of the stator iron core, and the rectangular copper wire cross connection element and the rectangular copper wire outlet element are connected between the first set of the rectangular copper wire base winding elements and the last set of the rectangular copper wire base winding elements in series. The middle portion of the base winding element body I of each rectangular copper wire base winding element and the middle portion of the base winding element body II of the rectangular copper wire base winding element are twisted together, and the straight sides of the two element bodies located on the same side are attached side by side. A certain span is formed between the straight side a of each element body on the front side and the straight side b of the corresponding element body on the rear side. The straight side a of each element body is inserted into the first layer position of the corresponding winding groove and the second layer position of the corresponding winding groove. The straight side b of each element is inserted into the third layer position of another corresponding winding groove and the fourth layer position of another corresponding winding groove. The defect that the sides of the elements are easily scratched through the bending method of a structure welding end of an existing rectangular copper wire stator assembly, and therefore defective products are formed after insulating enameled leather falls is overcome, power generation capacity and power generation efficiency of the engine are improved, and temperature rise and noise are reduced.

Owner:JINZHOU WONDER AUTO DIANZHUANGPIN

Novel permanent magnet motor with high reliability and high power density

InactiveCN109599958AImprove fault toleranceIncrease phase independenceMagnetic circuit stationary partsCooling/ventillation arrangementFilling ratePerformance index

The invention discloses a novel permanent magnet motor with high reliability and high power density. A stator adopts a modular structure, an isolated strip-shaped structure is designed at the center of a groove to match a modular main stator core, and a winding adopts a fractional slot concentrated winding structure having a span of 1. A rotor can adopt a conventional surface patching structure, ahighly polymagnetic Hallbach permanent magnet array structure or a built-in permanent magnet structure. The novel permanent magnet motor has the advantages of greatly improving the winding process bymeans of the matching of the modular stator structure, the isolated strip-shaped structure and a cross section shape of a conducting wire, thereby improving the slot filling rate of the motor from the processing technology. In addition, through the thermal conduction and magnetic isolation functions of the isolated strip-shaped structure, the performance indexes such as the electromagnetic torqueand the amount of permanent magnets and the like of the motor are basically not affected while reducing the motor winding temperature and improving the interphase independence of the winding.

Owner:JIANGSU UNIV

Stator assembly method and laminated stator manufactured by same

ActiveCN101710765ABig spaceReduce eccentricityMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringAxial distance

The invention provides an assembly method of a laminated stator for a motor, which comprises the steps of: a, providing a plurality of laminated plates, wherein each laminated plate comprises a ring part with a center line and a plurality of teeth arranged at intervals of equal angle distances along the circumferential direction of the ring part, and the teeth of all laminated plates are equal; b, sequentially coaxially fixing the laminated plates to enable the laminated plates to be arranged at a distance of preset axial distance mutually; and c, rotating the laminated plates around the common center line to a preset angle position, pressing the laminated plates to enable the ring parts of the laminated plates to be overlapped on the axial direction, wherein the teeth of the laminated plates are crossly arranged along the circumferential directions of the ring parts, and thereby a tooth of another laminated plate is arranged between every two adjacent teeth of each laminated plate. The invention also provides a laminated stator manufactured by the assembly method.

Owner:NIDEC MOTOR (QINGDAO) CORPORATION

Segmentation iron core and coiling method for motor

InactiveCN101414766AIncrease slot fill rateMagnetic circuit stationary partsManufacturing dynamo-electric machinesMortise and tenonMechanical engineering

The present invention relates to a block for a stator segmenting iron core in a compressor motor. Wherein, the gear top part and the gear root part of the block are parallel with each other so as to ensure the groove shape to constitute a complete trapezoid; the block is designed with a mortise structure so as to connect the adjacent blocks.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

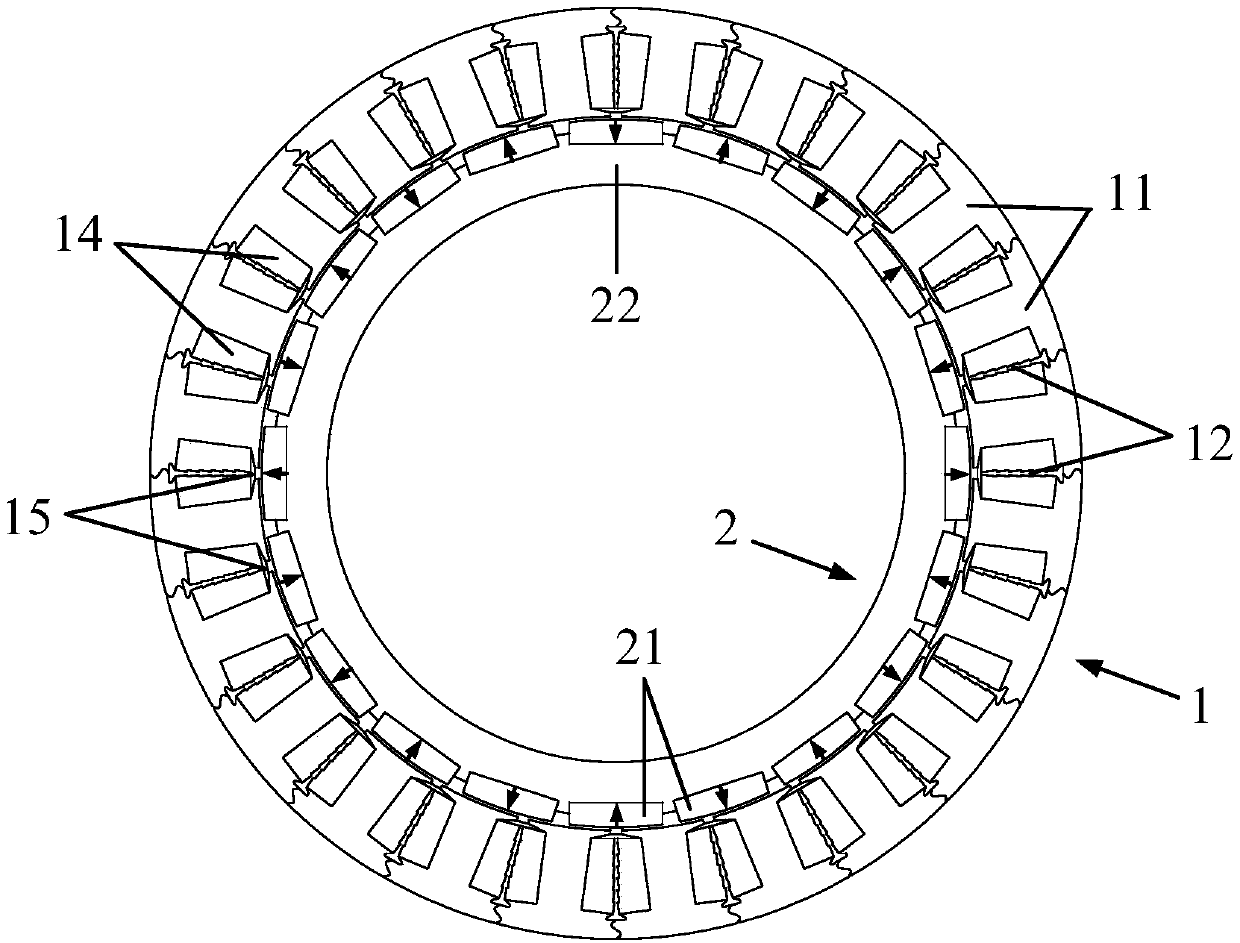

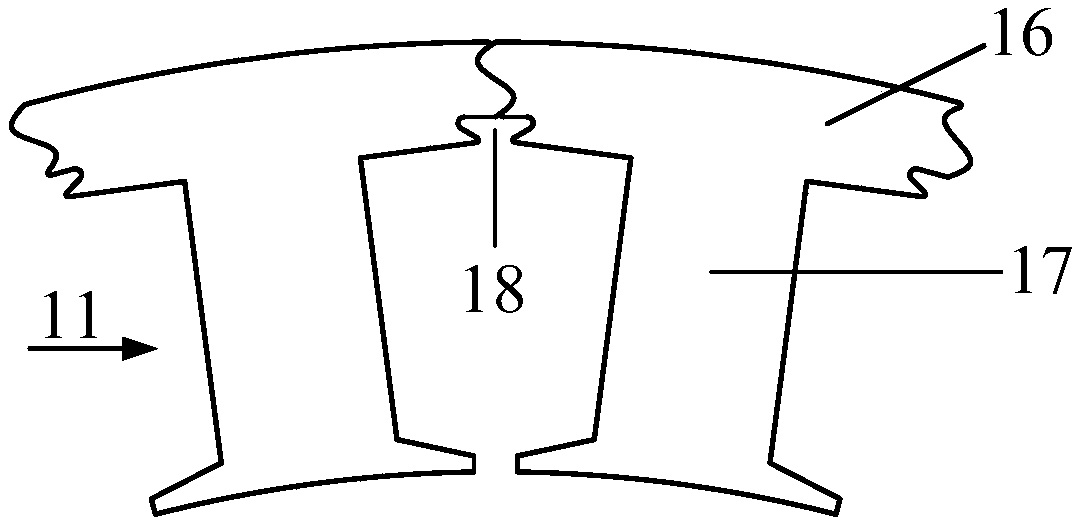

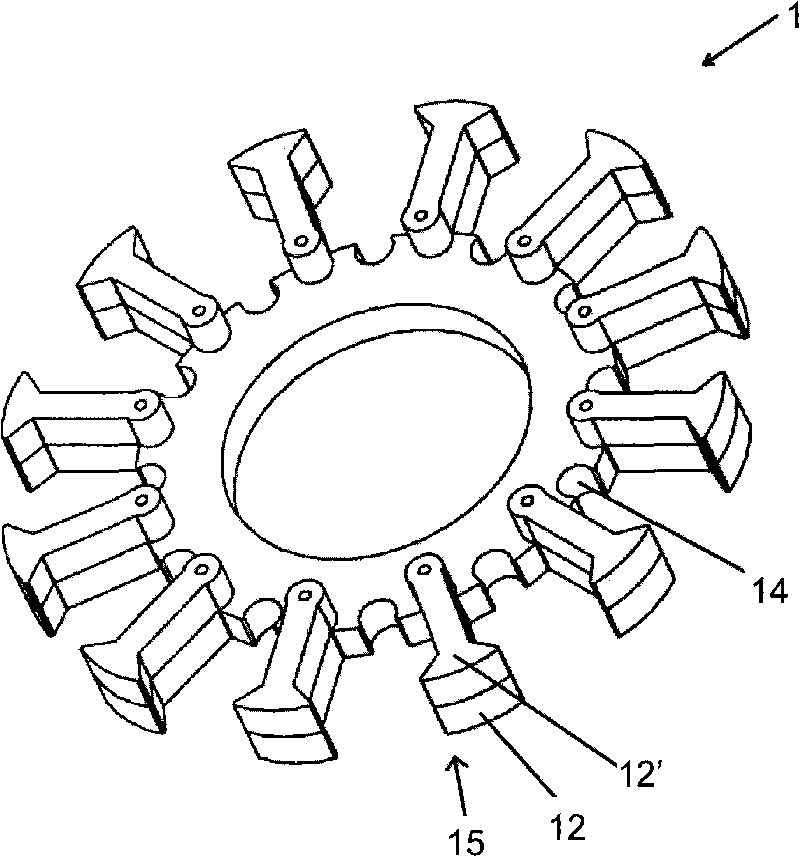

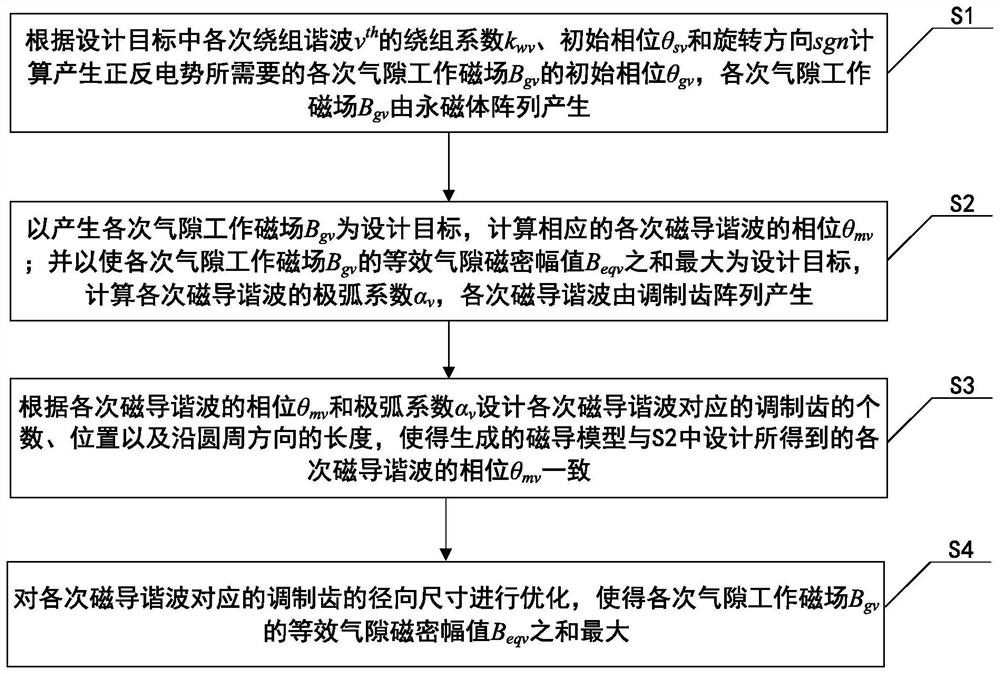

Permanent magnet motor topology construction method based on working magnetic field harmonic orientation, and motor

ActiveCN112421919AIncreased torque output capabilityGive full play to the electromechanical energy conversion abilitySynchronous machine detailsMagnetic circuit rotating partsElectric machineHarmonic

Owner:HUAZHONG UNIV OF SCI & TECH

Polyphase permanent magnet motor with leakage reactance adjustable structure

InactiveCN102664504AReduce torque fluctuationImprove efficiencyMagnetic circuit stationary partsPropulsion systemsPermanent magnet motorLinear motor

The invention discloses a polyphase permanent magnet motor with a leakage reactance adjustable structure, and belongs to the technical field of motors. The motor can be a cylindrical rotating motor as well as a flat linear motor. The air gap side of a stator core is a smooth surface, and core slots are axially reserved on the other side of the stator core. A plurality of core slots are uniformly distributed on the surface of a stator. A coil rack is fixedly arranged on the air gap side of the stator core, and is uniformly provided with a plurality of coil slots along a circumferential direction. The coil slots are in one-to-one correspondence with the stator slots. The centerlines of the coil slots and corresponding core slots are positioned on the same radius. One active side of each coil of an armature winding is embedded into a wire casing, and the other active side of the coil is embedded into a stator slot opposite to the wire casing. The stator slot is an open slot, a closed slot or a semi-open slot. The polyphase permanent magnet motor has the advantages of high winding accuracy, high insulation characteristics, short end part, high efficiency and small torque fluctuation.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com