Novel permanent magnet motor with high reliability and high power density

A high power density, permanent magnet motor technology, applied in the aerospace field, can solve the problem that the cooling system is difficult to meet the high power-to-weight ratio, and achieve the effect of increasing phase independence, improving fault tolerance performance, and increasing winding slot fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

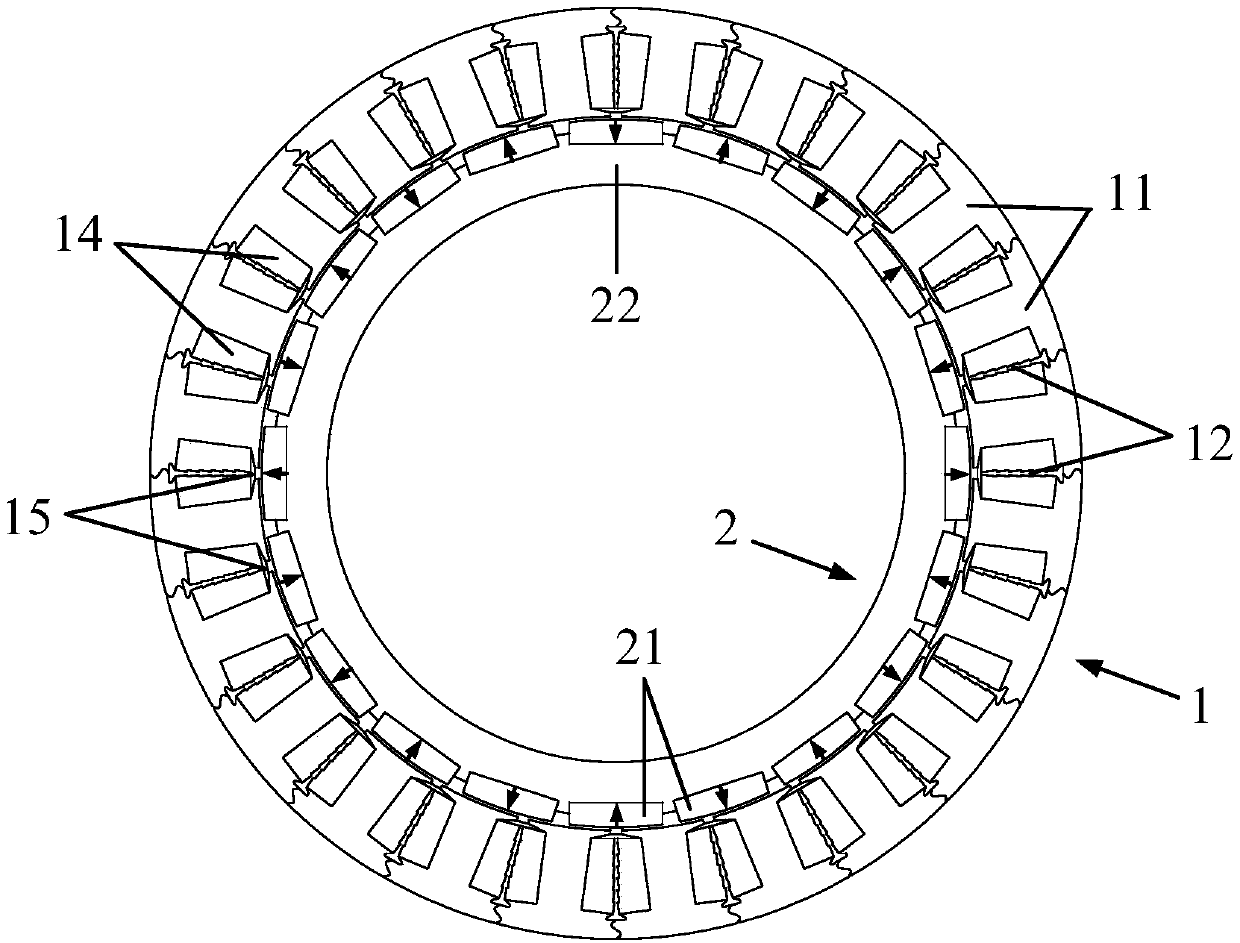

[0037] Please refer to figure 1 , The present invention is a high reliability, high power density design method for a permanent magnet motor, comprising a stator 1, a rotor 2, and an air gap between the stator 1 and the rotor 2. The slots 14 of the stator 1 are used to place windings. For the specific structure and proportional relationship of rotor 2, see figure 2 .

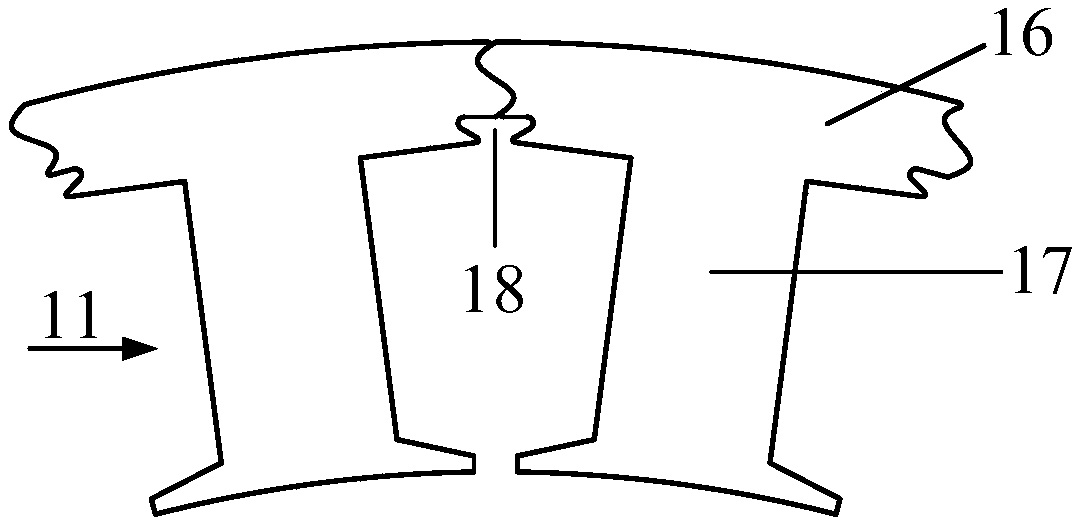

[0038] A novel permanent magnet motor with high reliability and high power density, comprising a stator (1) and a rotor (2); the stator (1) comprises a modular stator structure (11), an isolated strip structure (12), an armature Windings (14), slot wedges (15); the modular stator structure (11) includes a stator yoke (16) and a stator tooth (17), and the armature winding (14) is wound on the stator tooth (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com