Stator assembly method and laminated stator manufactured by same

An assembly method and lamination technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of low slot full rate and many winding heads, etc. Increase the space, reduce the eccentricity, and overcome the effect of many winding connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

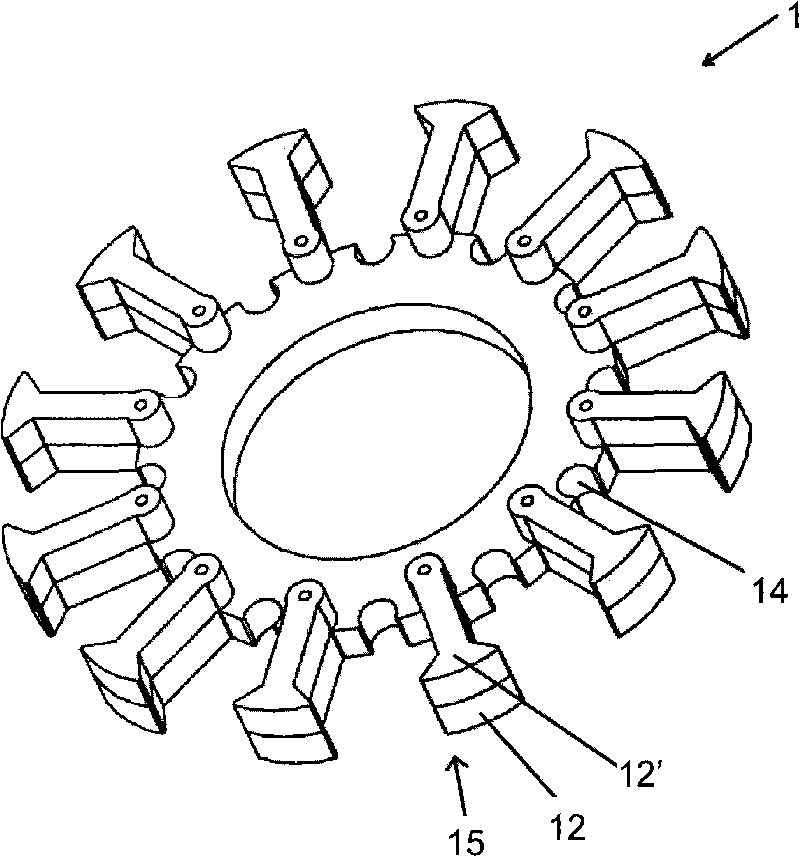

[0036] figure 1 Shown is a thinner lamination 10 than a conventional stator lamination. The sheet 10 has a ring portion 11 and tooth pieces 12 arranged at equal angular intervals along the outer circumference of the ring portion. The tooth piece 12 is T-shaped as a whole, and has a tooth root portion 121 , a tooth body portion 122 and a tooth end portion 123 along the radial direction. The tooth end portion 123 has an arc surface in the circumferential direction. The configuration of the tooth piece 12 can prevent the winding wire from slipping off from the tooth. The tooth tip portions of all the teeth of the entire foil 10 define an imaginary peripheral surface. Preferably, the gear piece 12 is integrated with the ring portion 11 . As an example, the foil 10 is shown with 12 teeth. A positioning hole 13 is provided at the tooth root of each gear piece 12 . Optionally, a notch 14 is provided at the central part of the ring portion 11 between two adjacent teeth (ie, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com