Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Play a coupling role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-crosslinked aqueous traffic paint and method for using same

ActiveCN1721486AGood chemical stabilityImprove wear resistanceTraffic signalsCoatingsEmulsionLacquer

The present invention is self-linking water thinned road mark paint and its preparation and usage. The road mark paint is storage stable and has solid content of at least 75 %, and anionic self-linking silicone propylene emulsion as main material. Specifically, it consists of anionic self-linking silicone propylene emulsion 20-50 weight portions, distilled water 1-5 weight portions, methanol 1-5 weight portions, filming assistant 1-5 weight portions, dispersant 1-3 weight portions, moistener 0.1-1 weight portions, disinfecting mildew inhibitor 0.1-0.5 weight portions, defoaming agent 0.1-0.5 weight portions, and pigment and stuffing 20-80 weight portions. It may be painted to road directly or on primer, and may be used widely for different kinds of road.

Owner:阿克苏诺贝尔功能涂料(常州)有限公司

Glass fiber impregnating compound and preparation method and application thereof

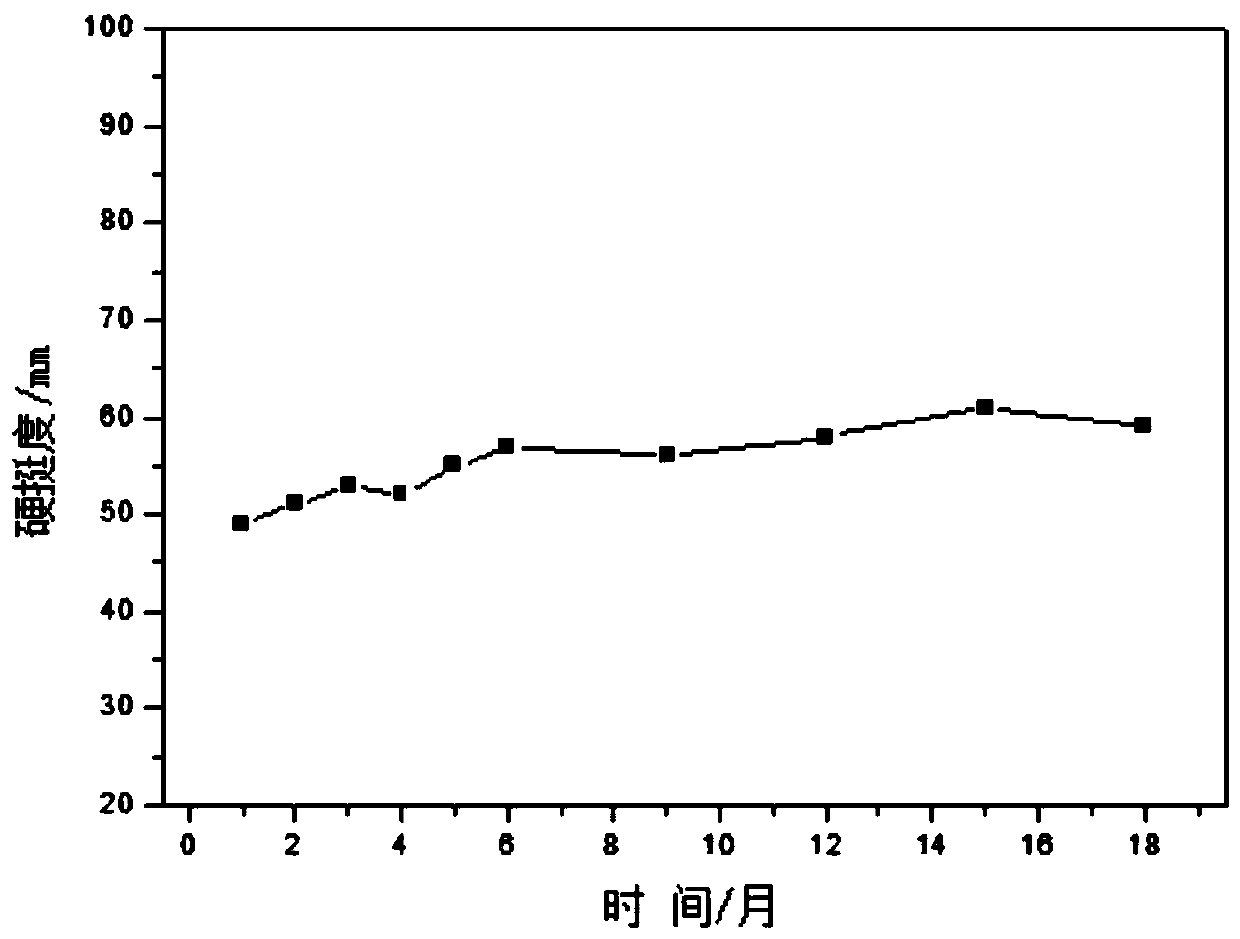

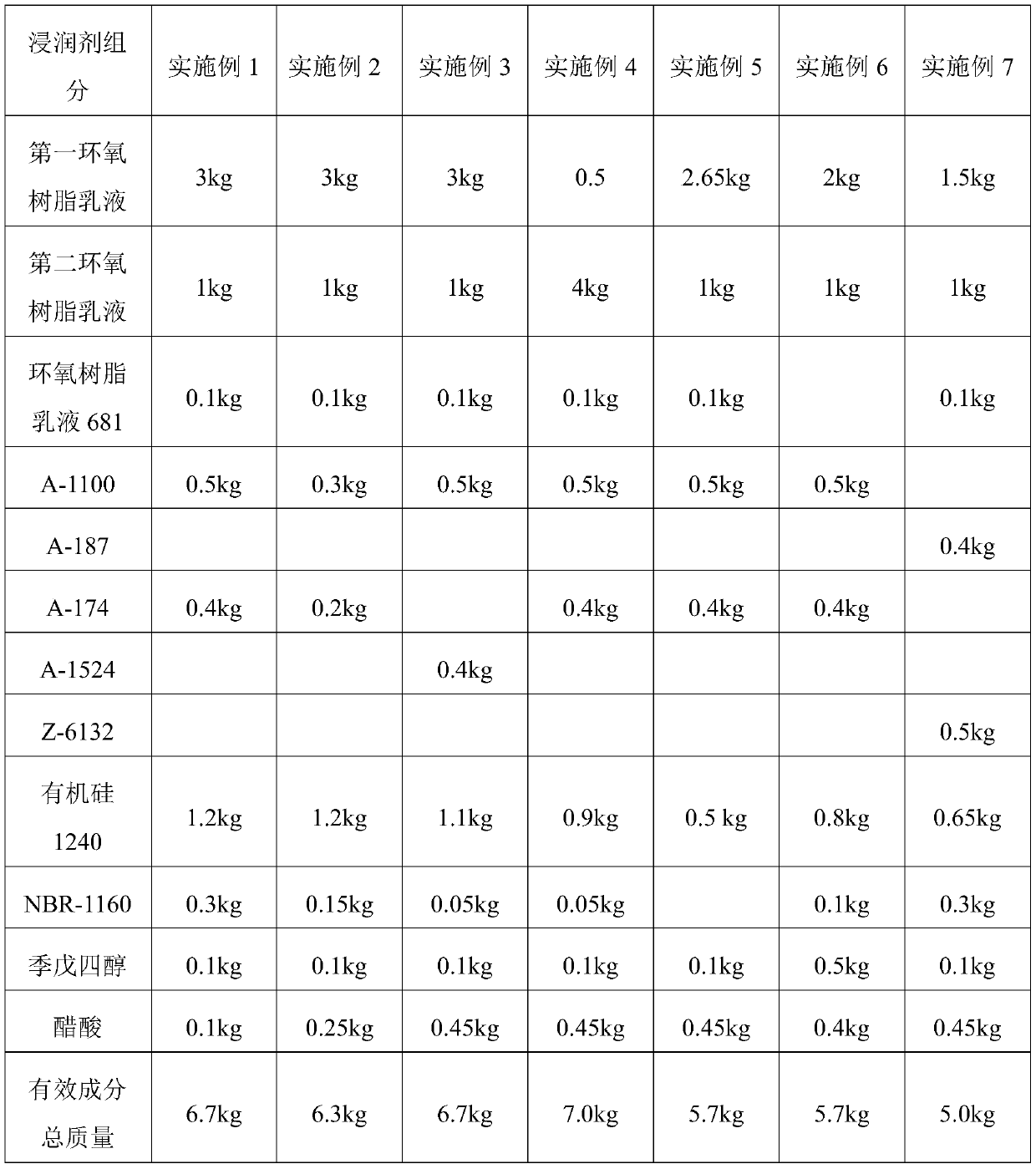

The invention belongs to the technical field of impregnating compounds, and discloses a glass fiber impregnating compound and a preparation method and application thereof. The impregnating compound comprises a film-forming agent, a coupling agent, a lubricant, a wetting agent and a pH regulator, wherein the film-forming agent comprises two bisphenol A type epoxy resin emulsions with different epoxy equivalents. Compared with usage of an epoxy resin emulsion with a single epoxy equivalent as a film-forming agent, the film-forming agent disclosed by the invention has the advantages that the film-forming agent can ensure sufficient coating force of the epoxy resin emulsions on the surfaces of yarns and allow the yarns to have better softness; even if the yarns are stored for a long time, theyarns still have low stiffness, which is beneficial for subsequent processing and mechanical strength of a composite material; and meanwhile, the yarns have better damp-heat resistance and still havea good strength retention rate in a high-temperature and high-humidity environment due to matched use of the film-forming agent and the coupling agent.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

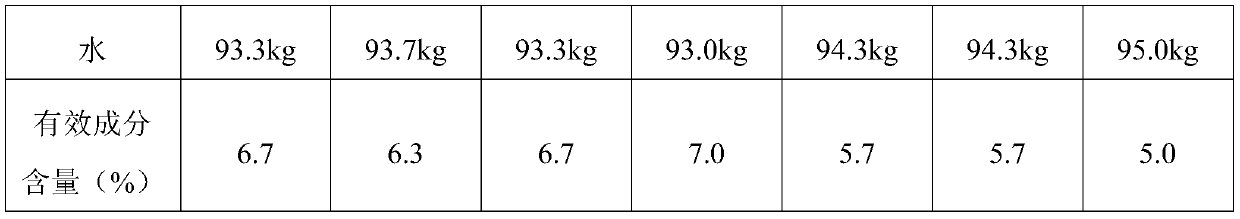

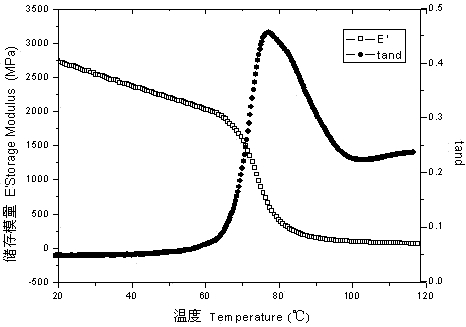

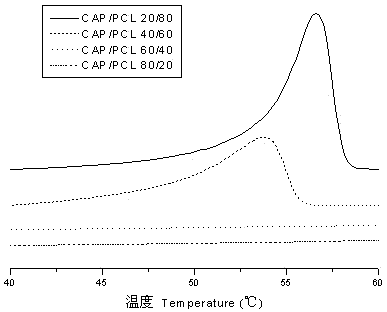

Biodegradable polymer material compatibilized and blended by lignocellulose and preparation method thereof

The invention discloses a biodegradable polymer material compatibilized and blended by lignocellulose and a preparation method thereof. The biodegradable polymer material is composed of a resin mixture and a compatibilizer. The resin mixture is composed of resin and cellulose acetate or cellulose acetate propionate which is prepared from cellulose of poplar wood pulp. The resin is selected from any one of polycaprolactone, polylactic acid and polyhydroxybutyrate. The compatibilizer is a block copolymer of polycaprolactone-acid anhydride compound and the use amount of the compatibilizer is 2-30% of the total mass of the resin mixture. The preparation method provided by the invention comprises the following steps of: mixing celluosic resins to obtain the resin mixture; then compulsively feeding after adding the resin mixture and the compatibilizer into a feed bin of a double-screw extruder; cooling the extrudate by air and then dicing the extrudate into particles to obtain resin particles. The biodegradable polymer material and the preparation method provided by the invention have advantages of environmental friendliness, low cost, good combination property, stable product performance and higher promotion value.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

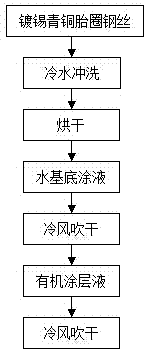

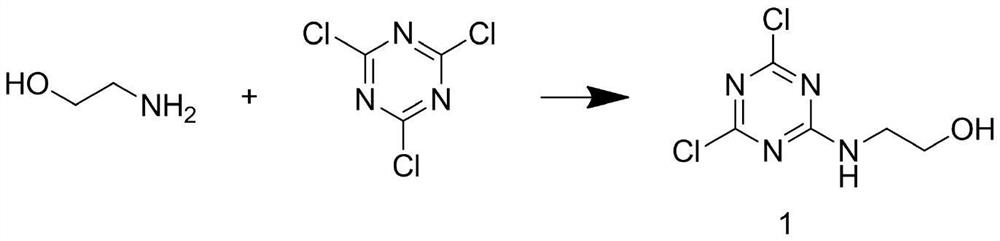

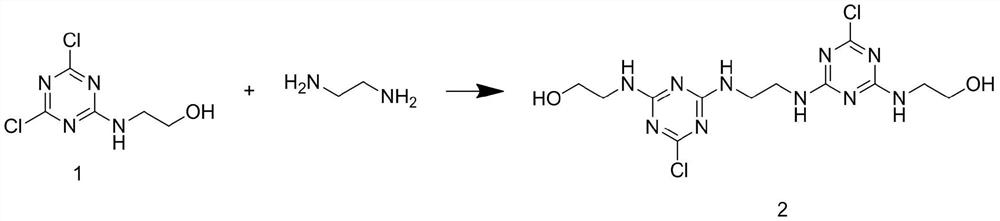

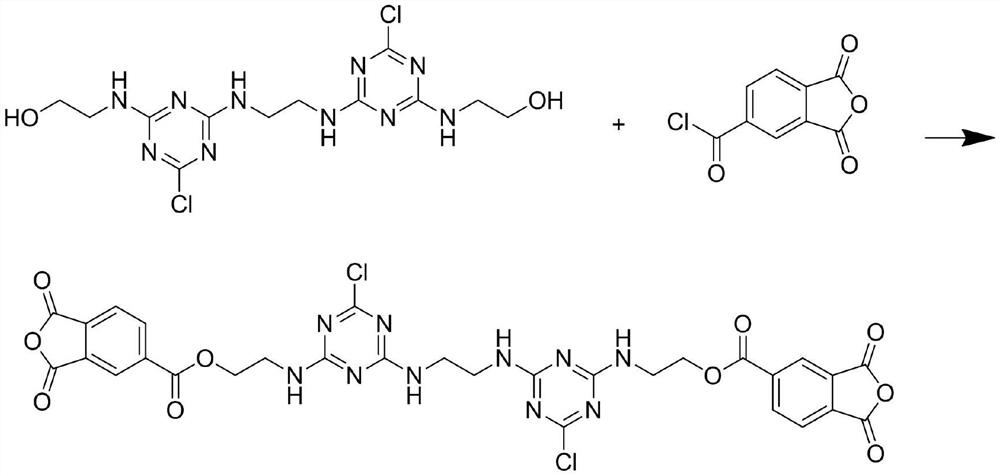

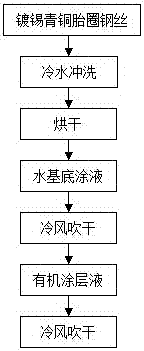

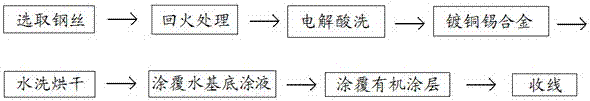

Water-based first coating for tire bead steel wire plating aftertreatment

ActiveCN104497871AImprove adhesionAdhesive rate increasedLiquid/solution decomposition chemical coatingWater basedOctanoic Acids

The invention discloses a water-based first coating for tire bead steel wire plating aftertreatment. The water-based first coating is prepared from at least one of N-beta (aminoethyl)-gamma-diethylaminopropyl-methyldimethoxysilane (triethoxyl silicon propyl) tetrasulfide, bi(triethoxyl silicon propyl) disulfide and 3-sulfo-octanoic acid-1-propyl triethoxyl silane, as methanol, ethanol and water. Hydrolysis groups at one end of the molecular chain of the silane coupling agent in the water-based first coating are subjected to hydrolysis and react with a steel wire substrate so as to be combined together, and organic groups at the other end of the molecular chain can react with organic components in an aftertreatment process, so that inorganic metal and organic resin are effectively connected; when the water-based first coating is applied to tire bead steel wire plating aftertreatment, the adhesive force of a tire bead steel wire and rubber can be effectively improved, the adhesive adhesion rate of the surface of the adhered steel wire is increased, and the preservation time of the steel wire is prolonged.

Owner:JIANGSU XINGDA STEEL TYPE CORD

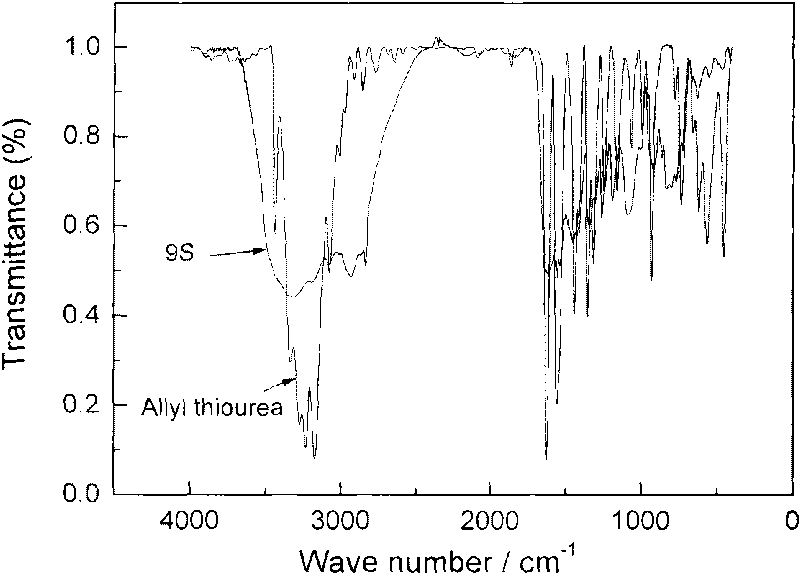

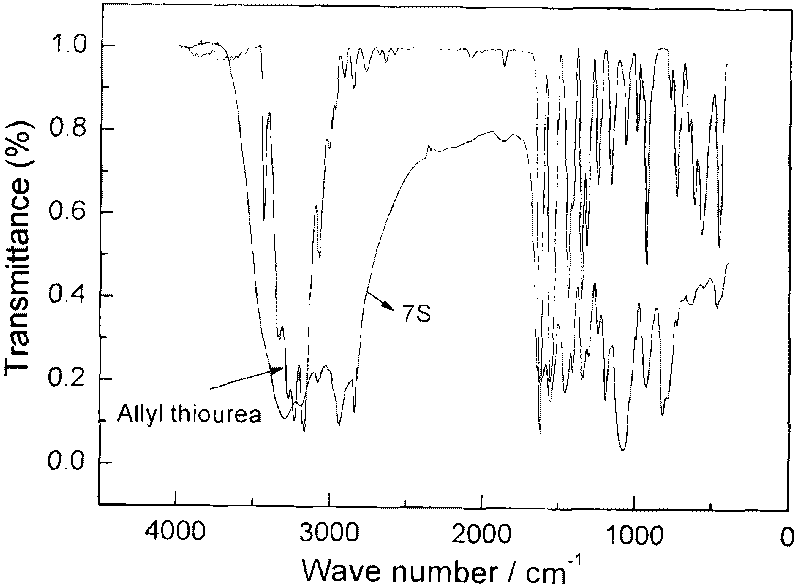

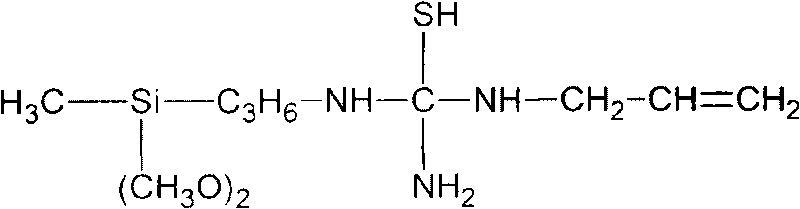

Preparation method of silane coupling agent containing allyl sulfydryl and amino and usage thereof

InactiveCN101747532AAct as modifierReduce and inhibit oxygen inhibitionGroup 4/14 element organic compoundsNon-macromolecular adhesive additivesPrepolymerAddition reaction

The invention discloses a preparation method of a silane coupling agent containing allyl sulfydryl and amino and a usage thereof. The molecular structural formula of the silane coupling agent is (R1O)3-xSiR2xR3(NHR4)yNHz(SHCNH2NHCH2CH=CH2)m. The silane coupling agent is obtained through addition reaction of 1-2 mole allylthiourea and 1 mole silane coupling agent with the molecular formula of (R1O)3-xSiR2xR3(NHR4)yNH2, wherein R1 and R2 are straight chain or branched alkyl of same or different 1-6 carbon atoms, R3 is alkylidene and aryl of 1-6 carbon atoms or aryl alkylidene and alkyl arylene of 6-10 carbon atoms, and R4 is alkylidene of 1-6 carbon atoms, x is 0 or 1, y is 0, 1 or 2, z is 0 or 1, and m is 2-z. Compared with the traditional allyl monomer, the silane coupling agent can be used as active diluent monomer of ultraviolet curing prepolymer, the sulfydryl is contained in the molecule, the inhibition of the oxygen to the ultraviolet curing process can be effectively reduced, the ultraviolet curing speed is improved, the function of the silane coupling agent can be brought into play, and the adhesion function of the coating adhesive and the matrix is improved.

Owner:浙江凌志新材料有限公司

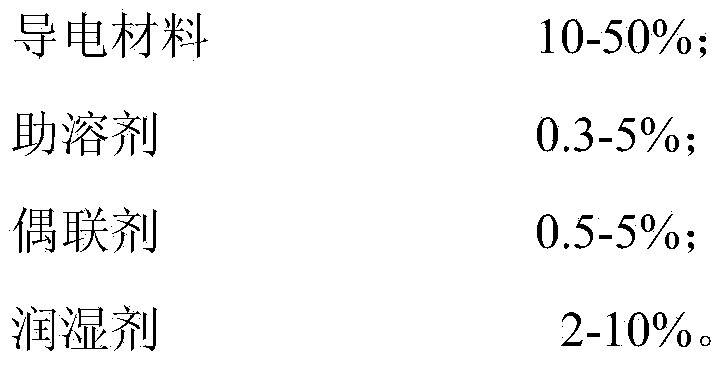

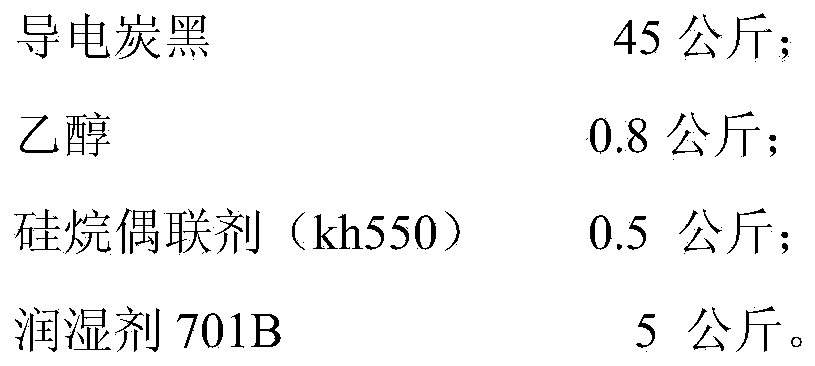

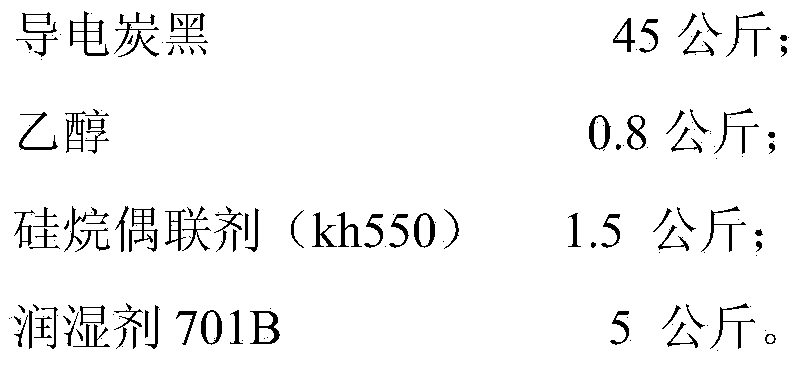

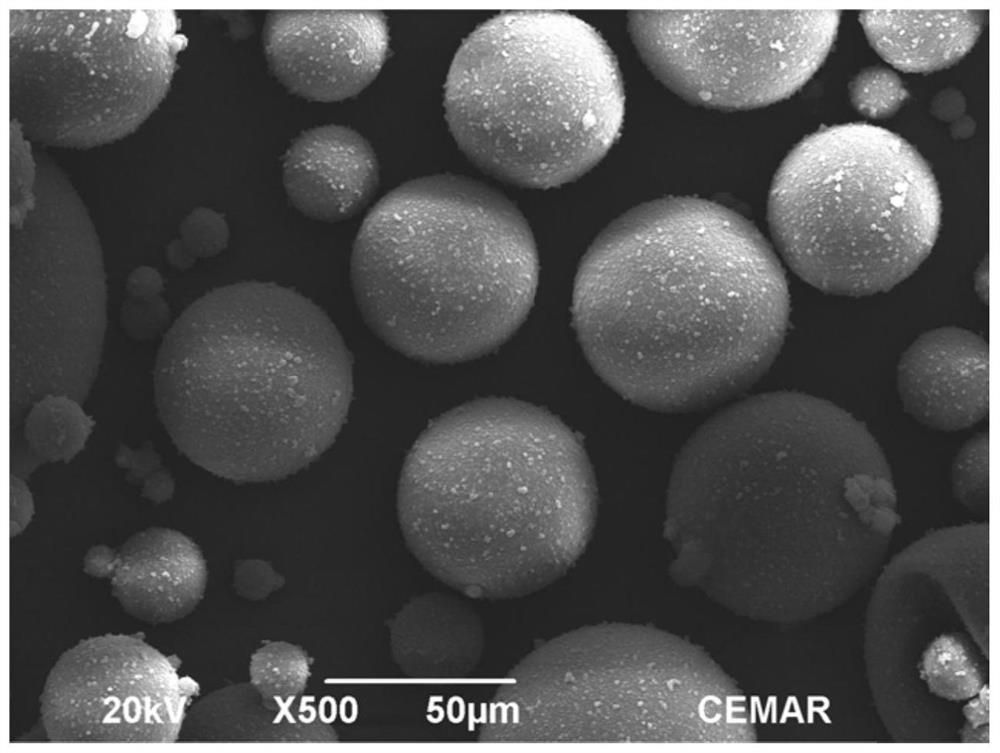

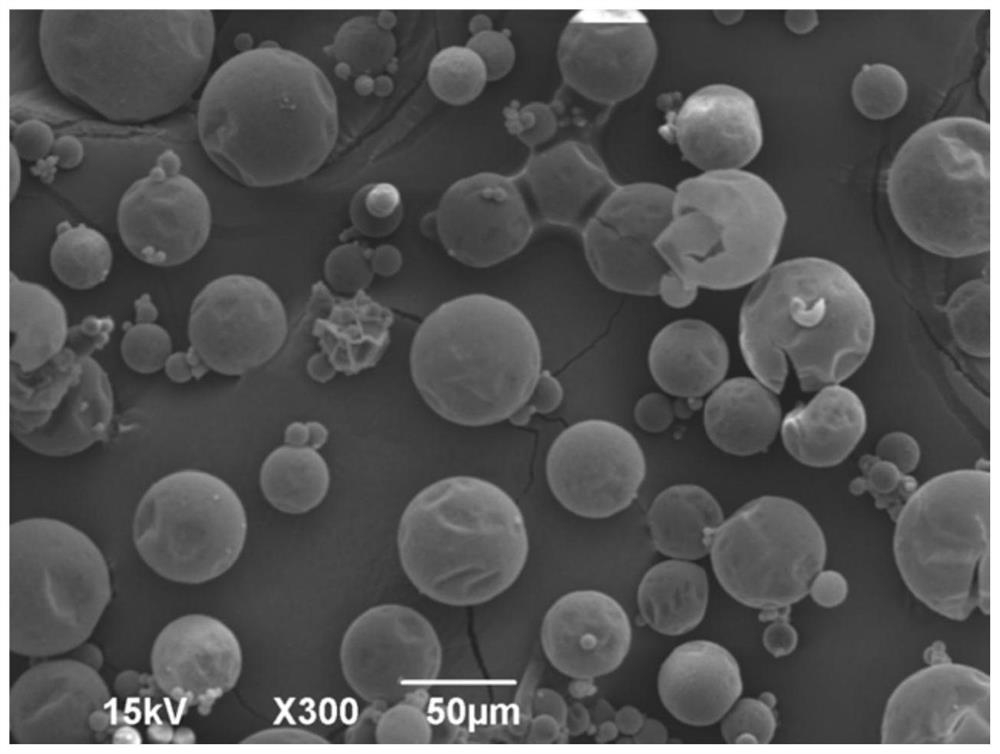

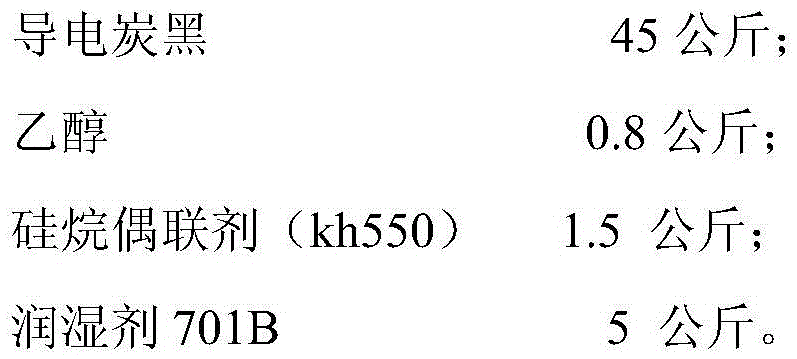

Special high-conductivity material for conductive powder coating and preparation method of special high-conductivity material

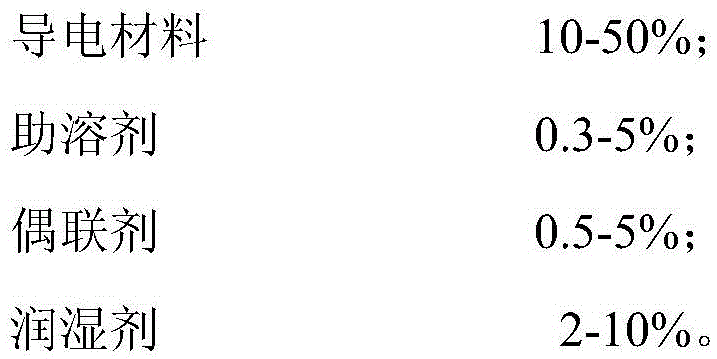

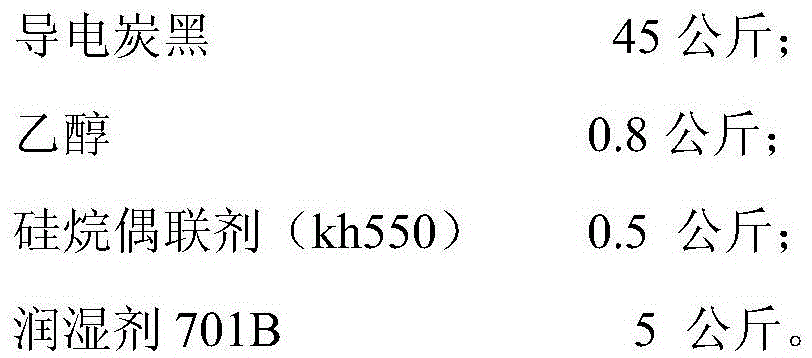

InactiveCN104356737AImprove interface performanceImprove compatibilityPowdery paintsElectrically-conductive paintsConductive polymerConductive materials

The invention relates to a special high-conductivity material for a conductive powder coating. The special high-conductivity material is prepared from the following raw materials in parts by weight: 10-50 parts of a conductive material, 0.3-5 parts of a cosolvent, 0.5-5 parts of a coupling agent and 2-10 parts of a wetting agent. By the adoption of a constant-temperature high-speed mixing technology, a preparation material is applied to the conductive powder coating, and polar groups such as hydroxide radical and anhydride are introduced, so that the conductive material is liable to be in contact with resin to form a space conductive network, and the conductivity is improved; moreover, the high-conductivity material can be reacted with the hydroxide radical on the surface of inorganic filler, so that reactive silanol is generated, and the interface property, the compatibility, the dispersion property and the flowability of the synthesized resin and the inorganic filler are effectively improved. The phenomenon of layering of the conductive material and a resin base material in a production process is avoided; furthermore, the prepared conductive powder coating is stable in conductivity; when the coating layer achieves the same conductivity, the technology compared with a common production technology has the advantages that the use amount of the conductive material is reduced by 10-40 percent, and the cost is reduced.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

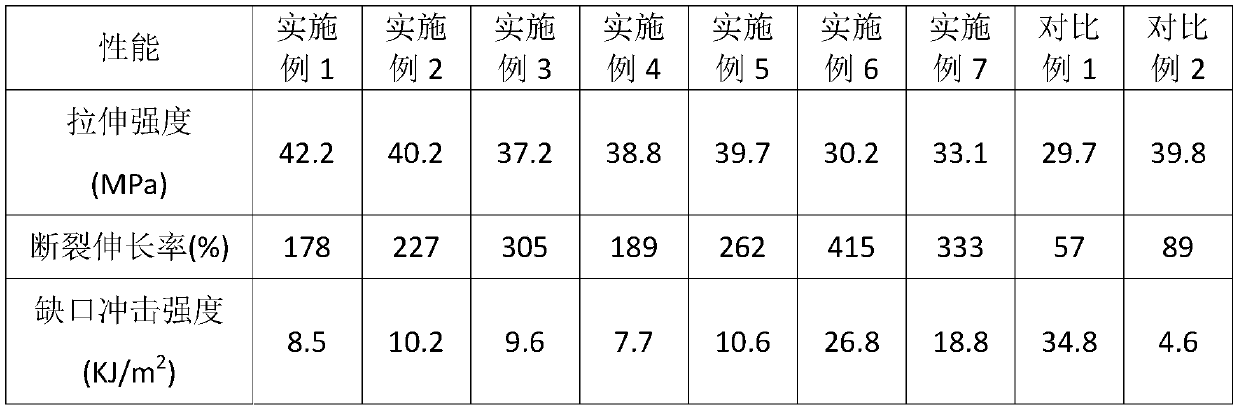

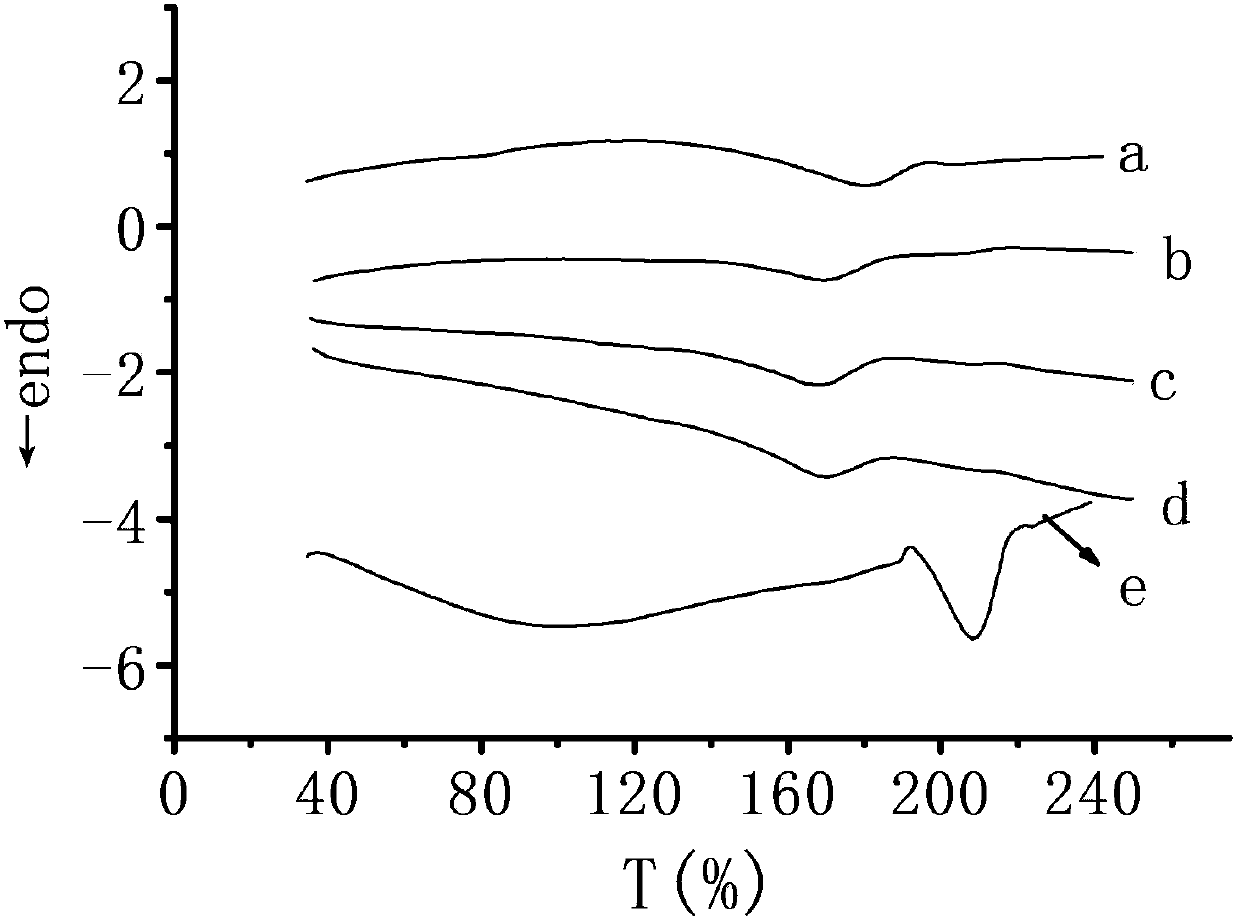

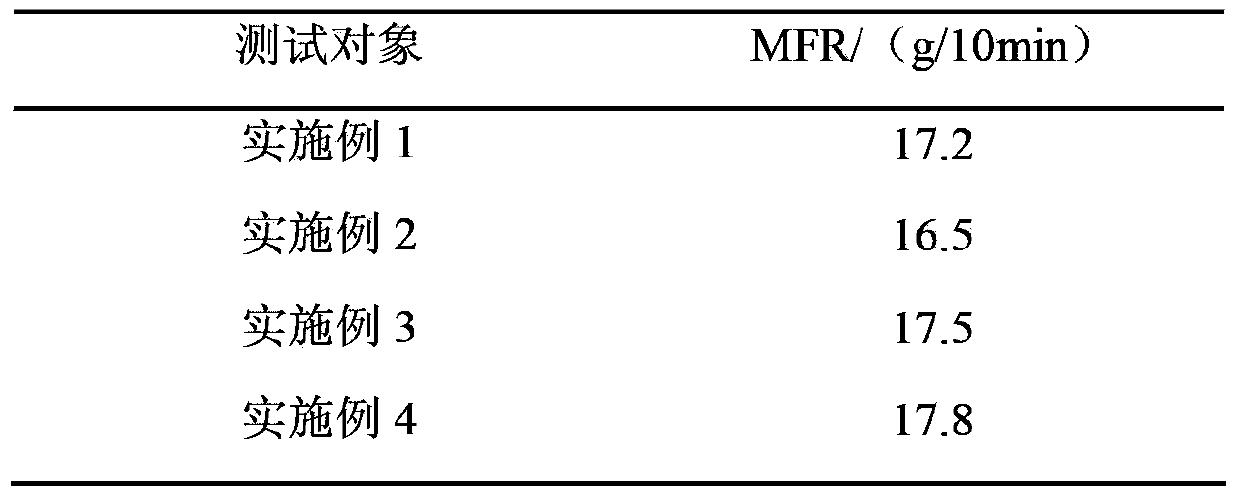

PET material with ultrahigh elongation at break and preparation method thereof

The invention discloses a PET material with ultrahigh elongation at break and a preparation method thereof, and belongs to the technical field of polymer material modification. The PET material with the ultrahigh elongation at break is prepared from the following components in parts by weight: 75 to 90 parts of PET, 10 to 25 parts of toughening agent and 0.2 to 1 part of an antioxidant. An ethylene-acrylate elastomer grafted with glycidyl methacrylate (GMA) and a thermoplastic polyester elastomer (TPEE) jointly toughen the PET, so that a synergistic effect is generated, the elongation at breakof the PET is greatly improved, and the application field of the PET material is expanded.

Owner:上海聚威新材料股份有限公司

Self-crosslinked aqueous traffic paint and method for using same

ActiveCN1324099CGood chemical stabilityImprove wear resistanceTraffic signalsCoatingsPolymer scienceDistilled water

The present invention is self-linking water thinned road mark paint and its preparation and usage. The road mark paint is storage stable and has solid content of at least 75 %, and anionic self-linking silicone propylene emulsion as main material. Specifically, it consists of anionic self-linking silicone propylene emulsion 20-50 weight portions, distilled water 1-5 weight portions, methanol 1-5 weight portions, filming assistant 1-5 weight portions, dispersant 1-3 weight portions, moistener 0.1-1 weight portions, disinfecting mildew inhibitor 0.1-0.5 weight portions, defoaming agent 0.1-0.5 weight portions, and pigment and stuffing 20-80 weight portions. It may be painted to road directly or on primer, and may be used widely for different kinds of road.

Owner:阿克苏诺贝尔功能涂料(常州)有限公司

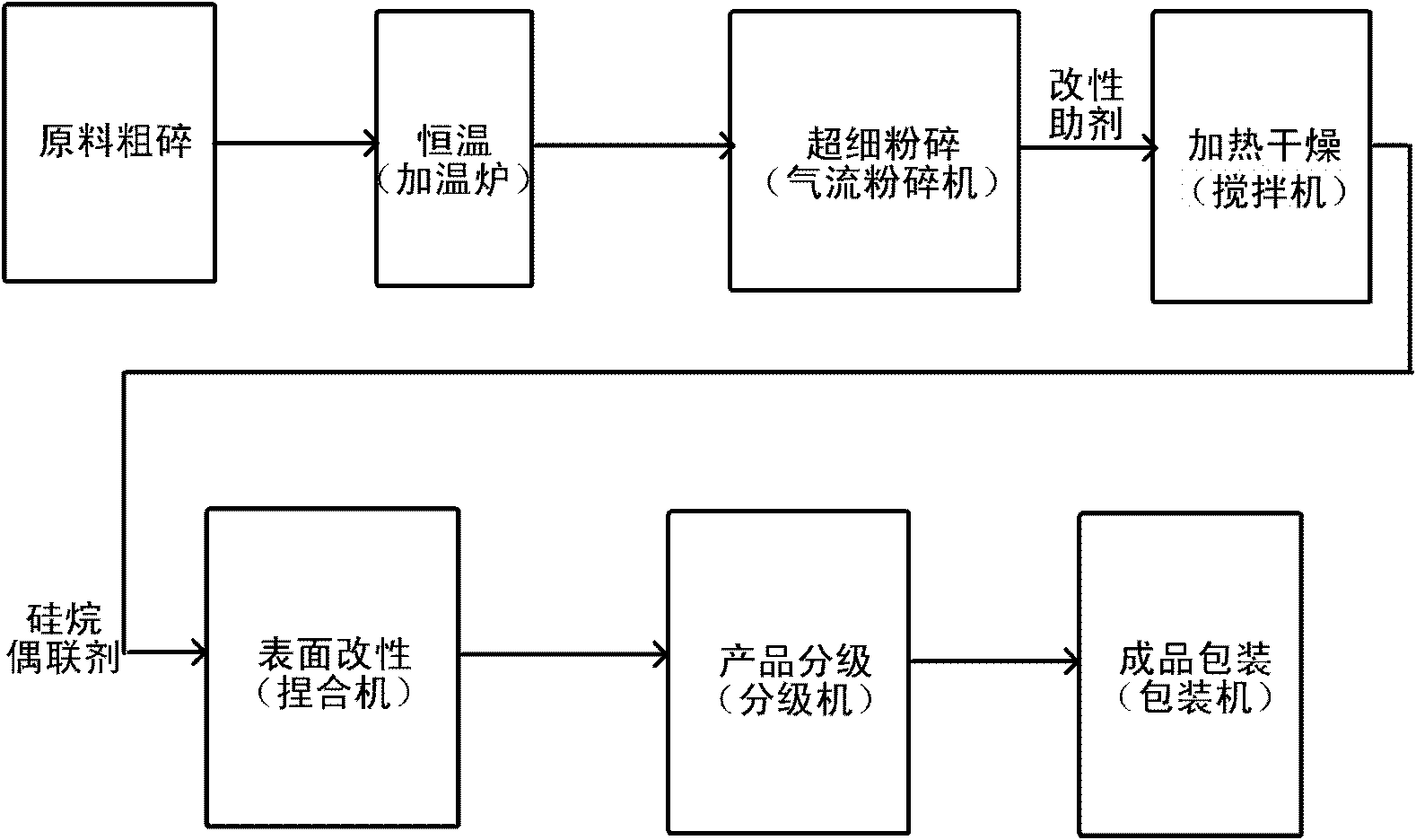

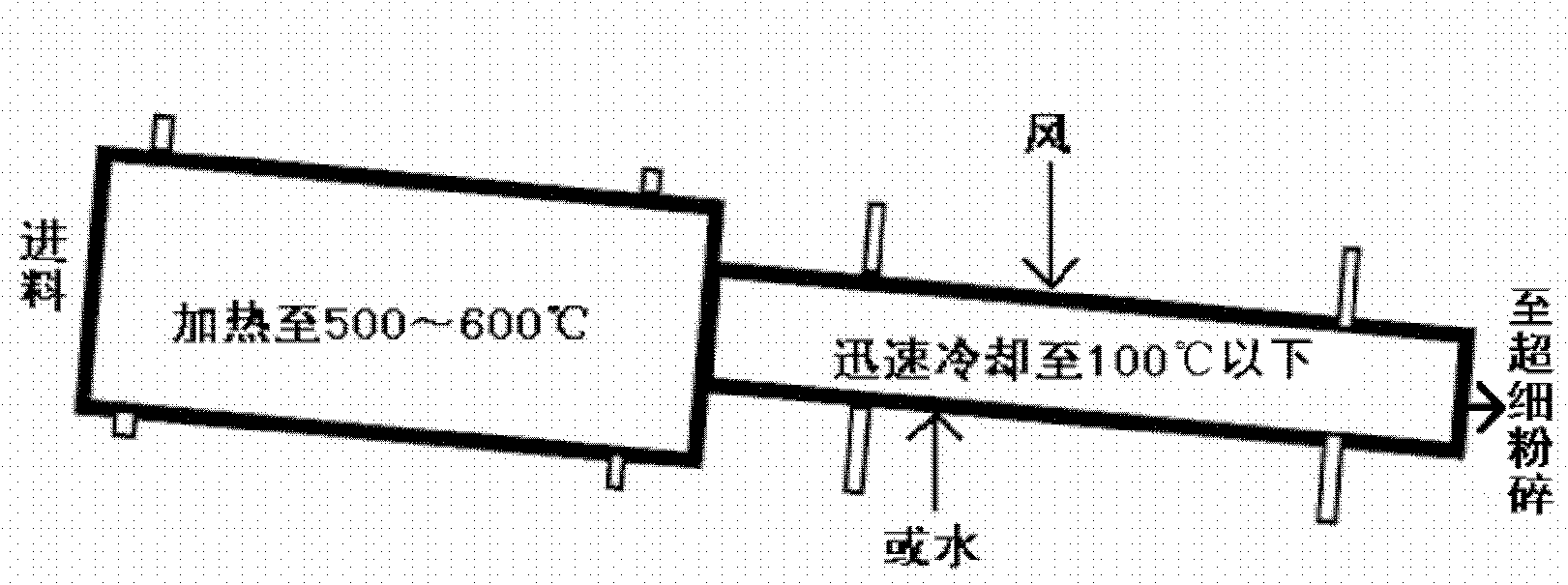

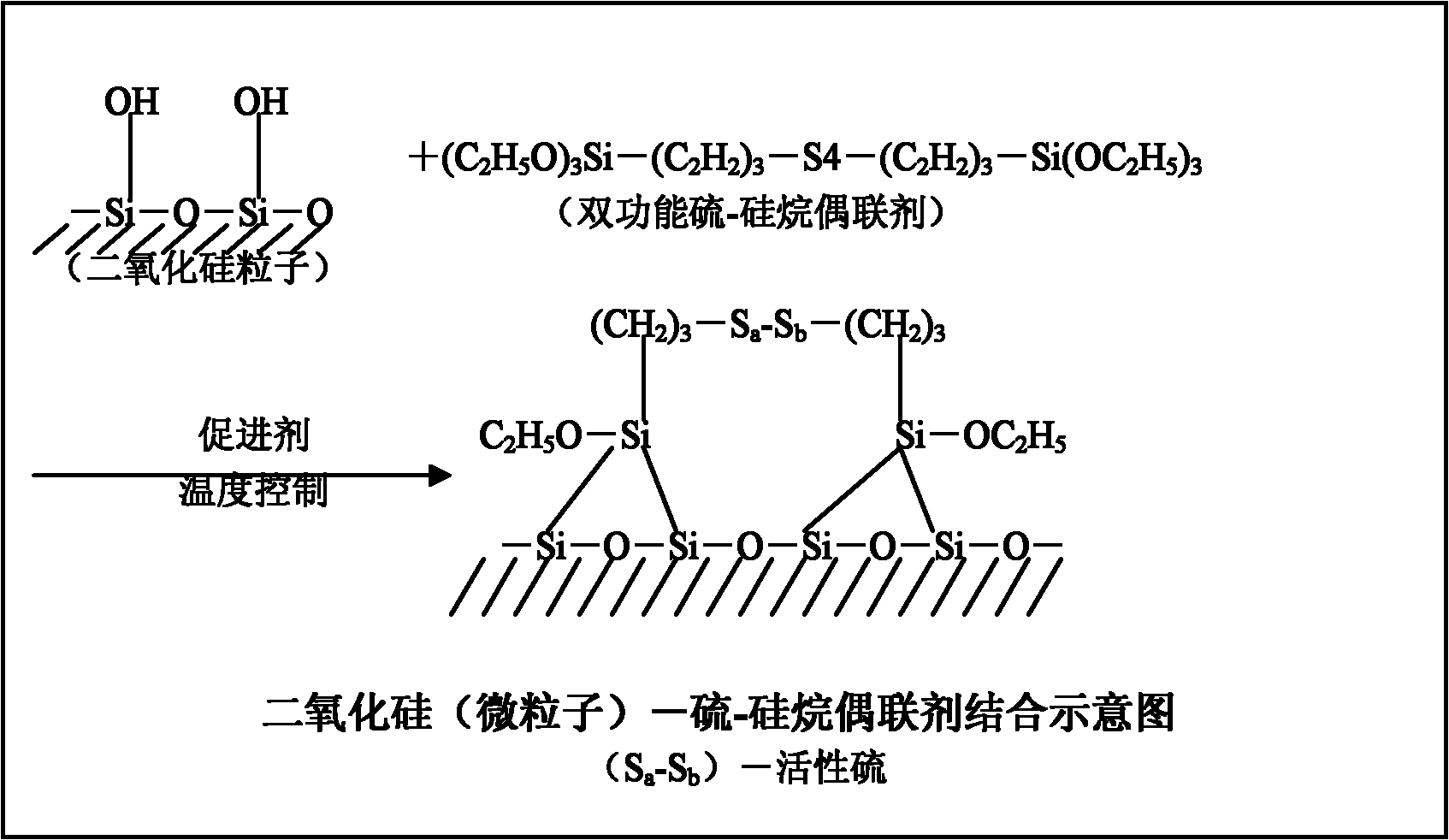

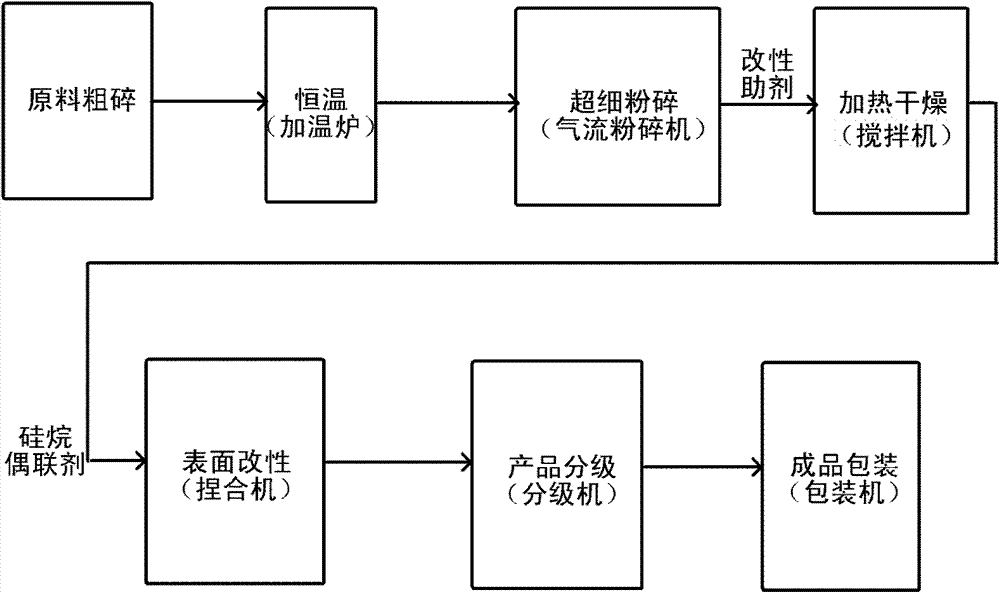

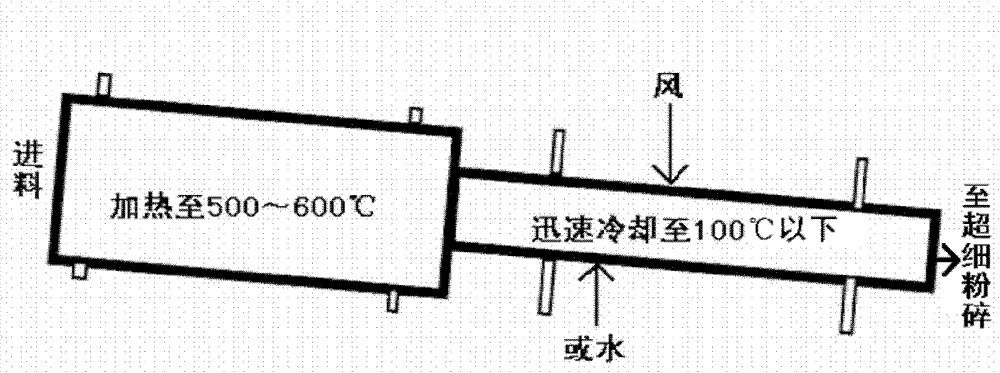

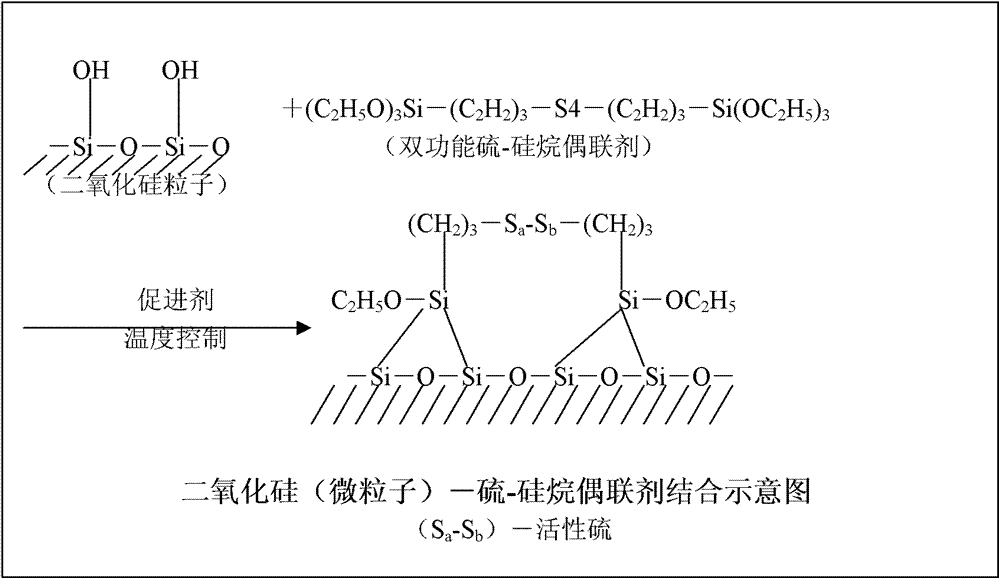

Crosslinking modification method and composite material of vitric acidic lava micro powder

InactiveCN101921499ALow priceNo pollution problemPigment treatment with organosilicon compoundsPigment physical treatmentPolymer scienceCarbon black

The invention provides a crosslinking modification method and a composite material of vitric acidic lava micro powder. By the method, a novel vitric acidic lava / difunctional silane coupling agent composite material can be prepared from natural rocks and can be applied to reinforcing agents and reinforcing fillers of rubber and the like. With low price, the composite material can replace reinforcing agents and reinforcing fillers of white carbon black, and other rubber and plastics; in addition, the production process of the composite material has no environment pollution.

Owner:WUHAN SHENGYE TECH

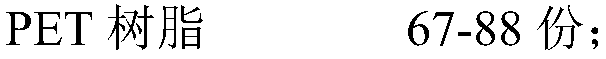

Injection molding grade glass fiber reinforced PET (Polyethylene Terephthalate) micro-foamed composite material and preparation method thereof

The invention discloses an injection molding grade glass fiber reinforced PET (Polyethylene Terephthalate) micro-foamed composite material and a preparation method thereof. The composite material comprises 96-98wt% of a PET composite material and the balance of a chemical foaming agent, wherein the PET composite material comprises PET resin, a toughening agent, a cross-linking agent, modified glass fiber, an antioxidant, a lubricant and other aids. According to the invention, carbimide propyl triethoxysilane is adopted to modify the surface of alkali short cut glass fiber strands so as to enable the surface of the glass fiber strands to be endowed with active groups, the alkali short cut glass fiber strands are added into the PET resin to implement a chemical reaction with terminal hydroxyl, then a coupling function is achieved, the glass fiber dispersion is promoted, the fibers are distributed in a staggered manner to form a three-dimension net, a chain segment physical cross-linkingfunction is enhanced, and the sliding of a molecular chain is limited, so that the melt viscosity of a PET chain segment can be increased, and the mechanical strength of the composite material can beimproved.

Owner:ORINKO NEW MATERIAL CO LTD

Thermo-oxidative aging resistant PVC tubular product and preparation method thereof

The invention discloses a thermo-oxidative aging resistant PVC tubular product and a preparation method thereof. Modified nano barium sulfate is taken as an ageing resistant agent, the nano barium sulfate is firstly modified through sodium stearate, and the sodium stearate is wrapped on the surface of the nano barium sulfate, so that the dispersibility of the nano barium sulfate in a base body is improved, simultaneously the compatibility of the nano barium sulfate and the PVC base body is also improved, and the degree of crystallinity of the PVC improved; therefore, the material of the base body is denser, the oxygen diffusion rate is reduced, and the thermal oxidation stability of the material is improved; then, a rear earth coupling agent is used for graft modification, the rear earth coupling agent can play a coupling role, a relatively firm wrapping layer can be formed on the surface of the nano barium sulfate due to a unique outer electron layer structure of rear earth elements, inorganic rigid particles using rare earth complexes as shells and the nano barium sulfate as cores are formed, and the inorganic rigid particles are of a relatively high toughening modification effect on the PVC tubular product.

Owner:安徽盛华管业有限公司

Abrasion-proof toughened PVC pipe modified by addition of rare earth coupling agent activated vermiculite and preparation method thereof

The invention discloses an abrasion-proof toughened PVC pipe modified by addition of rare earth coupling agent activated vermiculite and a preparation method thereof. The rare earth coupling agent activated vermiculite is used as packing and added into raw materials, the adding amount is small, and the cost is low; the vermiculite is treated with a rare earth coupling agent, the rare earth coupling agent can play a role in coupling, and a firm wrapping layer is formed on the surface of vermiculite powder due to the unique outer shell structure of rare earth elements, so that inorganic rigid particles with rare earth coordination compounds as shells and vermiculite particles as cores are formed, and the inorganic rigid particles have a high toughening and modification effect on the PVC pipe; meanwhile, organic modification treatment of the vermiculite enhances the interface bonding strength with matrix resin, and a liminated structure is likely to be stripped in the rubbing process, so that the abrasion-proof performance of the PVC pipe is effectively improved.

Owner:安徽盛华管业有限公司

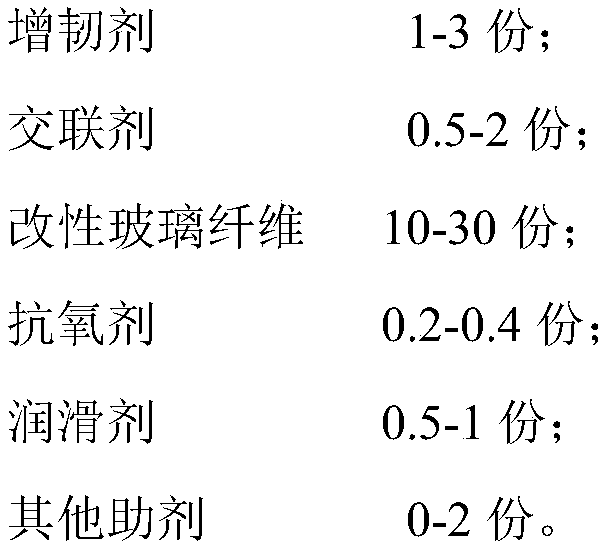

Double-shell self-repairing microcapsule, and preparation method and application thereof

ActiveCN111790325AImprove waterproof performanceHigh mechanical strengthNon-macromolecular adhesive additivesAnti-corrosive paintsPolymer scienceHigh humidity

The invention provides a double-shell self-repairing microcapsule, and a preparation method and application thereof. The double-shell microcapsule comprises a core material, a first wall material layer wrapping the core material and a second wall material layer wrapping the first wall material. The double-shell microcapsule provided by the invention is provided with two wall material layers, and thus has high mechanical strength; the double-shell microcapsule is a single-component repairing system, and after a coating is damaged, the microcapsule is broken to release isocyanate core material which reacts with moisture in air for curing so as to intelligently repair damage; and meanwhile, in a high-humidity environment, the isocyanate core material in the microcapsule can absorb moisture slowly permeating into the coating, so the waterproof performance of a coating material is enhanced.

Owner:THE HONG KONG UNIV OF SCI & TECH

A special high-conductivity material for conductive powder coating and its preparation method

InactiveCN104356737BImprove interface performanceImprove compatibilityPowdery paintsElectrically-conductive paintsConductive materialsSolvent

The invention relates to a special high-conductivity material for a conductive powder coating. The special high-conductivity material is prepared from the following raw materials in parts by weight: 10-50 parts of a conductive material, 0.3-5 parts of a cosolvent, 0.5-5 parts of a coupling agent and 2-10 parts of a wetting agent. By the adoption of a constant-temperature high-speed mixing technology, a preparation material is applied to the conductive powder coating, and polar groups such as hydroxide radical and anhydride are introduced, so that the conductive material is liable to be in contact with resin to form a space conductive network, and the conductivity is improved; moreover, the high-conductivity material can be reacted with the hydroxide radical on the surface of inorganic filler, so that reactive silanol is generated, and the interface property, the compatibility, the dispersion property and the flowability of the synthesized resin and the inorganic filler are effectively improved. The phenomenon of layering of the conductive material and a resin base material in a production process is avoided; furthermore, the prepared conductive powder coating is stable in conductivity; when the coating layer achieves the same conductivity, the technology compared with a common production technology has the advantages that the use amount of the conductive material is reduced by 10-40 percent, and the cost is reduced.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

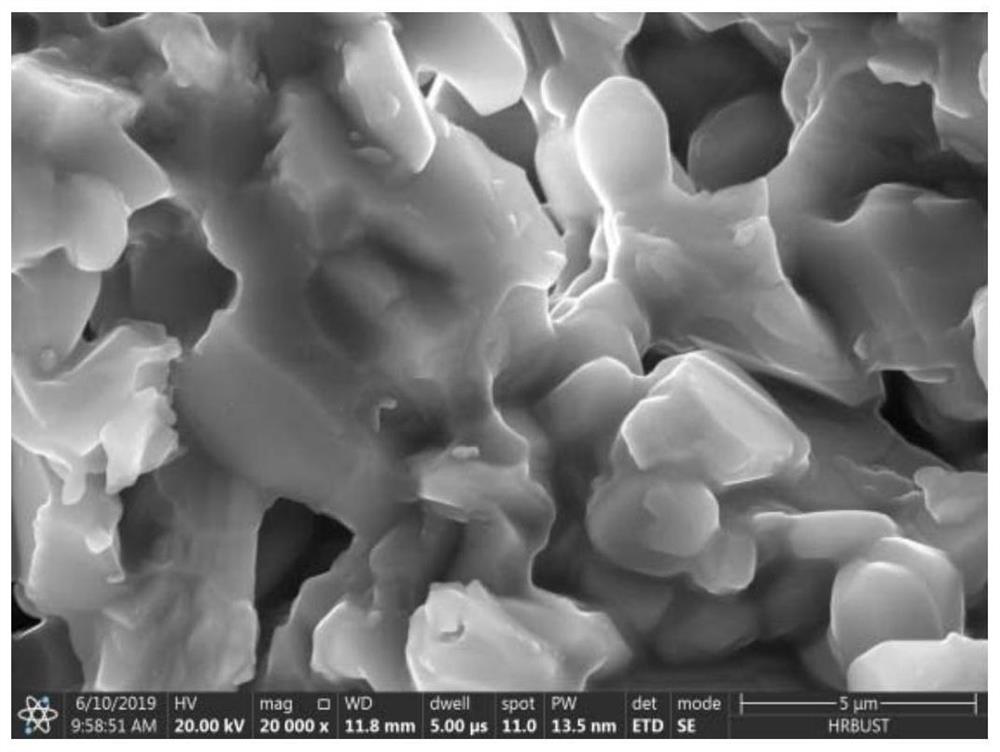

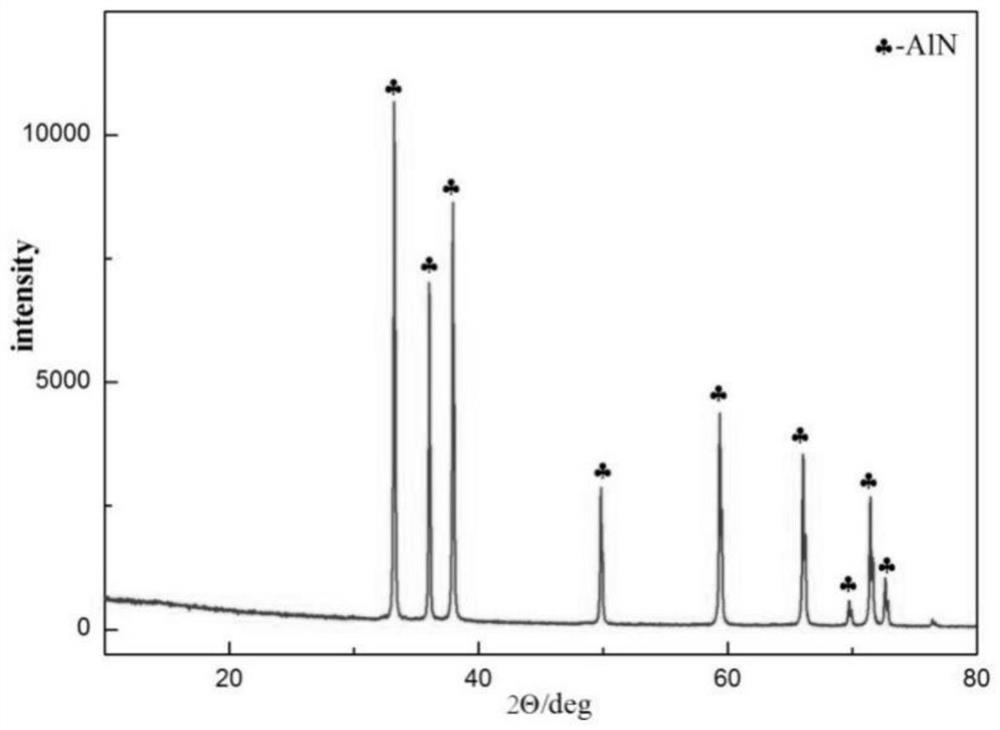

Preparation method of porous raw material for aluminum nitride crystal growth

InactiveCN112195512AHave mechanical strengthPlay a coupling rolePolycrystalline material growthFrom condensed vaporsFreeze-dryingAluminium powder

The invention relates to a preparation method of a porous raw material for aluminum nitride crystal growth, and belongs to the technical field of aluminum nitride crystal raw material preparation. Inorder to solve the problems that the existing aluminum nitride raw material is relatively compact and is not beneficial to raw material volatilization and crystal growth, the invention provides a preparation method of a porous raw material for aluminum nitride crystal growth. The method comprises the following steps: adding aluminum nitride powder subjected to hydrolysis-resistant pretreatment into a sodium alginate solution, carrying out stirring and ball milling to obtain mixed slurry; and pouring the obtained mixed slurry into a mold, uniformly spraying a calcium chloride solution onto thesurface of the slurry, freeze-drying the slurry, sintering in a protective gas atmosphere, pickling, washing with water, and drying to obtain the porous aluminum nitride raw material. The method is simple to operate and low in cost, the porous raw material with the porosity of 42-50% can be prepared, volatilization of aluminum nitride is facilitated, the utilization rate of the aluminum nitride raw material is high, and the method has positive influence on growth of aluminum nitride crystals.

Owner:哈尔滨科友半导体产业装备与技术研究院有限公司

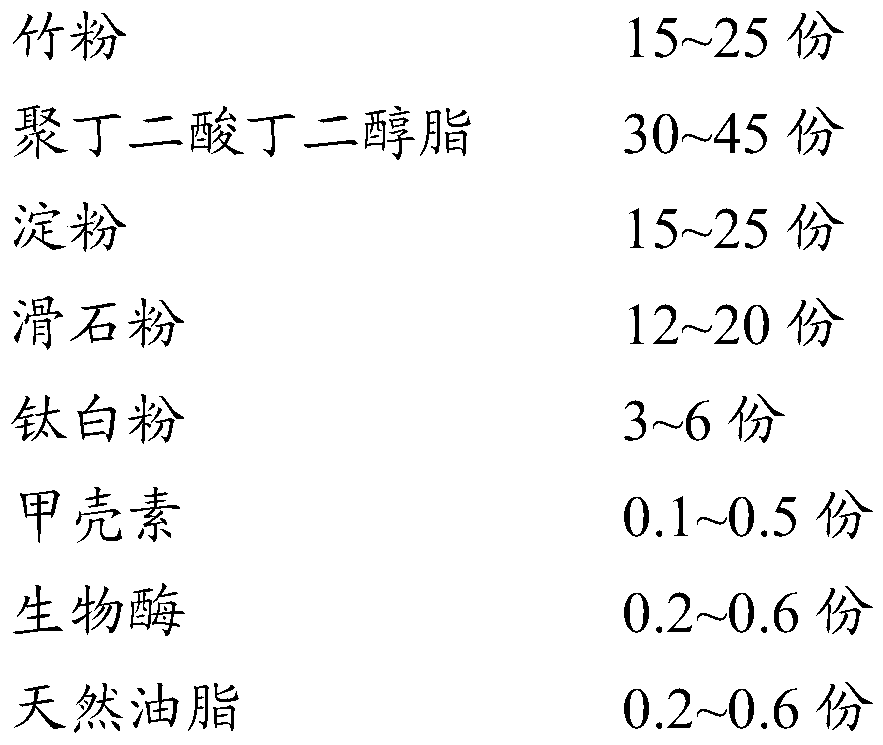

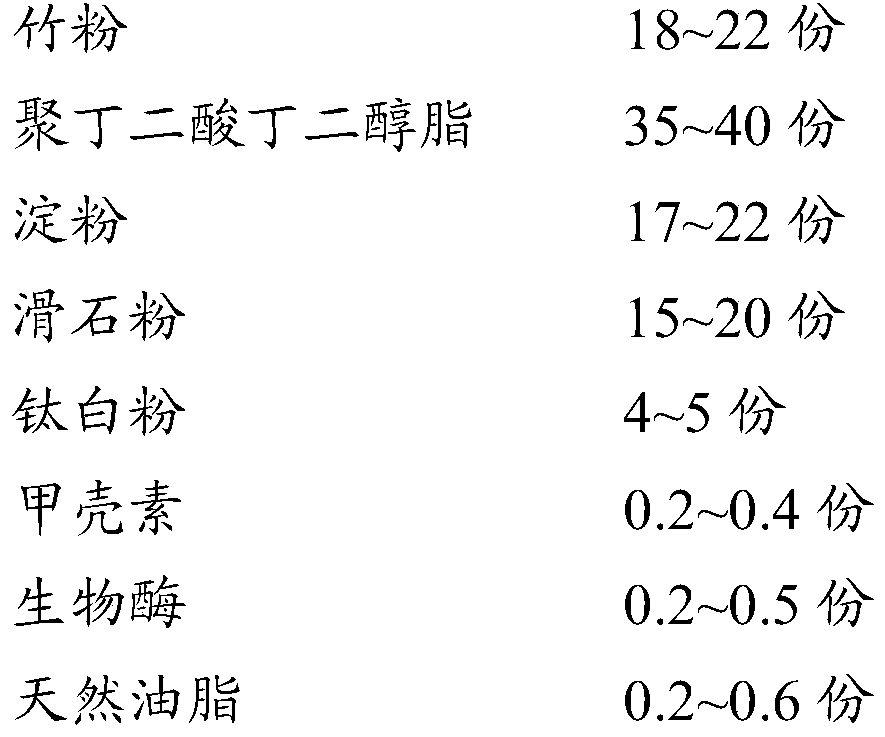

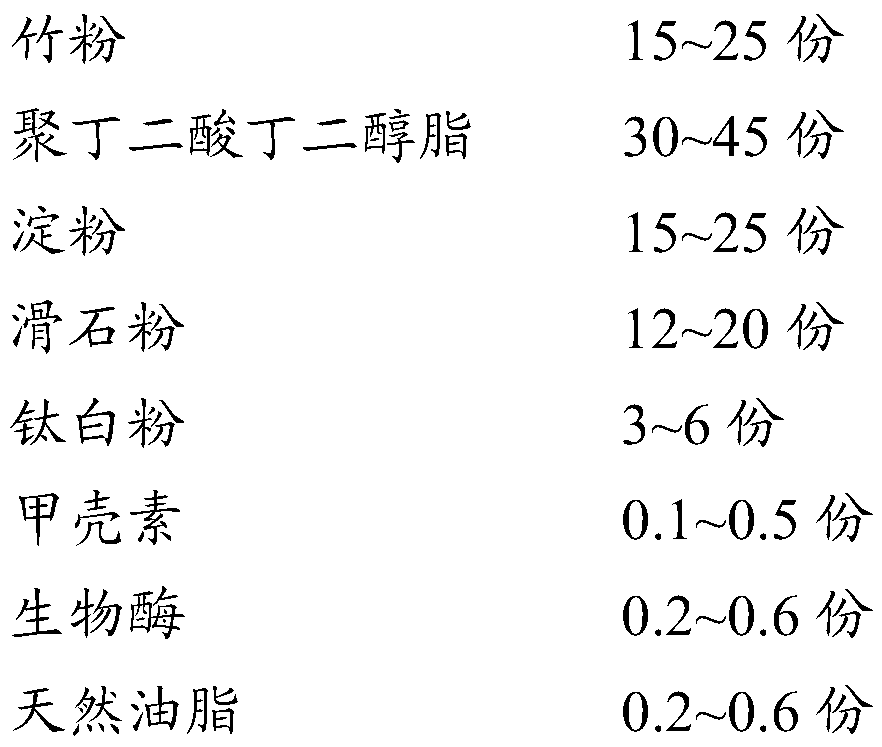

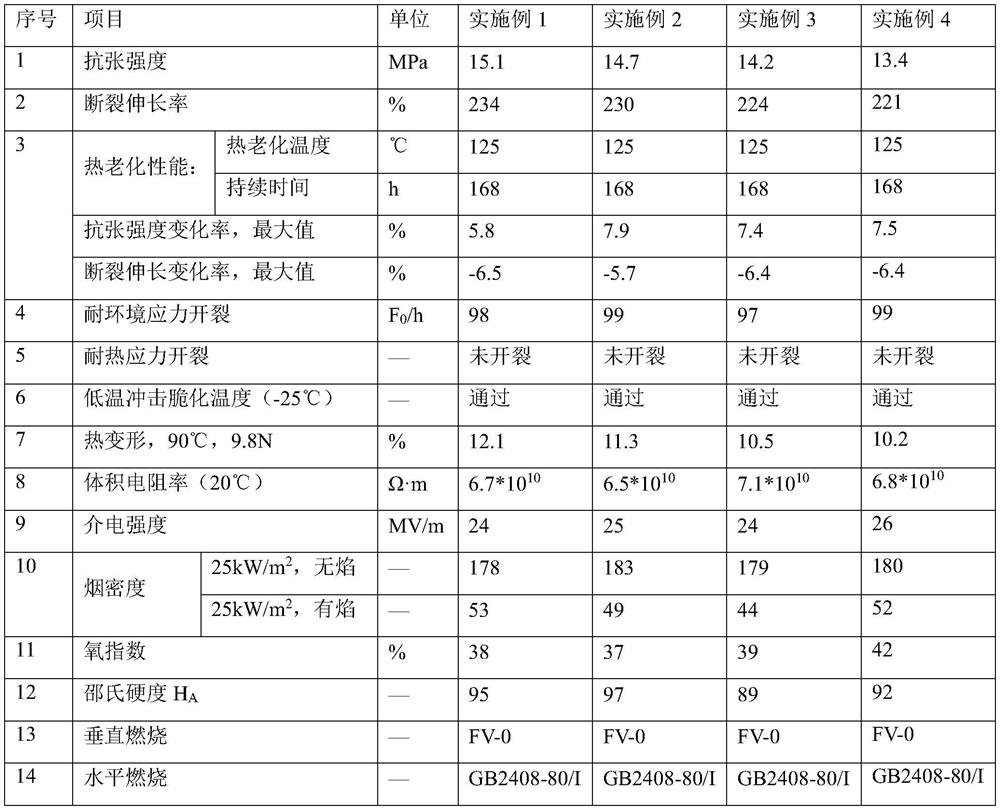

Bamboo powder/poly(butylene succinate)/starch biodegradable plastic and preparation method thereof

InactiveCN111560159ASources are extensive and secureExcellent physical and chemical propertiesPolymer sciencePolymer chemistry

The invention provides bamboo powder / poly(butylene succinate) / starch biodegradable plastic and a preparation method thereof. The bamboo powder / poly(butylene succinate) / starch biodegradable plastic provided by the invention comprises the following components in parts by weight: 15-25 parts of bamboo powder, 30-45 parts of poly(butylene succinate), 15-25 parts of starch, 12-20 parts of talcum powderand the like. The bamboo powder / poly(butylene succinate) / starch biodegradable plastic prepared by the invention is wide in raw material source and safe, does not contain any chemical additive with toxic and side effects, can be used for producing disposable tableware products such as knives, forks, spoons, cup covers, straws, bowls and lunch boxes, can be completely degraded after being used, andis short in degradation period.

Owner:汕头市雷氏塑化科技有限公司

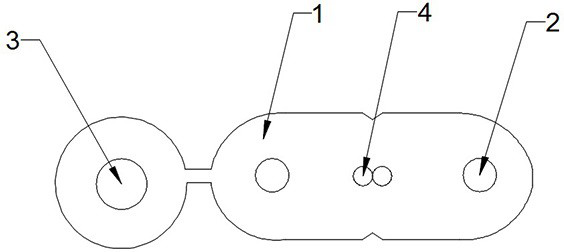

Low-smoke halogen-free self-supporting butterfly-shaped leading-in optical cable with non-metal reinforcers

ActiveCN112034570AImprove compatibilityImprove performanceFibre mechanical structuresPhysicsPolyolefin

The invention discloses a low-smoke halogen-free self-supporting butterfly-shaped leading-in optical cable with non-metal reinforcers. The low-smoke halogen-free self-supporting butterfly-shaped leading-in optical cable comprises an optical fiber ribbon, reinforcers, astrengthening component and a sheath, wherein the two reinforcers are symmetrically arranged, the optical fiber ribbon is arrangedbetween the two reinforcers, the strengthening component is arranged beside one reinforcer, and the optical fiber ribbon, the reinforcers and the strengthening component are fixed by means of the sheath; and a sheath material of the sheath is prepared from the following raw materials in parts by weight: 130-150 parts of a polyolefin base material, 35-51 parts of a composite flame retardant and 0.05-0.1 part of an antioxidant. The sheath provided by the invention also has an excellent flame-retardant effect and excellent mechanical properties when the low flame retardant is added.

Owner:SICHUAN TIANYI COMHEART TELECOM

High-performance double-sided tooth crawler belt for robot and preparation method of high-performance double-sided tooth crawler belt

PendingCN114539642ASimple manufacturing methodEasy to operate and controlEndless track vehiclesMethacrylateEpoxy

The invention discloses a high-performance double-sided toothed crawler belt for a robot and a preparation method thereof.The high-performance double-sided toothed crawler belt comprises a synchronous belt framework and a sizing material wrapping the synchronous belt framework, and the synchronous belt framework comprises a synchronous belt body, first belt teeth arranged on the inner side of the synchronous belt body and second belt teeth arranged on the outer side of the synchronous belt body; the rubber material is prepared from the following raw materials in parts by weight: 5 to 8 parts of polysiloxyborane hyperbranched polymer containing epoxy group, 10 to 30 parts of fluorinated phosphazene rubber, 10 to 20 parts of epoxy nitrile rubber, 70 to 90 parts of nitrile rubber and 2-[3-(2H-benzotriazole-2-yl)-4-hydroxyphenyl] The adhesive is prepared from the following components in parts by weight: 8 to 13 parts of ethyl 2-methacrylate / vinyl trimethoxy silane / phenyl vinyl sulfone / hydroxyethyl acrylate copolymer, 2 to 4 parts of octavinyl-POSS (Polyhedral Oligomeric Silsesquioxane), 0.8 to 1.2 parts of zinc 8-hydroxyquinoline, 5 to 8 parts of vulcanizing agent, 30 to 40 parts of filler and 0.8 to 1.2 parts of potassium hydroxide. The double-sided tooth crawler disclosed by the invention is good in aging resistance, excellent in high and low temperature resistance and wear resistance, good in mechanical property and long in service life.

Owner:NINGBO FULONG SYNCHRONOUS BELT

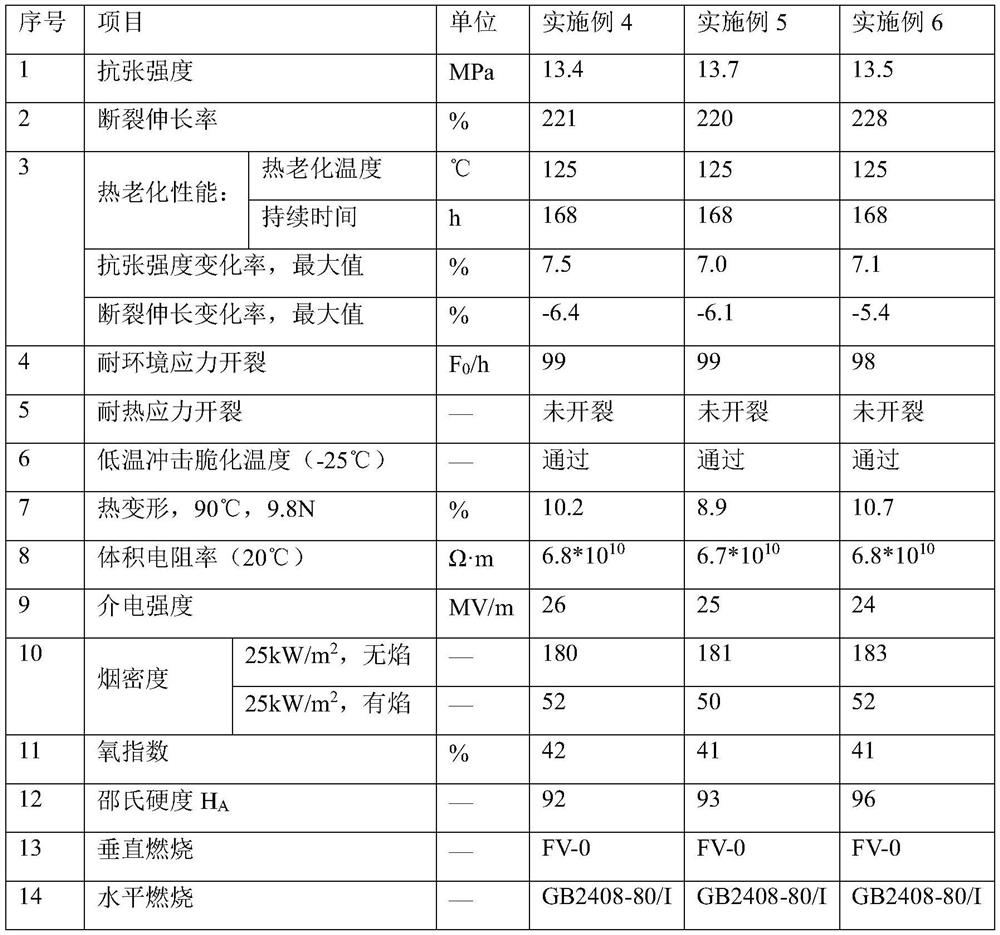

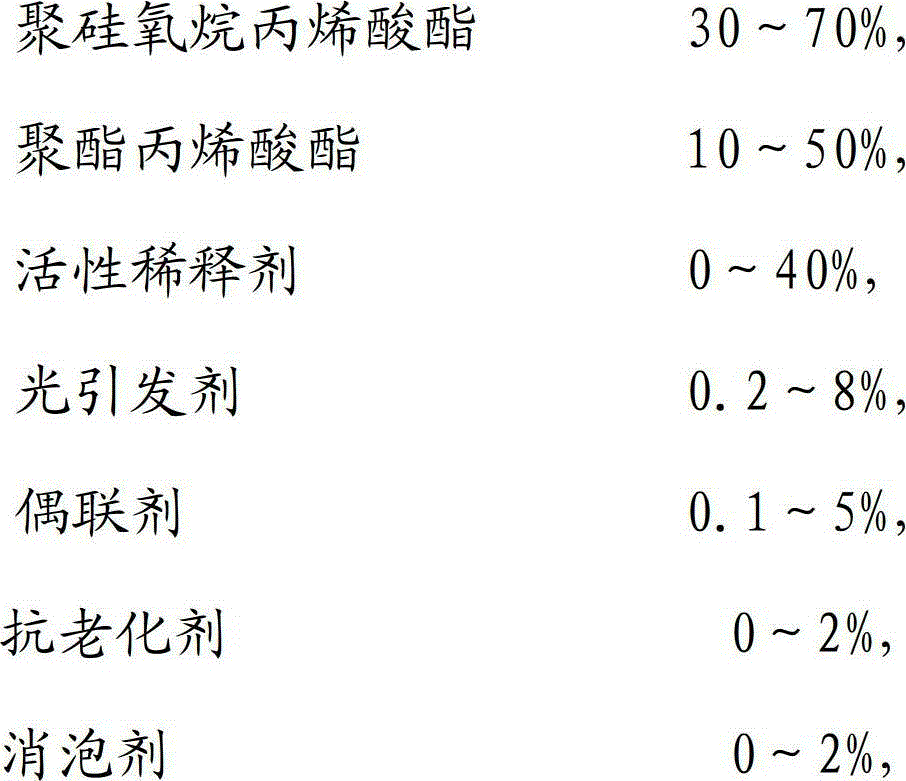

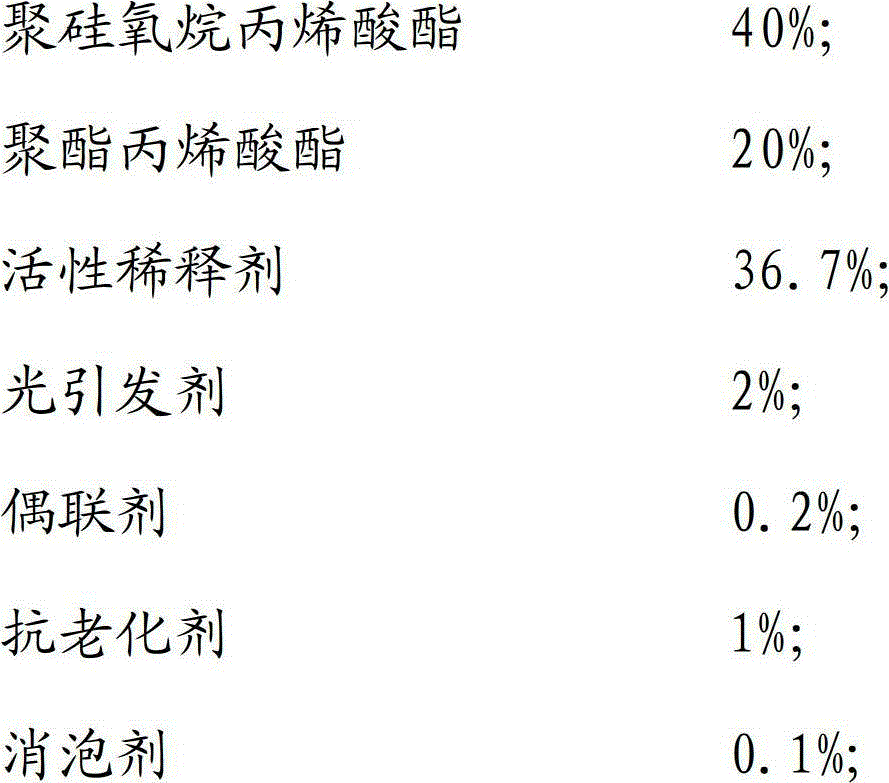

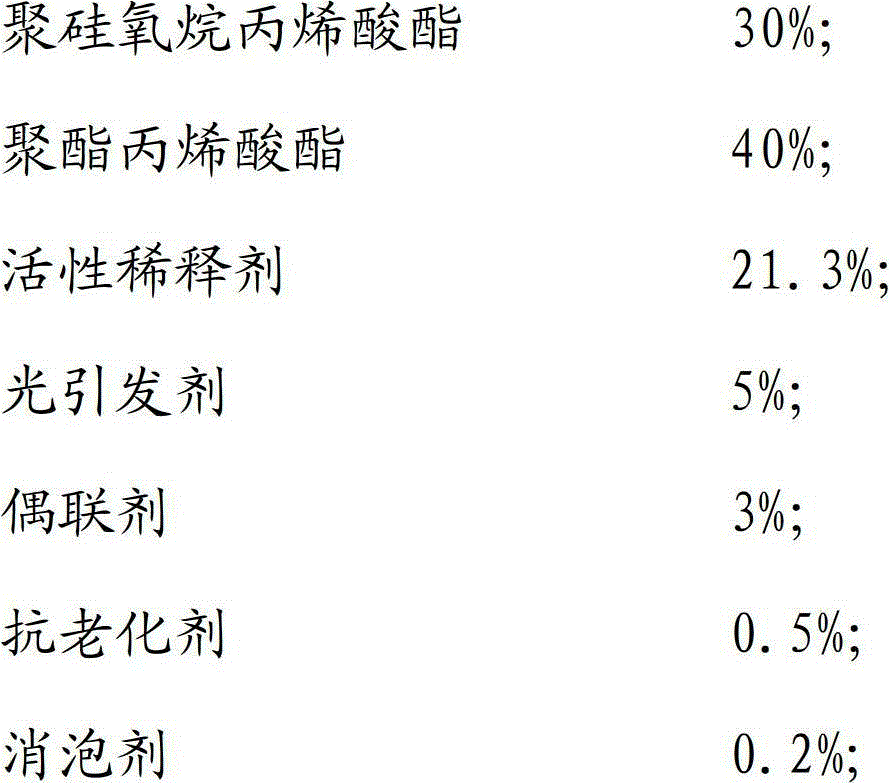

Radiation cured adhesive for indium tin oxide (ITO) circuit and module protection

ActiveCN102102007BReactivePlay a coupling rolePolyureas/polyurethane adhesivesNon-linear opticsPolyesterPolymer science

The invention provides a radiation cured adhesive for indium tin oxide (ITO) circuit and module protection, which comprises the following components in percentage by mass: 30 to 70 percent of polysiloxane-acrylic ester, 10 to 50 percent of polyester acrylate, 0 to 40 percent of reactive diluent, 0.2 to 8 percent of photoinitiator, 0.1 to 5 percent of coupling agent, 0 to 2 percent of antiaging agent and 0 to 2 percent of defoamer, wherein the reactive diluents is an acrylate with a single(double or multiple) functional group; the photoinitiator is a cracking initiator, a hydrogen abstracting type initiator or a combination of the two; the coupling agent is a silane coupling agent; and the antiaging agent is one or several of a phenol antioxygen, an amine antioxygen, a sulfur compound antioxygen, a phosphorus compound antioxygen and an organic metal salt antioxygen. In the curing process of the adhesive, moisture is not required to participate in reaction, the adhesive can be cured quickly in the irradiation of ultraviolet, and then package can be accomplished; and thus, the production efficiency is improved greatly, energy is saved and raw material cost is reduced.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Production process of high-extensibility plastic packaging film

ActiveCN113265079AImproved performance against UV agingImprove heat resistanceBlow moldingAir compression

The invention discloses a production process of a high-extensibility plastic packaging film, and belongs to the technical field of packaging films, and the production process comprises the following steps: 1, weighing raw materials in parts by weight; 2, drying the raw materials in a vacuum oven at 45 DEG C, then mixing, carrying out extrusion granulation in a twin-screw extruder at the temperature of 160 DEG C, blowing into cylindrical film bubbles by air compression, carrying out blow molding film forming in a film blowing auxiliary machine to form a film product, and finally cutting, separately rolling and packaging to obtain the high-extensibility plastic packaging film. The modified polypropylene carbonate is added, the modified polypropylene carbonate is obtained by mixing and extruding polypropylene carbonate, a modifier and auxiliary components, and the modifier plays a coupling role in a reaction process, so that a three-dimensional network structure is formed, and the mechanical property and chemical stability of the film are enhanced.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

A kind of water-based coating solution for post-plating treatment of bead steel wire

ActiveCN104497871BImprove adhesionAdhesive rate increasedLiquid/solution decomposition chemical coatingTire beadWater based

Owner:JIANGSU XINGDA STEEL TYPE CORD

Copper inner electrode conductive paste for multilayer ceramic capacitor and application of copper inner electrode conductive paste

ActiveCN113178328AGood dispersionPrevent oxidationFixed capacitor electrodesStacked capacitorsConductive pasteOrganic solvent

The invention provides a copper inner electrode conductive slurry for a multilayer ceramic capacitor and an application of the copper inner electrode conductive paste. The conductive paste comprises the following raw materials in parts by mass: 40-50 parts of copper powder; 0.1 to 2 parts of tantalum powder; 1-5 parts of ceramic powder; 0.1-2 parts of a dispersant; 0.1 to 0.2 part of a stabilizing agent; and 22.1 to 43 parts of glue. The glue comprises the following substances: an organic solvent, resin and a thixotropic agent in a mass ratio of (80-98): (2-4): (0.1-0.2). According to the invention, tantalum powder and mixed ceramic powder are added into a copper paste formula, an appropriate dispersing agent is selected, and the surface of copper powder is coated with oleic acid, so that oxidation of the copper paste can be effectively prevented before the copper paste is formed, the copper powder is better dispersed in the subsequent processing process, and copper electron migration can be effectively prevented during sintering due to addition of the tantalum powder. And the mixed ceramic powder is added to effectively inhibit the shrinkage of the copper electrode, so that the continuity of the copper layer is good.

Owner:大连海外华昇电子科技有限公司

Cobalt material with multi-sheet stacked structure for negative electrode of supercapacitor and preparation method thereof

ActiveCN108417405BIncrease spacingAvoid reunionHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneIon

The invention discloses a cobalt material with a multi-sheet stacked structure used for the negative electrode of a supercapacitor and a preparation method thereof, which belongs to the field of nanocomposite material preparation and solves the problem of poor connectivity between sheets, poor stability, and small gap spacing caused by the existing preparation method The problem. The technical scheme that the present invention adopts is as follows: a kind of preparation method of the cobalt material of multi-sheet stacked structure that is used for supercapacitor negative pole, graphene, Co(NO3) 2, urea, NH4F powder, hexadecyl trimethyl bromide Ammonium chloride and ethanol are added to water and mixed evenly, then reacted at high temperature to obtain the first precipitate; the first precipitate is washed and dried in turn to obtain the solid of graphene and cobalt composite material; the solid of graphene and cobalt composite material After being added to the ionized water for mixing, it is added to the chloride ion solution to react to obtain the second precipitate; the second precipitate is washed and dried in sequence to obtain a cobalt material with a multi-sheet stacked structure. The invention is used for preparing negative pole material of supercapacitor.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

A kind of preparation method of high-performance polyvinyl alcohol/graphene composite film

ActiveCN108892905BImprove mechanical propertiesImprove thermal efficiencyGrapheneComposite filmPolyvinyl alcohol

The invention belongs to the technical field of polymer composite material preparation, in particular to a preparation method for polyvinyl alcohol / graphene composite thin film. A new technology method is adopted to prepare the polyvinyl alcohol / graphene composite thin film, in-situ polymerization is conducted to prepare a polyvinyl alcohol / oxidized graphene solution, then a small amount of dopamine is added and reacts with the solution at the certain temperature and under an alkaline condition, after drying, the film is formed, and the polyvinyl alcohol / graphene composite thin film is prepared. Compared with a solution blending method, the composite thin film prepared by adopting the method has excellent mechanical and heat-resisting properties.

Owner:JIANGSU YANGNONG CHEM GROUP +2

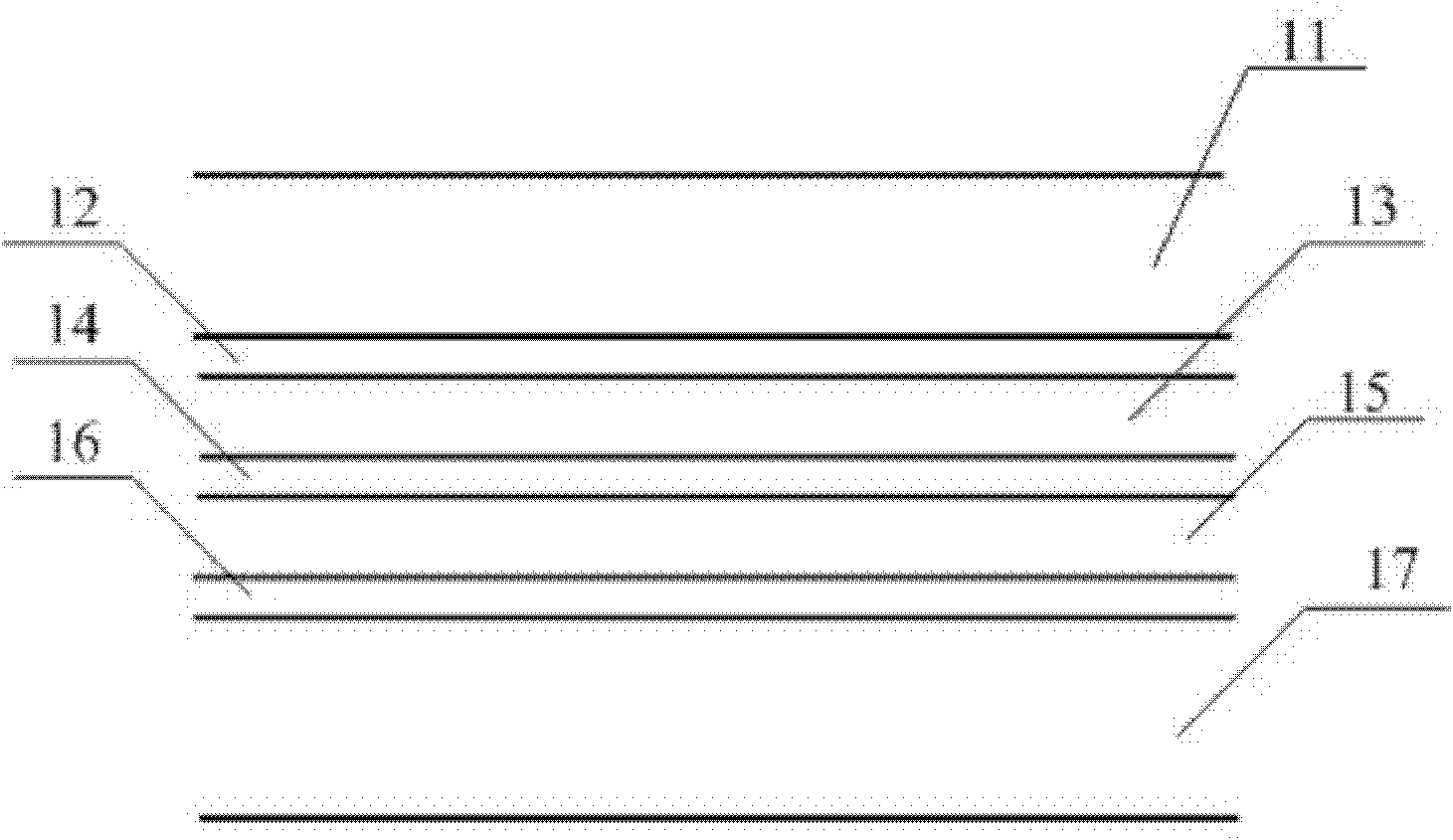

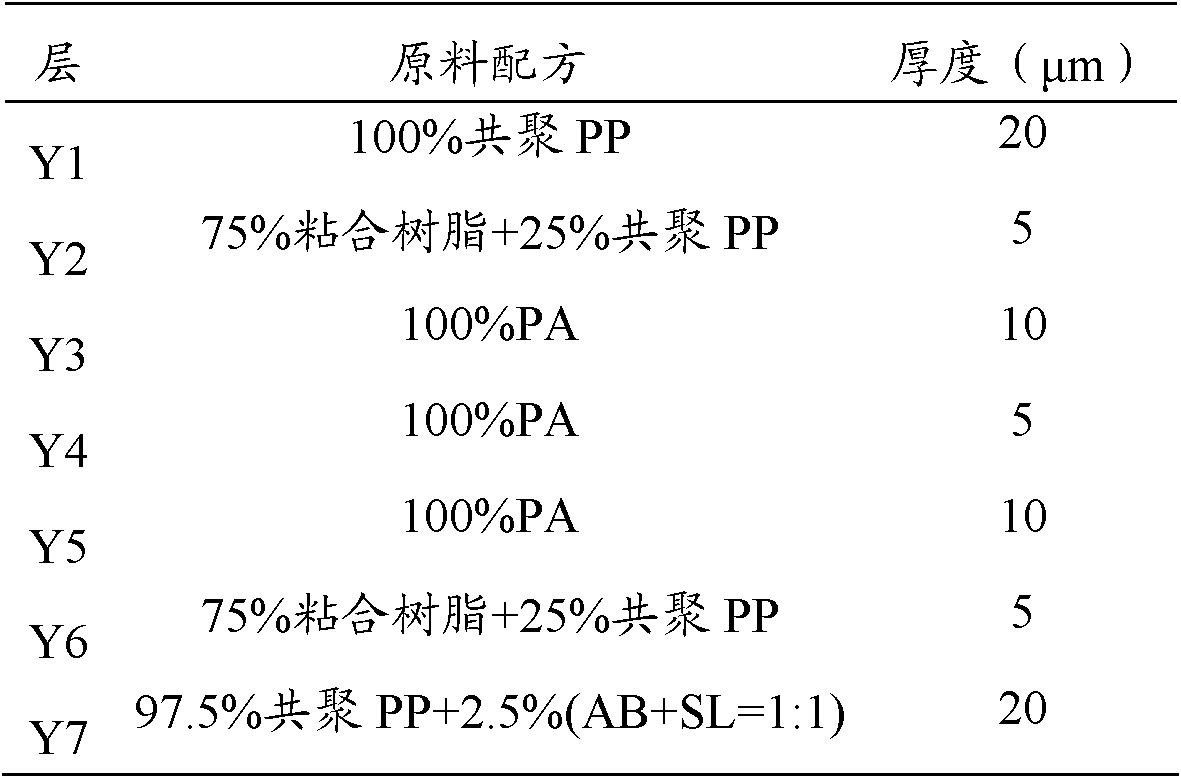

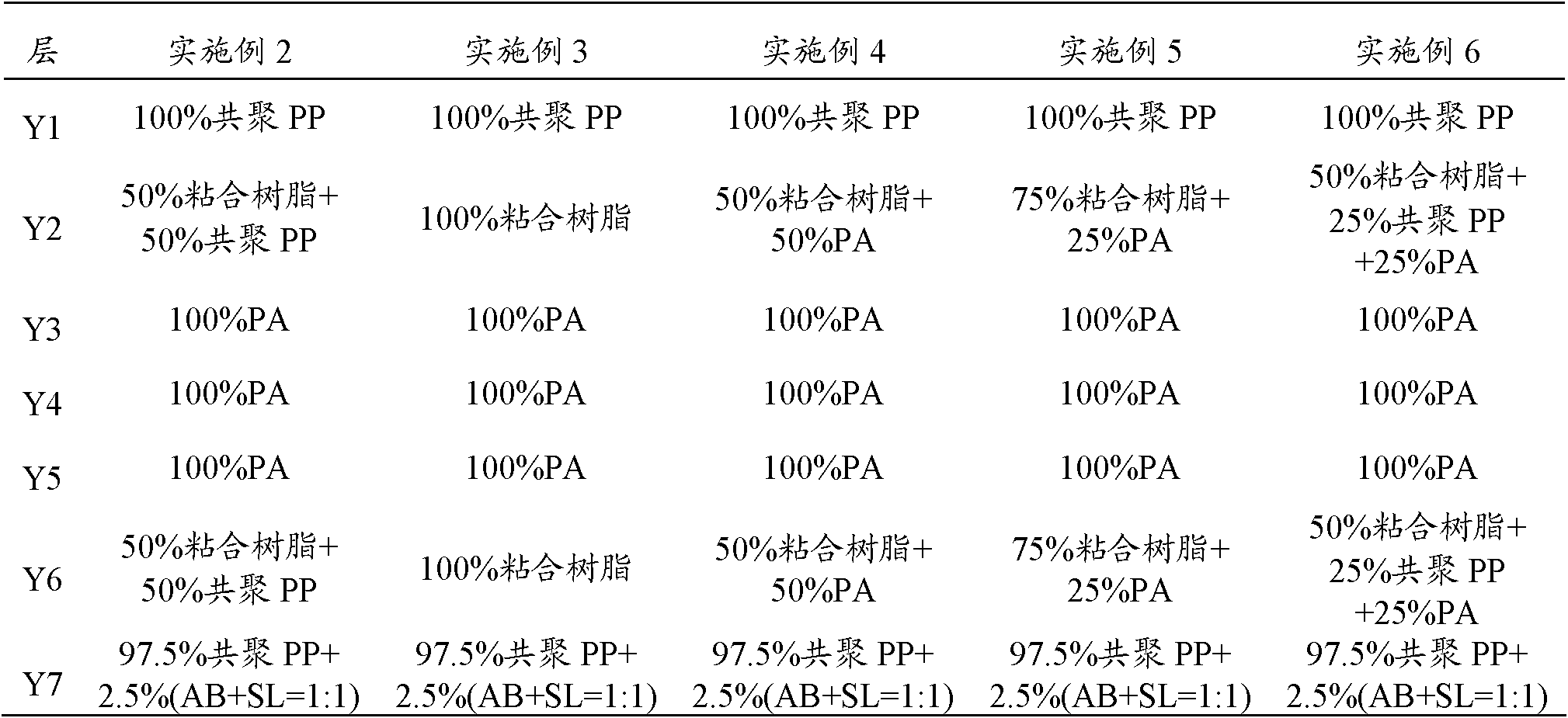

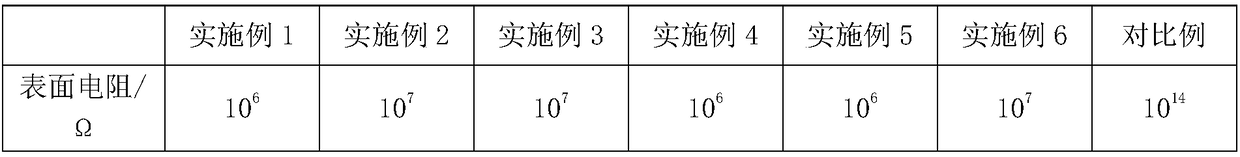

Transparent steaming and boiling-resistant film and preparation method thereof

ActiveCN102229269BExcellent retort resistanceGood compatibilityFlexible coversWrappersComposite filmWater vapor

The invention provides a transparent steaming and boiling-resistant film. The transparent steaming and boiling-resistant film comprises a first polypropylene layer, a first adhesive resin layer and a polyamide layer which connect according to a successive order, wherein, the first adhesive resin layer is composed of adhesive resin and polypropylene, the polypropylene accounts for 20% to 30% of the first adhesive resin layer. The invention also provides a method for producing the transparent steaming and boiling-resistant film. Experiments show that the tensile force of the transparent steaming and boiling-resistant film with thickness of 75mum produced by the invention can reach 48(N / 15mm) / 52(N / 15mm), the thermal sealing strength before boiling is 35 (N / 15mm), the thermal sealing strength after boiling is 28 (N / 15mm), and the stripping phenomenon of the polypropylene layer and the polyamide layer can not occur before or after boiling, the transit quantity of water vapor is not higher than 2.75, the transit quantity of oxygen is not higher than 21.48, a PA / RCPP composite film with thickness of 85 mum prepared by using a dry type composite method has comparable performance.

Owner:HUANGSHAN NOVEL

A kind of preparation method of conductive nylon material

The invention provides a preparation method of a conductive nylon material. The method includes the following steps: (1) preparing an ionic liquid from n-butyl bromide and N-vinylimidazole; (2) calcining carbon nanotubes, and processing the calcined carbon nanotubes with a mixed acid to obtain acid processed carbon nanotubes; (3) preprocessing the acid processed carbon nanotubes with titanium chloride to obtain preprocessed carbon nanotubes; (4) carrying out a grafting reaction on the preprocessed carbon nanotubes and the ionic liquid to prepare a conductive agent; (5) weighing nylon and other raw materials according to corresponding weight parts; and (6) mixing the raw materials, and carrying out extruding granulation to obtain the conductive nylon material. The conductive nylon material prepared in the invention has good conductivity.

Owner:深圳智裳科技有限公司

Production Process of Tin Bronze Tempered Bead Wire Highly Bonded to Rubber

ActiveCN104593579BImprove adhesionAdhesive rate increasedFurnace typesLiquid/solution decomposition chemical coatingWater basedAlloy

Owner:JIANGSU XINGDA STEEL TYPE CORD

Method for improving compressive strength of alkaline pellets prepared from limestone

PendingCN113151672AHigh compressive strengthImprove the "bonding" effectPhysical chemistryCompressive strength

The invention discloses a method for improving the compressive strength of alkaline pellets prepared from limestone. The method comprises the following steps that 1, treated magnesium oxide is prepared; 2, mixed mineral powder is prepared; and 3, a roasted material is prepared and pelletized, prepared green pellets are screened and roasted, and the use amount of adhesive bentonite is controlled to be 1%-2.5% of the weight of the roasted material. Magnesium oxide is subjected to primary treatment, so that magnesium oxide has high porosity, oxygen can enter the pellets through pores in the oxygen enrichment process, oxidation of iron ore particles is improved, the compressive strength of the pellets is improved, and the technical problems that the compressive strength of the alkaline pellets prepared from the limestone can be improved by increasing the roasting temperature within a certain range, but energy consumption is increased by the too high temperature, and the compressive strength of the pellets is affected due to the fact that excessive liquid phases are generated are solved.

Owner:铜陵博锋实业有限公司

Melting processing method for polyvinyl alcohol composite material

InactiveCN102675785BImproved melt processing propertiesEnabling Melt ProcessingRoom temperaturePVA - Polyvinyl alcohol

The invention discloses a melting processing method for a polyvinyl alcohol composite material. The method comprises the following steps of: uniformly mixing polyvinyl alcohol at the temperature of 70-100 DEG C to obtain a mixture; uniformly mixing 100 parts by mass of the mixture, 10-30 parts by mass of a small molecular composite plasticizing agent and 0.5-5 parts by mass of an aid at the temperature of 70-120 DEG C, and cooling to the room temperature; and adding into a double screw extruder for extruding and pelletizing. By reasonably selecting a composite system of the small molecular plasticizing agent and adding an appropriate amount of aid, thermoplastic processing and molding of polyvinyl alcohol are realized successfully. According to the method, the problem of melting processing of polyvinyl alcohol is solved, and the processing property, physical property, appearance and the like of the composite material are improved.

Owner:HEFEI UNIV OF TECH

Crosslinking modification method and composite material of vitric acidic lava micro powder

InactiveCN101921499BLow priceNo pollution problemPigment treatment with organosilicon compoundsPigment physical treatmentPolymer scienceCarbon black

The invention provides a crosslinking modification method and a composite material of vitric acidic lava micro powder. By the method, a novel vitric acidic lava / difunctional silane coupling agent composite material can be prepared from natural rocks and can be applied to reinforcing agents and reinforcing fillers of rubber and the like. With low price, the composite material can replace reinforcing agents and reinforcing fillers of white carbon black, and other rubber and plastics; in addition, the production process of the composite material has no environment pollution.

Owner:WUHAN SHENGYE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com