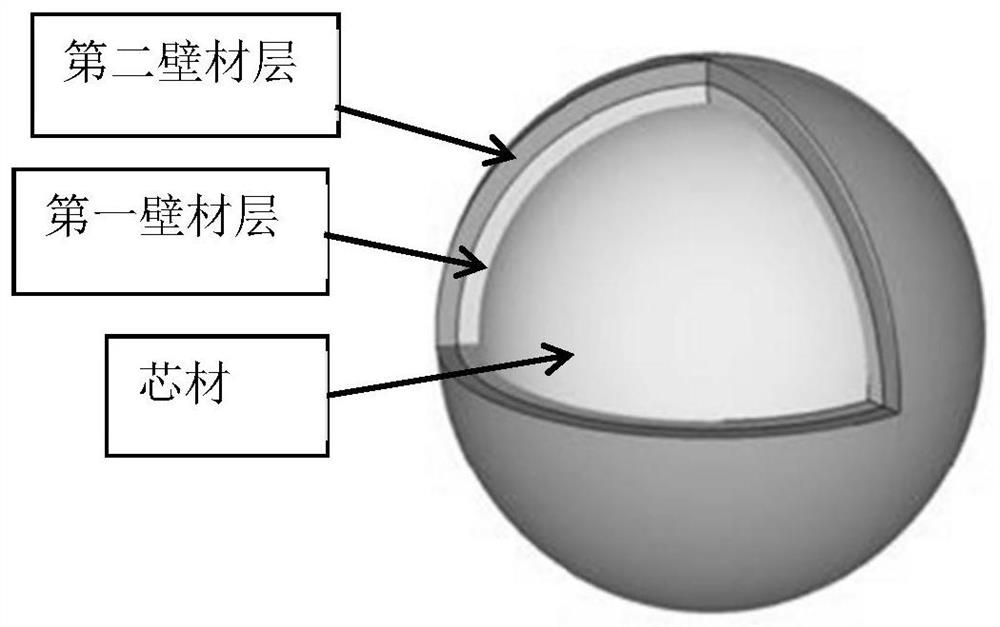

Double-shell self-repairing microcapsule, and preparation method and application thereof

A technology of microcapsules and double shell layers, applied in the field of coatings, can solve the problems of high cost, difficult to achieve uniform particle size of microcapsules, weak mechanical strength of microcapsules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

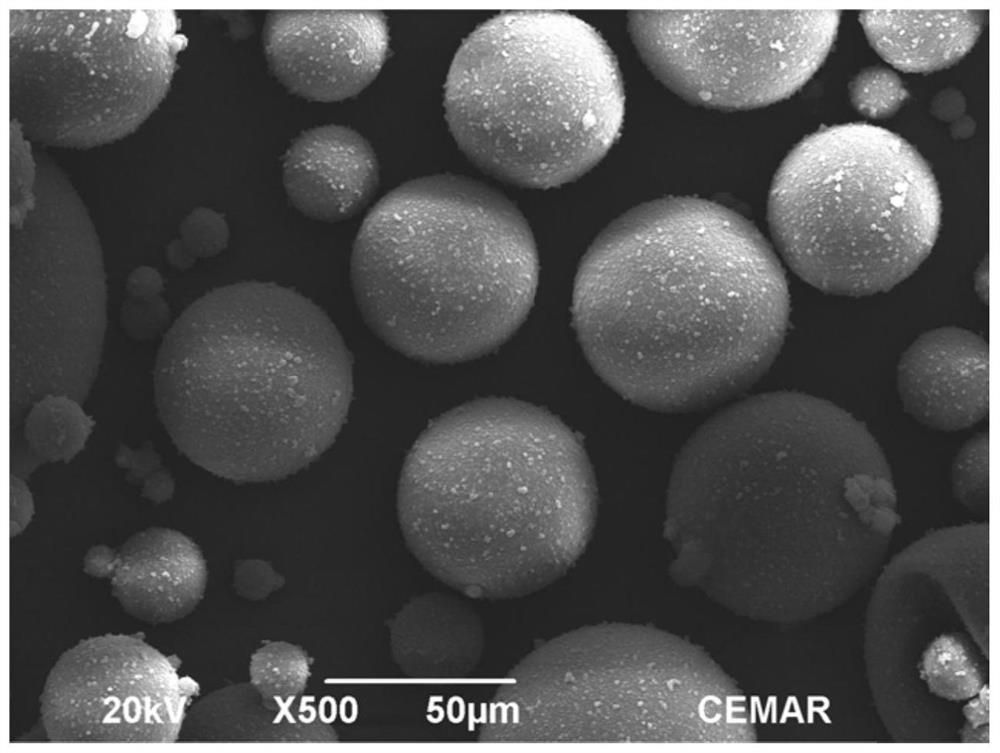

Image

Examples

Embodiment 1

[0068] Embodiment 1: a kind of double shell microcapsule and preparation method thereof:

[0069] (1) 100g of water, 3g of gum arabic were added to the beaker, constant temperature at 40°C, and stirring at 500rpm for 10min to obtain an emulsifier solution;

[0070] (2) 14g of 4,4'-dicyclohexylmethane diisocyanate and 1g of Huntsman Suprasec2644 were added to the beaker, stirred at room temperature 500rpm to obtain an oil phase;

[0071] (3) above-mentioned oil phase is added in emulsifier solution, at 40 ℃, after 1200rpm stirring 20min, add 3g 1,4-butanediol, 1g glycerol and 0.5g sorbitol, adjust stirring speed to 500rpm, be warming up to After reacting at 60 °C for 100 min, single-shell microcapsules were obtained, and the reaction system was cooled to below 30 °C;

[0072] (4) 3g of resorcinol and 3g of polyethylene-maleic anhydride copolymer are dissolved in 100g of water and mixed, and added into the above-mentioned single-shell microcapsules;

[0073] (5) 8g of urea is ...

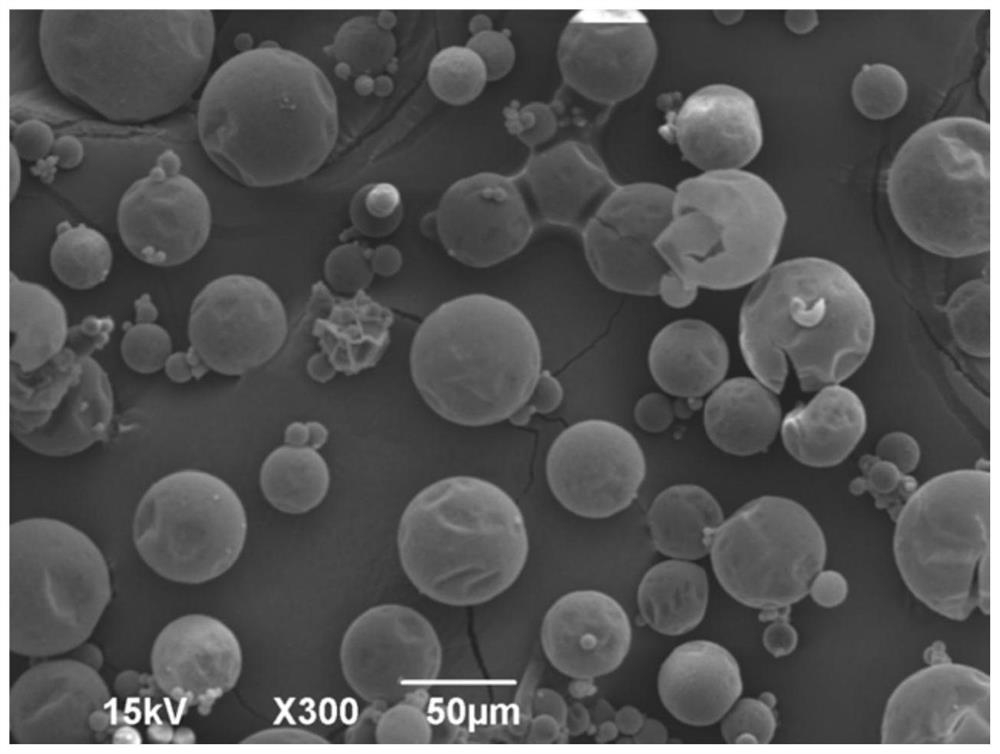

Embodiment 2

[0074] Embodiment 2: a kind of double shell microcapsule and preparation method thereof:

[0075] (1) add 100g water, 2g polyvinyl alcohol 1788 in the beaker, 45 ℃ of constant temperature, 500rpm stirring 10min, obtain emulsifier solution;

[0076] (2) 13g of 4,4'-dicyclohexylmethane diisocyanate was added to the beaker, heated at 40°C, 2g of hexamethylene diisocyanate was added, and stirred at 500 rpm to obtain an oil phase;

[0077] (3) above-mentioned oil phase is added in emulsifier solution, at 45 ℃, after 1000rpm stirring 15min, add 6g tetraethylene pentamine, the polyethyleneimine of 1g molecular weight 1800, adjust stirring speed to 400rpm, be warming up to 65 ℃ of reaction 70min, the obtained product was centrifuged and washed with water for 5 times to remove the amines and emulsifier in the solution for subsequent use to obtain single-shell microcapsules;

[0078] (4) mixing 5g urea with 13g mass fraction of 37% formaldehyde solution, stirring at 500rpm, and adjusti...

Embodiment 3

[0080] Embodiment 3: a kind of double shell microcapsule and preparation method thereof:

[0081] (1) add 200g water, 1.5g polyvinyl alcohol 1788, 0.5g polyoxyethylene octyl phenol ether-10, 40 ℃ constant temperature, 500rpm stirring 60min in the beaker, obtain emulsifier solution;

[0082] (2) adding 26g of 4,4'-dicyclohexylmethane diisocyanate, 2g of Huntsman Suprasec2644, and 2g of Wanhua HT-10 to the beaker, stirring at room temperature at 500 rpm to obtain an oil phase;

[0083] (3) adding the above-mentioned oil phase to the emulsifier solution, at 40°C, after stirring at 1200rpm for 20min, add 4g of 1,3-propanediol, 1g triethanolamine and 0.6g sorbitol, adjust the stirring speed to 500rpm, and heat up to 60°C After 100min of reaction, single-shell microcapsules are obtained, and the reaction system is cooled to below 30°C;

[0084] (4) 4g of resorcinol and 2.5g of polyethylene-maleic anhydride copolymer are dissolved in 200g of water and mixed, and added to the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com