Radiation cured adhesive for indium tin oxide (ITO) circuit and module protection

A technology of radiation curing and adhesives, which is applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., which can solve the problems of long time, at least 48 hours, poor fluidity of RTV-1, hidden dangers of LCM reliability, etc. problems, to achieve the effects of high environmental test reliability, good product application reliability, and improved production efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

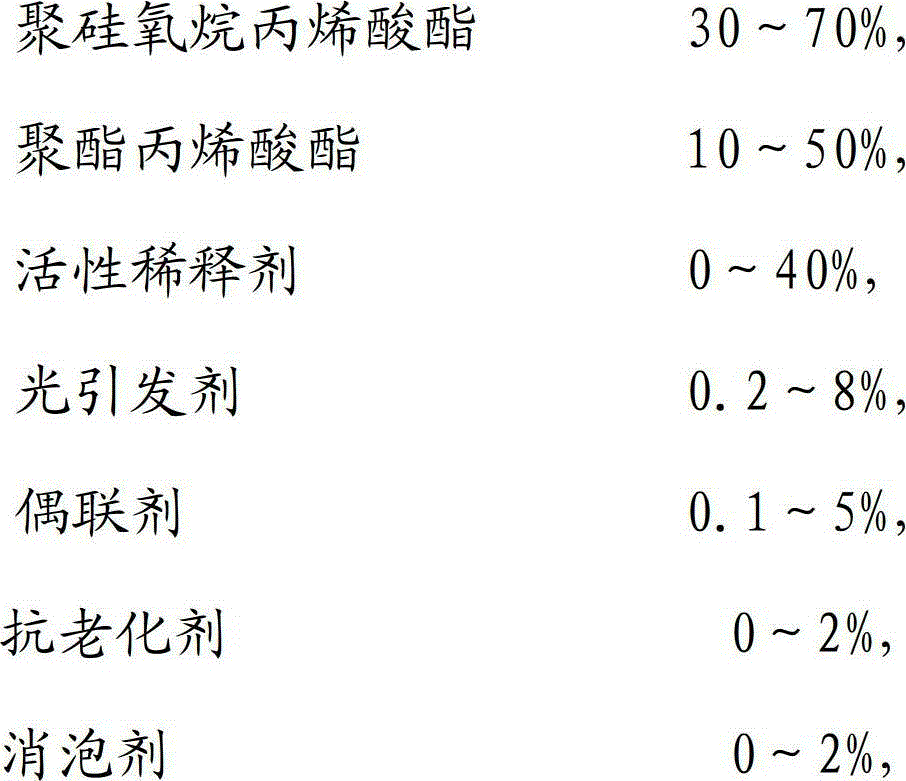

[0033] A radiation curing adhesive used for ITO circuit and module protection, by weight, contains components and the percentage content of each component is as follows

[0034]

[0035] Described polyester acrylate is polyester acrylate CN922; Described reactive diluent is isobornyl acrylate (IBOA), 1,6 hexanediol diacrylate (HDDA) and trimethylolpropane triacrylate (TMPTA ), wherein the mass content of IBOA in the radiation-curable sealant is 9%, the mass content of HDDA in the radiation-curable sealant is 18.7%, and the mass content of TMPTA in the radiation-curable sealant is 9%; photoinitiator is cracking photoinitiator 184; coupling agent is silane coupling agent, choose γ-methacryloxypropyl trimethoxysilane (KH570); anti-aging agent is antioxidant 1010 ; The defoamer is silicone defoamer BYK-088.

[0036] The polysiloxane acrylate is self-made, and by weight, the contained components and the mass percentages of each component are:

[0037] Isocyanates: 50%

[...

Embodiment 2

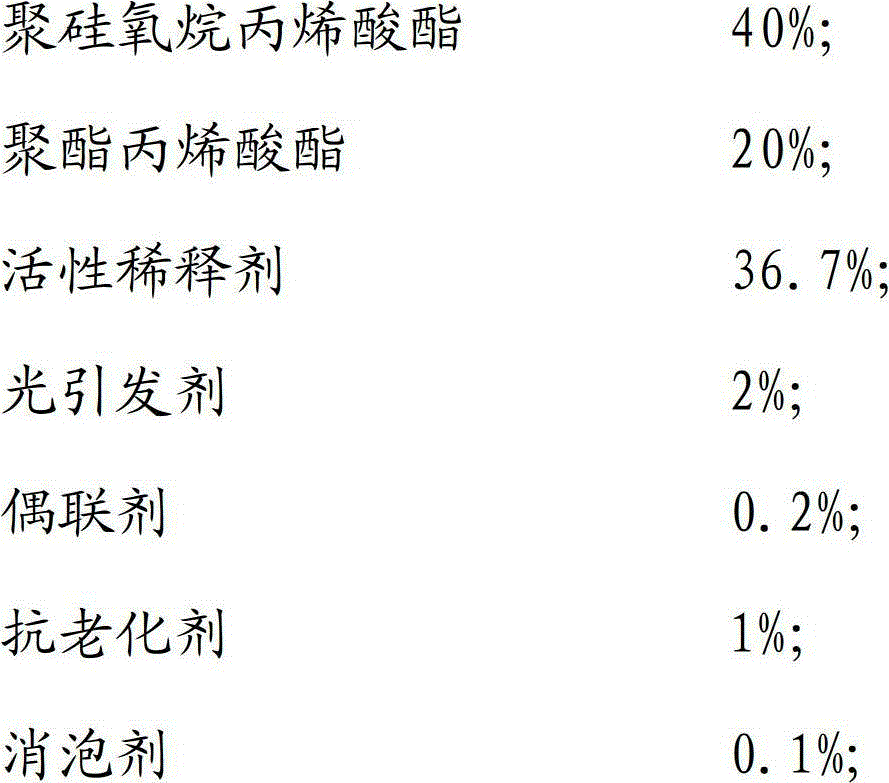

[0049] A radiation curing adhesive used for ITO circuit and module protection, by weight, contains components and the percentage content of each component is as follows

[0050]

[0051] The polyester acrylate is polyester acrylate CN736; the reactive diluent is a mixture of isobornyl methacrylate (MIBOA), tripropylene glycol diacrylate (TPGDA) and dipentaerythritol hexaacrylate (DPHA) , wherein the mass content of MIBOA in the radiation-cured sealant is 10.8%, the mass content of TPGDA in the radiation-cured sealant is 3.6%, and the mass content of TMPTA in the radiation-cured sealant is 7.1%; The photoinitiator is a mixture of cleavage-type photoinitiator 184 and photoinitiator TPO; the coupling agent is a silane coupling agent, and γ-methacryloxypropyl trimethoxysilane (KH570) is selected; the anti The aging agent is antioxidant 2246; the defoamer is non-organic silicon defoamer Airex920.

[0052] The polysiloxane acrylate is self-made, and by weight, the contained comp...

Embodiment 3

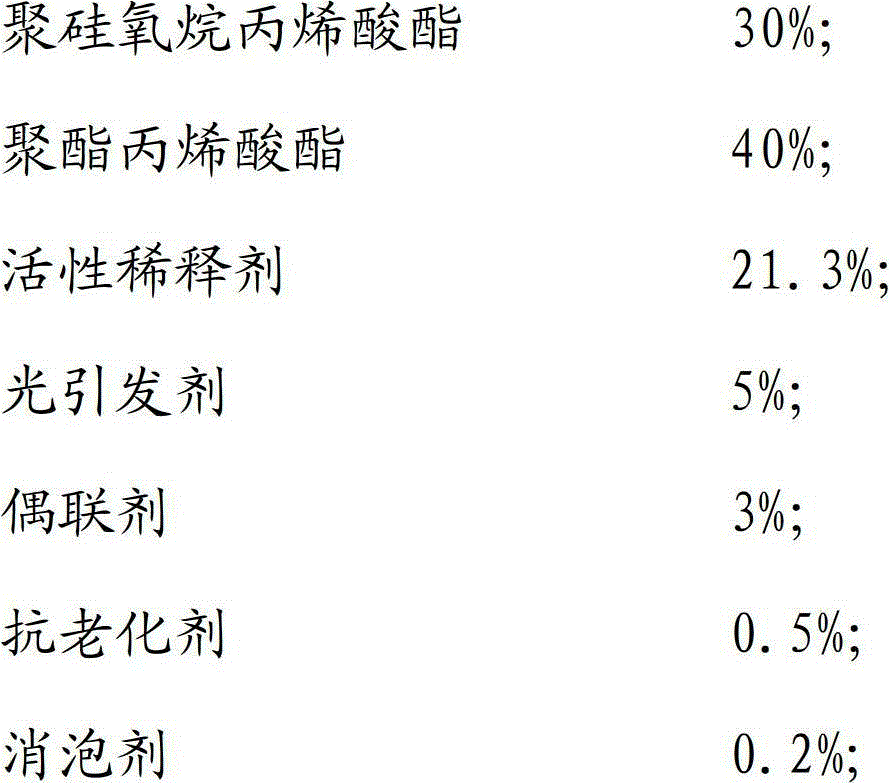

[0064] A radiation curing adhesive used for ITO circuit and module protection, by weight, contains components and the percentage of each component is as follows,

[0065]

[0066]

[0067] Described polysiloxane acrylate is polysiloxane acrylate prepared in embodiment 1; Described polyester acrylate is polyester acrylate CN736; Described reactive diluent is isobornyl methacrylate (MIBOA ); the photoinitiator is a cleavage-type photoinitiator TPO; the silane coupling agent is a mixture of vinyltrimethylsilane and 3-methacryloxypropyltrimethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com