Crosslinking modification method and composite material of vitric acidic lava micro powder

A composite material, cross-linking modification technology, applied in the direction of fibrous filler, dyeing organosilicon compound treatment, dyeing physical treatment, etc., can solve the problem of low quality of rubber and plastic products, complicated white carbon black manufacturing process, environmental pollution, etc. problem, to achieve the effect of simple structure, low price and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

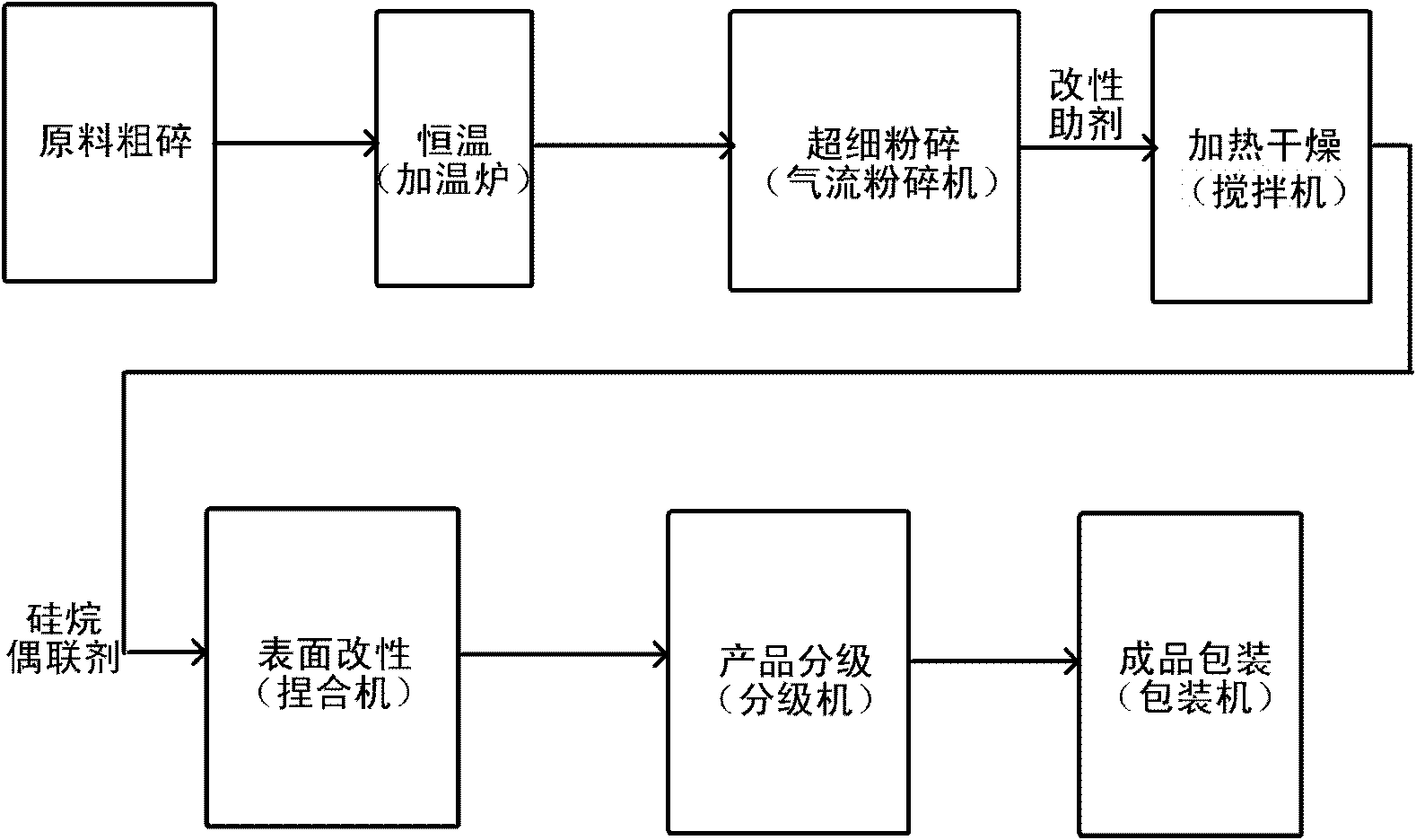

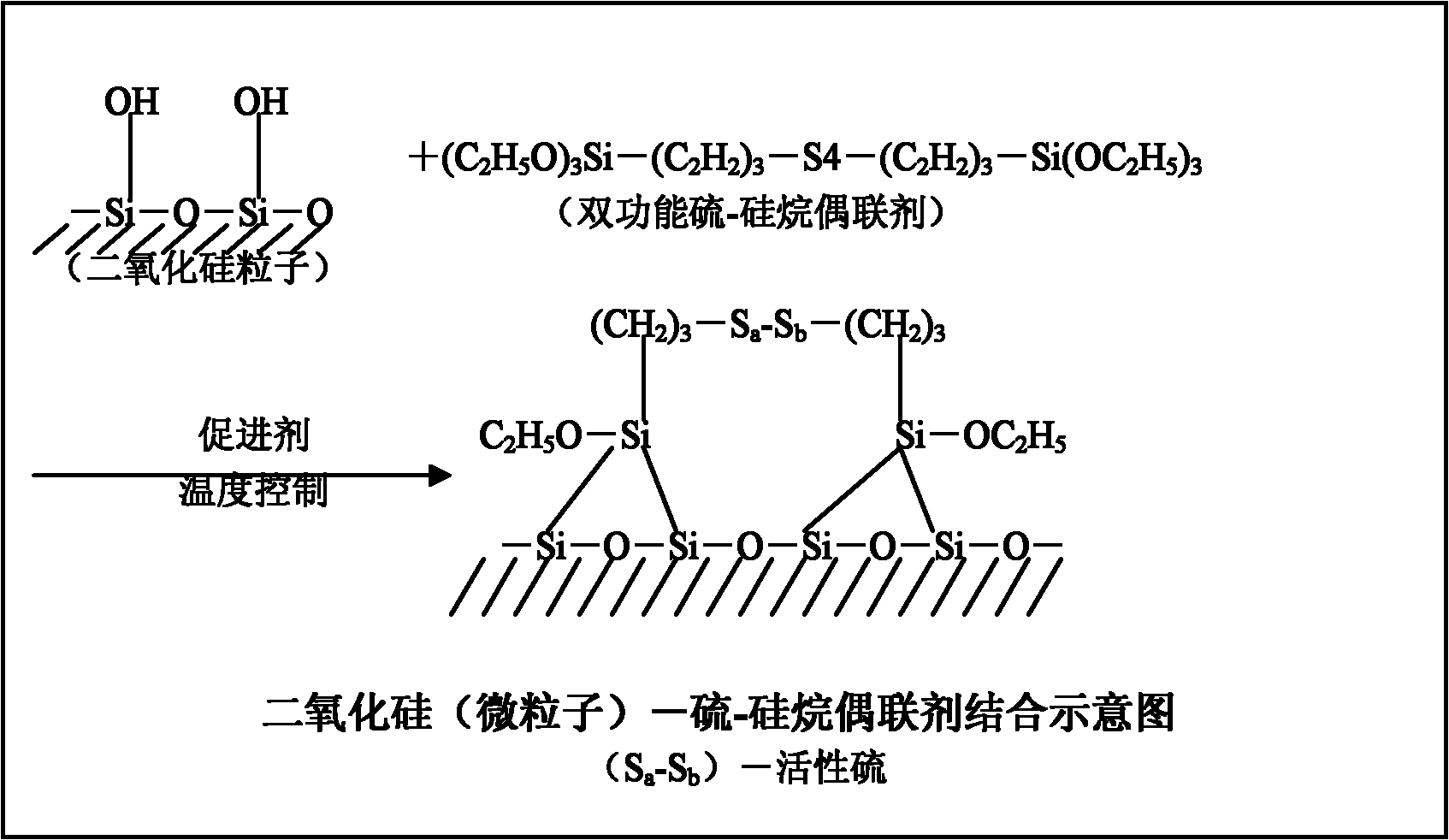

[0025] Such as figure 1 Shown is the process flow chart of the cross-linking modification method of the glassy acidic lava micropowder provided by the embodiment of the present invention. The cross-linking modification method of the vitreous acidic lava micropowder provided by the invention comprises the following processes:

[0026] Raw materials: Vitreous acidic lava (commonly turpentine, obsidian, perlite, etc.), widely distributed in my country, with large reserves, often exposed to the surface, easy to mine, the price of raw ore is only 100-200 yuan / ton.

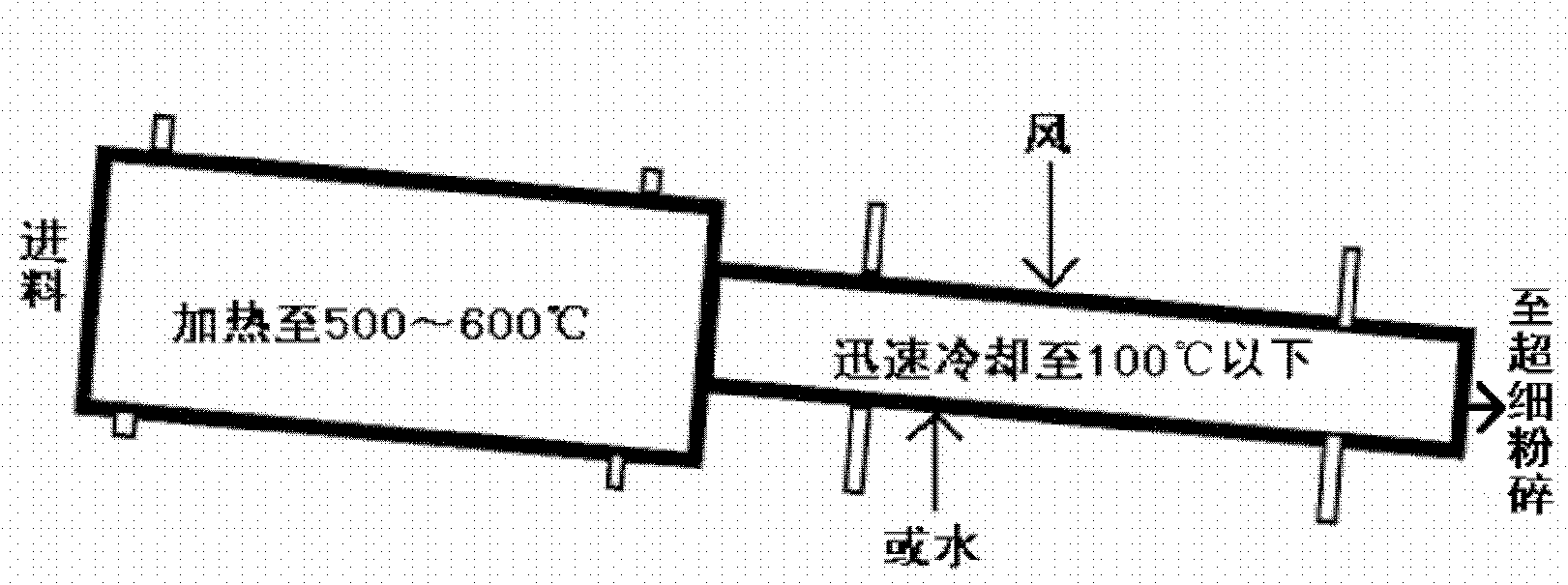

[0027] Crushing and pretreatment of raw materials: including coarse crushing and ultrafine crushing; rocks are heated to 500-600°C after coarse crushing and before ultrafine crushing, and rapidly cooled to below 100°C. Its purpose is twofold: one is to remove the adsorbed water in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com