A kind of water-based coating solution for post-plating treatment of bead steel wire

A bead wire and substrate technology, applied in coating, liquid chemical plating, metal material coating process, etc., can solve the problem of shortening the service life of the tire, affecting the performance of the tire, and weak adhesion between the bead wire substrate and the rubber. and other problems, to achieve the effect of increasing the adhesion rate and enhancing the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: A water base coating solution for post-plating treatment of bead wires, consisting of 0.7% N-β (aminoethyl)-γ-aminopropylmethyldimethoxysilane, 0.1 % bis(triethoxysilylpropyl) tetrasulfide, 0.16% bis(triethoxysilylpropyl) disulfide, 0.04% 3-thiooctanoyl-1-propyl trisulfide Composed of ethoxysilane, 60% methanol, 30% ethanol, and the rest of water, use a 6cm cotton thread soaked in the above water-based coating solution, apply it on the surface of a 0.95mm tinned bronze bead wire, and one end of the silane coupling agent The hydrolyzed group undergoes hydrolysis and reacts with the steel wire matrix to combine, and the organic group at the other end can react with the organic components in the post-treatment process to effectively connect the inorganic metal and the organic resin; compared with the single-coated organic coating liquid, First apply the water-based coating solution and then apply the organic coating solution, the adhesion between the steel wire ...

Embodiment 2

[0014] Example 2: A water-based coating solution for post-plating treatment of bead wires, consisting of 0.8% N-β (aminoethyl)-γ-aminopropylmethyldimethoxysilane, 0.15 % of bis(triethoxysilylpropyl) disulfide, 0.1% of 3-thiooctanoyl-1-propyltriethoxysilane, 60% of methanol, 25% of ethanol, and the balance of water Composition: use 8cm cotton thread soaked in the above water-based coating solution, and apply it on the surface of 1.20mm tinned bronze bead wire. The group can react with the organic components in the post-treatment process, effectively connecting the inorganic metal and the organic resin; compared with the single-coating organic coating solution, the water base coating solution is first coated and then the organic coating solution, and the steel wire and the organic coating solution The adhesion between rubber and the adhesive rate after bonding are significantly improved. After this treatment, the adhesive force between the steel wire and rubber is greater than 1...

Embodiment 3

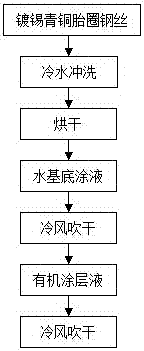

[0015] Embodiment three: see figure 1 Shown, a kind of post-plating coating treatment method for bead steel wire comprises the steps:

[0016] ①Select high-strength plated bead wire with a tin bronze coating weight of 0.39-0.58g / kg, a tin content of 4-10%, and a diameter of 1.30mm;

[0017] ②Rinse with cold water to remove the impurity ions remaining on the surface of the steel wire in the previous process, and dry the steel wire in an oven at 160°C;

[0018] ③Apply the steel wire obtained in step ② with a 5cm cotton thread to the water base coating solution used for the post-plating treatment of bead steel wires according to the present invention. The water base coating solution contains N-β (aminoethyl)-γ-ammonia with a mass fraction of 0.6%. Propylmethyldimethoxysilane, 0.05% bis(triethoxysilylpropyl) tetrasulfide, 0.15% 3-thiooctanoyl-1-propyltriethoxysilane, 60% Methanol, 28% ethanol, the balance is water, and then dried by cold air;

[0019] 4. smear organic coating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com