Cobalt material with multi-sheet stacked structure for negative electrode of supercapacitor and preparation method thereof

A technology of supercapacitors and stacked structures, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of unfavorable ion transport in the electrolyte, poor stability of the connection state, and small gap spacing, etc., to achieve improved connectivity. State and stability, ease of material desorption, and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

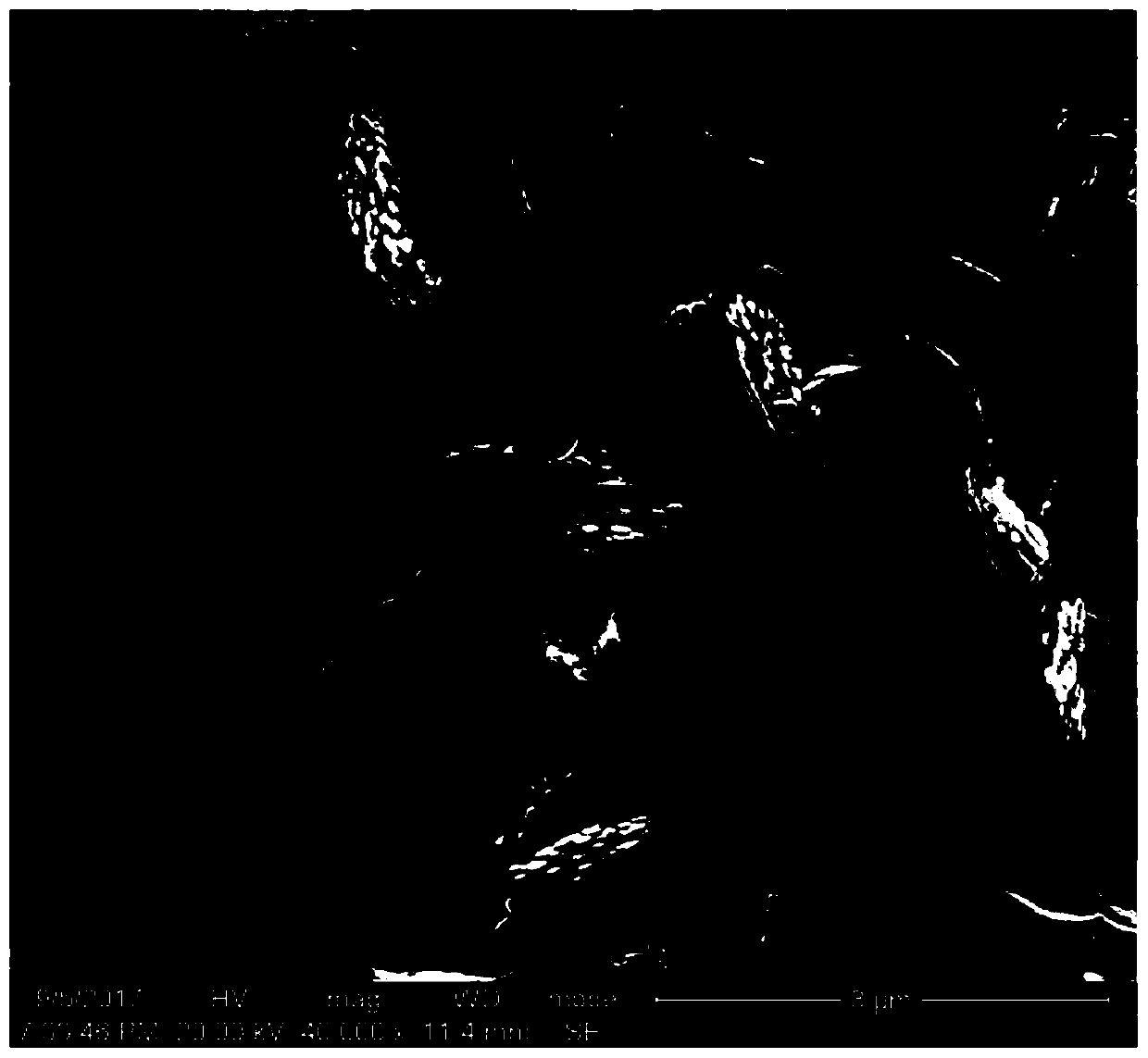

[0042]Solve the problem that the preparation method of the existing cobalt material with multi-layer stacked structure is complicated and difficult to operate; the material morphology of the prepared multi-layer stacked structure is not only not conducive to the transport of ions in the electrolyte, but also cannot be well alleviated. The problem of material desorption caused by expansion of materials during electrochemical related tests; and the problems of poor connectivity, poor stability, and small gap spacing between sheets.

[0043] The present invention utilizes a solvothermal method, under high temperature conditions, cobalt material grows in situ on the surface of graphene, on the one hand, this composite material utilizes the high specific surface area of graphene, and cobalt is inserted into the strongly wrinkled sheet of graphene, Increasing the distance between graphene sheets not only prevents the agglomeration of graphene itself, but also further increases the ...

Embodiment 1

[0046] 1) The concentration of graphene is 0.5-3g / L, weigh the graphene, add 13-20mL water to fully stir and sonicate;

[0047] 2) Weigh 0.5g of cobalt nitrate Co(NO 3 ) 2 , 50-500mg of urea and 100mg of NH 4 F powder, join step 1) in the graphene solution that obtains, stir 10 minutes;

[0048] 3) Weigh 2.5-25 mg of cetyltrimethylammonium bromide (CTAB) powder and add it to the mixed solution obtained in step 1), and stir for 10 minutes;

[0049] 4) Measure 5-13mL of ethanol and add it to the above mixed solution, and stir for 10 minutes;

[0050] 5) Transfer the liquid obtained in step 4) to a polytetrafluoroethylene reactor, react at 100-200 degrees Celsius, and the reaction time is 6-24 hours to obtain the first precipitate;

[0051] 6) Take the sediment for the first time and carry out centrifugal washing with water and ethanol;

[0052] 7) drying at a temperature of 30-100 degrees Celsius for 12 hours to obtain a solid of graphene and cobalt composite material;

[...

Embodiment 2

[0057] 1) The concentration of graphene is 0.5g / L, weigh the graphene, add 13mL water to fully stir and sonicate;

[0058] 2) Weigh 0.5g of Co(NO 3 ) 2 , 50mg of urea and 100mg of NH 4 F powder, join step 1) in the graphene solution that obtains, stir 10 minutes;

[0059] 3) Weigh 2.5 mg of CTAB powder and add it to the mixed solution obtained in step 2), and stir for 10 minutes;

[0060] 4) Measure 13 mL of ethanol and add it to the mixed solution obtained in step 3), and stir for 10 minutes;

[0061] 5) Transfer the liquid obtained in step 4) to a polytetrafluoroethylene reactor, react at 120 degrees Celsius, and the reaction time is 12 hours to obtain the first precipitate;

[0062] 6) Take the sediment for the first time and carry out centrifugal washing with water and ethanol;

[0063] 7) drying at a temperature of 70 degrees Celsius for 12 hours to obtain a solid of graphene and cobalt composite material;

[0064] 8) Weigh 10 g of NaCl solid and add it to 1 L of de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com