Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Meet the requirements of the use environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resistant stainless steel with high-lasting strength and manufacturing method thereof

ActiveCN101705437ASimple structureMeet the requirements of the use environmentTemperature control deviceFurnace typesPower stationSuperheater

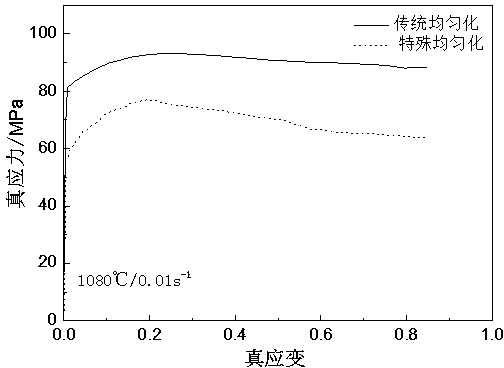

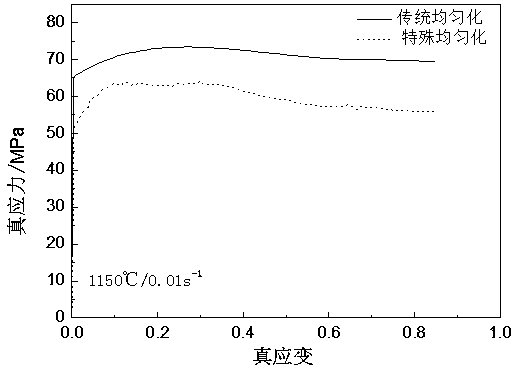

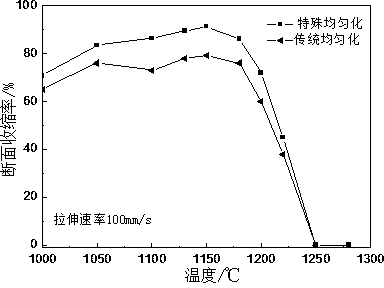

The invention discloses a heat-resistant stainless steel with high-lasting strength and a manufacturing method thereof. The heat-resistant stainless steel includes the following components by percentage: 24.00-26.00 of Cr, 17.00-23.00 of Ni, 0.05-0.75 of Si, 0.15-2.00 of Mn, less than or equal to 0.030 of P, less than or equal to 0.030 of S, 0.04-0.10 of C, 0.15-0.35 of N, 0.01-5.00 of RE, and 0.20-0.60 of M, wherein M is Nb and Ta. The manufacturing method comprises the following steps: 1. smelting: smelting molten steel in accordance with component requirements of the stainless steel; 2. pouring billet steel; 3. hot-rolling the billet steel: a. heating, the temperature of a uniform temperature section in a furnace is at the temperature of 1130 DEG C plus or minus 50 DEG C, and the soaking time is 80 minutes plus or minus 10 minutes; and b. rolling or forging, the initial rolling / initial forging temperature is at the temperature of 1100 DEG C plus or minus 50 DEG C, and the finishing rolling / finishing forging temperature is at the temperature of 860 DEG C plus or minus 50 DEG C; and 4. heat treatment, the solid solution temperature is at the temperature of 1175 DEG C plus or minus 75 DEG C, and water quenching after heat preservation. Through deduction by tests after sampling the stainless steel manufactured by the method, manufactured seamless tubes can satisfy the use requirements of superheaters and reheaters of ultra-supercritical power station boilers.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Nickel-based alloy for tubes of boiler of ultra-supercritical power station and preparation method thereof

ActiveCN103993202AImprove stabilityMeet the requirements of the use environmentPower stationSuperheater

The invention provides a nickel-based alloy for tubes of a boiler of an ultra-supercritical power station and a preparation method thereof and belongs to the field of metallurgy. The nickel-based alloy comprises the following chemical components in percentage by weight: 23.5-25.5% of Cr, 19.0-23.0% of Co, 1.4-1.9% of Al, 1.05-1.4% of Ti, 1.2-1.5% of Nb, 0.3-0.5% of Mo, 0.03-0.06% of C, 0.002-0.006% of B, 0.04-0.07% of Zr, not more than 0.5% of Si, not more than 0.5% of Mn, not more than 0.003% of S, not more than 0.005% of P, not more than 4.0% of Fe and the balance of Ni and inevitable impurity elements, wherein, the amount of Al and Ti is not less than 2.45% and the ratio of Ti / Al is 0.75-0.95. The nickel-based alloy tubes obtained according to the preparation method provided by the invention can meet the requirements of using environments of boiler superheaters / reheaters of advanced ultra-supercritical power stations.

Owner:TAIYUAN IRON & STEEL GROUP

Method for preparing grinding silk

InactiveCN101994167AExcellent productivityReduce wearOther chemical processesArtifical filament manufactureInvestment materialContact phase

The invention relates to a method for preparing a super-tough super-strong specific grinding silk. In the invention, the performance of a polyamide resin slice is adjusted through adjusting auxiliary materials, such as antioxidant, a flexibilizer and / or a reinforcing agent and the like, artificial diamond grinding particles subjected to coupling agent treatment is added to produce the grinding silk with excellent performance. A contact phase of the artificial diamond grinding particles subjected to the coupling agent treatment and the polyamide resin slice is solid-liquid blending by means of segment charging, so as to reduce the abrasion of a building-block type single screw rod extruder by using the artificial diamond grinding particles, and feed volumes are respectively regulated to obtain a plurality of grinding silks having the proportion content of grinding materials, so that the product meets the requirement on various trenchant use environment. The product developed by the process has the advantage of better grinding performance, and can be normally used in the environment of high temperature and acid base.

Owner:慈溪市洁达纳米复合材料有限公司

Resistance brazing welding method for titanium aluminum alloy turbine and steel shaft

InactiveCN102380678AMeet the requirements of the use environmentUniform end surface temperatureSoldering apparatusTurbochargerWeld seam

The invention introduces a resistance brazing welding method for a titanium aluminum alloy turbine and a steel shaft. The method is characterized by comprising the following steps of: adding brazing filler metal between an aluminum turbine and the steel shaft; melting the brazing filler metal by utilizing resistance heat; applying upsetting force; unloading components after keeping for a period of time; and performing distressing and annealing on the components to obtain a combined part of the turbine and the steel shaft. In the resistance brazing welding method for the titanium aluminum alloy turbine and the steel shaft, the temperature on the overall surface can be more uniform by a connection method for heating by utilizing resistance heat; joint tissues and performance uniformity are good after welding, so that the weld seam strength is higher than that in common brazing welding and can reach 190 MPa; and simultaneously, the production efficiency is higher and batch production is easier to realize. A weld assembly obtained by adopting the method meets the requirement on use environment of a turbocharger.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

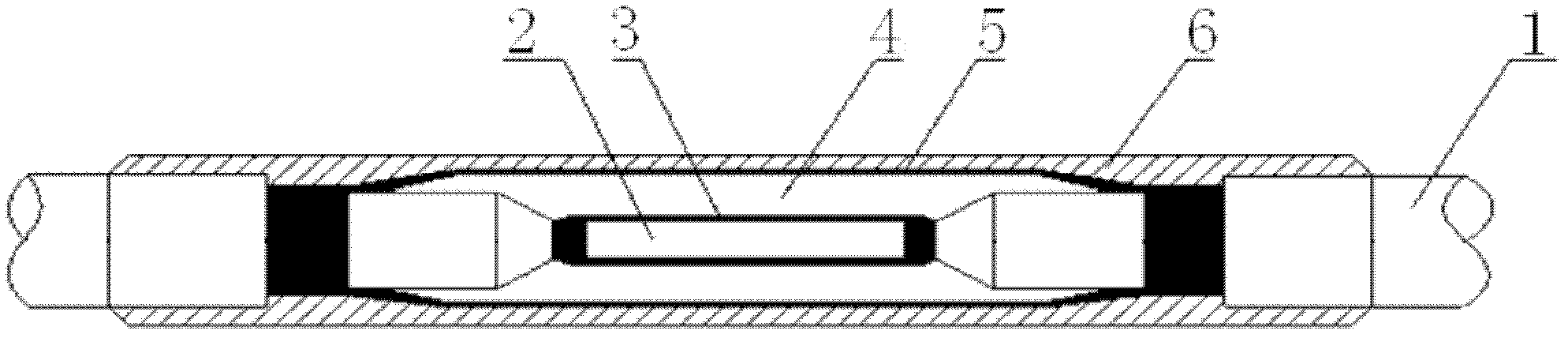

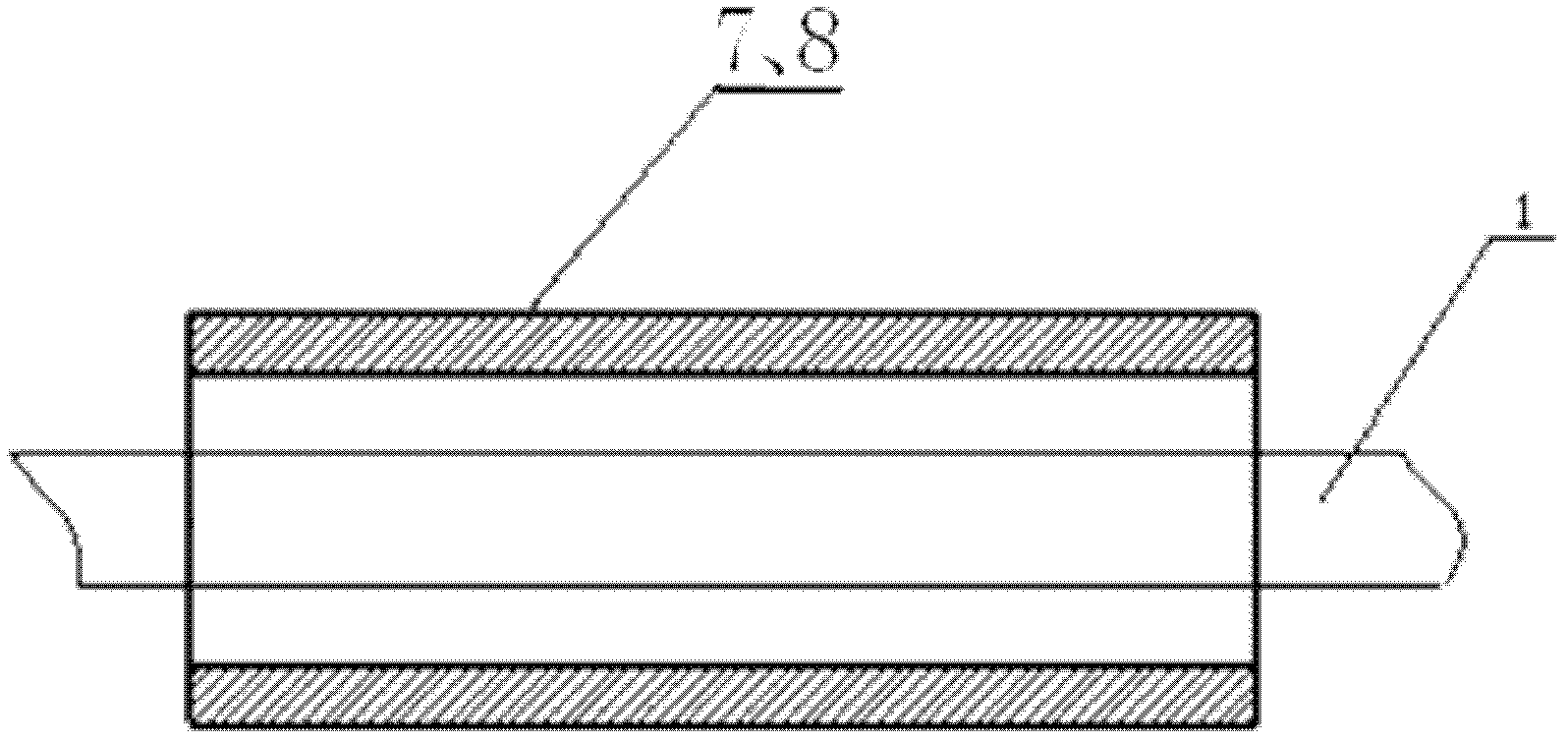

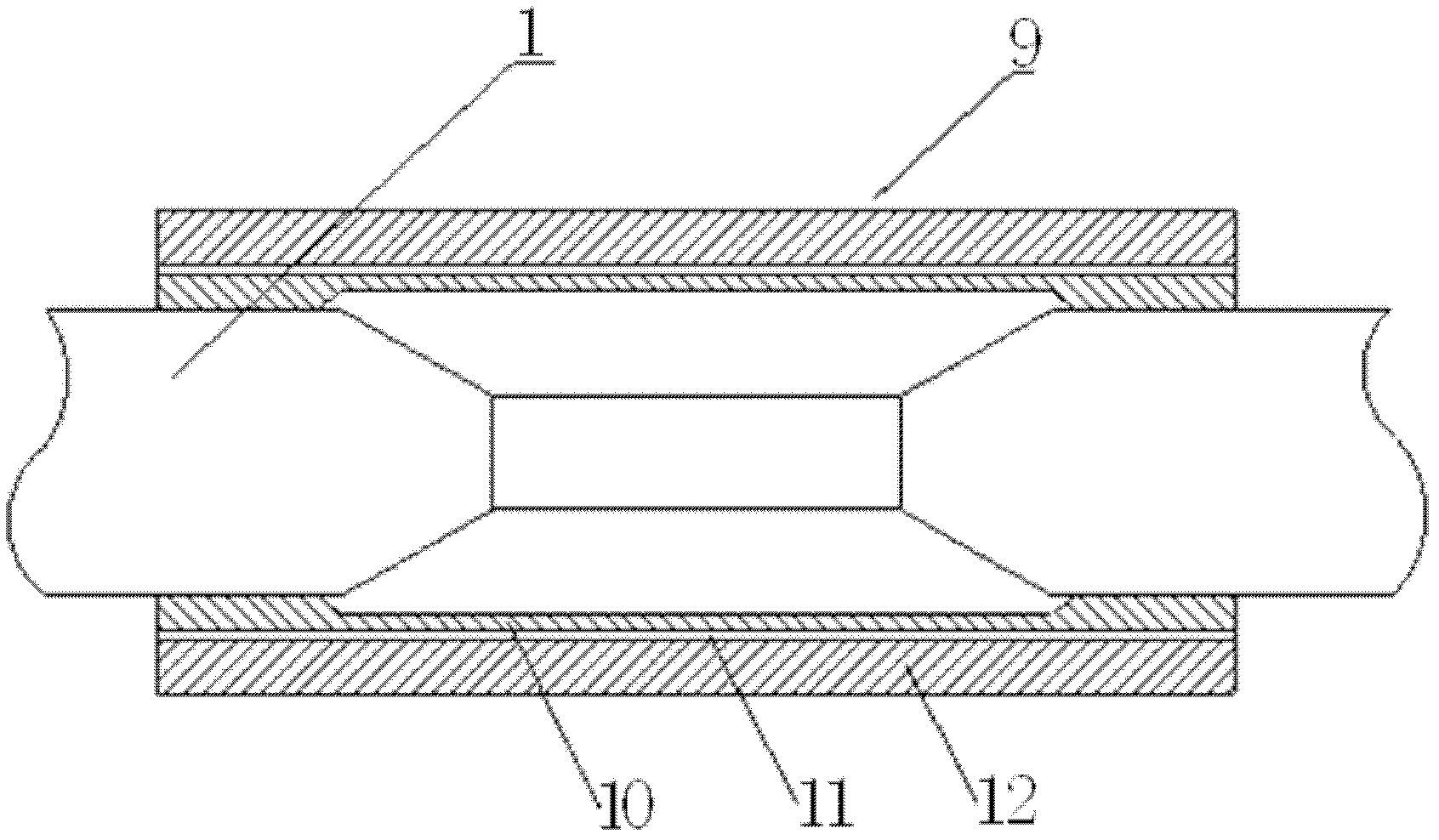

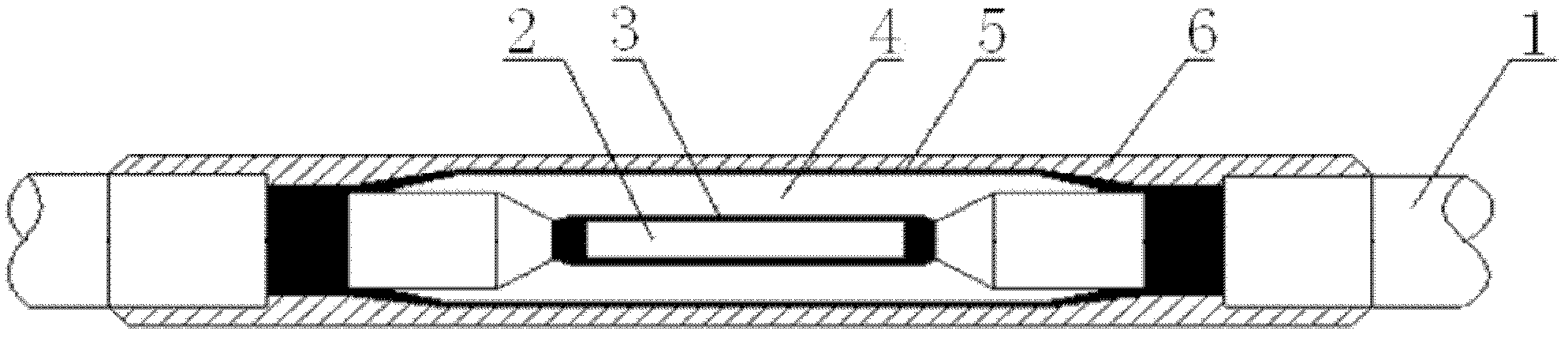

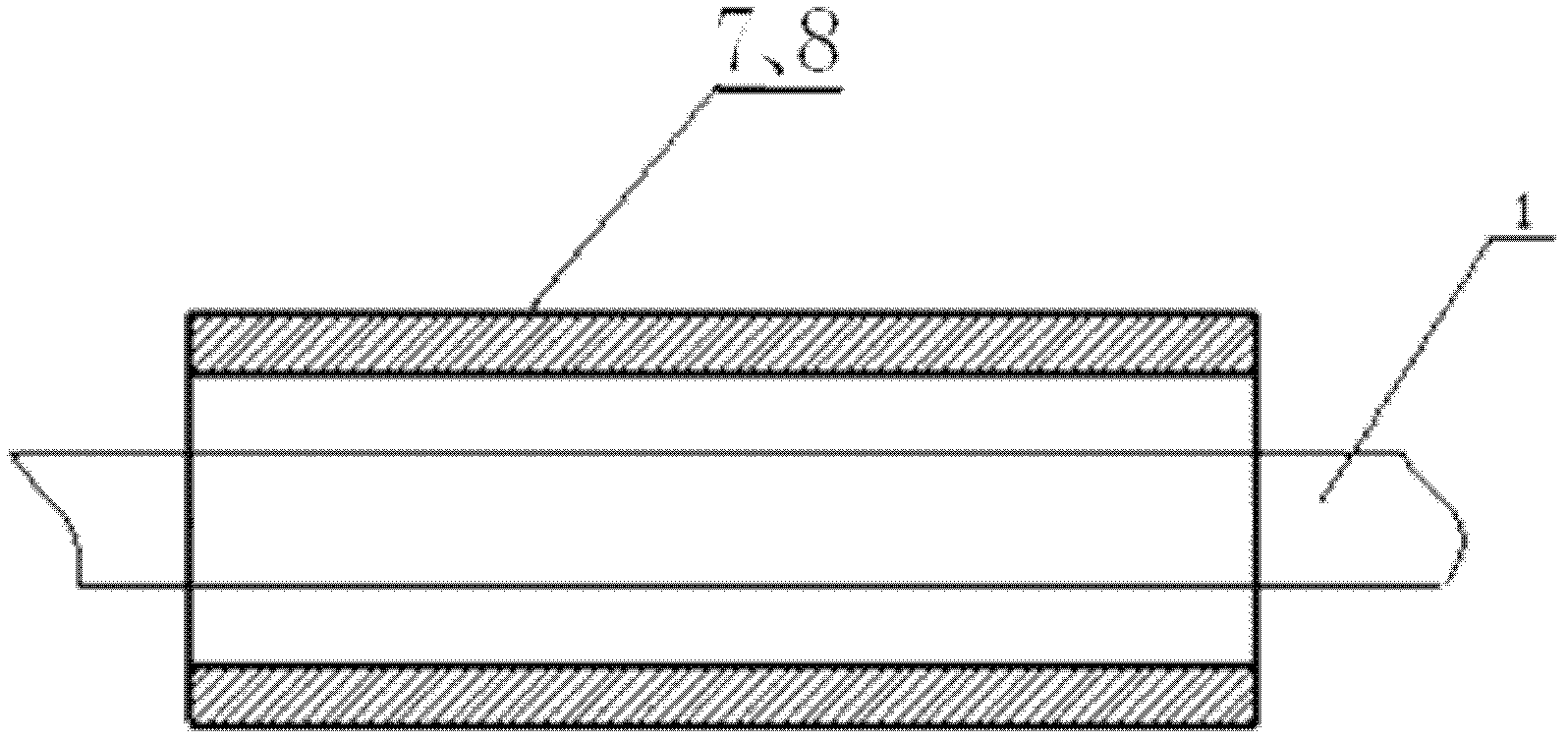

Method for manufacturing flexible joint of large-length submarine cable

ActiveCN102593764AImprove performanceOvercome lengthApparatus for joining/termination cablesVulcanizationElectrical conductor

The invention discloses a method for manufacturing a flexible joint of a submarine cable capable of satisfying the requirements of high-voltage and ultrahigh-voltage use situations. The method comprises the steps as follows: 1) conductor connection; 2) conductor shield and vulcanization; 3) insulation extrusion; 4) insulation vulcanization; 5) insulation shield and repair; and 6) metal sheath recovery, wherein the insulation vulcanization process is that an insulated cable is put into a vulcanizing mould, nitrogen gas filled into the vulcanizing mould during the vulcanization cannot leak, cooling water systems at the two ends of the vulcanizing mould are simultaneously kept unblocked, so as to keep the temperature at the two ends of the cable below 70 DEG C; when the temperature reaches 235 to 245 DEG C and the nitrogen gas pressure is 1.5Mpa, insulation vulcanization begins, and the temperature and the pressure are regulated through a valve and a power source; and after the vulcanization is conducted for 120 minutes, the power source is cut off, the temperature is reduced below 100 DEG C while the pressure is kept at1.5Mpa, gas is discharged to release the pressure, and when the pressure is zero, the vulcanizing mould is opened and the cable is taken out. When the cable produced by adopting the manufacturing method disclosed by the invention is used as the submarine cable in high-voltage and ultrahigh-voltage situations, the performance of the cable is excellent and the requirements of the use environments are satisfied.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD +1

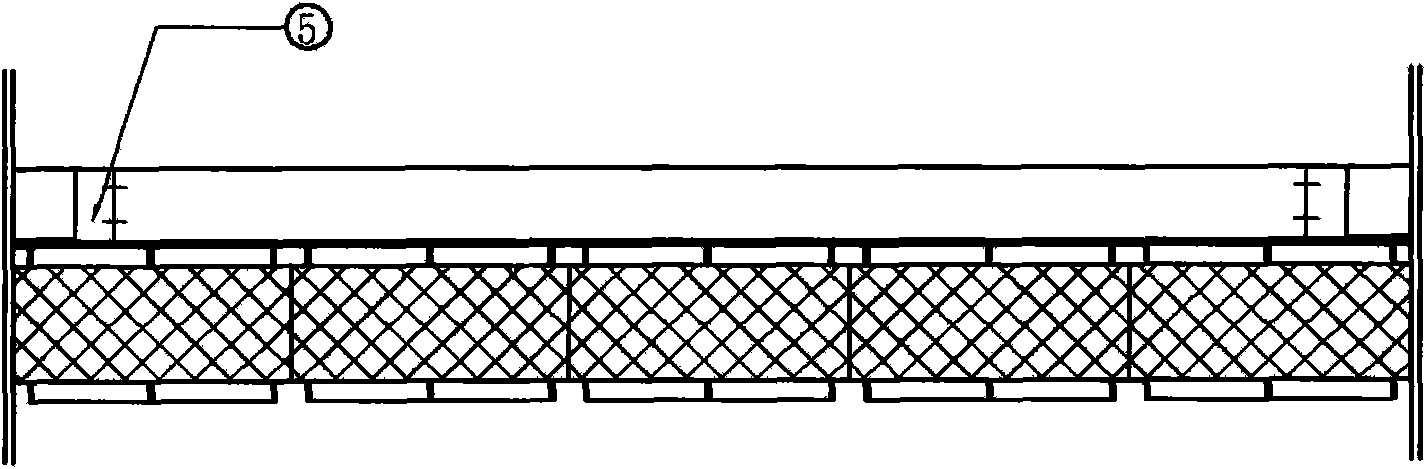

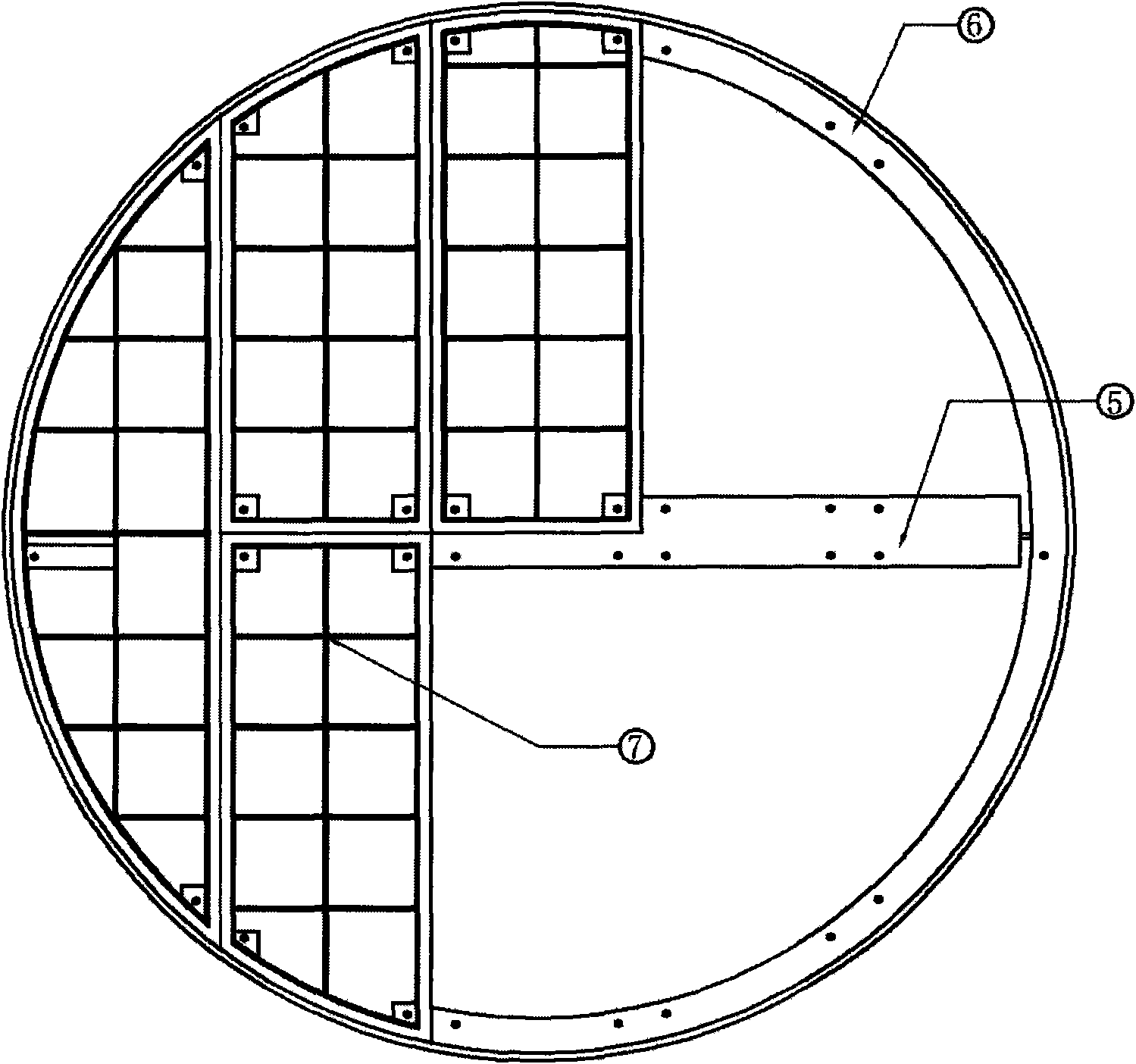

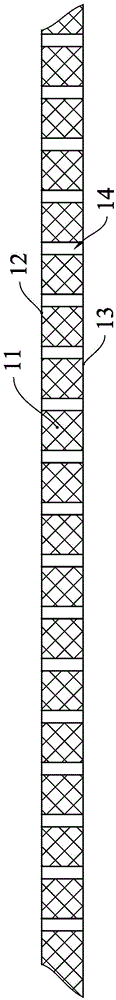

High-efficiency foam destroyer adopting metal base composite PTFE (Polytetrafluoroethylene)

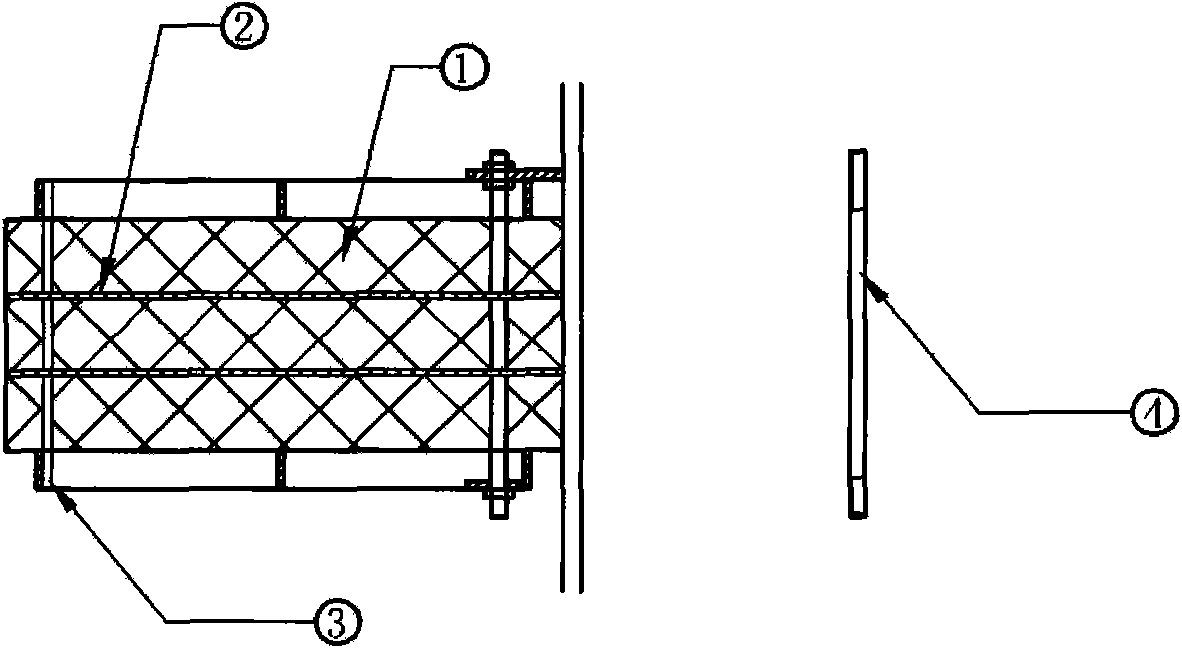

InactiveCN101869780AExtended service lifeHigh strengthFiltration separationFoam dispersion/preventionMetal gridChemical industry

The invention discloses a high-efficiency foam destroyer adopting metal matrix composite PTFE (Polytetrafluoroethylene). The integral foam destroyer mainly comprises a metal base composite PTFE separate mesh, a layered PTFE porous grid plate and a bolt fixing combination metal grid, wherein the metal base composite PTFE separate mesh is made from metal base composite PTFE material with is compounded with metal wires in the fibering process of PTFE. As a critical component in a chemical tower, the foam destroyer is a high-efficiency gas-liquid separation device and can be widely used in a chemical industry, a petroleum industry, a pharmaceutical industry, a light industry, an environmental protection industry and the like, especially suitable for the gas-liquid separation of vinylamine / water; in addition the foam destroyer not only can filter larger foams suspended in airflows, but also can filter liquid sprays of 0.2-0.5 micrometer.

Owner:SHANGHAI METAL WIRE MESH PROD

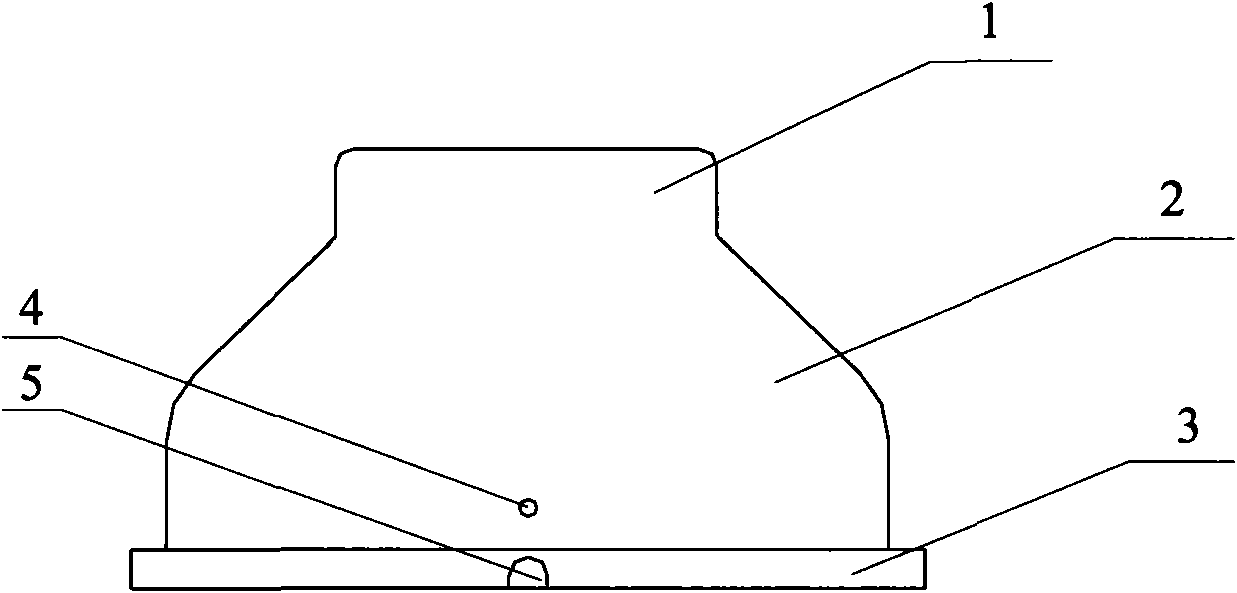

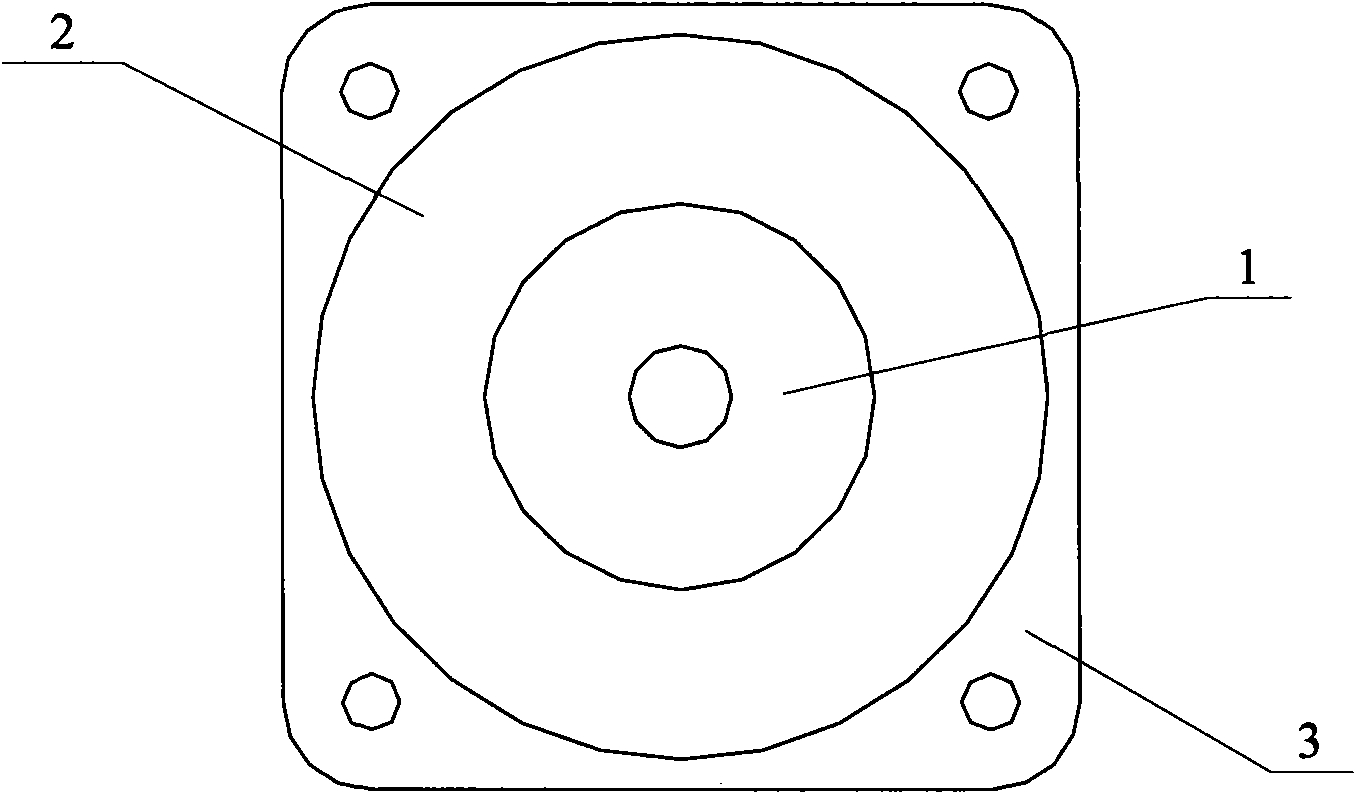

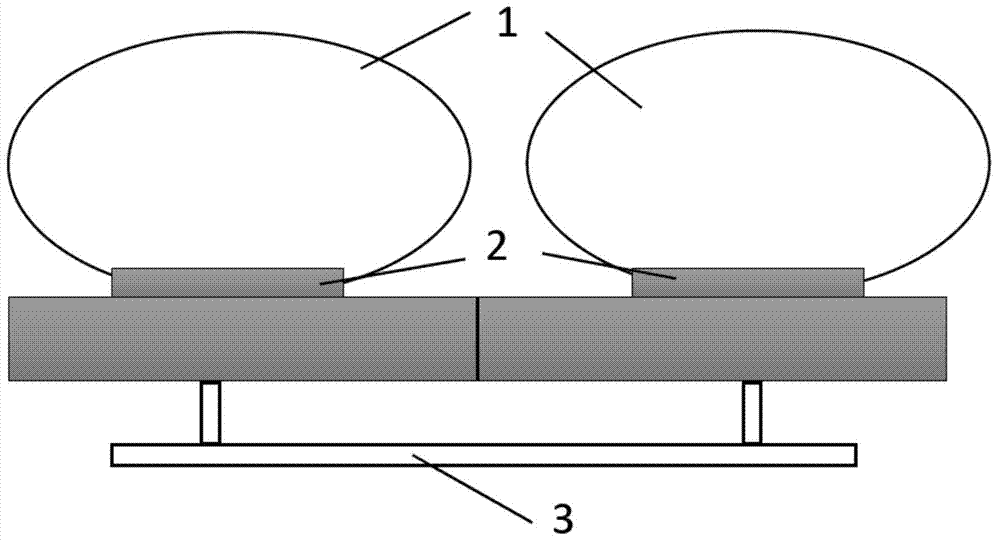

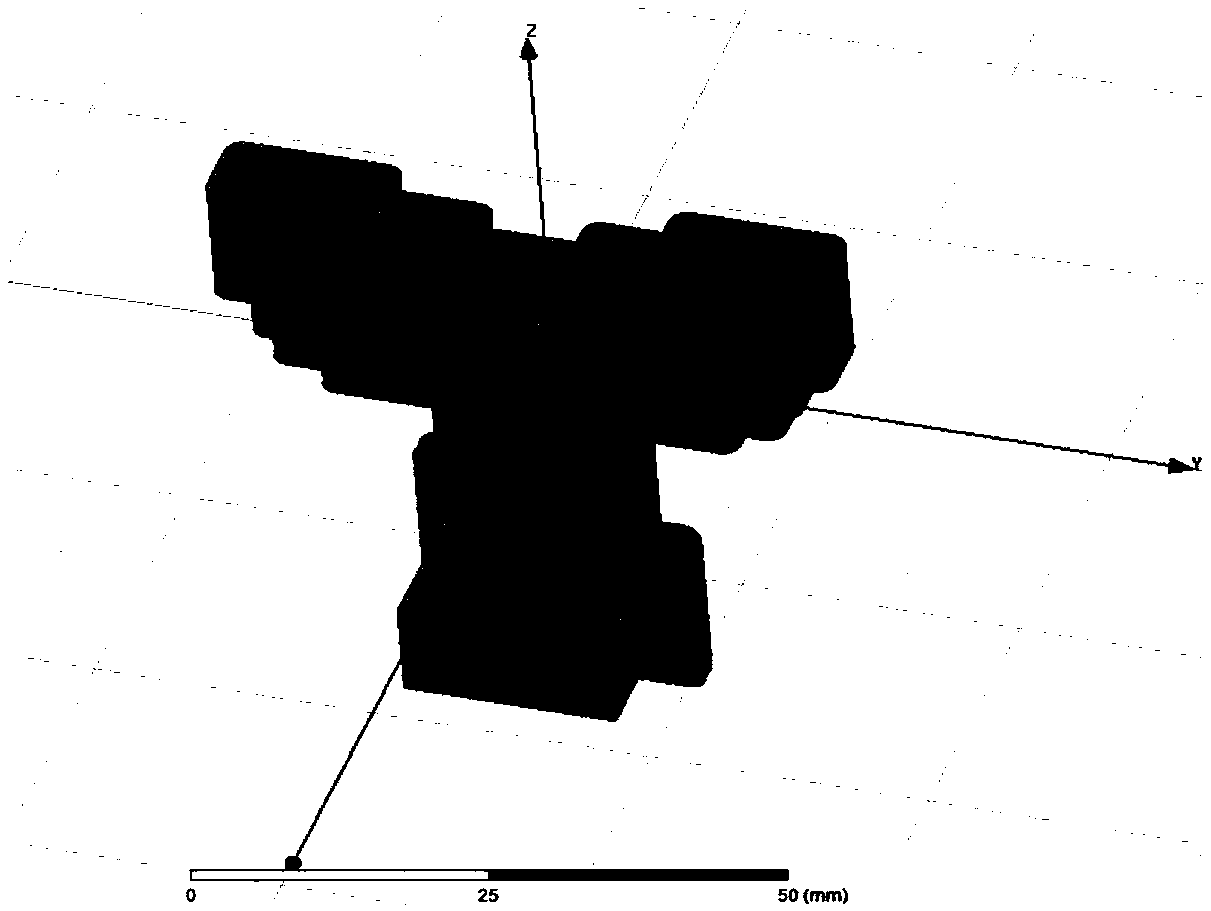

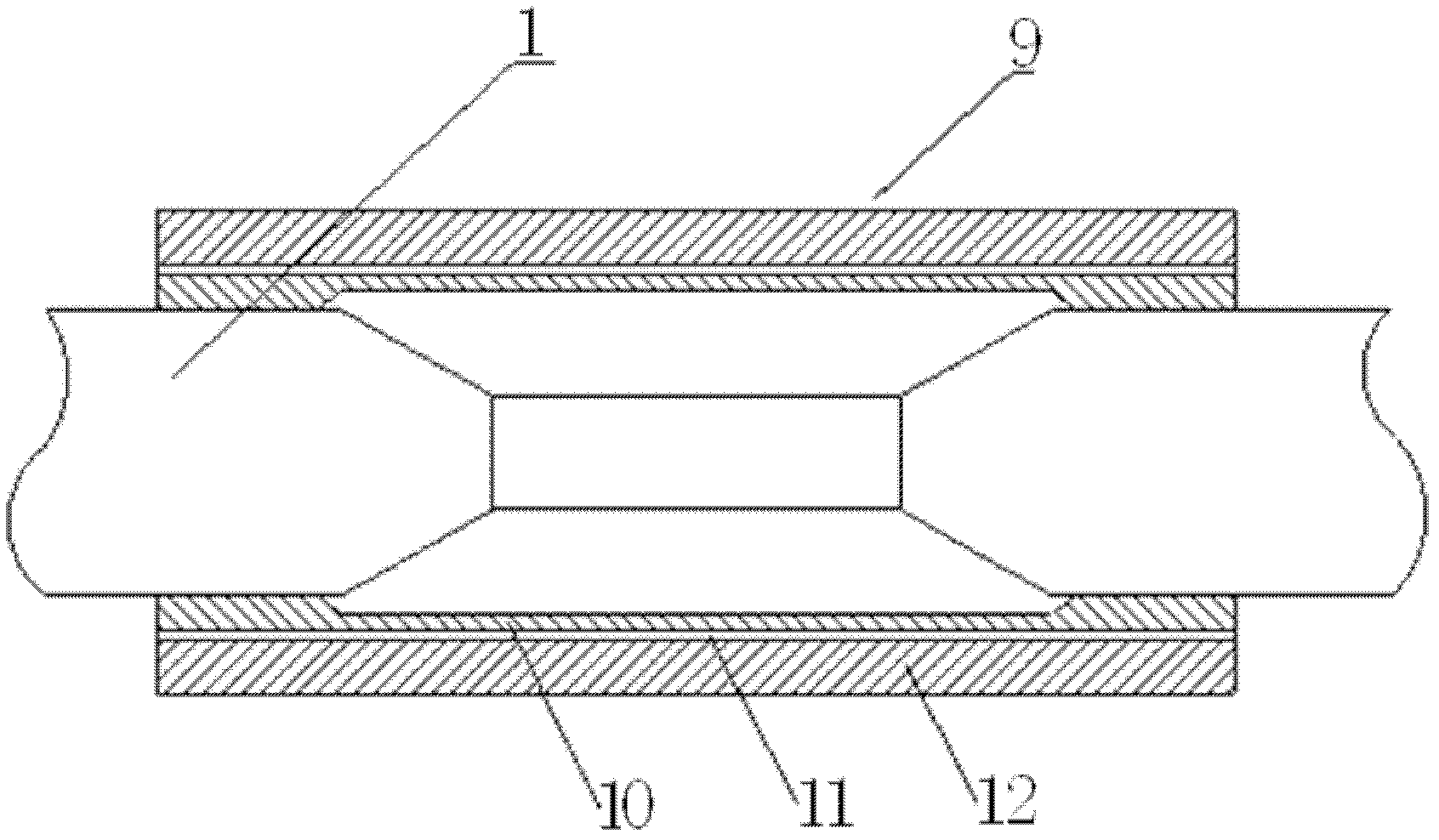

Rubber buffering and vibration isolating elastomer structure

The invention relates to a rubber buffering and vibration isolating elastomer structure which comprises an upper metal part, a rubber part and a lower metal part. An internal cavity structure is adopted by the rubber body of the invention to increase the buffering stroke of the rubber body, and the buffering deformation of the rubber body can reach 100%; and if the space along the axial direction of the elastomer structure is large enough, the buffering deformation can reach about 150%. The design of the cavity structure greatly increases the buffering deformation stroke of the rubber part by 2-4 times of the traditional rubber isolator, thereby greatly improving the buffering effect. The structure of the invention adopts the design of a gas channel; on the one hand, by the design of the gas channel, when the elastomer bears the impact load, because the action time of the load is short, the gas in the cavity is quickly discharged outwards through the gas channel, and the friction action of the gas and the channel increases the damping of the elastomer structure, thereby increasing the buffering effect of the elastomer structure; and on the other hand, by the design of the gas channel, the gas in the cavity can be smoothly discharged under the action of the load to avoid the uneven deformation of the rubber part caused by sealing of the cavity, thereby ensuring the rigidity stability of the elastomer structure in the deformation process.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

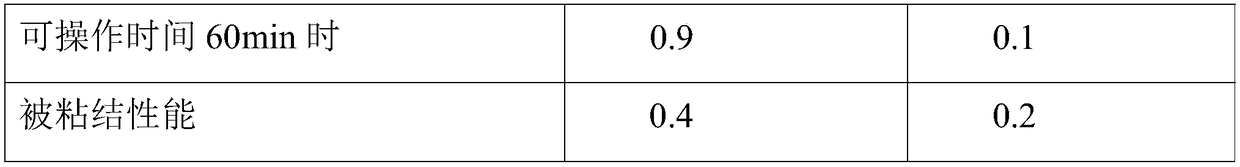

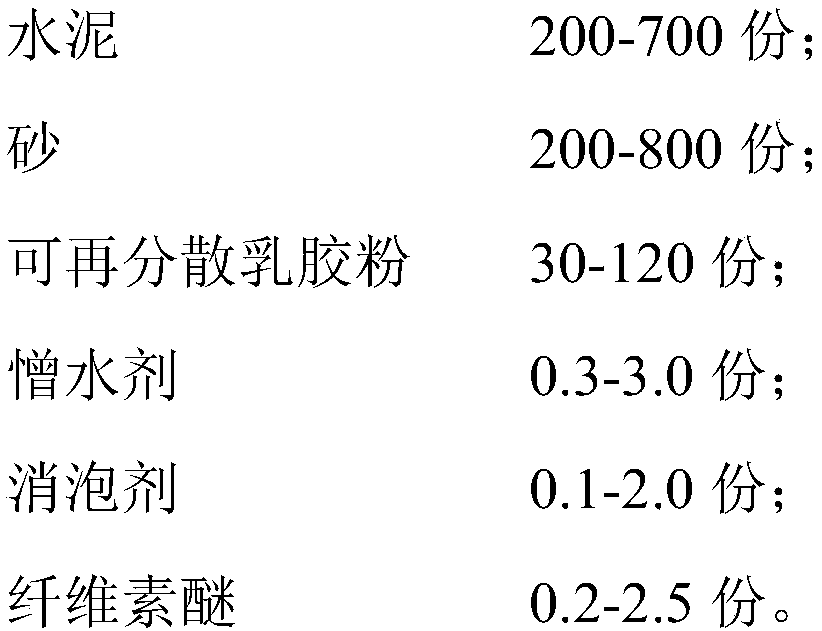

Interface mortar for steel structural exterior wall with anticorrosive coating layer

ActiveCN109020370AGood tensile bond strengthHigh tensile bond strengthCovering/liningsFreeze thawingCellulose

The invention relates to an interface mortar for a steel structure outer wall with an anticorrosive coating layer. The interface mortar comprises, by weight, 200-700 parts of cement, 200-800 parts ofsands, 30-120 parts of redispersible latex powder, 0.3-3.0 parts of a water repellent, 0.1-2.0 parts of a defoaming agent and 0.2-2.5 parts of cellulose ether. The interface mortar can effectively ensure the adhesion with the surface of a steel structure base layer with the anticorrosive coating layer, and has good bonded performance with a thermal insulation mortar, a bonding mortar, a plasteringmortar, a waterproof mortar and other mortars. Compared with traditional interface mortars for concrete and the masonry base layer, the interface mortar in the invention has the advantages of good affinity with the surface of the steel structure with the anticorrosive coating layer, high tensile bond strength, good bonded performance, small decrease of the tensile bond strength after water immersion, freeze-thawing and heat treatment, good durability, and meeting of the requirements of the use environment of the steel structure exterior wall with the anticorrosive coating layer.

Owner:HANGXIAO STEEL STRUCTURE

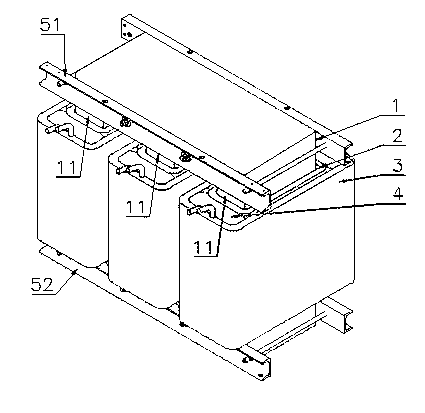

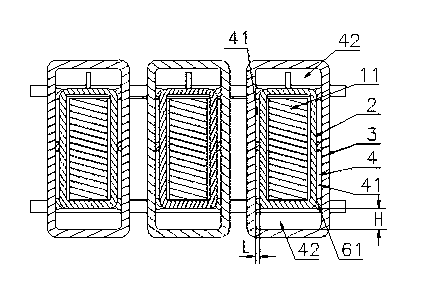

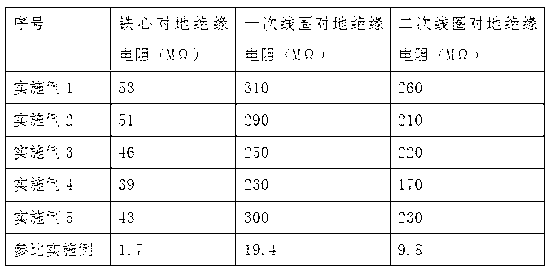

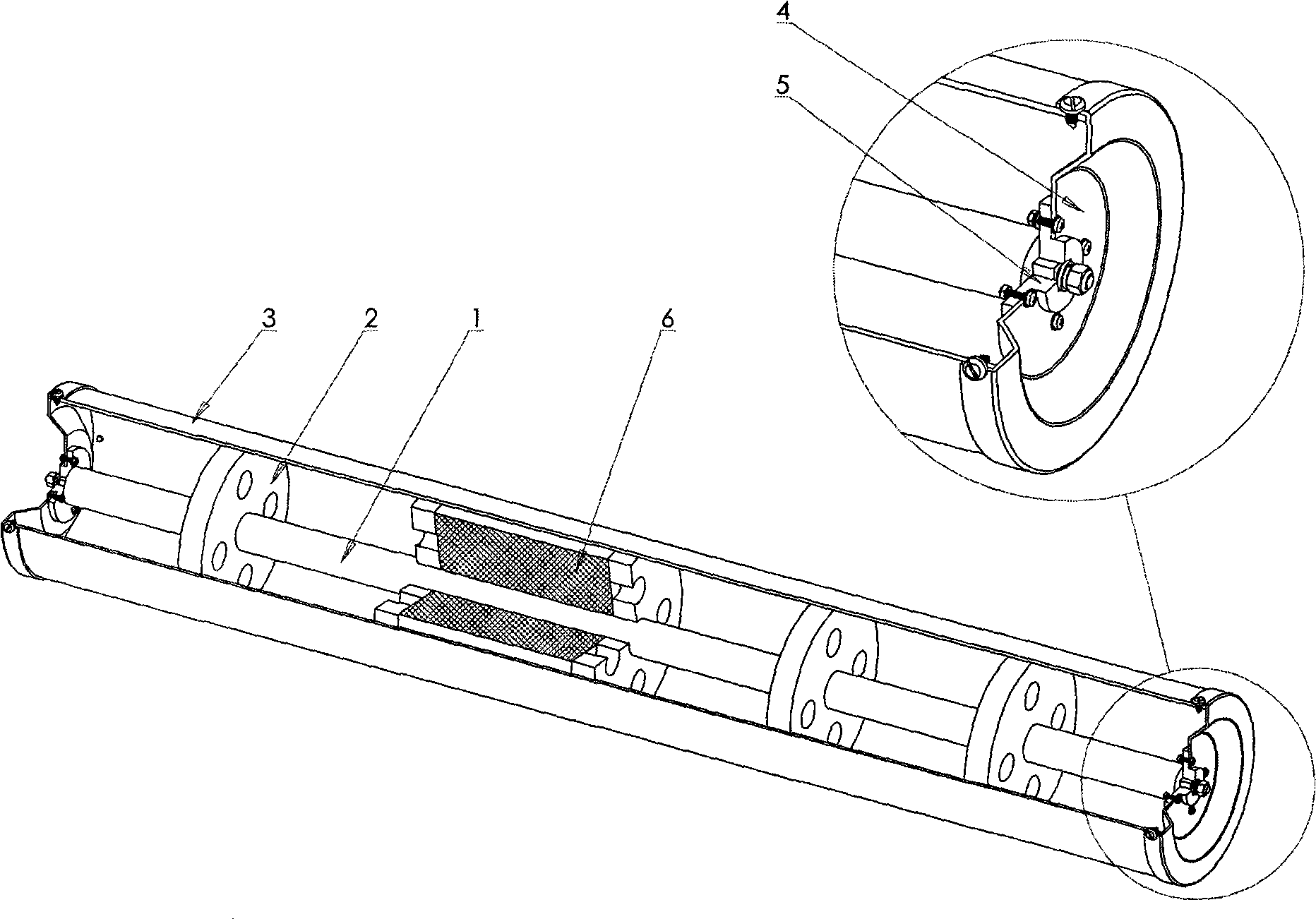

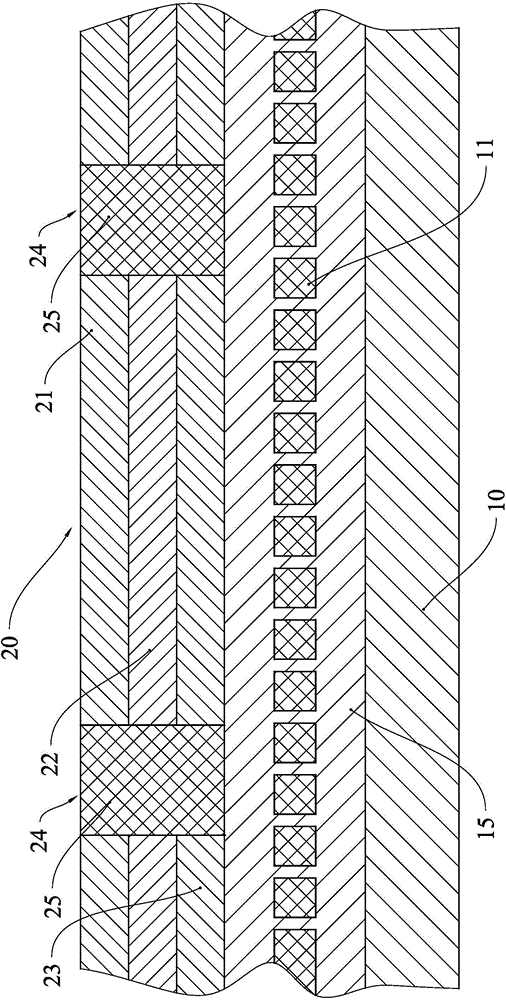

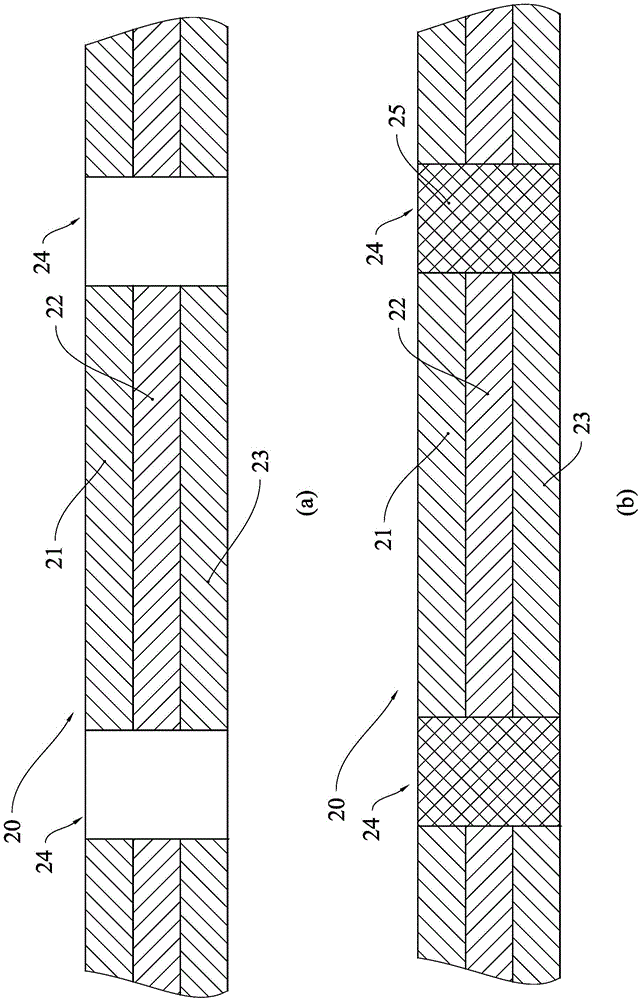

Epoxy resin pouring dry type transformer for electric locomotive

ActiveCN103177853AReasonable structural designTo achieve short-circuit impedance requirementsTransformers/inductances coolingTransformers/inductances coils/windings/connectionsEpoxyThermodynamics

The invention discloses an epoxy resin pouring dry type transformer for an electric locomotive. The transformer comprises an iron core which is formed by connecting of a plurality of core limbs which are arranged transversely, a secondary coil and a primary coil are arranged on each core limb from interior to exterior in sequence, and an air flue is formed between each secondary coil and each primary coil. The cross sections of the core limbs, the secondary coils and the primary coils are of a rectangular shape, each air flue comprises a transverse air flue and a longitudinal air flue communicated with the transverse air flue, the width of each transverse air flue is formed by the transverse distance between each secondary coil and each primary coil, the width of each longitudinal air flue is formed by the longitudinal distance between each secondary coil and each primary coil, and the width of each longitudinal air flue is larger than that of each transverse air flue. The epoxy resin pouring dry type transformer is small in size and light in weight, can satisfy impedance requirements, has good waterproof effect, and can sufficiently cope with all kinds of special operating environments encountered in the process of operating of the epoxy resin pouring dry type transformer for the electric locomotive.

Owner:PEARL ELECTRIC

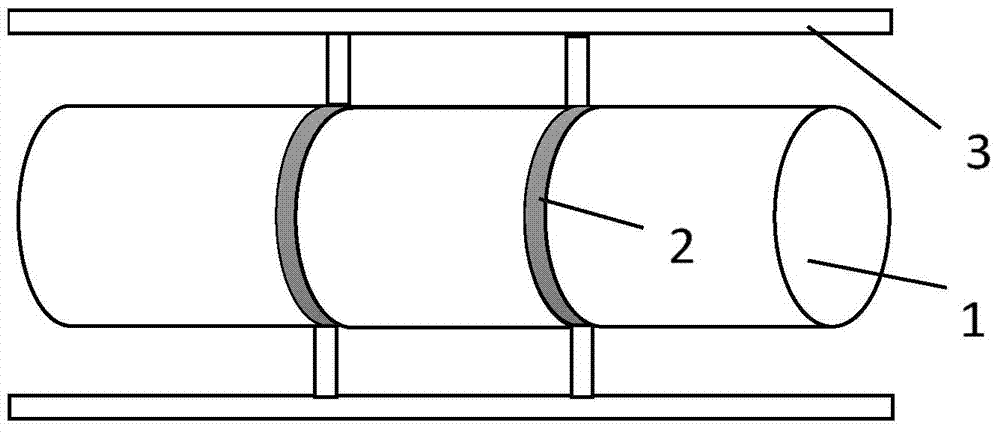

Heat energy storage element

InactiveCN101532699AEasy maintenanceAdjust the number of groups at willLighting and heating apparatusEnergy efficient heating/coolingStored energyCeramic brackets

The invention relates to an energy storage element, in particular to a heat energy storage element which makes use of electric heating to store energy for a solid. The heat energy storage element comprises a shell, wherein a heating pipe is arranged in the shell, the two ends of the heating pipe are fixed on end covers at the two ends of the shell, the middle parts of the end covers at the two ends of the shell are provided with ceramic insulating stools, the centers of the ceramic insulating stools are provided with electrodes which are connected with the heating pipe, a ceramic bracket is arranged in the shell and is sleeved on the heating pipe, and a solid heat storage body is arranged in a hollow cavity formed by the shell, the ceramic bracket and the heating pipe. The heat energy storage element has the advantages that the volume of the energy storage element can be adjusted according to the capacity of the stored energy, or a plurality of energy storage elements are overlapped; and the maintainability of a single energy storage element is good, the group number of the heat storage capacity can be adjusted at random, and the solid heat storage body can improve the heating temperature to change more electric energy into heat energy to be stored.

Owner:SHENYANG SHIJIE ELECTRIC

Graphite substrate and manufacture method thereof, LED module and manufacture method thereof

InactiveCN104883814ASimple preparation processReduce manufacturing costFlexible printed circuitsCircuit susbtrate materialsGraphite substrateMetal

The invention provides a graphite substrate and a manufacture method thereof, an LED module and a manufacture method thereof; the graphite substrate comprises a flexible graphite flake; a metal layer is arranged above the graphite flake; a radiation layer is arranged below the graphite flake; the graphite flake is provided with a plurality of through holes penetrating the top surface and the bottom surface of the graphite flake; the graphite flake is connected with the metal layer through a bonding glue filling the through holes, and the bonding glue directly connects the top surface of the graphite flake with the bottom surface of the metal layer; the graphite flake manufacture method comprises the following steps: arranging the plurality of through holes on the flexible graphite flake, wherein each through hole penetrates the top surface and the bottom surface of the graphite flake; placing a bonding sheet above the graphite flake, placing the metal layer above the bonding sheet, heating the bonding sheet so as to melt the bonding sheet, thus forming the bonding glue filling the through holes; solidifying the bonding glue. The graphite flake directly makes contact with the bonding glue; the heat generated by the LED chip can be fast transferred to the graphite flake, thus realizing fast radiation of the LED module.

Owner:RAYBEN TECH ZHUHAI

Flexible peristaltic pump

ActiveCN104763620ASimple structureImprove reliabilityFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEigenstrain

The invention provides a flexible peristaltic pump. The flexible peristaltic pump comprises a pump unit, a fixing unit and a connecting unit, wherein the pump unit is of a bag shaped structure manufactured through a driving film, comprising at least one opening channel through which liquid can flow in and out; a film prepared from an intelligent soft material can be externally excited to expand and contract under the eigenstrain so as to generate driving power for the peristaltic pump to pump in and pump out the liquid; the fixing unit is of a rigid structure and used for supporting the pump unit and the connecting unit, wherein the connecting unit is of a flexible structure for connecting the pump unit into a chain so as to ensure the flexibility characteristic of the whole peristaltic pump; an automatic valve is arranged in the connecting unit to control liquid to flow in and out; the fixing unit is used for supporting the pump unit. According to the flexible peristaltic pump, the driving film material and the special structure enable further simplifying of the peristaltic pump structure, so that the stability, reliability, efficiency and economy of the peristaltic pump can be improved, and the working noise can be reduced. The flexible peristaltic pump can be widely applied to the fields of chemical engineering, mining and metallurgy, paper-making, paint coatings, foods, ceramics, petroleum, water treatment, medicine preparation, and medical apparatuses and instruments in the future, and particularly plays an important role in artificial organ.

Owner:ZHEJIANG UNIV

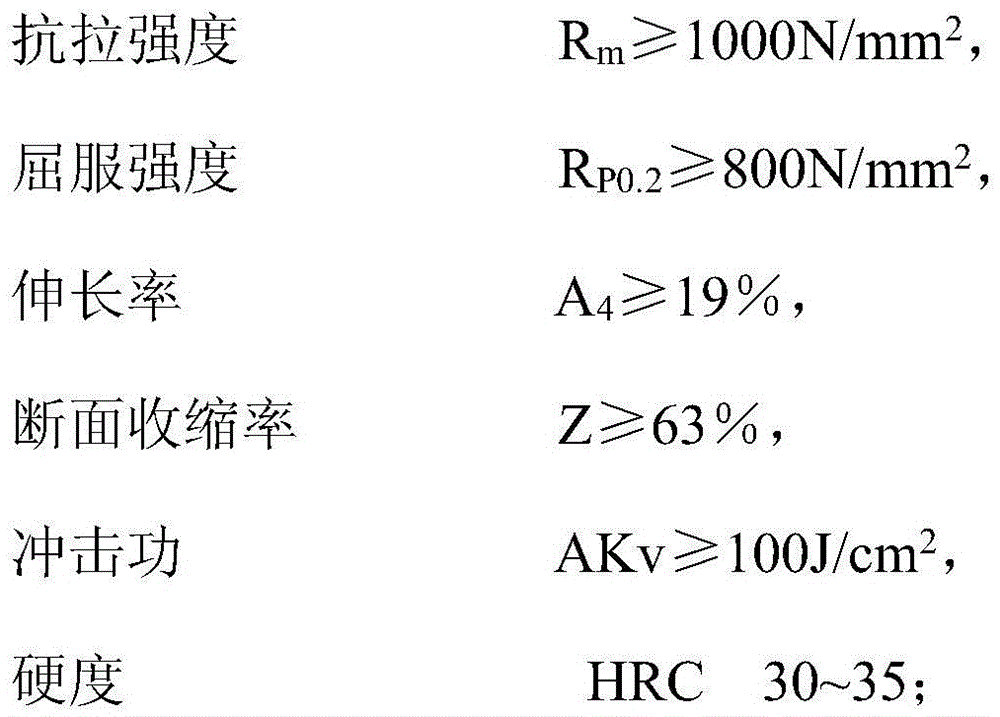

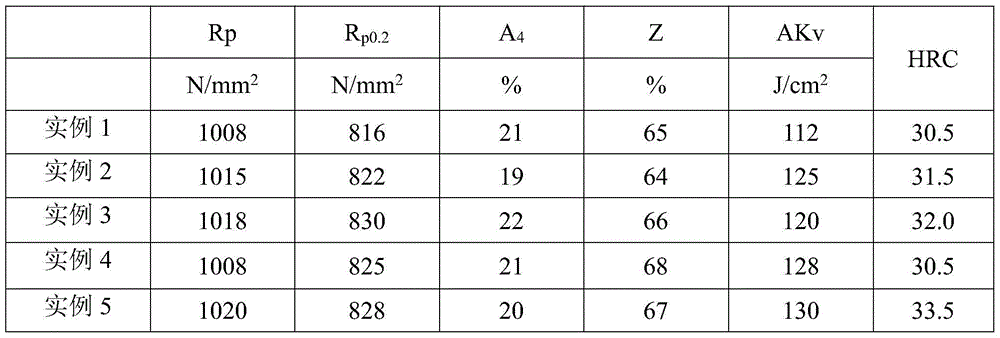

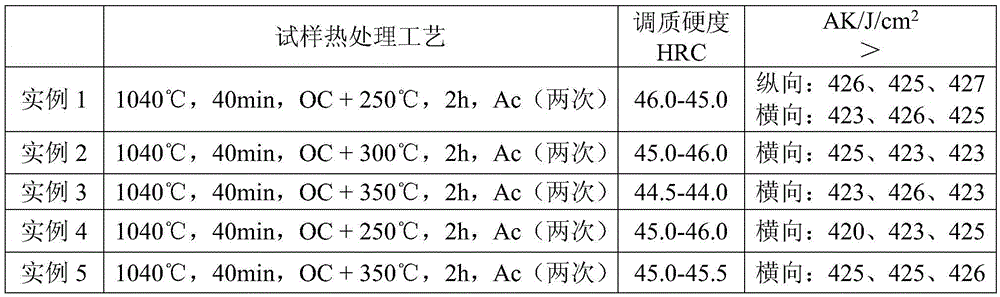

Plastic die steel with high intensity, high toughness and high corrosion resistance and production method thereof

InactiveCN105543653AHigh strengthImprove toughnessFurnace typesHeat treatment furnacesIngotHigh intensity

The invention discloses a plastic die steel with high intensity, high toughness and high corrosion resistance. The plastic die steel comprises C, Si, Cr, Mo, Ni, W, V, Mn and the balance Fe and other impurities. The invention further discloses a production method of the plastic die steel with high intensity, high toughness and high corrosion resistance. The method includes the following steps of placing all the components into a non-vacuum induction furnace for primary smelting and then carrying out external refining to obtain consumable electrodes, remelting and refining the consumable electrodes to obtain electroslag ingots, carrying out heating forging or rolling on the electroslag ingots to obtain a primary plastic die steel product, and carrying out spheroidizing annealing thermal treatment and surface treatment on the primary plastic die steel product to obtain the finished plastic die steel product. The plastic die steel with high intensity, high toughness and high corrosion resistance can be produced through the method, the overall properties such as intensity, toughness and corrosion resistance are superior to those of existing plastic die steel #1.2316, and the service environment demands of current medium-and-high end plastic die steel with high intensity and high toughness in China can be met.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

Pipeline dredging machine

The invention provides a pipeline dredging machine. The pipeline dredging machine comprises a water pipe; a spraying head is connected with a water pipe; the spraying head comprises a shaft part and a spraying head side wall, wherein the shaft part is connected with the water pipe, and the spraying head side wall is arranged out of the shaft part and is provided with a hollow cylindrical shape; a rear spraying hole is formed in the shaft part of the spraying head and is used for pushing the spraying head to move forward; a side spraying hole is formed in the side wall of the spraying head and is used for cleaning, and the axis of the side spraying hole is perpendicular to the axis of the rear spraying hole; and a drilling bit capable of rotating is arranged on the forefront of the spraying head and plays a role in cutting a blocking body. According to the provided pipeline dredging machine, aiming at natural deposition dredging of a buried pipeline of an outdoor railway tunnel, calcium carbonate and silt precipitated by the natural environment can be effectively dredged, the maximum dredging length of the pipeline dredging machine is up to 50 m, and the pipeline dredging machine can pass smoothly at the corners not exceeding 90 degrees; appearance design of the pipe dredging machine conforms to requirements of the tunnel using environment, and stable working of the equipment can be ensured.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

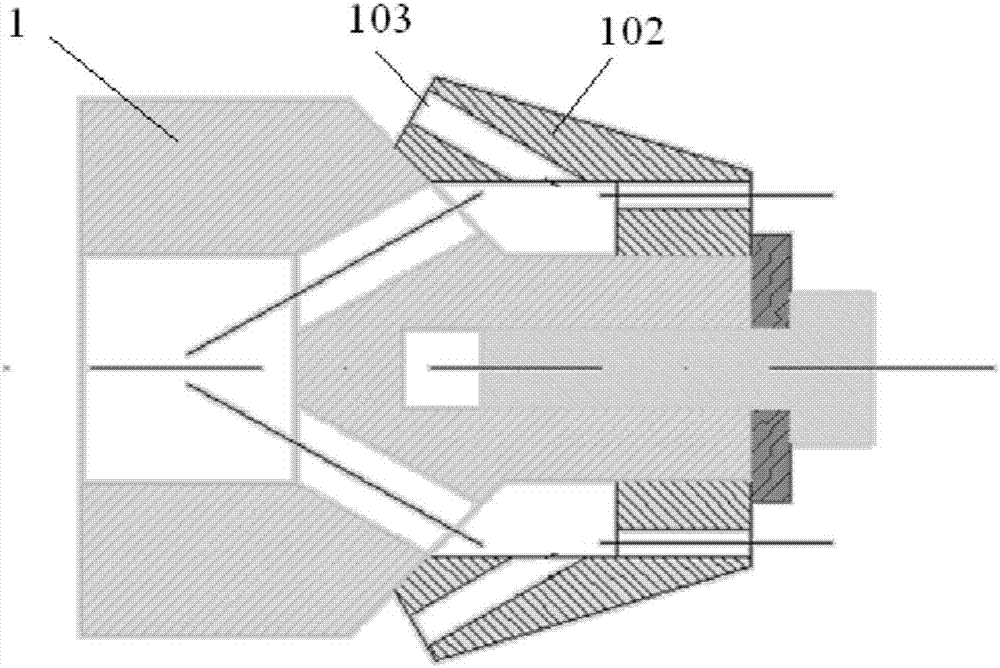

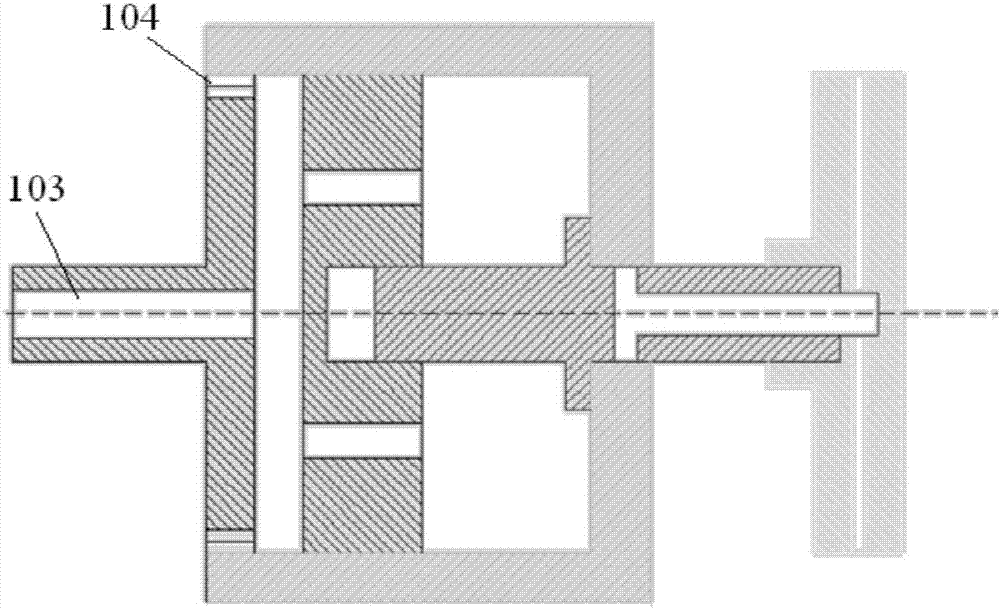

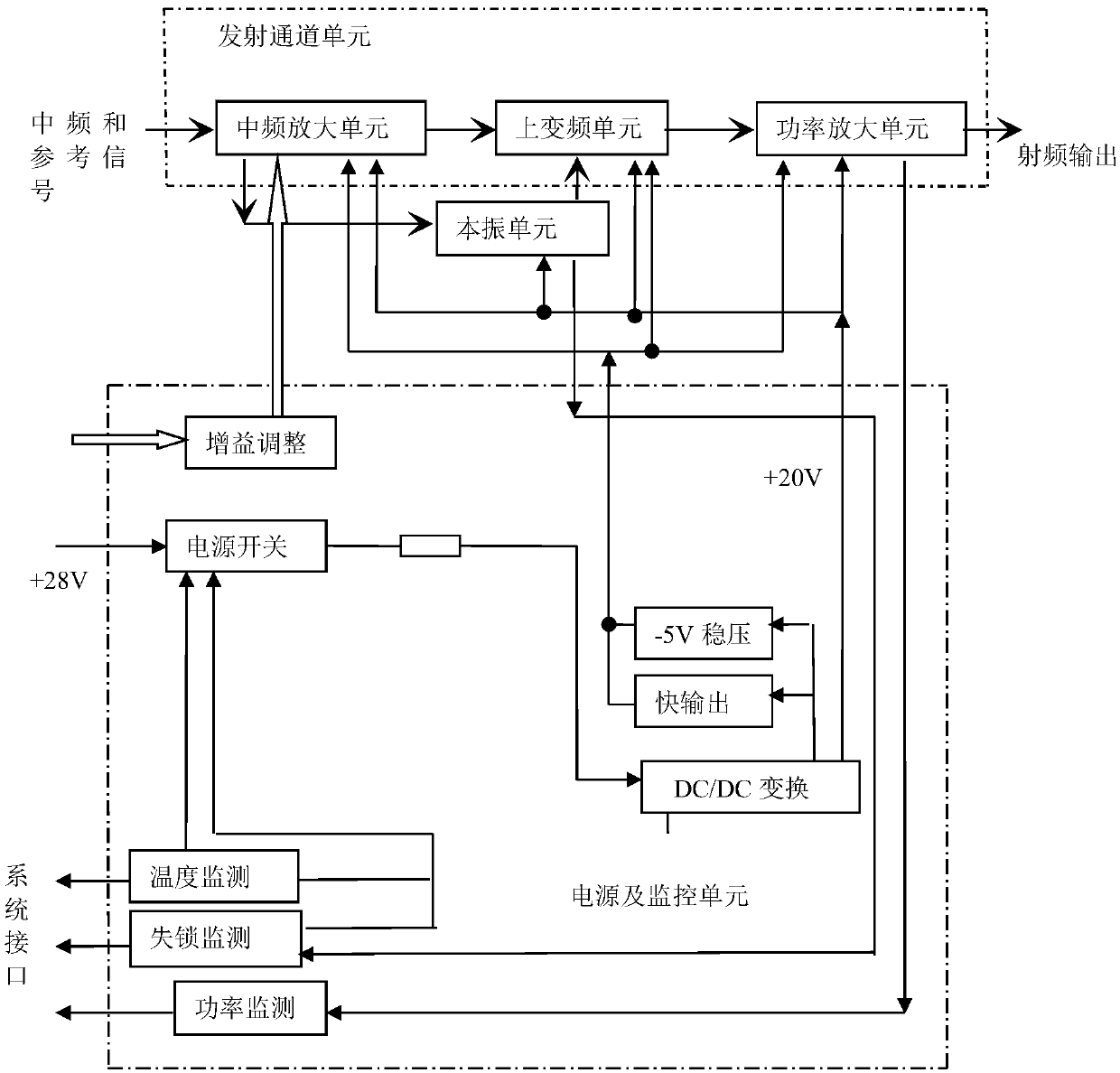

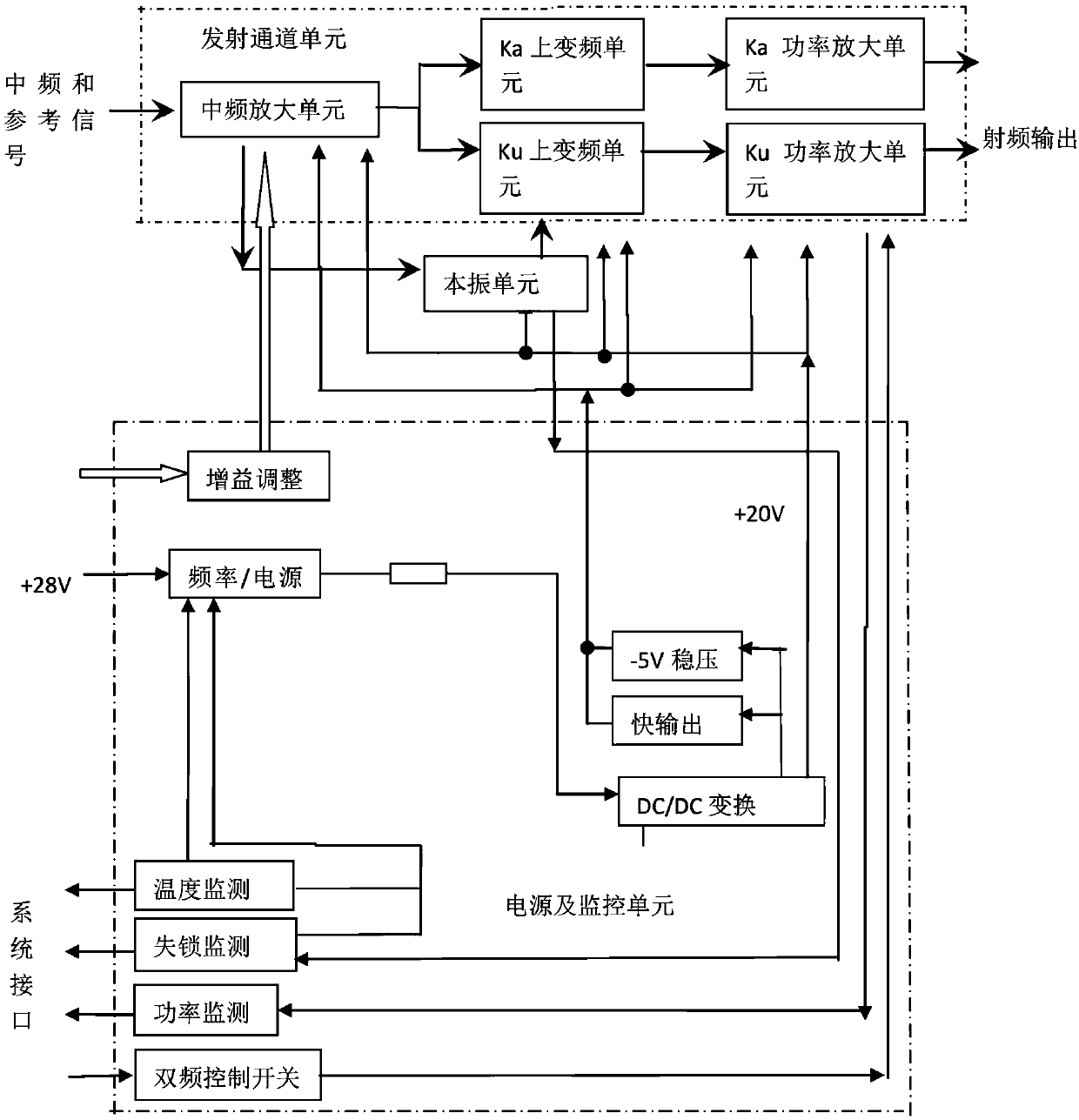

Ka/Ku dual-frequency BUC of integrated design

ActiveCN109639293AReduce power consumptionImprove efficiencyPower amplifiersRF amplifierRadio frequencyIntermediate frequency

The invention discloses a Ka / Ku dual-frequency BUC of an integrated design. The BUC includes an intermediate-frequency signal and reference signal shared input port, two radio frequency output ports,a power input port and a low-frequency control signal input port. The Ka / Ku dual-frequency BUC is integrated with frequency up-conversion units and power amplification units on two frequency bands ofKa and Ku. The frequency up-conversion units and the power amplification units realize switching through a control terminal, and have a shared heat dissipation unit, power supply unit and monitoring unit at the same time. The intermediate-frequency input end of the dual-frequency BUC receives a signal, the Ka frequency band or the Ku frequency band is selected through the control terminal, power amplification is carried out on the selected frequency band, and the same is sent to an antenna. According to the small-volume Ka / Ku dual-frequency BUC of the invention, dual-frequency integrated alternate working can be carried out to ensure that a commercial aircraft flies in global airspace across different regions and different satellite communication frequency bands, and arbitrary switching and real-time communication can be realized.

Owner:HEBEI DONGSEN ELECTRONICS TECH

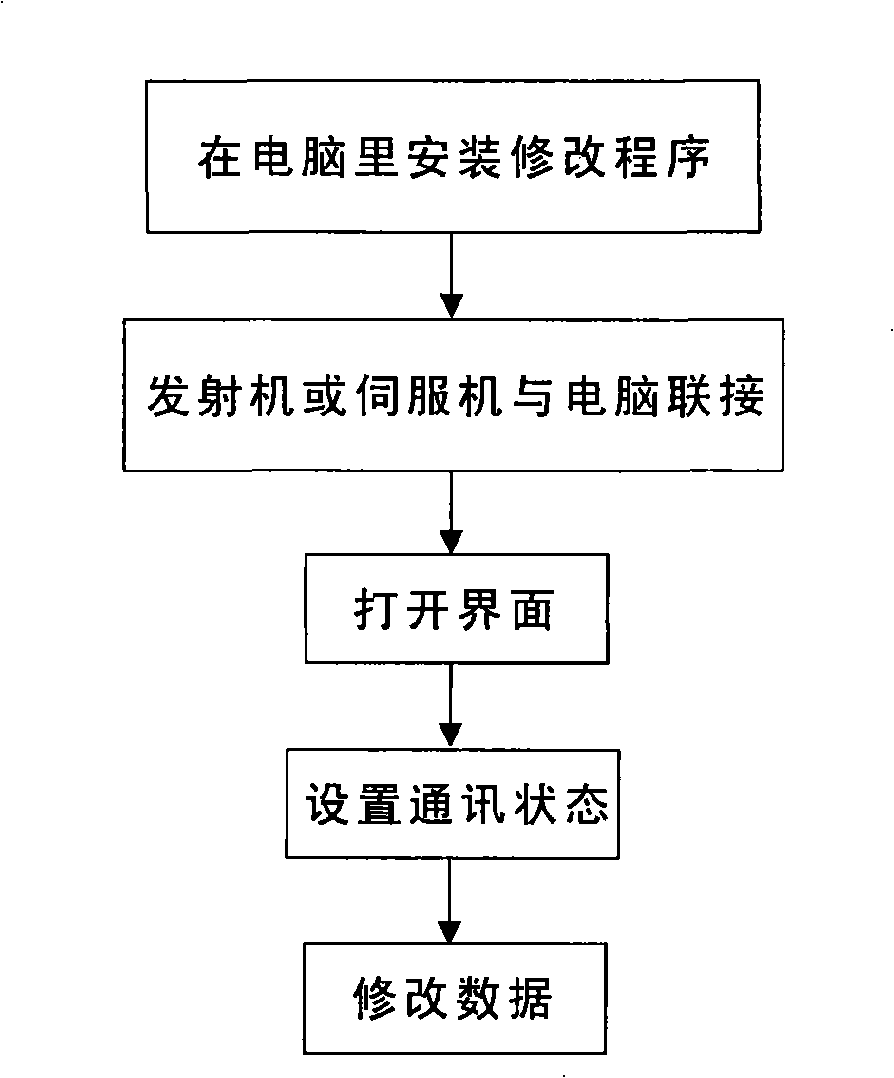

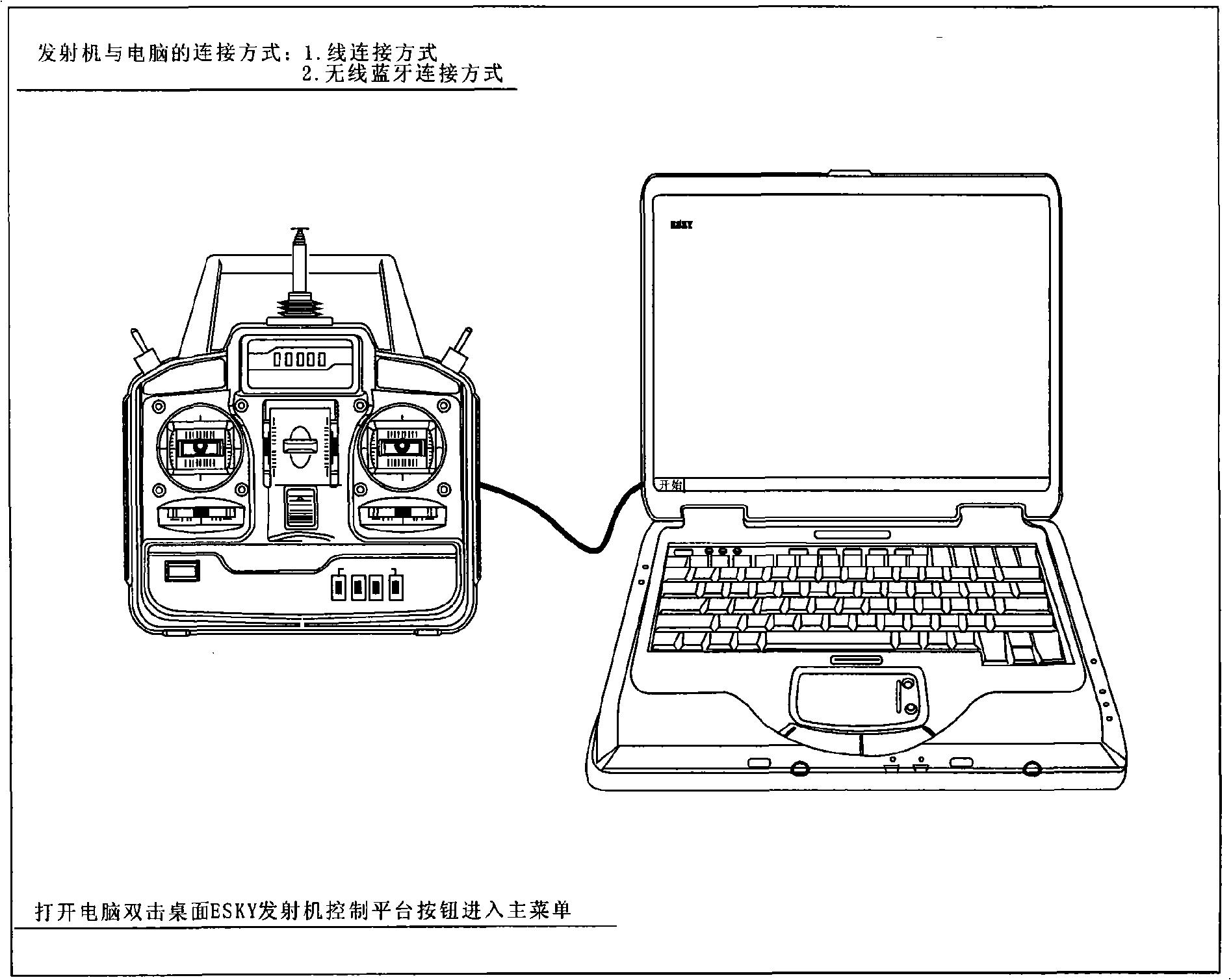

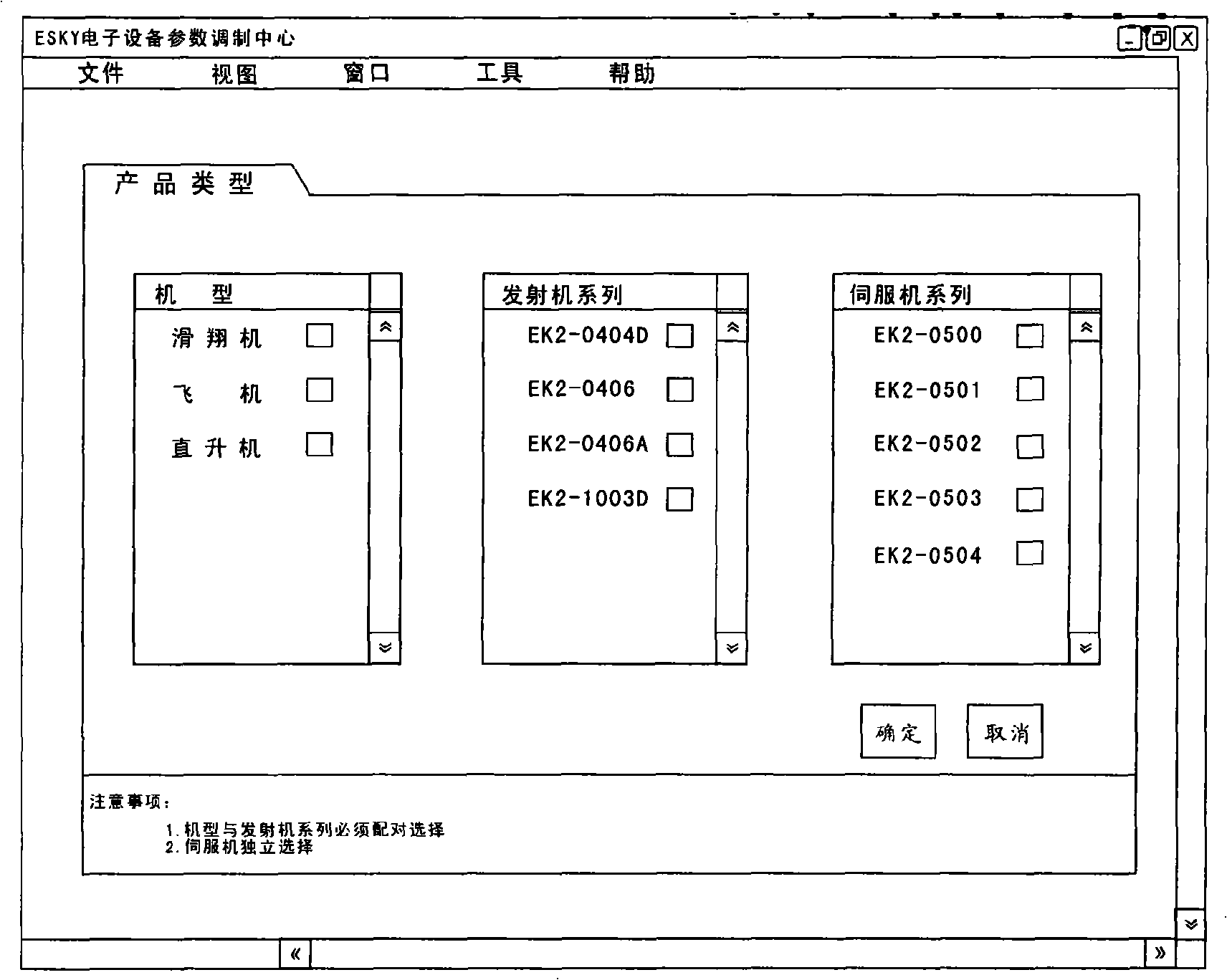

Model electronic equipment parameter modulator approach

InactiveCN101266569AReduce consumption costMeet the requirements of the use environmentSoftware testing/debuggingSpecial data processing applicationsThe InternetSoftware engineering

The invention discloses a modulating method for the parameter of the electron device, the technique problem to be solved is to conveniently modulate the parameter set inside a electron device model. The method in the invention comprises the following steps: an transmitter procedure and the revised procedure of a servo-motor is mounted in an computer, an transmitter or a servo-motor terminal is connected with the computer, open an electron device parameter modulating centre interface, a manipulator modulates the data to read, write and modify data for the terminal. Compared with the existing technology, the invention downloads the needed data of a model aircraft into the storage of the transmitter of a control terminal using software through computer to modify the parameter inside the model electron device, which makes the model electron device break through the long time size restriction of the self product, and that the parameter can not be modified, the same product can adapt the different needs of the users to satisfy the request of the using environment, reduced the consumer cost of the consumer.

Owner:沈安平

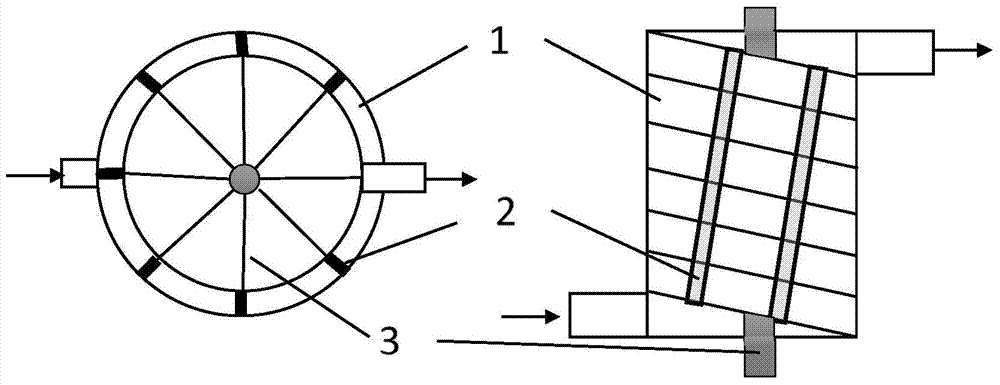

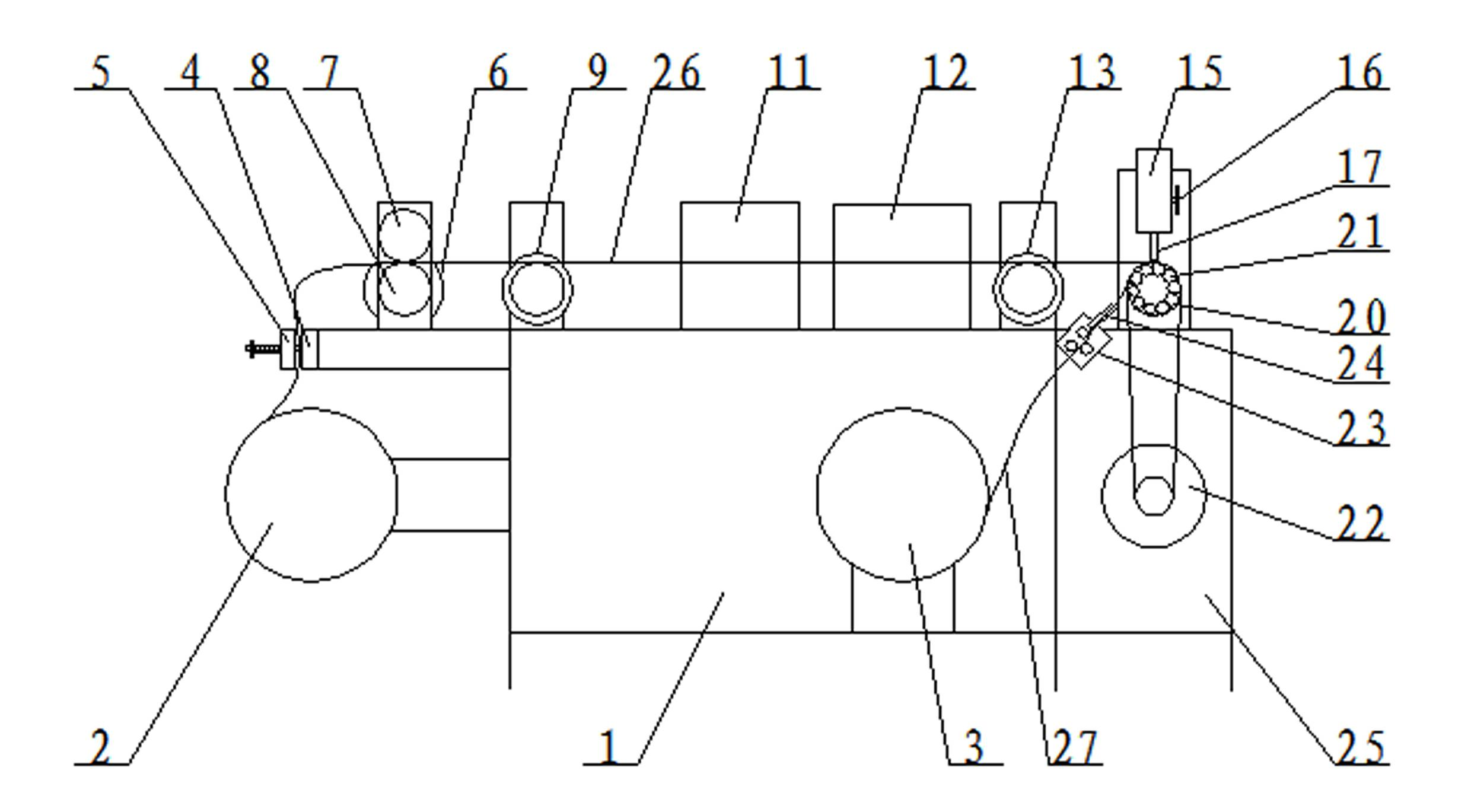

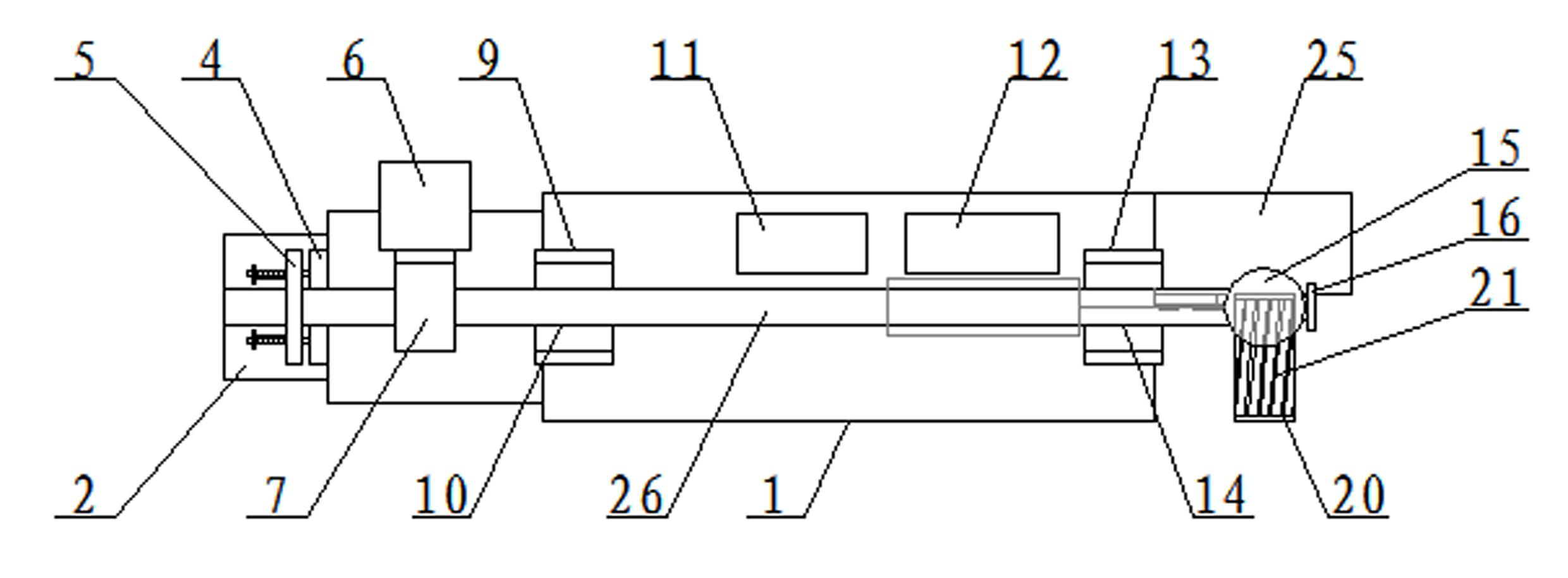

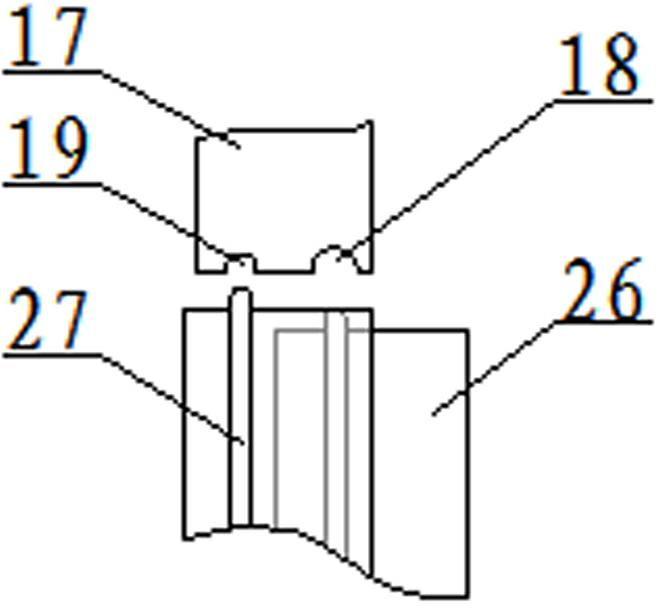

Ultrasonic welding equipment for porous sound attenuation air inlet tube of non-woven fabric helical air filter

The invention relates to ultrasonic welding equipment for a porous sound attenuation air inlet tube of a non-woven fabric helical air filter. The equipment comprises an electric control box, a winding rotating device, a feeding traveling device and a sizing device which are all arranged on a machine frame; the feeding traveling device is connected with a non-woven fabric roll and a nylon yarn roll; the winding rotating device is controlled by the electric control box to rotate; the feeding traveling device is controlled by the electric control box to travel along the direction of the winding rotating device and feeds non-woven fabric strips and nylon yarns into the winding rotating device to rotate and wind the non-woven fabric strips and the nylon yarns from inside to outside; and the sizing device is used for synchronously sizing the non-woven fabric strips wound on the winding rotating device. The non-woven fabric strips and the hard nylon yarns are adopted to be uniformly and slantingly wound on a core rod at intervals and are sized, adhered and formed in a matched mode. The ultrasonic welding equipment has a simple and compact structure, is convenient to operate, and has simple processes and a short forming period. The requirement on a certain rigidity required when an automobile engine and the air filter need to be randomly bent in the abutting process under different assembly working conditions can be met. The ultrasonic welding equipment has a long service life, can be recycled and has no waste pollution.

Owner:JIANGSU XINGCHENXING AUTO ACCESSORIES

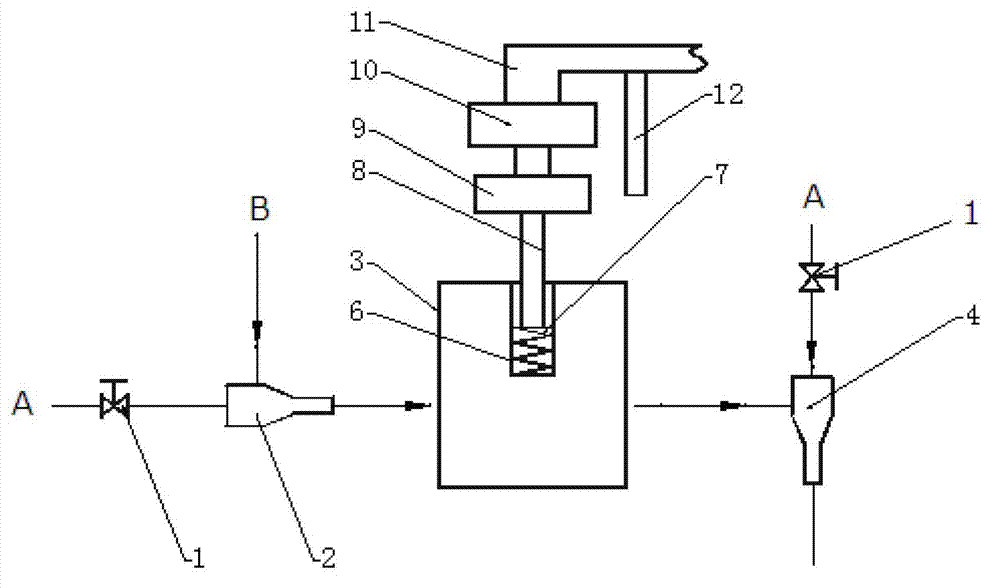

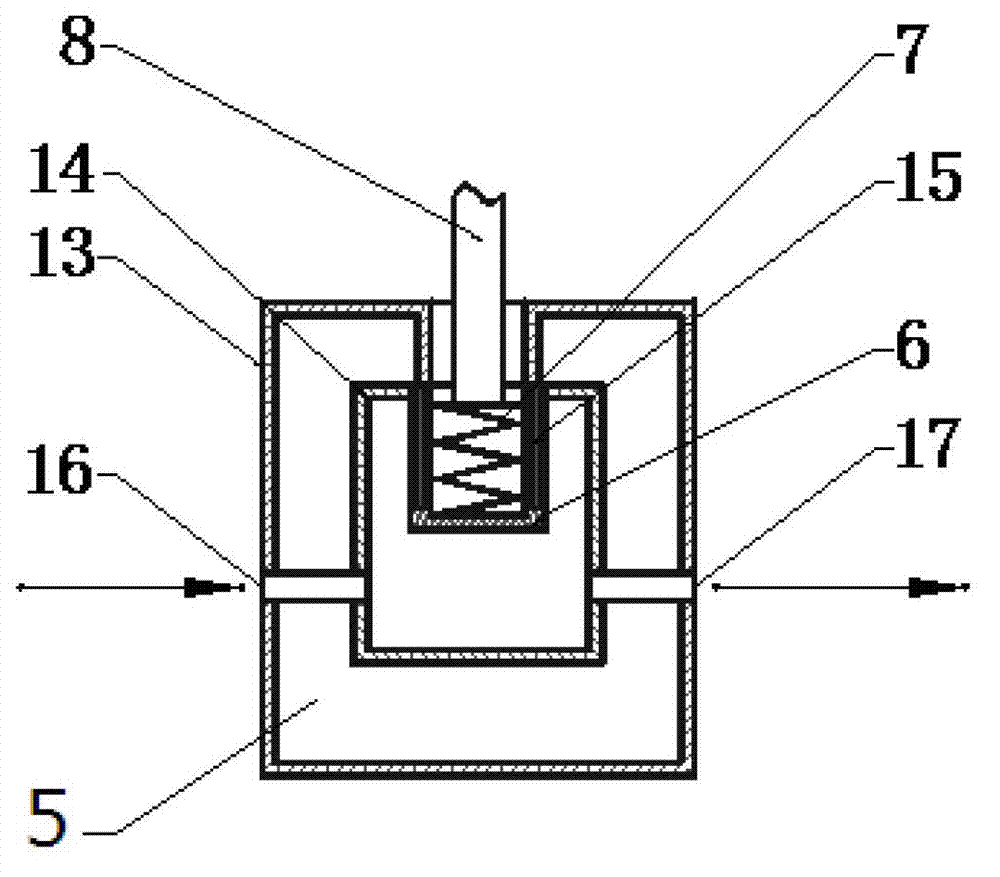

Device capable of testing elastic properties of springs in wide low-temperature zones

InactiveCN103115743AContinuously adjustable temperatureImprove cooling effectElasticity measurementDistribution systemEngineering

The invention discloses a device capable of testing elastic properties of springs in wide low-temperature zones. The device comprises a spring cavity for accommodating a tested spring and a testing system for spring force and deformation of the tested spring. The device is characterized in that the spring cavity is arranged in a cold trap, the cold trap is sequentially provided with a heat-insulation layer, a low-temperature cavity and the spring cavity from outside to inside, the spring cavity is placed on the inner upper portion of the low-temperature cavity and is isolated from the low-temperature cavity, the low-temperature cavity is provided with an inlet and an outlet which are communicated with a low-temperature working medium distribution system, the heat-insulation layer is wrapped on the outer portion of the low-temperature cavity, and a heat-insulation sandwich layer which is filled with air or is vacuum is arranged between the heat-insulation layer and the low-temperature cavity.

Owner:XI AN JIAOTONG UNIV

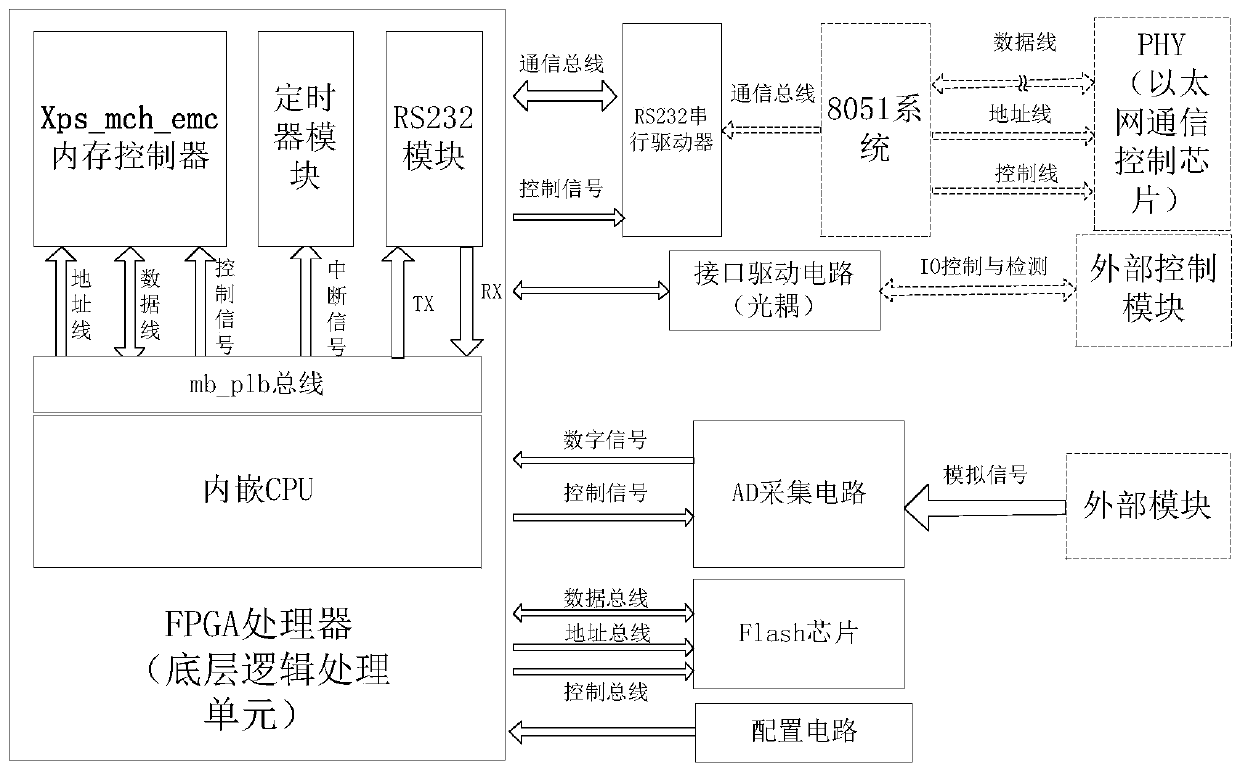

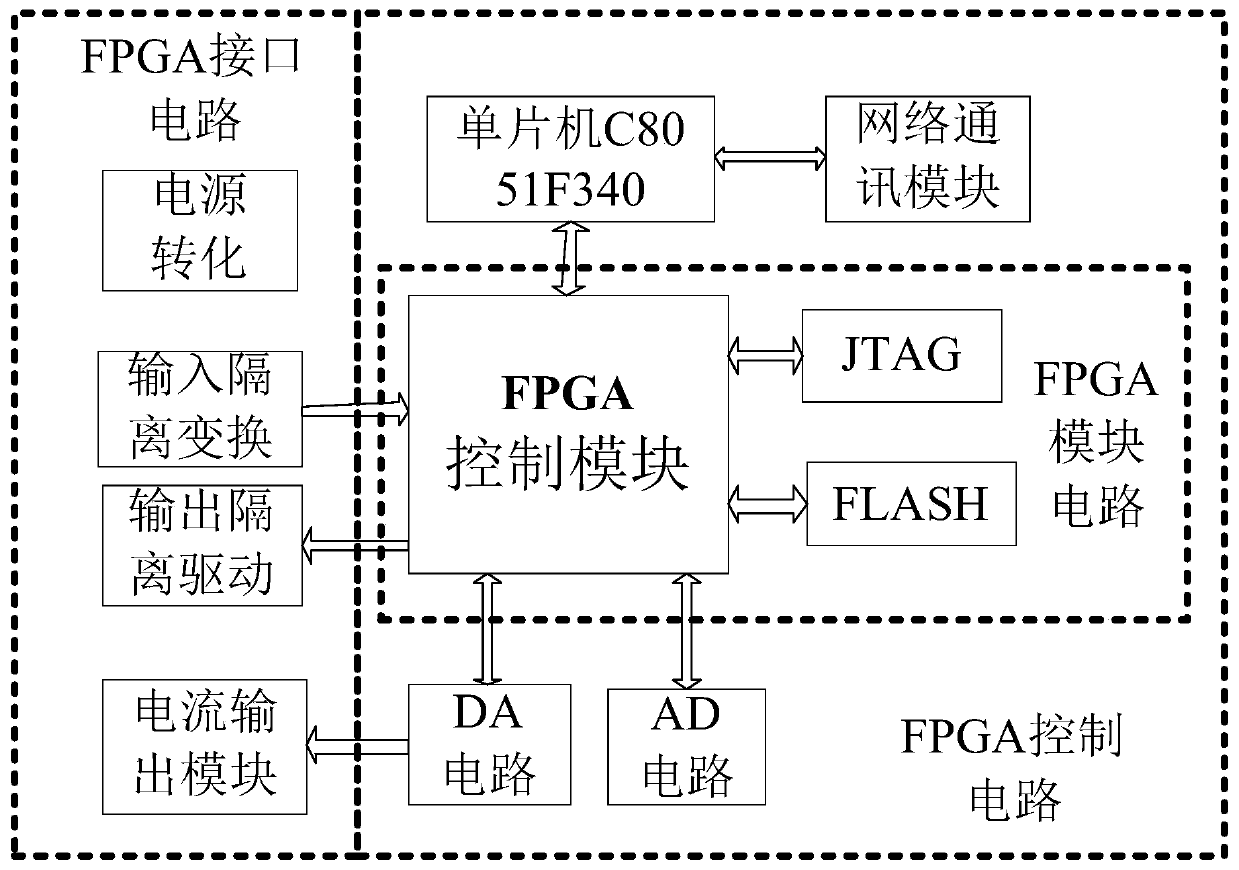

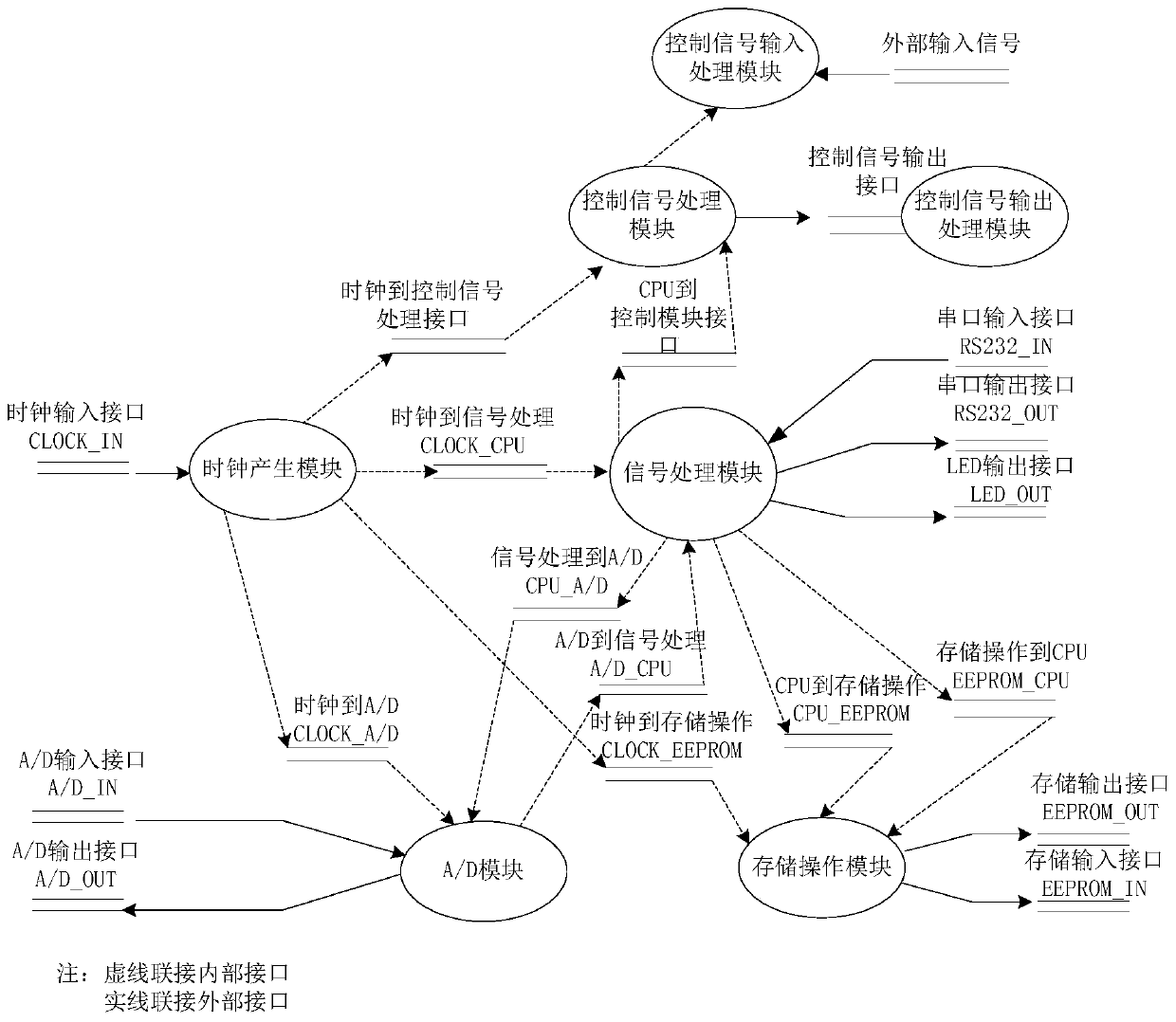

FPGA+8051 system controller

ActiveCN109752992AHigh degree of automationHighly integratedProgramme controlComputer controlMicrocontrollerMicrocomputer system

The invention provides an FPGA+8051 system controller. The system controller comprises a power supply module, an FPGA system module, an AD conversion module, an input isolation conversion module, an output isolation driving module, an 8051 single-chip microcomputer system and a network communication interface module; an FPGA+8051 control module is adopted to replace a PLC: a mature FPGA+8051 architecture mode is used for realizing logic control and network communication control; the quality grades of components are improved, the circuit design is rechecked and re-calculated, and the derating design is carried out, so that the I-stage derating of the components is guaranteed, and the working reliability of the controller is improved; an internal circuit can be clearly understood, so that afault can be rapidly positioned and eliminated after a product breaks down; and the product has the same power supply mode and mechanical interface as the PLC, and after PLC production is stopped or the PLC is updated, the FPGA+8051 control module can completely replace the PLC.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH

Cobalt-chromium-tungsten alloy material, cobalt-chromium-tungsten alloy ball for ball screw bearing and preparation method of cobalt-chromium-tungsten alloy ball, and ball screw bearing

The invention discloses a cobalt-chromium-tungsten alloy material, a cobalt-chromium-tungsten alloy ball for a ball screw bearing and a preparation method of the cobalt-chromium-tungsten alloy ball, and the ball screw bearing. The cobalt-chromium-tungsten alloy material is prepared from the following components in percentage by mass: 38 to 48 percent of cobalt, 31 to 41 percent of chromium, 16 to 18 percent of tungsten, 2 to 3 percent of nickel, 2 to 8 percent of graphite and less than or equal to 1 percent of iron and unavoidable impurity elements. With cobalt, chromium, tungsten, nickel and graphite which are used as main components, the cobalt-chromium-tungsten alloy material has the characteristics of resistance to corrosion and wear, high precision, long service life and the like, and can completely meet the requirements on a use environment and the performance of the ball screw bearing in a nuclear reactor loading and unloading device transmission system.

Owner:LUOYANG BEARING RES INST CO LTD

Method for manufacturing flexible joint of large-length submarine cable

ActiveCN102593764BImprove performanceMeet the requirements of the use environmentApparatus for joining/termination cablesVulcanizationElectrical conductor

The invention discloses a method for manufacturing a flexible joint of a submarine cable capable of satisfying the requirements of high-voltage and ultrahigh-voltage use situations. The method comprises the steps as follows: 1) conductor connection; 2) conductor shield and vulcanization; 3) insulation extrusion; 4) insulation vulcanization; 5) insulation shield and repair; and 6) metal sheath recovery, wherein the insulation vulcanization process is that an insulated cable is put into a vulcanizing mould, nitrogen gas filled into the vulcanizing mould during the vulcanization cannot leak, cooling water systems at the two ends of the vulcanizing mould are simultaneously kept unblocked, so as to keep the temperature at the two ends of the cable below 70 DEG C; when the temperature reaches 235 to 245 DEG C and the nitrogen gas pressure is 1.5Mpa, insulation vulcanization begins, and the temperature and the pressure are regulated through a valve and a power source; and after the vulcanization is conducted for 120 minutes, the power source is cut off, the temperature is reduced below 100 DEG C while the pressure is kept at1.5Mpa, gas is discharged to release the pressure, and when the pressure is zero, the vulcanizing mould is opened and the cable is taken out. When the cable produced by adopting the manufacturing method disclosed by the invention is used as the submarine cable in high-voltage and ultrahigh-voltage situations, the performance of the cable is excellent and the requirements of the use environments are satisfied.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD +1

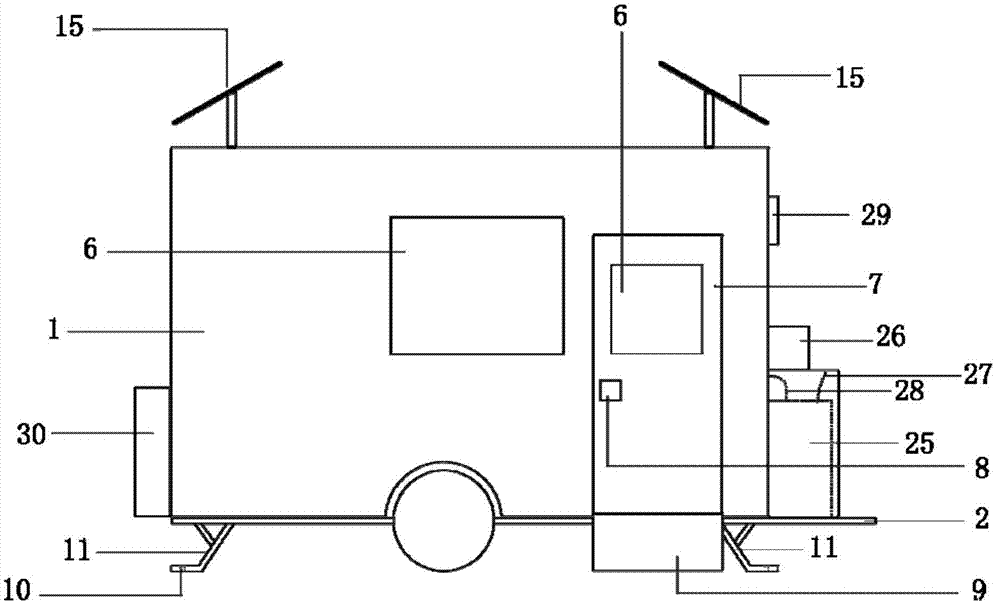

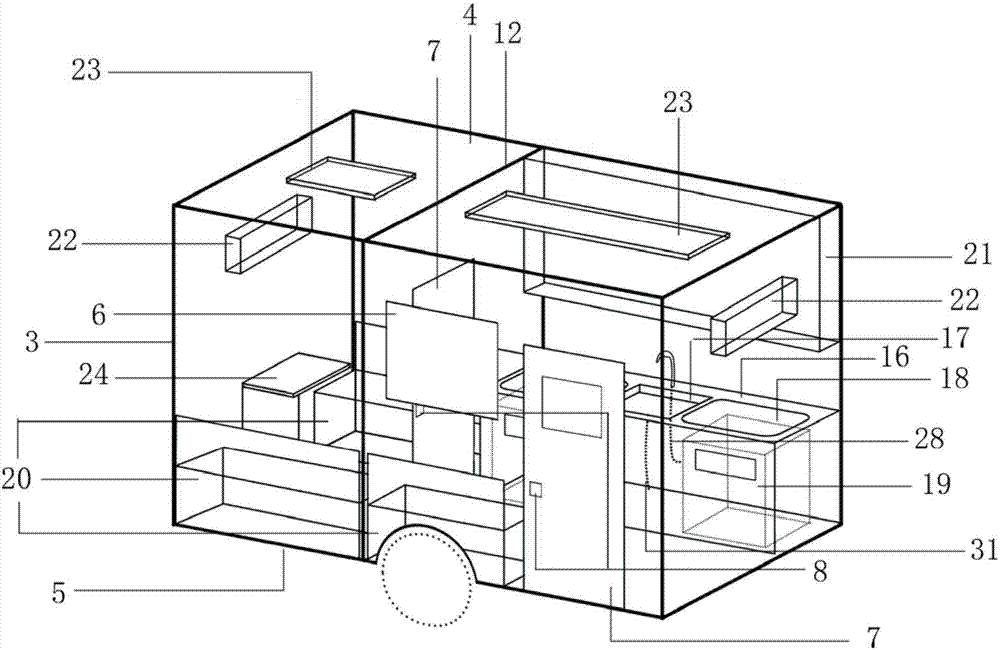

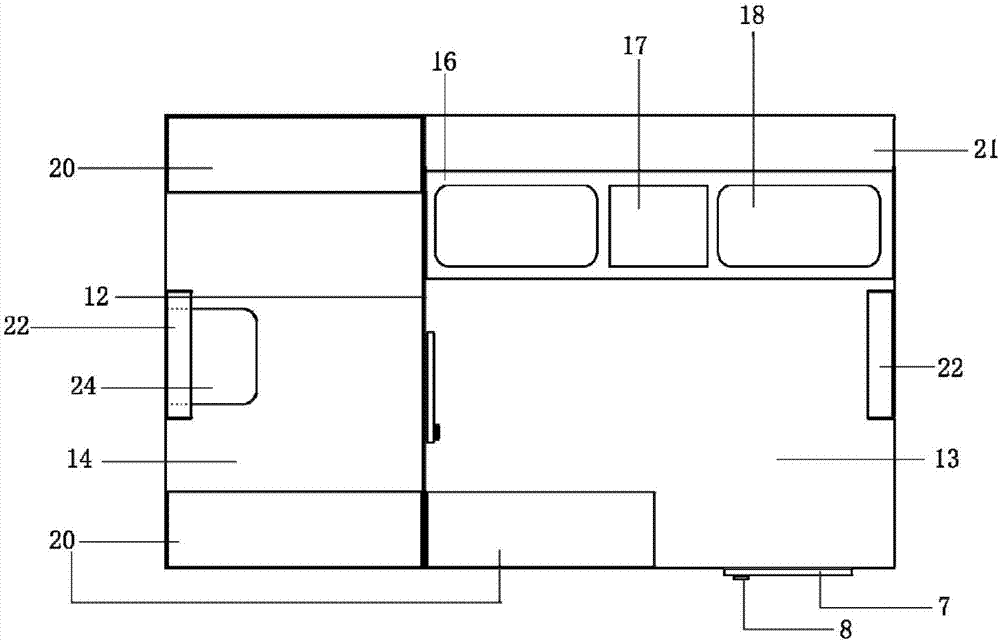

Movable-type infant caring compartment

PendingCN107366442AStable environmentConvenient breastfeedingSpecial buildingSmall buildingsCare infantsInfant feeding

The invention provides a movable-type infant caring compartment. The movable-type infant caring compartment comprises a compartment body, a chassis frame, tires, fixing frames and a division plate; the division plate is installed in the compartment body, so that the compartment body is divided into a nursing room for mum-infant feeding and a caring room for caring an infant; an interior door is arranged on the division plate, and the compartment body is installed on the chassis frame; the fixing frames with folding functions are installed below the chassis frame, and are used for tires of the movable compartment body being installed below the chassis frame; the compartment body is supported by the tires and unfolded fixing frames and is kept stationary on the ground. The movable-type infant caring compartment has the advantages that the movable-type infant caring compartment can be adapted to outdoor public environment with flexible and changeable pedestrian volume and can be moved and used repeatedly, female nursing is convenient, and meanwhile, male can be allowed to enter the caring room for caring the infant. The invention belongs to the field of infant caring equipment.

Owner:SOUTH CHINA UNIV OF TECH

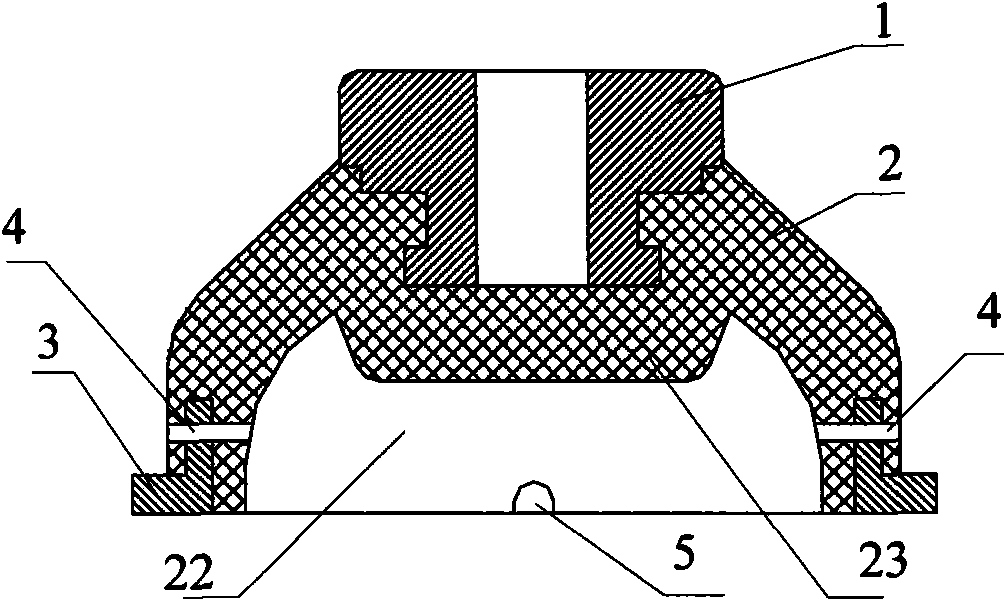

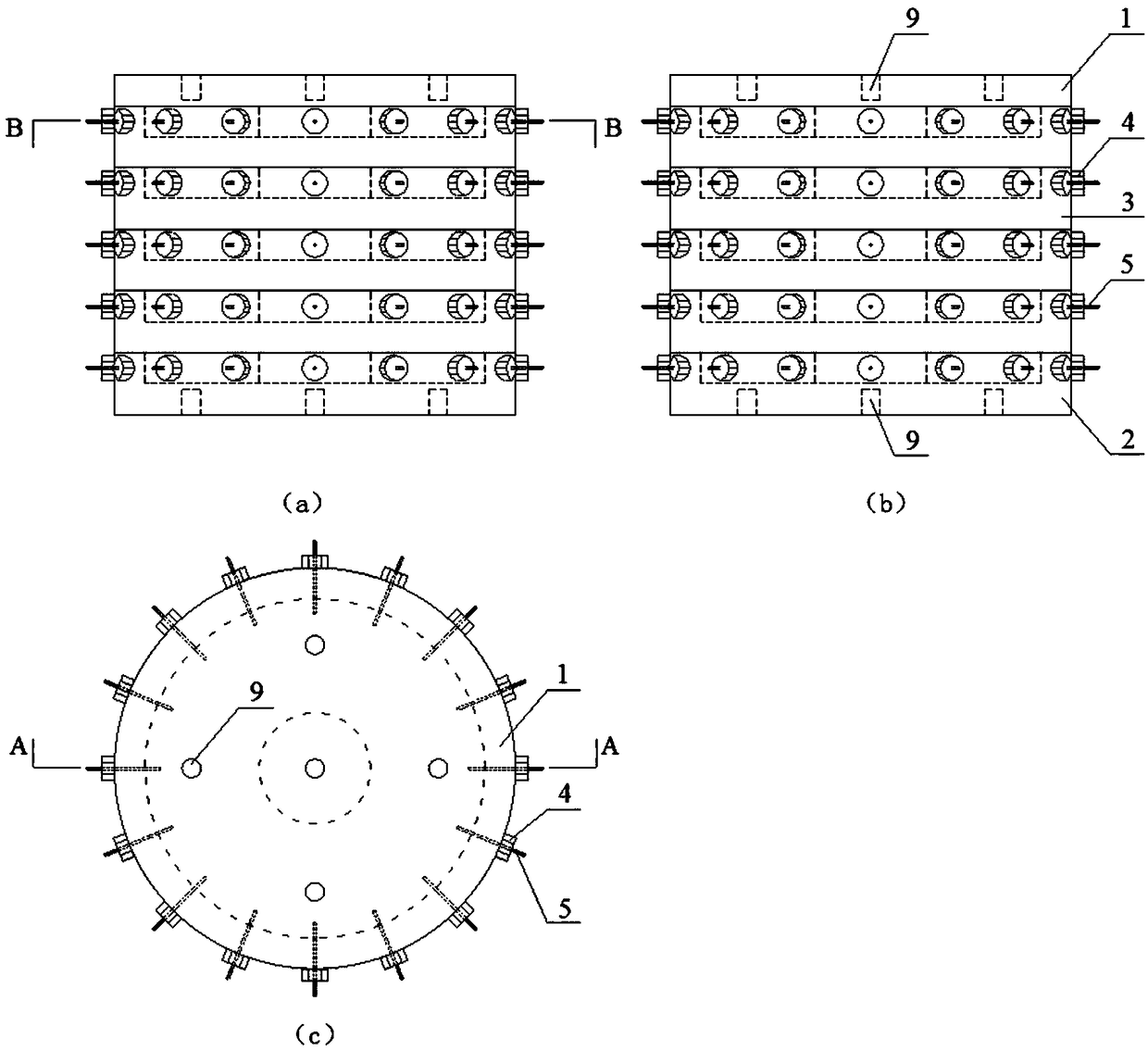

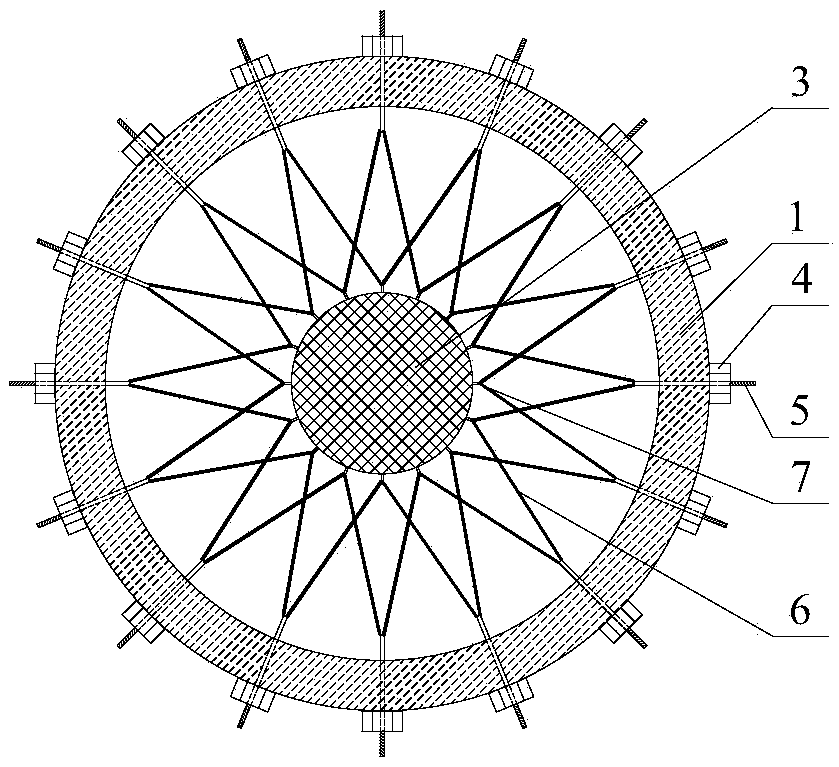

Multi-directional laminated variable-stiffness shape memory alloy damper and mounting method thereof

ActiveCN109267666AIncrease the itineraryWith variable stiffnessProtective buildings/sheltersBuilding material handlingVariable stiffnessResidual deformation

The invention discloses a multi-directional laminated variable-stiffness shape memory alloy damper and a mounting method thereof. A plurality of damper intermediate plates are laminated between a damper top plate and a damper bottom plate to form the damper of a cylindrical structure, and shape memory alloy wires are horizontally and symmetrically arranged between any vertically adjacent laminatedplates. The multi-directional laminated variable-stiffness shape memory alloy damper and the mounting method thereof have the advantages that the problems of smaller stroke, poor reset performance, poor durability, poor high and low temperature resistance and the like of an existing damper are solved, the structure is simple, the installation is convenient, and the multi-directional laminated variable-stiffness shape memory alloy damper can be widely applied to passive control over structures in the technical field of civil engineering and effectively reduces the vibration of structures or components and the residual deformation after strong vibration.

Owner:西安华清科教产业(集团)有限公司

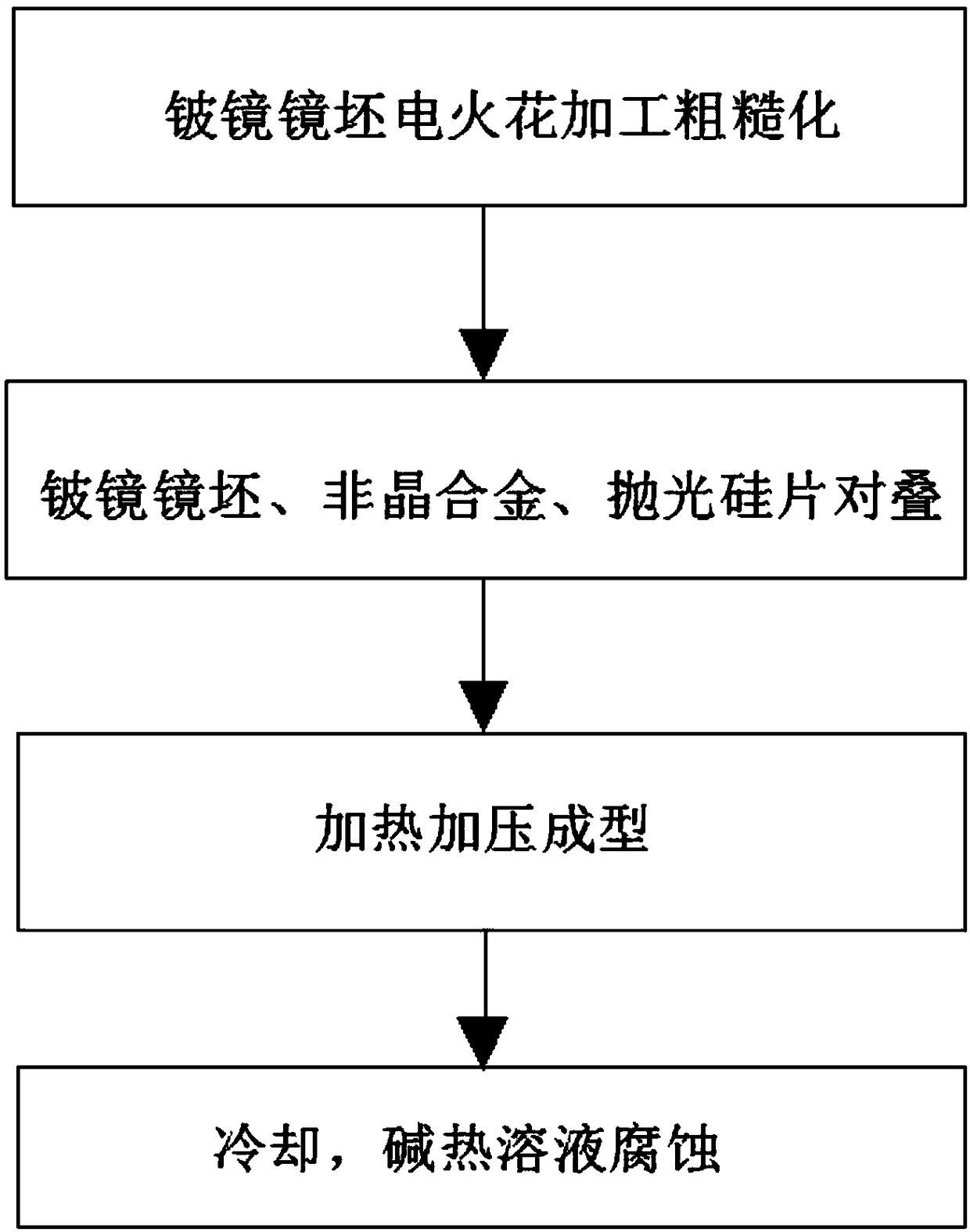

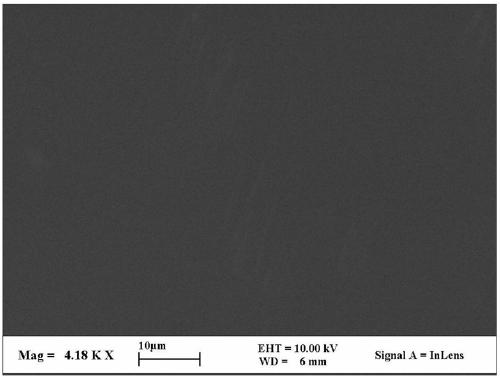

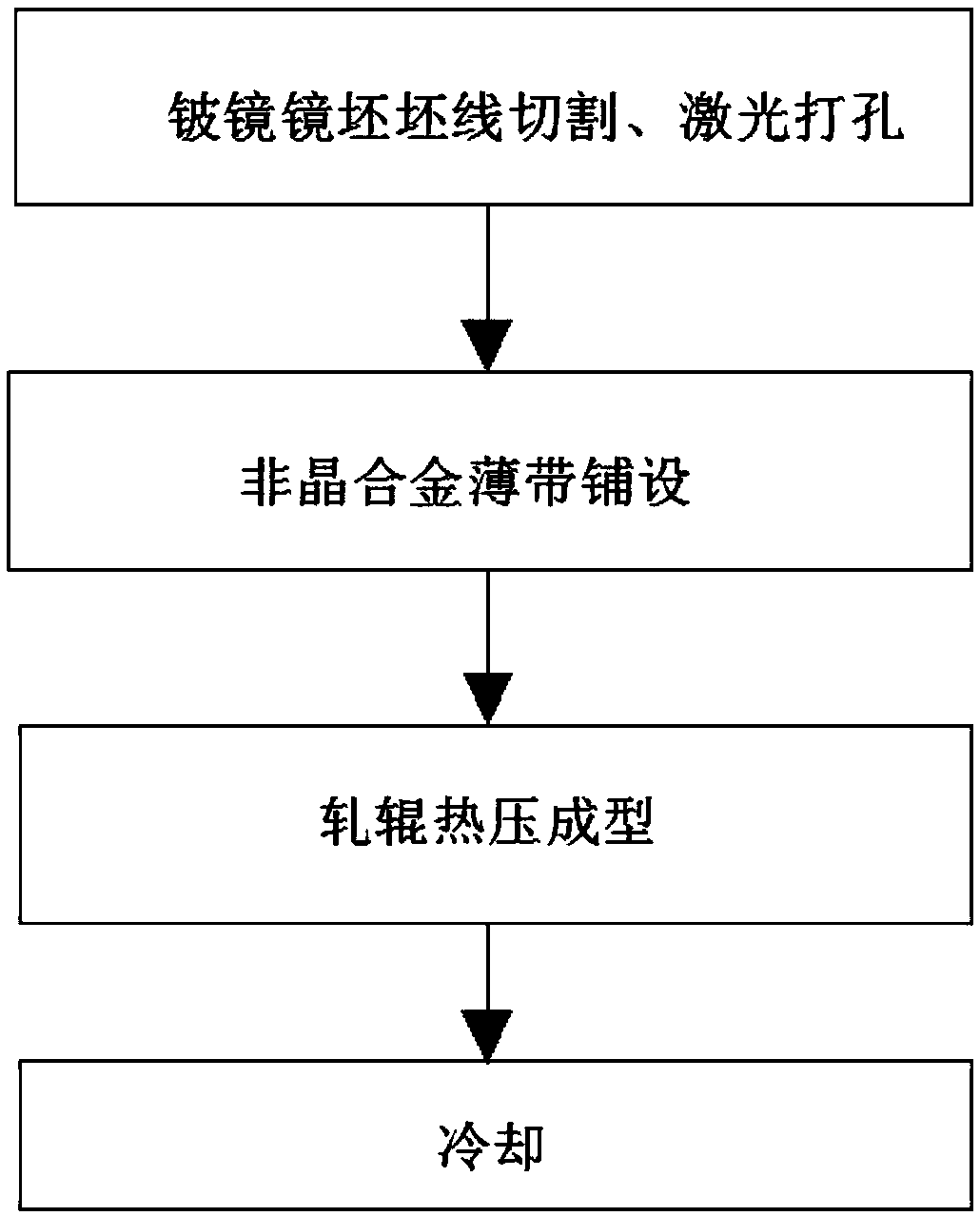

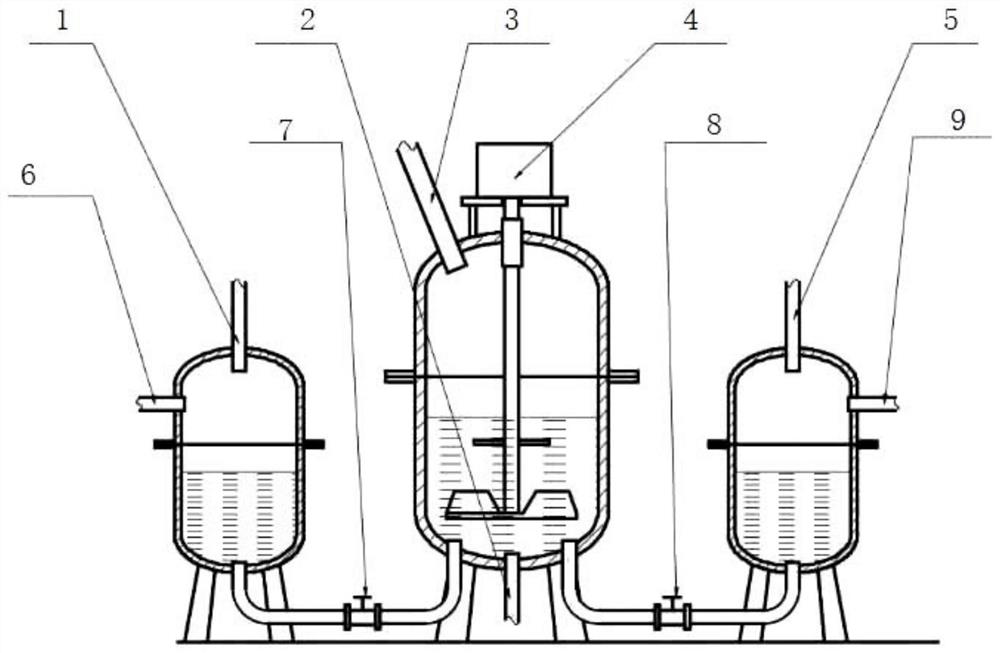

Beryllium mirror surface layer based on amorphous alloy and preparation method thereof

ActiveCN109136920ADesign scienceSimple processMetallic material coating processesSurface layerControllability

The invention discloses a beryllium mirror surface layer based on amorphous alloy and a preparation method thereof. The problems that in the prior, during beryllium mirror surface processing, the technology processes are long, and the cost is high are solved. According to the preparation method of the beryllium mirror surface layer based on amorphous alloy, under the pressure condition, the amorphous alloy is heated to a supercooling liquid phase temperature region, the amorphous alloy is subjected to thermoplastic forming, micro holes in beryllium mirror blanks are filled with the amorphous alloy, and then the beryllium mirror surface layer based on the amorphous alloy is obtained. The invention further discloses the beryllium mirror surface layer prepared by adopting the method. The beryllium mirror surface layer is scientific in design, simple in technology, high in controllability, low in production cost and environmentally friendly.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

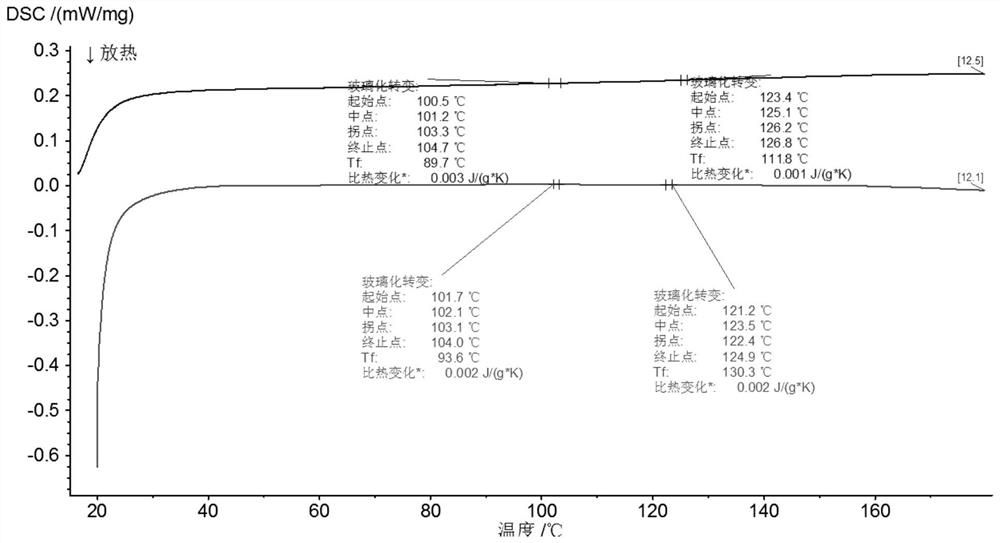

High-temperature-resistant high-pressure-resistant partial-discharge-free epoxy resin insulating material and preparation method thereof

PendingCN112940454AImprove the problem of insufficient high temperature resistance and excessive partial dischargeHigh purityPolymer scienceKaolin clay

The invention discloses a high-temperature-resistant high-pressure-resistant partial-discharge-free organic composite insulating material and a preparation method thereof. The material comprises the following raw materials in percentage by mass: 73-80% of glass fiber twistless roving, 8-10% of epoxy resin, 8-12% of tetrahydrophthalic anhydride, 1-5% of nano aluminum hydroxide and 1-5% of kaolin. The epoxy resin is obtained by compounding bisphenol A type E51 or E54 epoxy resin and glycidyl amine type multifunctional epoxy resin. The organic composite insulating material produced by using the formula is an advanced organic composite insulating material with the glass transition temperature of more than 160 DEG C, high temperature resistance, high pressure resistance and no partial discharge, so that the problems of insufficient high temperature resistance and overlarge partial discharge of the existing organic composite insulating material are solved.

Owner:陕西泰普瑞电工技术有限公司

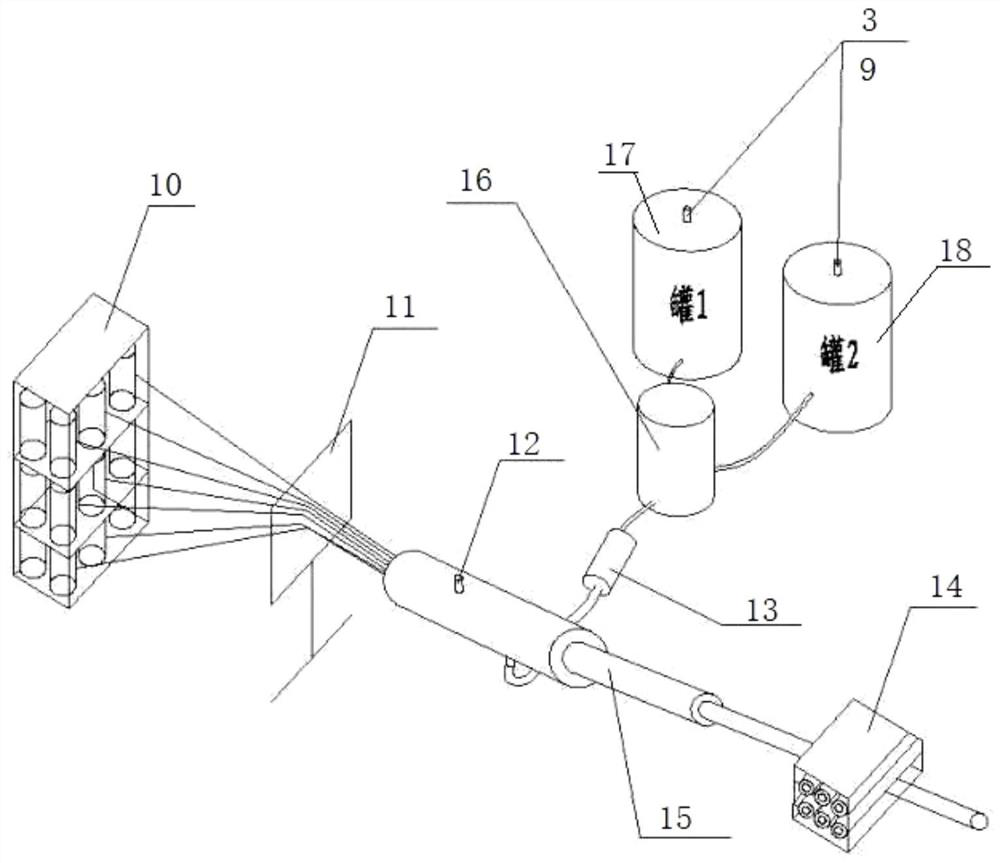

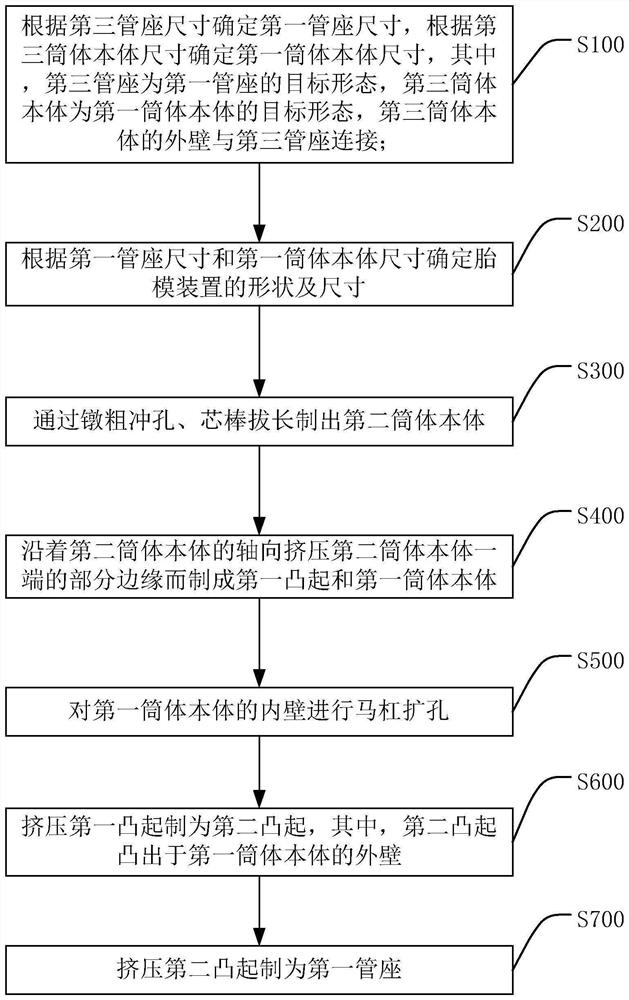

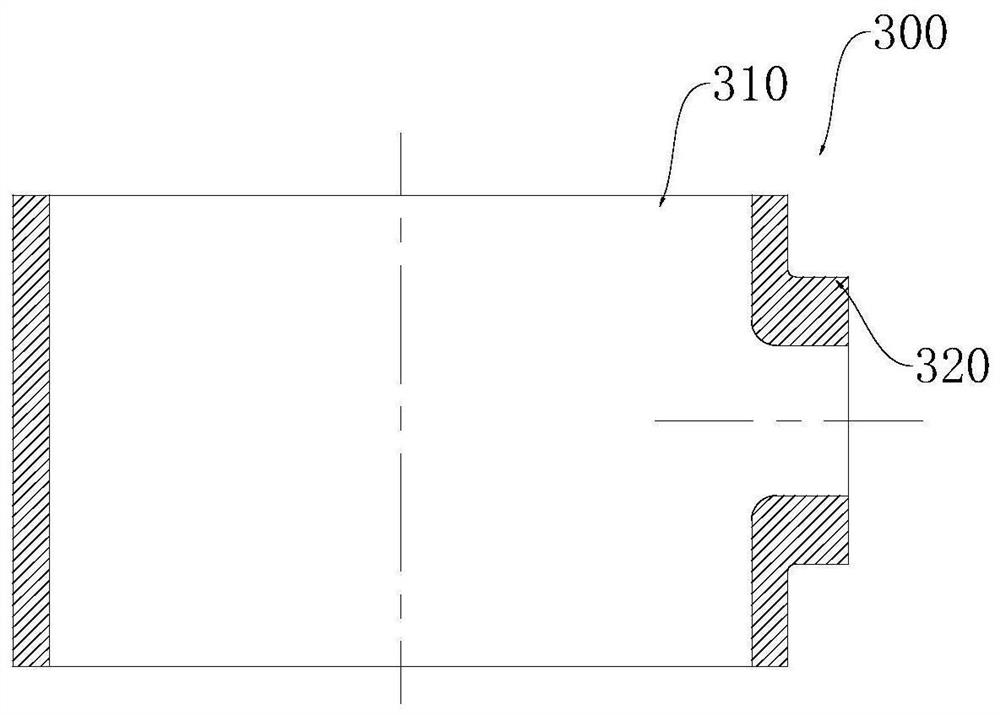

Molding bed forging method for barrel with side connection pipe seat and die

ActiveCN111702117ARaised in the correct directionAvoid weldsForging/hammering/pressing machinesHollow articlesAssembly lineMechanical properties of carbon nanotubes

The invention provides a molding bed forging method for a barrel with a side connection pipe seat and a die and particularly relates to the technical field of forging. A first barrel comprises a firstbarrel body and a first pipe seat, and the outer wall of the first barrel body is connected with the first pipe seat. The molding bed forging method comprises the steps that the first barrel body isprepared, and a first protrusion is manufactured on the edge of one end of the first barrel body; the first protrusion is squeezed to make the side wall of the first barrel body to protrude outwards to form a second protrusion; and the second protrusion is squeezed to be manufactured into the first pipe seat. According to the molding bed forging method for the barrel with the side connection pipeseat and the die, an integrated barrel forge piece with the side connection pipe seat formed with the molding bed forging method avoids welding lines fundamentally, and thus the service stability of abarrel component with the side connection pipe seat is ensured. Furthermore, a forging assembly line is reserved to the maximum degree, the comprehensive mechanical performance of the forge piece isimproved, and thus the requirements, such as the requirement that container equipment in the nuclear electrical field is subjected to nuclear radiation in long term, are met.

Owner:CHINA FIRST HEAVY IND +1

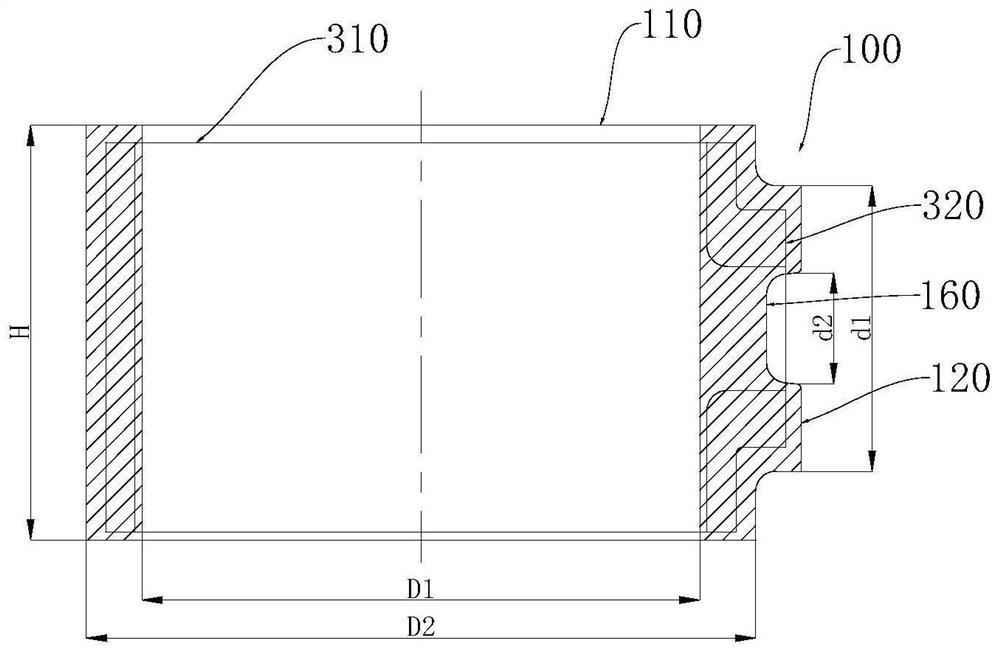

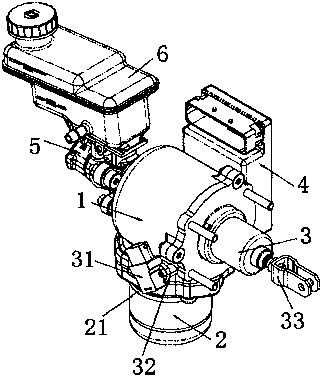

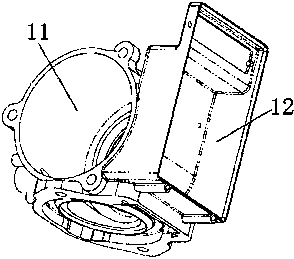

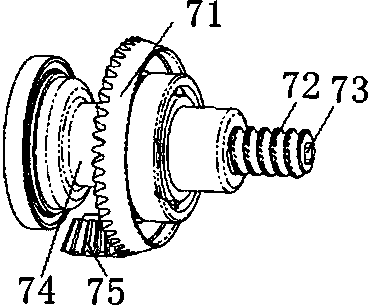

Motor protection type electric-controlled brake booster

PendingCN107554510AImplement waterproofing measuresExtended service lifeBraking action transmissionRubber ringElectric machinery

The invention discloses a motor protection type electric-controlled brake booster, which comprises an electric motor, a driving mechanism, a pedal input mechanism, a shell body component, an electronic control unit, a main brake cylinder and a fluid storage tank; the pedal input mechanism is fixedly installed at the back end part of the shell body component, and the electric motor is fixedly installed at the lower end part of the shell body component; the main brake cylinder is further fixedly equipped with one fluid storage tank, and the driving mechanism is fixedly installed at the inner endpart of the shell body component. Through sheathing an annular motor cover on the outer surface of the electric motor and coating glue water to the joint between the motor cover and the shell body component or sealing by a rubber ring, while sealing the joint between the annular motor cover and the motor by the rubber ring also, the waterproof measure of the motor is effectively realized, the using environment requirement of arranging the booster assembly at an engine cabin is satisfied, and the service life of the motor is prolonged.

Owner:GELUBO TECH CO LTD

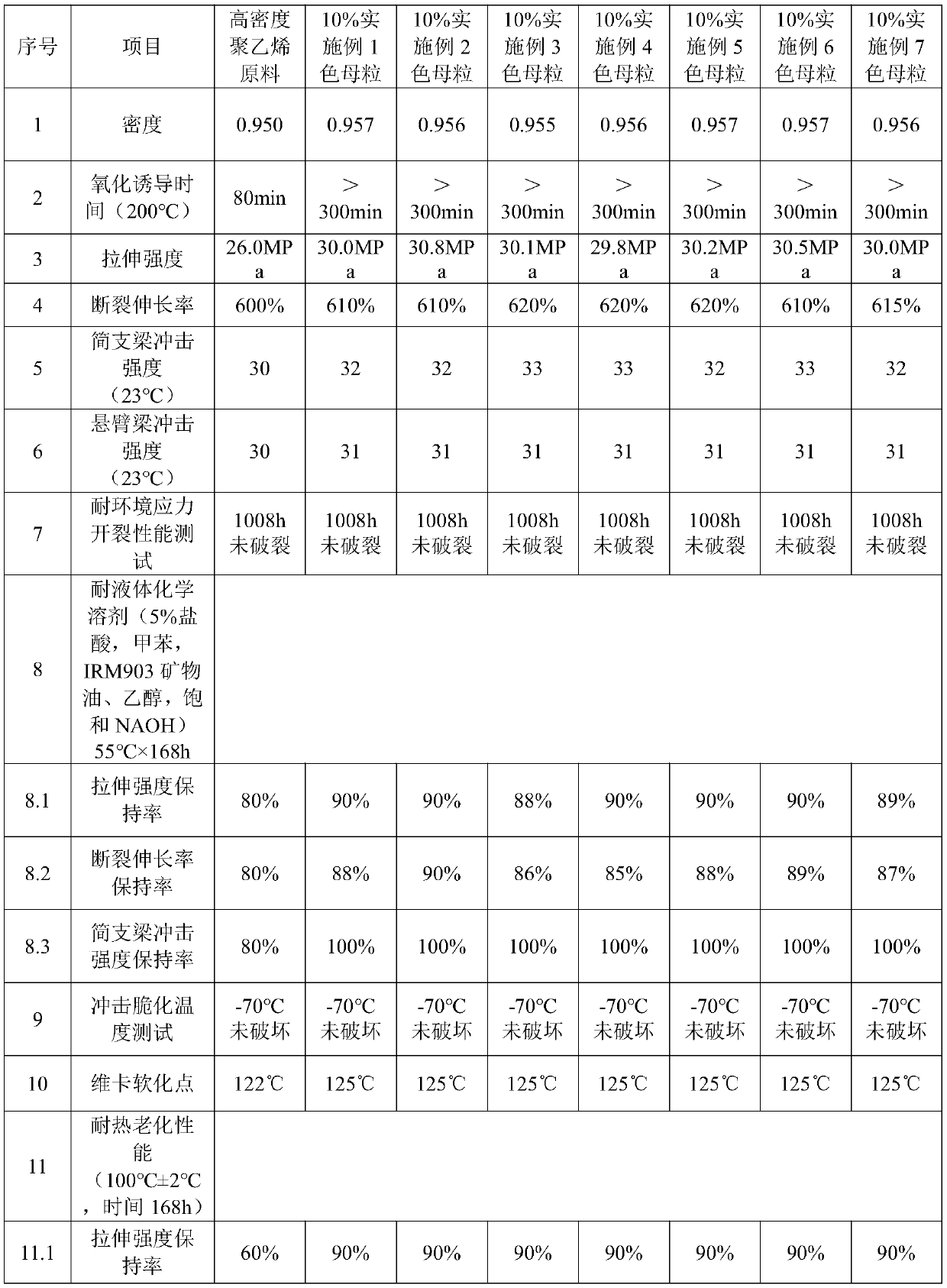

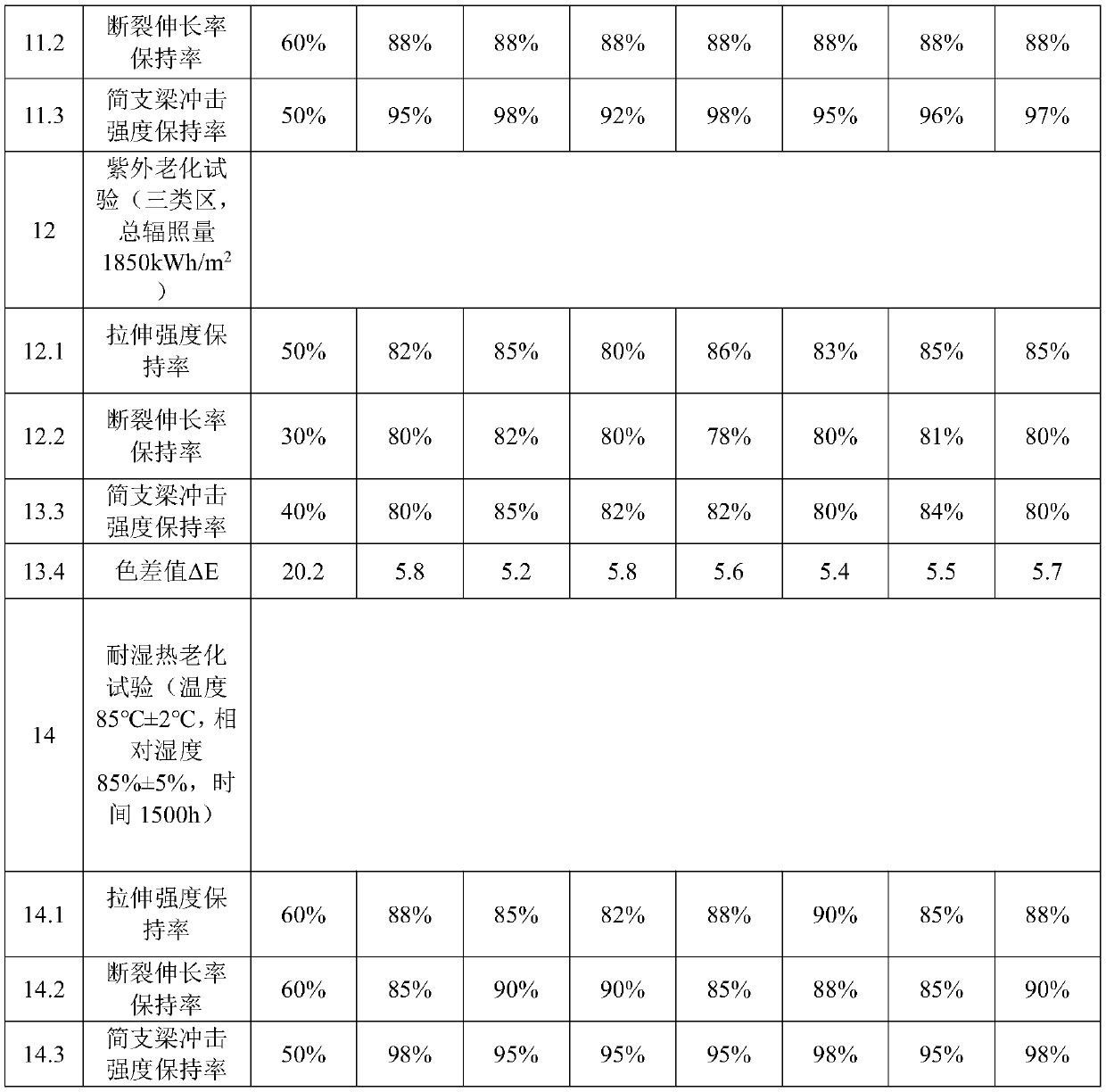

Long-acting weather-resistant color master batch and preparation method thereof

The invention relates to a long-acting weather-resistant color master batch and a preparation method thereof. The preparation method comprises the following steps: 45 to 65 percent of high density polyethylene, 4 to 6 percent of antioxidant, 1 to 3 percent of zirconia, 2 to 5 percent of ultraviolet absorber, 3 to 5 percent of dispersant, 5 to 10 percent of hindered amine light stabilizer, 15 to 25percent of titanium dioxide and 1 to 10 percent of pigment are uniformly mixed to obtain a mixed material, the mixing time is 15 to 20 minutes, and the mixing temperature is 40 to 50 DEG C; then, themixed material is added into an extruder for melt extrusion to obtain the long-acting weather-resistant color master batch. The long-acting weather-resistant color master batch of the invention has good compatibility with high-density polyethylene, and can not only protect the C-C main chain of the high-density polyethylene from being destroyed by high energy radiation under the action of ultraviolet light energy, but also can be used as a kind of toughening agent to further improve the overall mechanical properties of modified high density polyethylene.

Owner:ANHUI JIHONG MATERIAL TECH

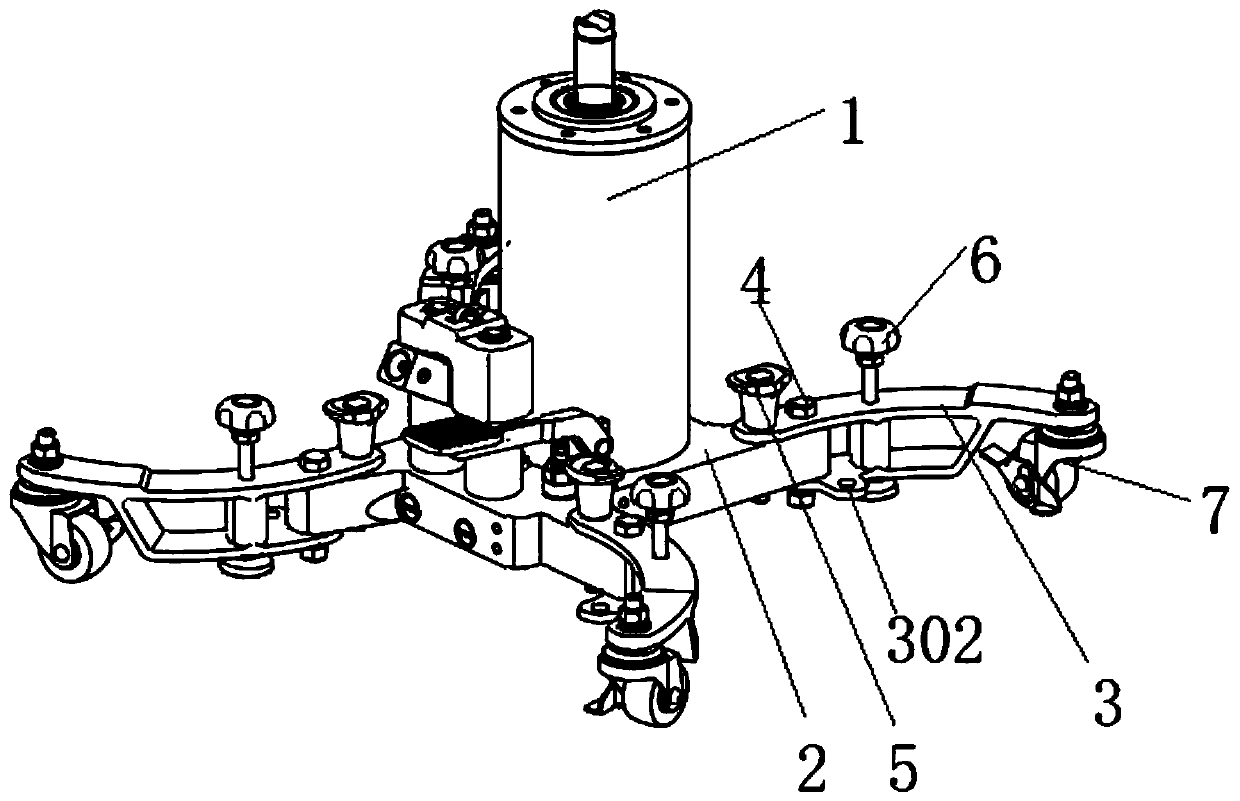

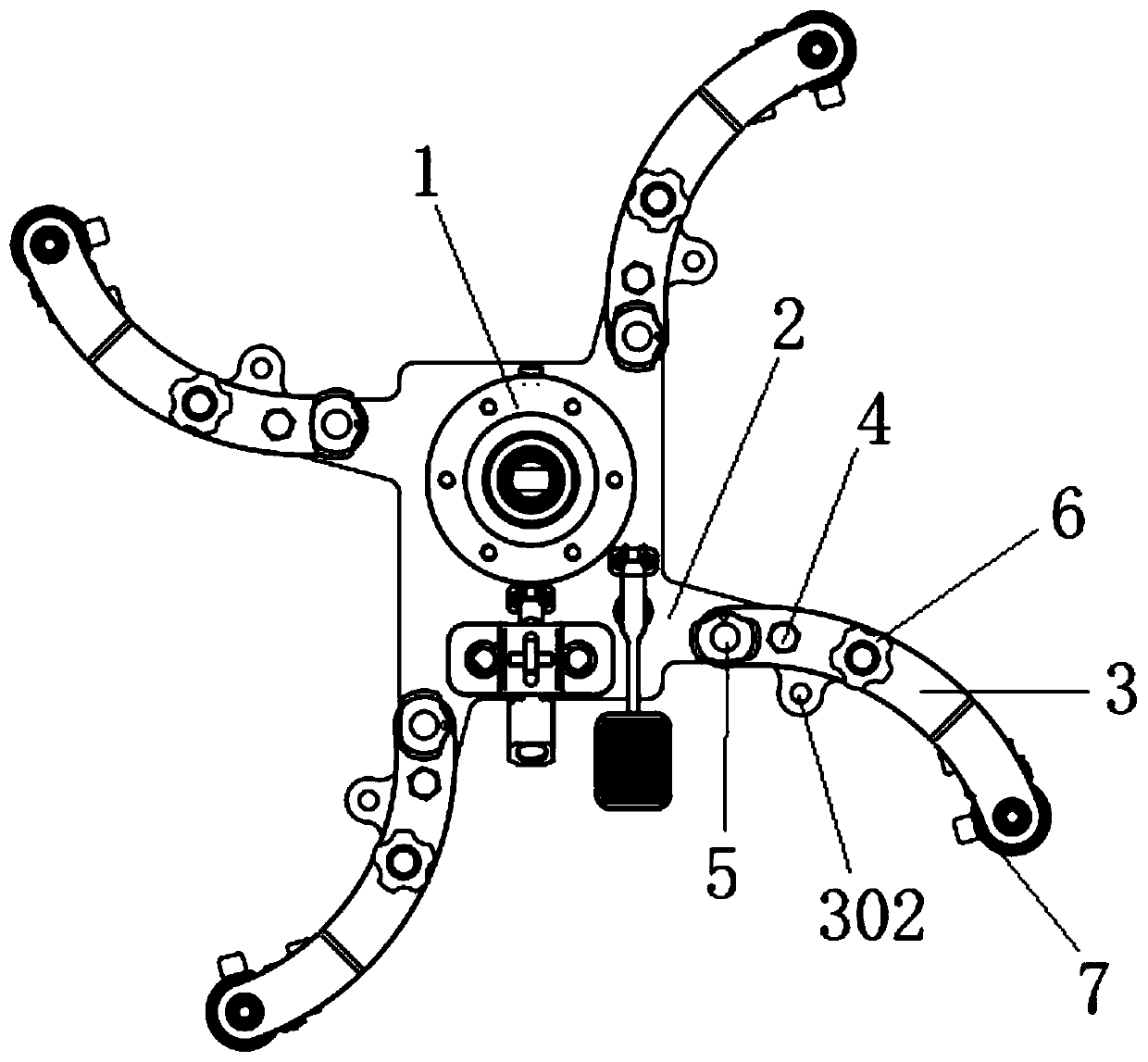

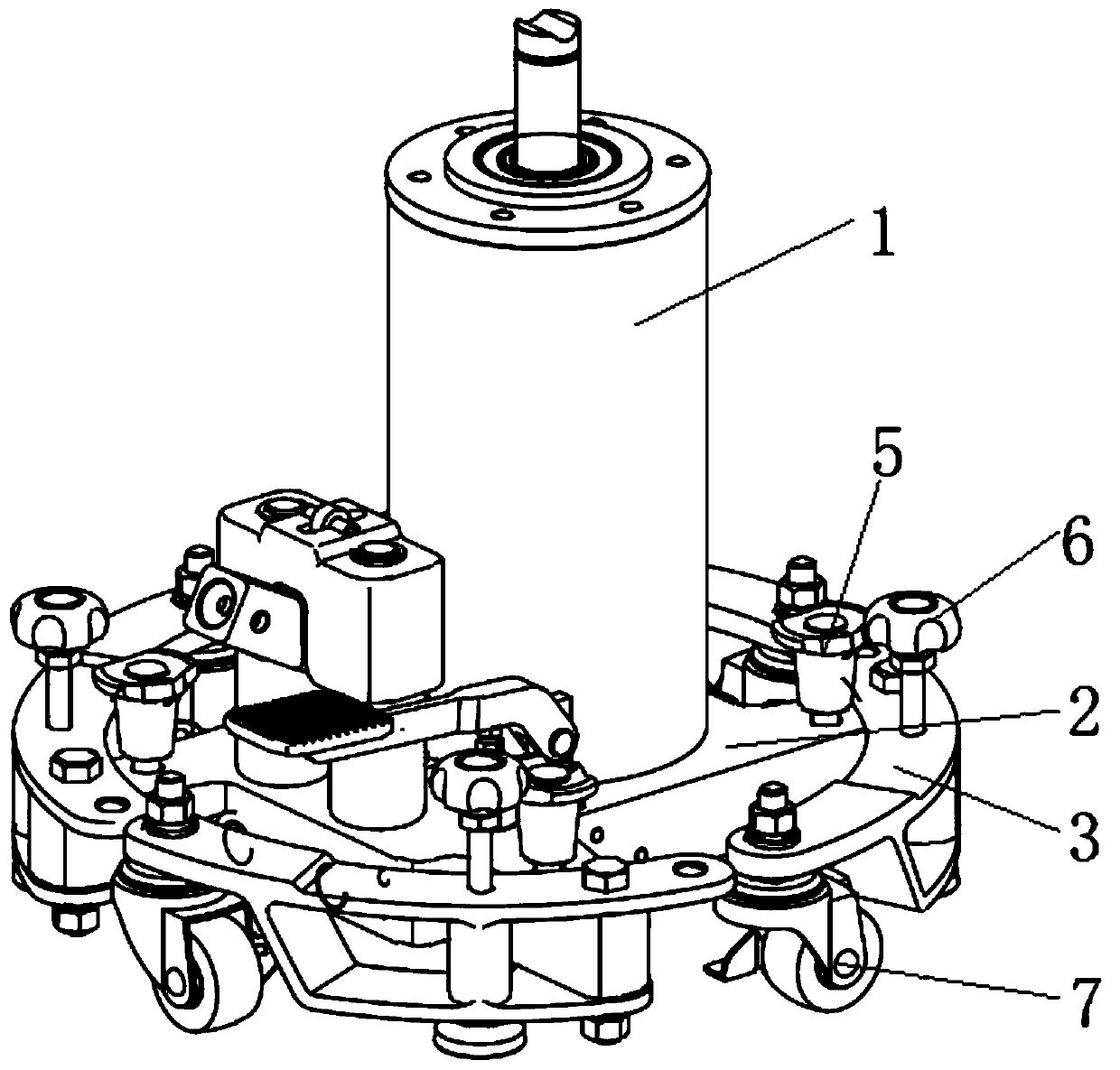

Hydraulic conveying jack with adjustable base supports

PendingCN110482430AEasy to controlImprove balanceLifting devicesStands/trestlesEngineeringBlock match

Owner:CHANGSHU TONGRUN AUTO ACCESSORY

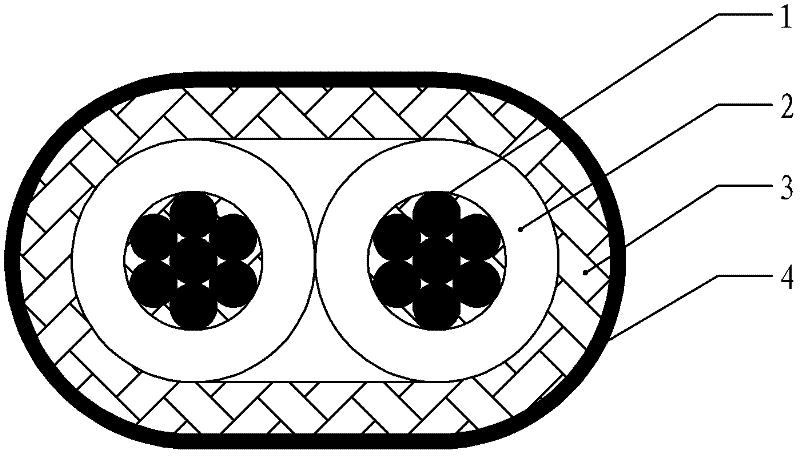

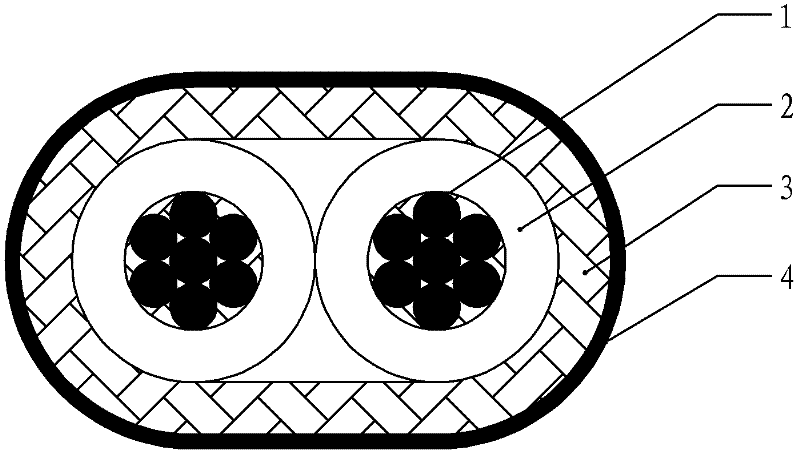

Cable for LVDS (Low-voltage Differential Signal) transmission

InactiveCN102394141AGuaranteed transmission qualityImprove stabilityNon-insulated conductorsCommunication cablesSilver plateInsulation layer

The invention relates to a signal transmission cable, in particular to a cable for LVDS (Low-voltage Differential Signal) transmission, which solves the problem that the conventional mediums for LVDS transmission in China affect signal quality during long-distance transmission. The cable includes two wire harnesses, a shielding layer and a sheath, wherein each wire harness is wrapped by an insulation layer, the two wire harnesses are located in the shielding layer, the sheath is located on the outer side of the shielding layer, each wire harness is formed by a plurality of wires which are twisted, the diameter of each wire is 0.16mm, the pitch diameter of each wire harness is no larger than 16 and no smaller than 8, each insulation layer is formed through the winding and sintering of 1-3 layers of turned polytetrafluoroethylene films, the shielding layer is formed through the weaving of soft round silver-plated wires, and the sheath is formed through the winding and sintering of polyimide / fluoroplastic laminated films. The signal transmission distance of the cable provided by the invention reaches 1,000mm-3,000mm; and the cable has high vacuum stability and ozone resistance and better irradiation-resisting performance, and can meet the service environment requirements of the outer space.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com