High-temperature-resistant high-pressure-resistant partial-discharge-free epoxy resin insulating material and preparation method thereof

An epoxy resin and high temperature resistant technology, which is applied in the field of organic composite insulating materials, can solve the problems of excessive partial discharge and insufficient high temperature resistance, and achieve the effects of increased bonding, good high temperature resistance and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

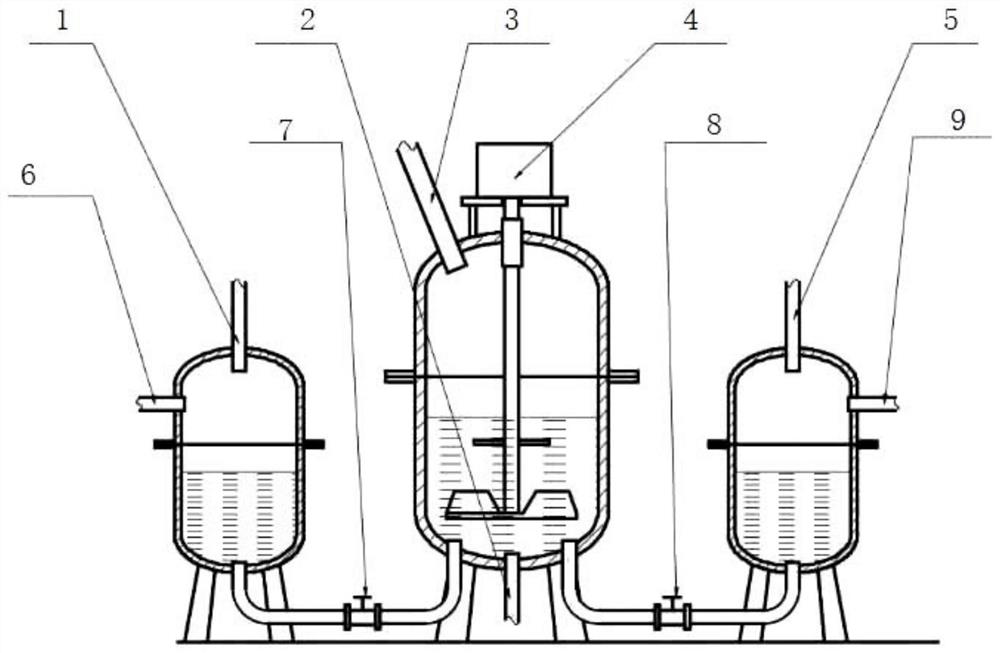

[0046] The invention provides the preparation method of above-mentioned organic composite insulating material, comprising:

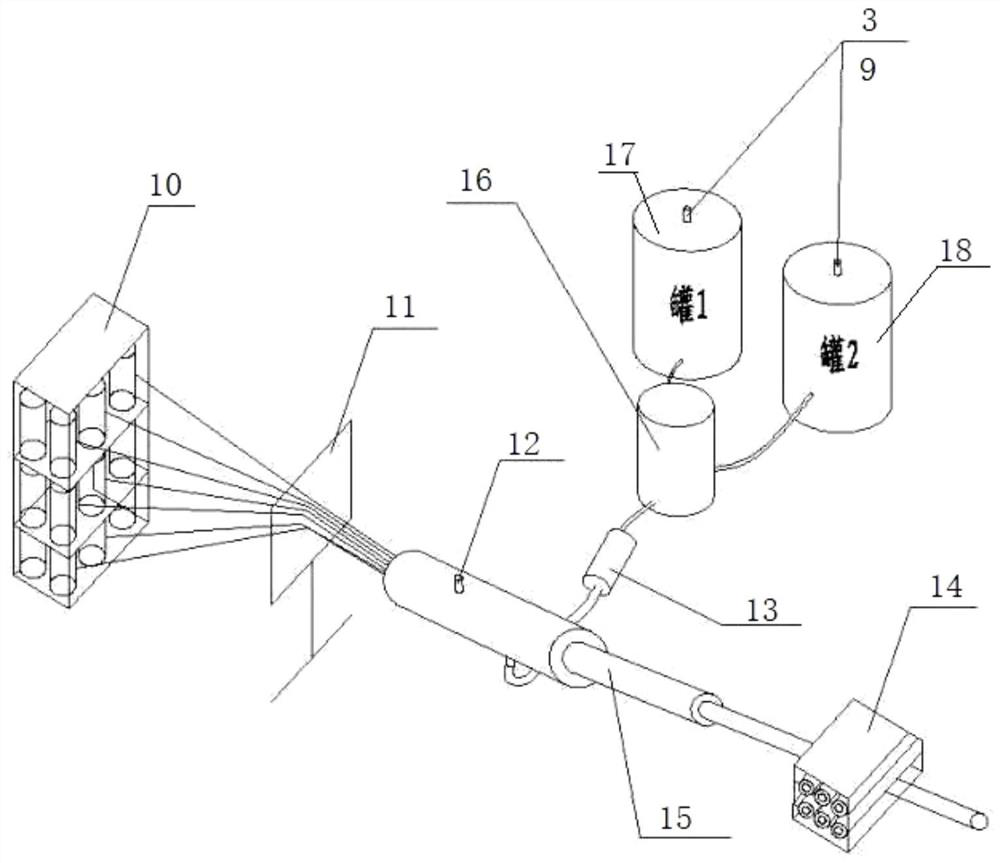

[0047] Warm one of E51 epoxy resin or E54 epoxy resin and polyfunctional glycidylamine epoxy resin, then add aluminum hydroxide differential and high-performance kaolin mixed epoxy resin and methyltetrahydrophthalamide Mix the acid anhydride with the accelerator and the hardening agent after mixing the toughening agent, stir evenly, put the stirred rubber into the dipping tank, dip the glass fiber roving through the dipping tank, pass the soaked glass fiber through The pre-forming vacuum device enters the forming mold, and the pre-forming vacuum device assists in vacuuming to remove the glue and the air bubbles and excess glue in the glass fiber roving, and then enters the forming mold to solidify and form to obtain the required insulating material.

[0048] Specific steps are as follows:

[0049] Step 1, put E51 epoxy resin or E54 epoxy resin and glyci...

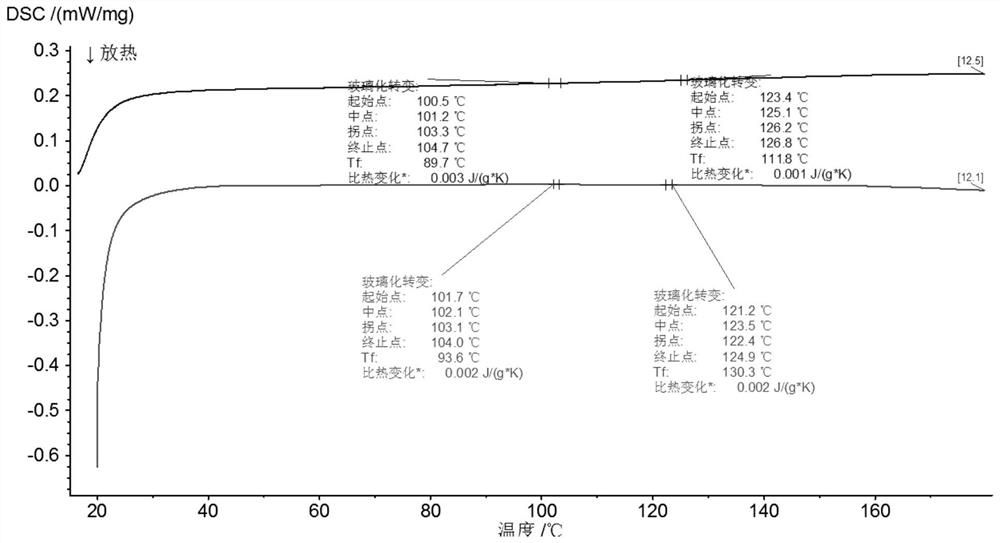

Embodiment 1

[0064] Step 1, put E51 epoxy resin and glycidylamine type multifunctional epoxy resin into the oven to heat, and set the temperature to 60 degrees.

[0065] Step 2, put the heated E51 epoxy resin and the heated glycidylamine multifunctional epoxy resin in a ratio of 60:40 into a vacuum mixing tank and stir evenly.

[0066] Step 3, putting a certain proportion of aluminum hydroxide micropowder and 5% of the amount of epoxy resin into the stirring tank stirring the epoxy resin and fully stirring evenly.

[0067] Step 4, put a certain proportion of high-quality kaolin and 5% of the amount of epoxy resin into the stirring epoxy resin mixing tank, stir well, and turn on the vacuum pump to vacuum during the stirring process, the vacuum gauge pressure reaches 0.9MPa, stir The good epoxy resin glue is put away for later use.

[0068] Step 5, put methyltetrahydrophthalic anhydride into a vacuum stirring tank, add the accelerator 2,4-dimethylimidazole in a certain proportion, 0.5% of t...

Embodiment 2

[0076] Step 1, put E54 epoxy resin and glycidylamine type multifunctional epoxy resin into an oven to heat, and set the temperature to 70 degrees.

[0077] Step 2, put the heated E54 epoxy resin and the heated glycidylamine type multifunctional epoxy resin in a ratio of 55:45 into a vacuum mixing tank and stir evenly.

[0078] Step 3, putting a certain proportion of aluminum hydroxide micropowder and 8% of the amount of epoxy resin into the stirring tank stirring the epoxy resin and fully stirring evenly.

[0079] Step 4, put a certain proportion of high-quality kaolin and 8% of the amount of epoxy resin into the epoxy resin mixing tank that is being stirred and stir well, and turn on the vacuum pump to vacuum during the stirring process. The vacuum gauge pressure reaches 0.5MPa, and stir The good epoxy resin glue is put away for later use.

[0080] Step 5, put methyltetrahydrophthalic anhydride into a vacuum stirring tank, add the accelerator 2,4-dimethylimidazole in a certa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com