Epoxy resin pouring dry type transformer for electric locomotive

An electric locomotive and epoxy resin technology, applied in the field of transformers, can solve the problems of increasing the size and weight of transformers, poor waterproof performance, and unreachable waterproof effects, etc., and achieve reasonable structural design, excellent waterproof performance, and scientific and reasonable pouring technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 Transformer for electric locomotive of the present invention

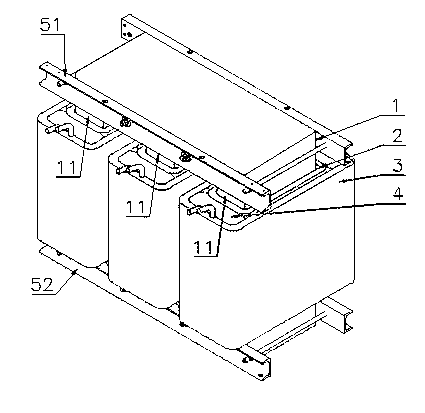

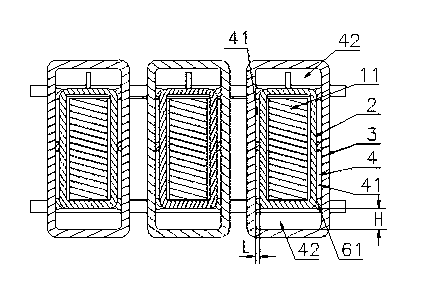

[0047] Such as figure 1 As shown, a transformer for an electric locomotive includes an iron core 1. The iron core 1 includes three iron core columns 11 arranged in parallel in the transverse direction, and the three iron core columns 11 are connected together by an upper yoke and a lower yoke to form an inverted The "day" font structure. Each core column 11 is provided with a secondary coil 2 and a primary coil 3 sequentially from the inside to the outside, and the core column 11 is inside, the secondary coil 2 is arranged in the middle to surround the core column 11, and the primary coil 3 is arranged on the The outside is to surround the core column 11 and the secondary coil 2 . A cooling air duct 4 is formed between each secondary coil 2 and the primary coil surrounding the secondary coil 2 . In addition, the iron core 1 is fixed on the bracket through the upper clip 51 and the lower cli...

Embodiment 2

[0067] Embodiment 2 Transformer for electric locomotive of the present invention

[0068] The transformer structure and coil curing process for electric locomotives of the present invention are the same as those in Example 1, the only difference being that in the pouring method, step 1) the medium and low viscosity resin formula is:

[0069] Phenolic resin 45wt%;

[0070] Methyltetrahydrophthalic anhydride 43wt%;

[0071] Polypropylene glycol 4wt%;

[0072] N, N-benzyldimethylamine 4wt%;

[0073] Inorganic pigments 4wt%.

[0074] The formula of unsaturated polyester insulating dipping varnish in step 2) is:

[0075] Polyethylene terephthalate: 94%;

[0076] Solvent: 6%.

Embodiment 3

[0077] Embodiment 3 Transformer for electric locomotive of the present invention

[0078] The transformer structure and coil curing process for electric locomotives of the present invention are the same as those in Example 1, the only difference being that in the pouring method, step 1) the medium and low viscosity resin formula is:

[0079] Phenolic resin 44wt%;

[0080] Methyltetrahydrophthalic anhydride 42wt%;

[0081] Polypropylene glycol 3wt%;

[0082] N, N-benzyldimethylamine 6wt%;

[0083] Inorganic pigment 5wt%.

[0084] The formula of unsaturated polyester insulating dipping varnish in step 2) is:

[0085] Polyethylene terephthalate: 92%;

[0086] Solvent: 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com