Beryllium mirror surface layer based on amorphous alloy and preparation method thereof

A technology of amorphous alloy and mirror layer, which is applied in the field of material science and engineering, can solve the problems of high cost and long process flow, and achieve the effects of low production cost, shortened process flow and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

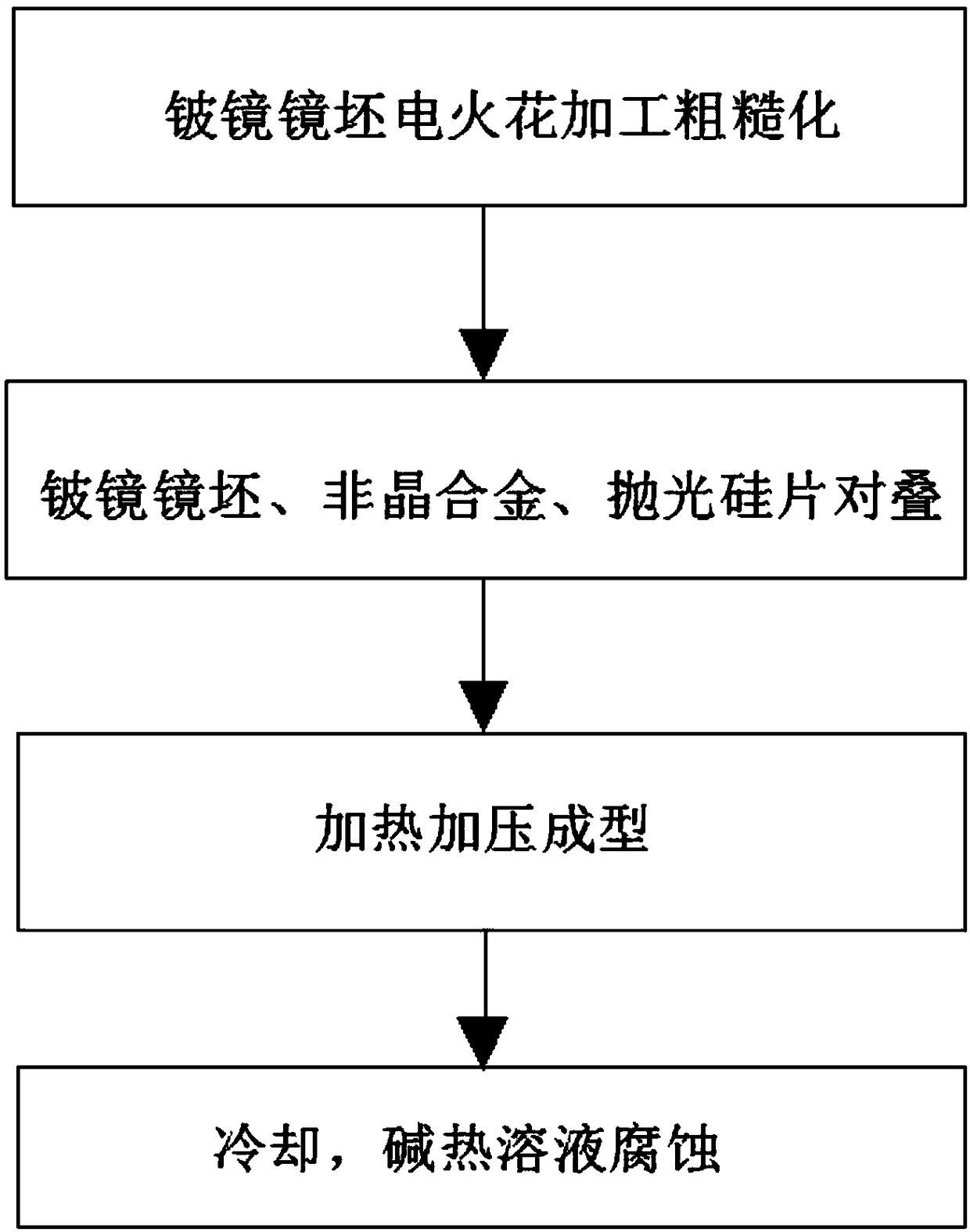

[0031] Preparation of small-sized beryllium mirror mirror layer based on amorphous alloy, the specific process is as follows figure 1 shown, including the following steps:

[0032] Step 1: Surface roughening of beryllium mirror blank:

[0033] Select a beryllium mirror blank with a diameter of about 10mm, and use electric discharge machining to process the beryllium surface of the beryllium mirror to roughen the surface and produce microscopic holes with a diameter of about 0.5mm and a depth of about 1mm.

[0034] Step 2: Beryllium mirror surface layer preparation of amorphous alloy:

[0035] choose Ni 62 PD 19 Si 2 P 17 The amorphous alloy thin slice and the polished silicon wafer both have a diameter of 10 mm and a thickness of the amorphous thin slice of 1 mm. The polished silicon wafer, the amorphous alloy thin slice and the beryllium mirror blank after the surface treatment in step 1 are stacked in sequence, wherein the polished surface of the polished silicon wafer...

Embodiment 2

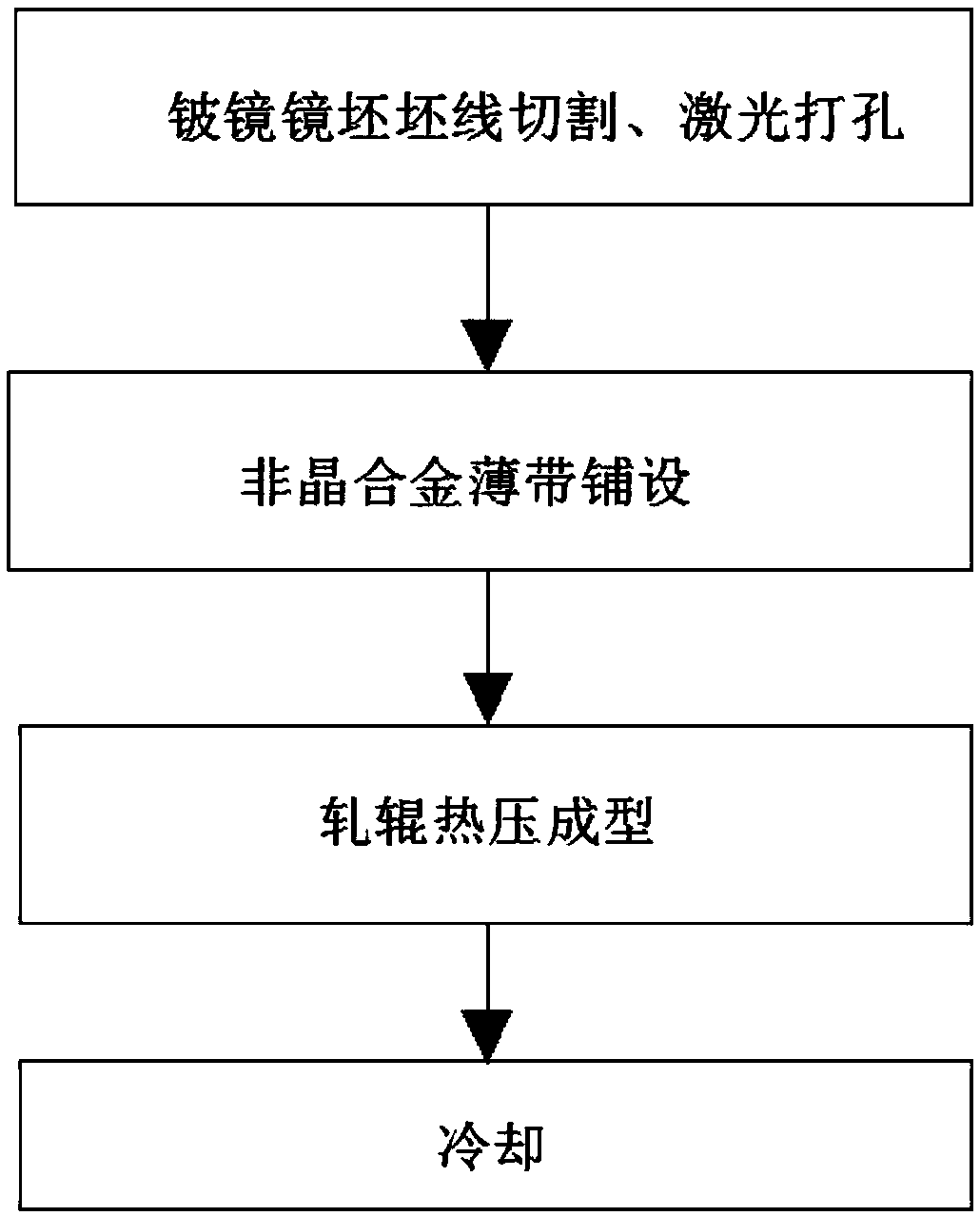

[0038] Preparation of mirror layer of large-sized beryllium mirror based on amorphous alloy, and its specific process flow figure 2 shown, including the following steps:

[0039] Step 1: Surface roughening of beryllium mirror blank:

[0040] Select a beryllium mirror blank with a diameter of about 50mm, and use wire cutting and laser drilling to process the beryllium surface of the beryllium mirror to make the surface rough. Among them, wire cutting produces micron-scale irregular fluctuations, which are randomly distributed on the entire surface of the beryllium mirror blank. Laser drilling produces micron empty arrays. The diameter of the holes is about 0.1mm, the depth is about 0.15mm, and the spacing is about 0.2mm.

[0041] Step 2: Beryllium mirror surface layer preparation of amorphous alloy:

[0042] Choose Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 A thin strip of amorphous alloy with a thickness of about 35 μm. Spread the amorphous alloy thin strip on the surface-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com