Pipeline dredging machine

A technology for dredging machines and pipelines, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of inconvenient use and insufficient stability of performance, so as to ensure stable operation of equipment, good dredging performance, and good The effect of natural forward ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 nozzle structure design

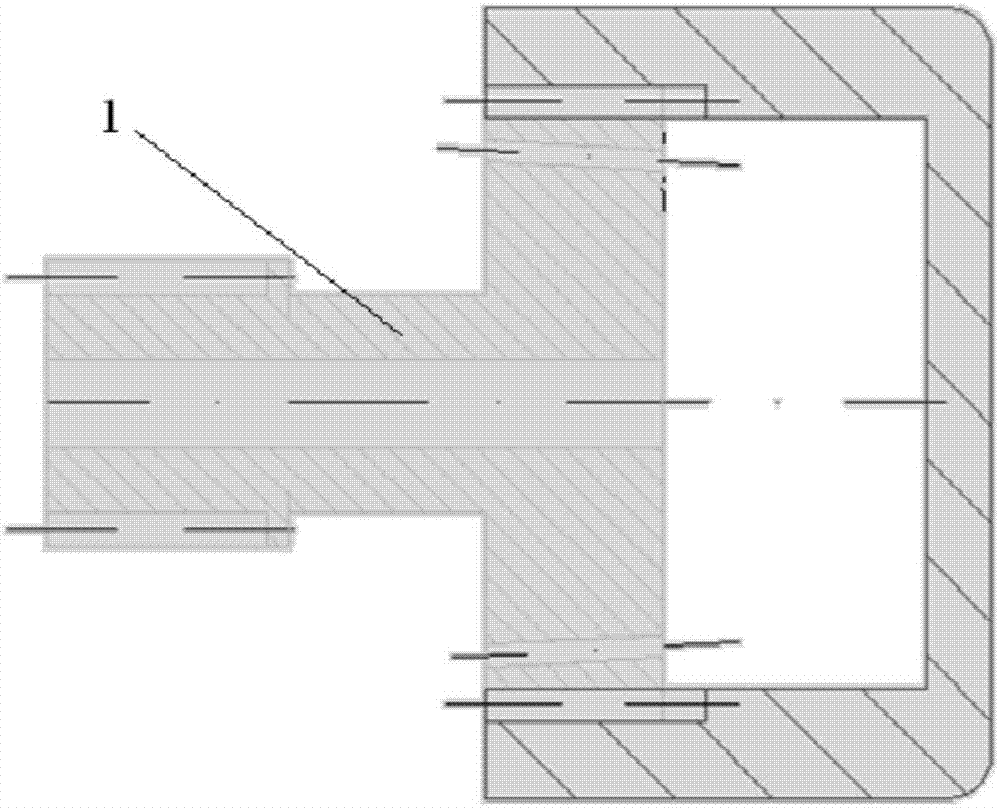

[0052] like figure 1 , the sprinkler head 1 has an integrated structure, and its appearance is cylindrical. The nozzle is mainly used to test the natural forward ability, and the nozzle is set at the rear of the nozzle, which is designed as 2 nozzles. Test with straight PVC pipe (see Figure 8 )

[0053] Test performance:

[0054] 1. Straight pipe passing capacity: the time to pass through a standard PVC straight pipe (length 4m) is 1 second.

[0055] 2. Bend pipe passing capacity: no less than two 90° elbows can be passed.

[0056] Problems: Because the cylindrical shape of the nozzle has edges, it will get stuck when encountering obstacles perpendicular to the pipe wall such as pipe joints.

Embodiment 2

[0057] Embodiment 2 nozzle structure design

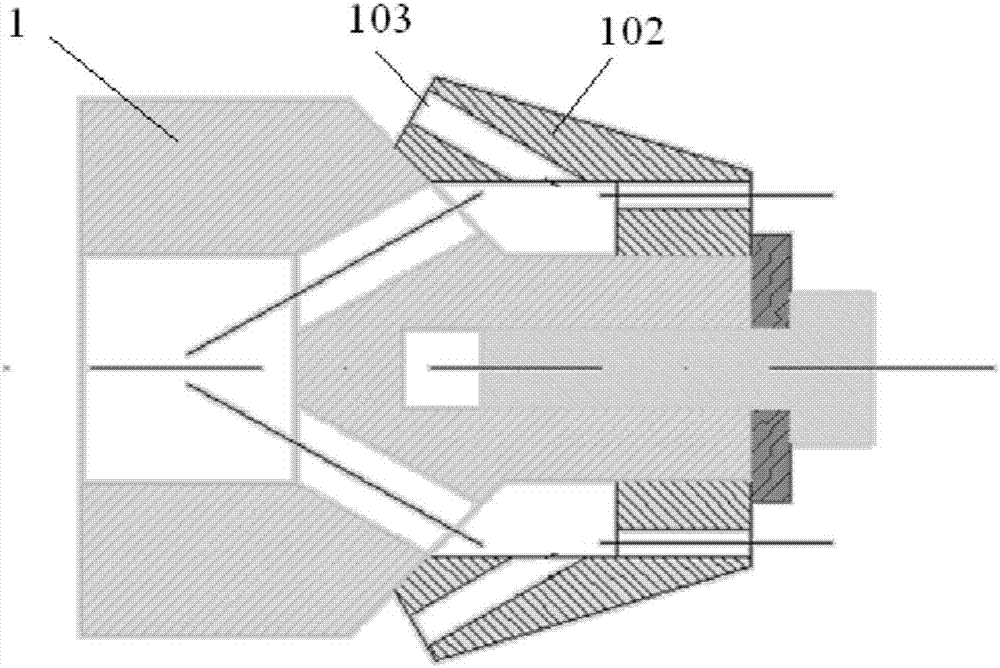

[0058] like figure 2 , the spray head 1 includes a shaft 101 connected to the dredge pipe, and a side wall 102 of the spray head arranged outside the shaft, the shaft of the spray head is provided with a rear spray hole 103, and the rear spray hole is used to push the spray head forward, There is also a backward nozzle hole on the side wall of the nozzle. The angle between the rear nozzle hole and the axis is increased, and the hole diameter is increased at the same time to test the influence of the same nozzle hole on the forward ability and cleaning ability;

[0059] The side wall 102 of the nozzle has a hollow cylindrical shape, and the side wall 102 of the nozzle has an inclination in appearance design, which improves the ability to overcome obstacles;

[0060] Increase the front spray hole 105.

[0061] Test performance:

[0062] 1. Straight pipe passing capacity: the time to pass through a standard PVC straight pipe (leng...

Embodiment 3

[0067] Embodiment 3 nozzle structure design

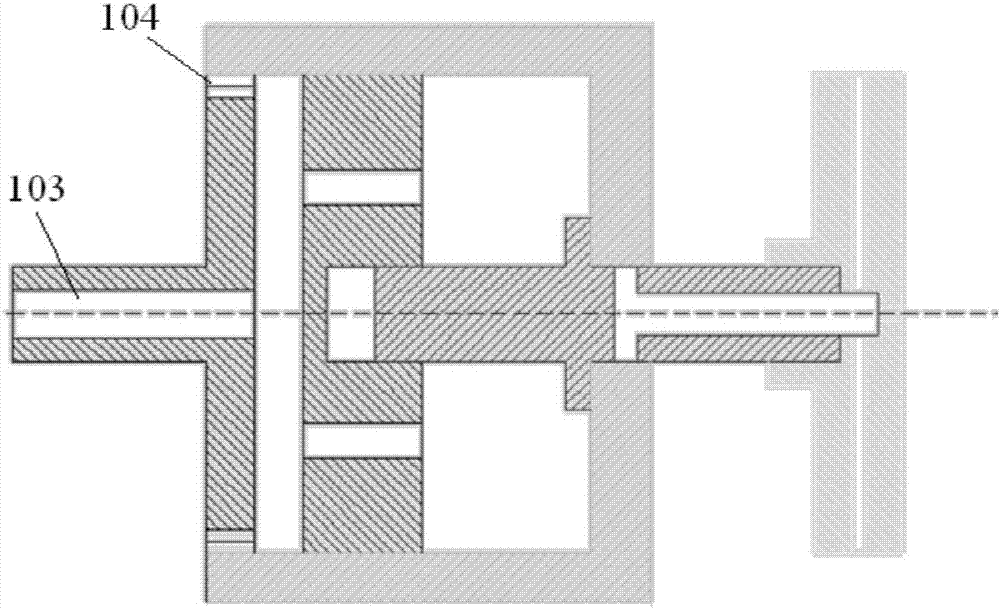

[0068] like image 3 Structurally, the rear nozzle hole 103 is used to push the nozzle forward; the side nozzle hole 104 that can rotate freely is set to test the cleaning ability and rotation ability of the side nozzle hole under different pressures.

[0069] Test performance:

[0070] 1. The nozzle maintains a good passing capacity;

[0071] 2. The side spray holes can clean the pipe wall.

[0072] problem appear:

[0073] Since the side nozzles clean the pipe wall and promote the rotation of the nozzle, the nozzle can rotate under low water pressure, but the cleaning effect is extremely poor. After increasing the water pressure, the cleaning effect is obvious, but the nozzle cannot rotate. Subsequent improvements revolve around the ability to perform spin cleaning while maintaining the forward travel and cleaning capabilities of the nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com