Long-acting weather-resistant color master batch and preparation method thereof

A color masterbatch and weather-resistant technology, applied in the field of polymers, can solve the problems of loss of use value, loss of strength, surface cracking, etc., and achieve the effects of avoiding oxidation and degradation, improving toughness, increasing strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

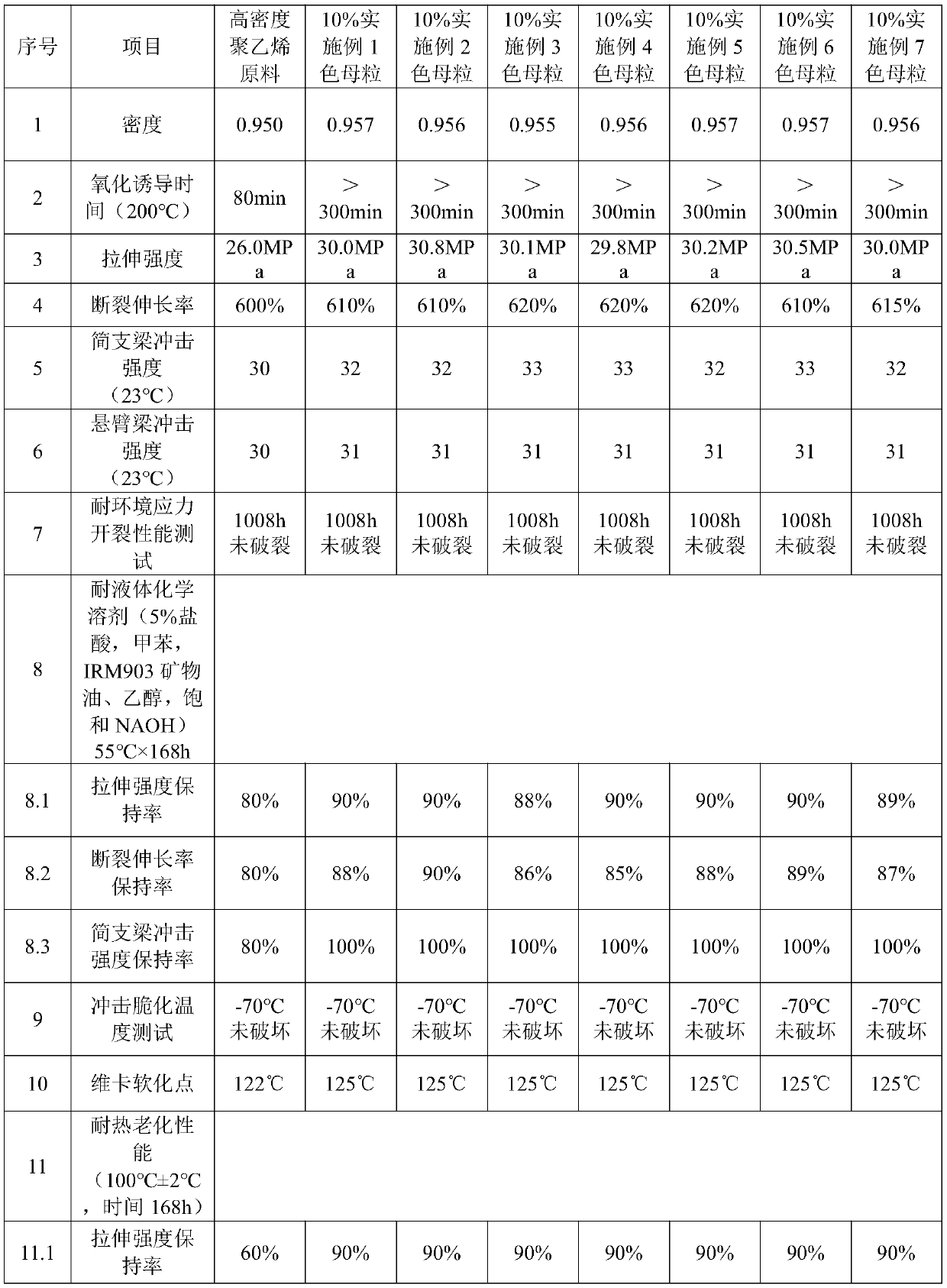

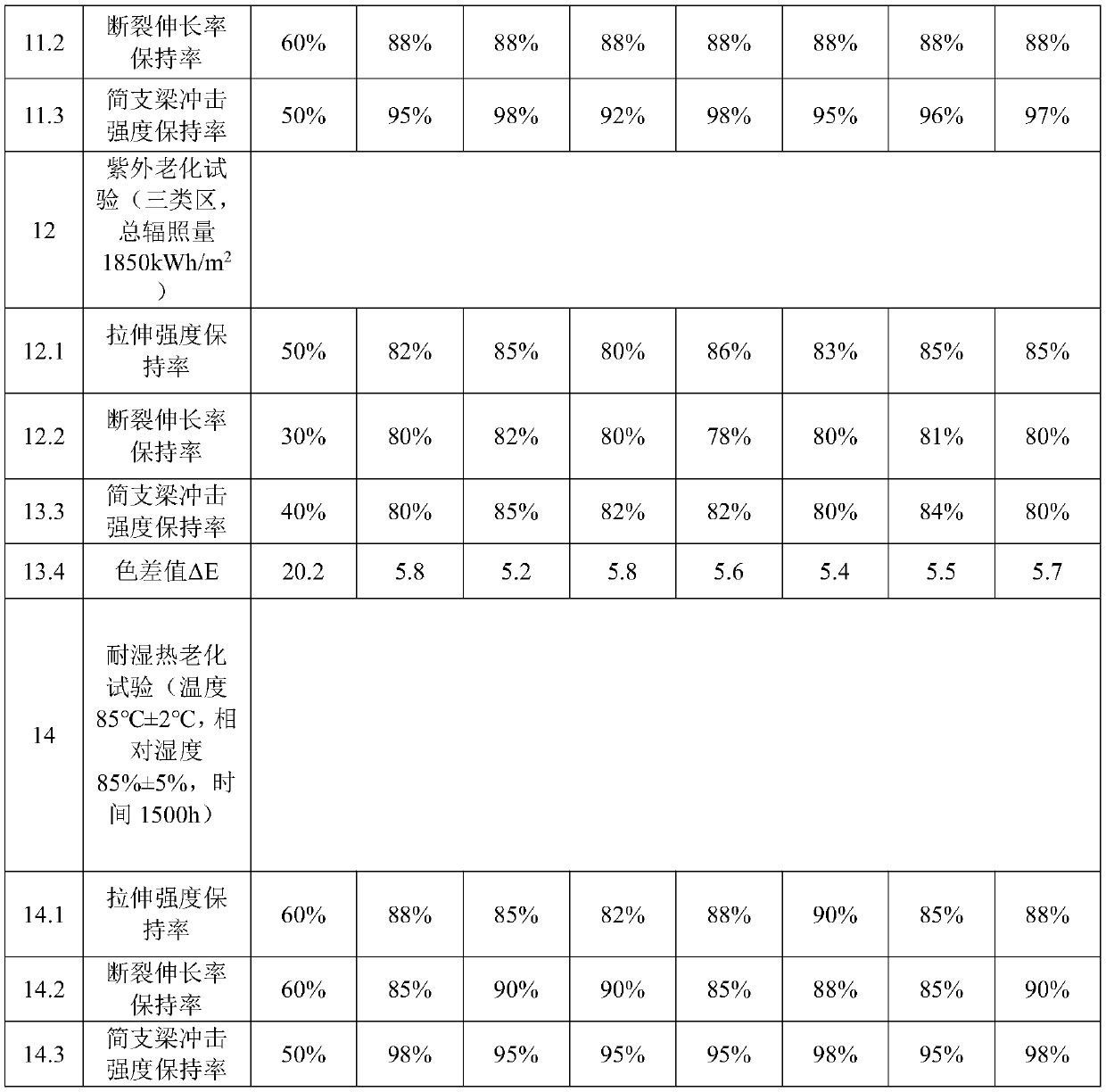

Examples

Embodiment 1

[0027] Step 1, take the following weight ratio raw materials:

[0028] High-density polyethylene 50kg, main antioxidant (hindered phenol antioxidant 1010) 3kg, secondary antioxidant (phosphite antioxidant 168) 3kg, zirconia 2kg, ultraviolet absorber (UV531) 5kg, dispersant B Bis-stearic acid amide 3kg, hindered amine light stabilizer (783) 9kg, titanium dioxide 20kg and pigment (phthalocyanine blue 15:3) 5kg;

[0029] First mix the dispersant with the pigment, then add the high-density polyethylene, antioxidant, zirconia, ultraviolet absorber, hindered amine light stabilizer and titanium dioxide in sequence, and then mix evenly under high-speed stirring conditions to obtain a compound Material, mixing time 18 minutes, mixing temperature 50°C;

[0030] Step 2: Add the above-mentioned compounded materials into the twin-screw extruder for melt extrusion. The temperature of each part of the twin-screw extruder is set as follows: Zone 1 100°C, Zone 2 170°C, Zone 3 180°C, Zone 4 18...

Embodiment 2

[0032] Step 1, take the following weight ratio raw materials:

[0033] High-density polyethylene 53kg, main antioxidant (hindered amine antioxidant 1076) 4kg, auxiliary antioxidant (phosphite antioxidant 168) 2kg, zirconia 1kg, ultraviolet absorber (UV326) 5kg, dispersant B Bis-stearic acid amide 3kg, hindered amine light stabilizer (783) 9kg, titanium dioxide 18kg and pigment (phthalocyanine blue 15:3) 5kg;

[0034] First mix the dispersant with the pigment, then add the high-density polyethylene, antioxidant, zirconia, ultraviolet absorber, hindered amine light stabilizer and titanium dioxide in sequence, and then mix evenly under high-speed stirring conditions to obtain a compound Material, mixing time 15 minutes, mixing temperature 45°C;

[0035] Step 2: Add the above-mentioned compounded materials into the twin-screw extruder for melt extrusion. The temperature of each part of the twin-screw extruder is set as follows: Zone 1 100°C, Zone 2 170°C, Zone 3 180°C, Zone 4 185...

Embodiment 3

[0037] Step 1, take the following weight ratio raw materials:

[0038] High-density polyethylene 52kg, main antioxidant (hindered phenol antioxidant 1010) 4kg, secondary antioxidant (phosphite antioxidant 168) 1kg, zirconia 1kg, ultraviolet absorber (UV327) 3kg, dispersant poly Vinyl wax 2kg, hindered amine light stabilizer (2020) 10kg, titanium dioxide 20kg and pigment (pyrrolopyrrole 254 red) 7kg;

[0039] First mix the dispersant with the pigment, then add the high-density polyethylene, antioxidant, zirconia, ultraviolet absorber, hindered amine light stabilizer and titanium dioxide in sequence, and then mix evenly under high-speed stirring conditions to obtain a compound Materials, the mixing time is 20 minutes, and the mixing temperature is 40°C;

[0040] Step 2: Add the above-mentioned compounded materials into the twin-screw extruder for melt extrusion. The temperature of each part of the twin-screw extruder is set as follows: Zone 1 100°C, Zone 2 170°C, Zone 3 180°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com