High-efficiency foam destroyer adopting metal base composite PTFE (Polytetrafluoroethylene)

A technology of metal matrix composite and PTFE, which is applied in the direction of foam dispersion/prevention, chemical instruments and methods, filtration and separation, etc. It can solve the problem of low smoothness of metal material surface, increased difficulty of maintenance and cleaning of demister, and ineffective collection of thick monofilaments And other problems, to achieve high strength, improve service life, enhance the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

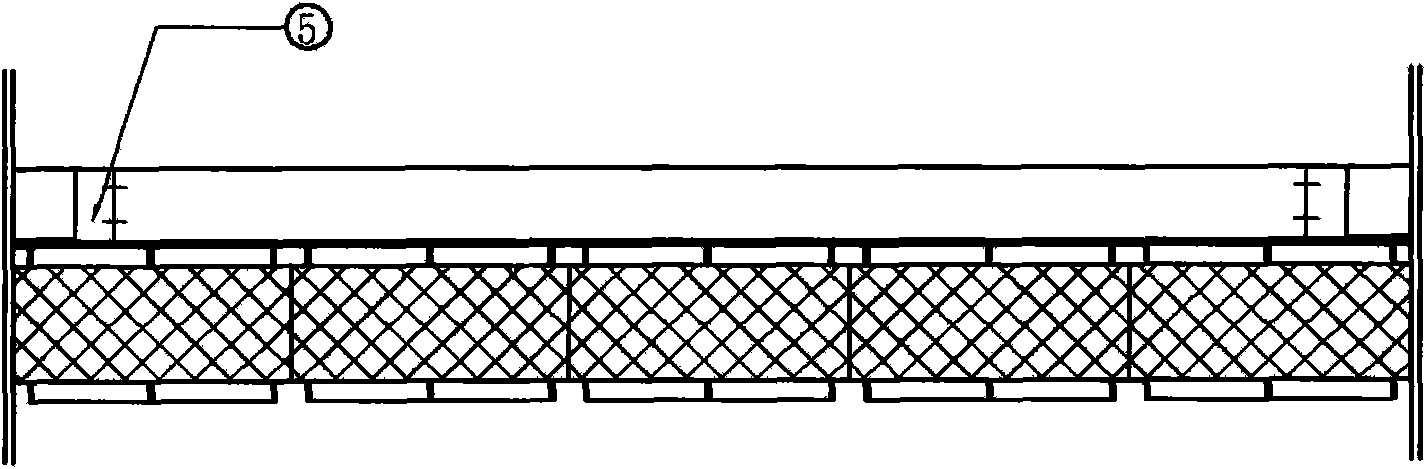

[0025] exist figure 1 Among them, the mesh block composed of metal-based composite PTFE separation mesh is clamped by the upper and lower grids and hoisted under the beam with bolts.

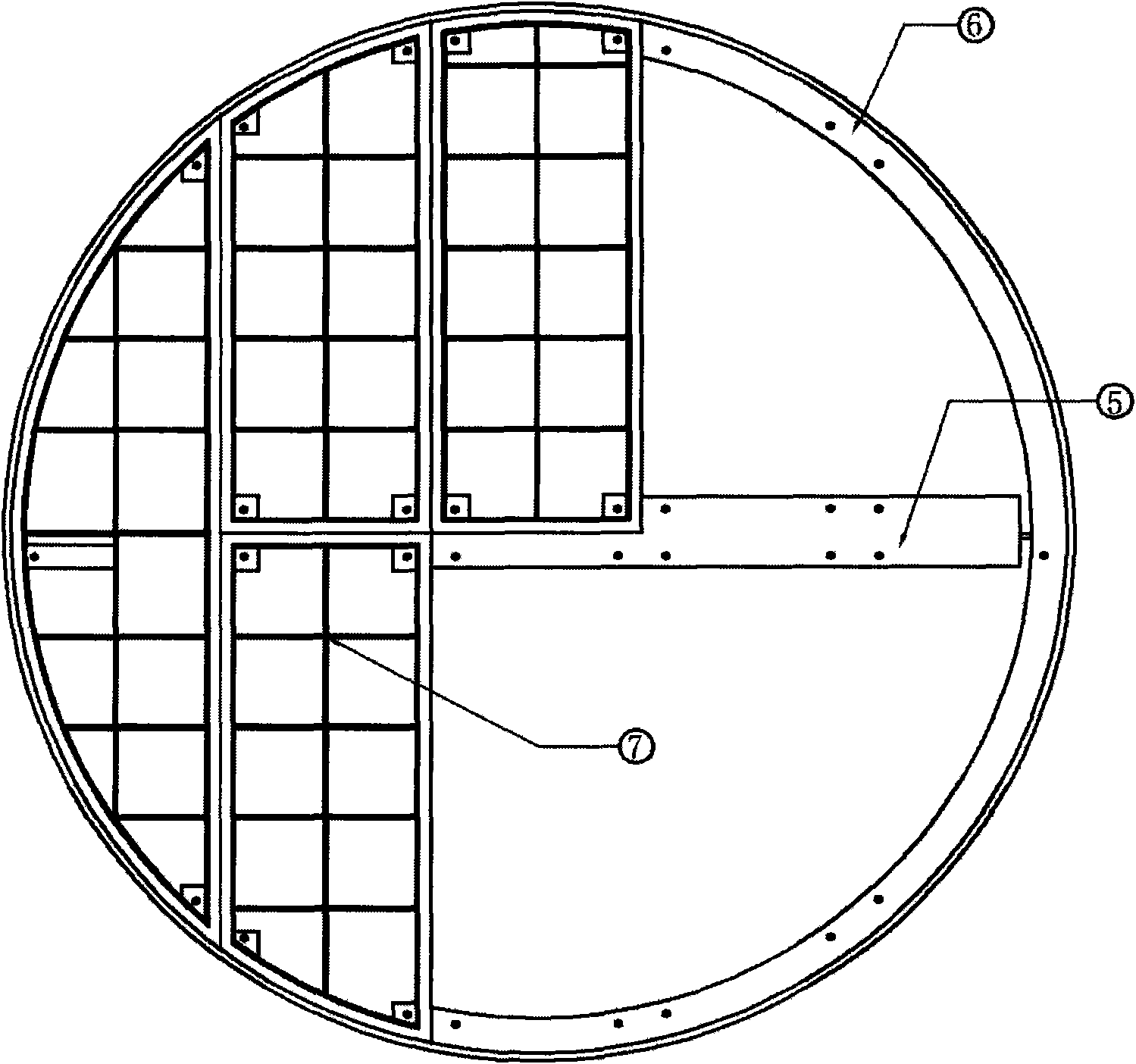

[0026] exist figure 2 , it shows that the bolt holes for hoisting are reserved at the corresponding positions of the support ring, and there are hoisting bolts at the four corners of the mesh block composed of each separated mesh.

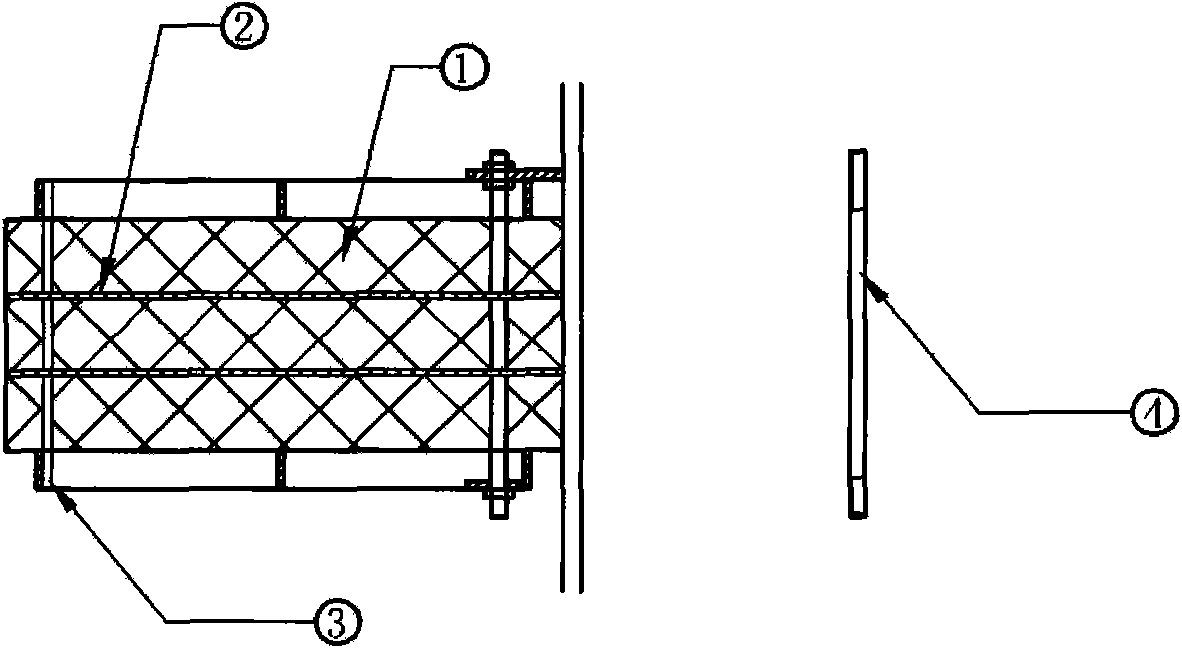

[0027] exist image 3 , shows the composition of each metal-based composite PTFE separation mesh block, which is composed of metal-based composite PTFE separation mesh, layered PTFE porous grid plate and bolt-fixed composite metal grid, in which the layered PTFE porous grid The plate divides the metal-based composite PTFE separation net into equal parts, and the number is determined by the height of the separation net that is actually required.

Embodiment 2

[0029] The manufacture method of described metal matrix composite PTFE separation net is as follows:

[0030] First, add 10% liquid extrusion aid isoparaffin to the PTFE powder, disperse evenly, let stand at a temperature of 40°C for 20 hours, extrude into a rod, pass through a combined roll machine at 60°C, and roll it into a film. Keep a certain speed and release the extrusion aid at a high temperature of about 260°C, prolong the cooling and setting time in the cooling setting furnace, keep at 60°C, add a separating agent to make PTFE start to separate out fibers; during the cooling process, add a certain proportion of water-dispersed PTFE, Composite the fiber into the stainless steel wire; then put the compounded material into the special oil-free self-lubricating multi-head special equipment to make a separation mesh, and add it between the separation mesh with a certain number of layers (generally 10-15 layers). The layered PTFE porous grid plate increases the collision o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com