Cable for LVDS (Low-voltage Differential Signal) transmission

A signal transmission and cable technology, which is applied in the field of signal transmission wiring harness and its production process, can solve the problems affecting signal quality, etc., and achieve the effect of meeting the requirements of the use environment, light weight, good vacuum stability and ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

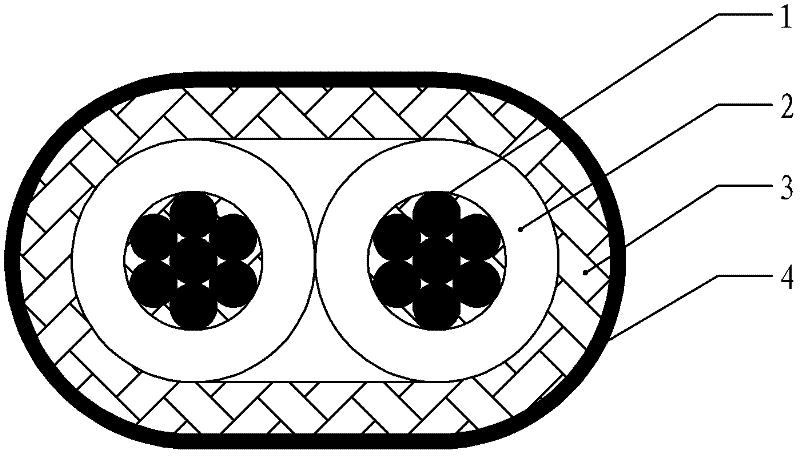

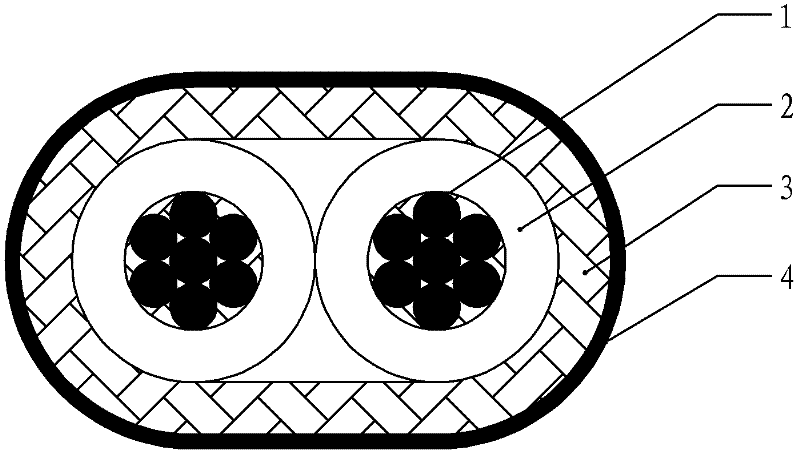

[0019] Specific implementation mode one: see figure 1 Describe the cable used for LVDS signal transmission described in this embodiment. The wire harness described in this embodiment is composed of two wire harnesses 1, a shielding layer 3 and a sheath 4, and each wire harness 1 is wrapped with an insulating layer 2. The two wire harnesses 1 are located inside the shielding layer 3, and the sheath 4 is located outside the shielding layer 3. The outer diameter of the shielding layer 3 is 1.05mm±0.03mm. Each wire harness 1 is composed of multiple wires twisted. The diameter is 0.16mm.

specific Embodiment approach 2

[0020] Specific embodiment 2: This embodiment is a further limitation of the structure of the wire harness 1 in the cable for LVDS signal transmission described in the specific embodiment 1. In this embodiment: each wire harness 1 can be composed of 7 wires Twisted composition, the nominal outer diameter of the 7 wires after twisted should be 0.48mm±0.01mm.

[0021] In the 7-wire twisting process, the stability of the pitch and outer diameter must be strictly controlled, that is, to ensure the consistency of the outer diameter of the entire wire harness 1.

[0022] In this embodiment, the pitch diameter ratio of the wire harness should not be greater than 16 and not less than 8, and the optimal parameter is 10±1.

[0023] The length asymmetry of the wire harness in this embodiment should not be greater than 5%.

[0024] The tension of the wire harness in this embodiment should be uniform.

[0025] In this embodiment, the wire may be a silver-plated copper wire, a silver-plat...

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is a further limitation of the cable structure for LVDS signal transmission described in Embodiment 1. In this embodiment, the insulating layer 2 is extruded by extrusion-grade polytetrafluoroethylene dispersion resin. Made or sintered by wrapping PTFE turning film.

[0032] When the insulating layer 2 is extruded from extrusion-grade polytetrafluoroethylene dispersion resin, the extruded concentricity should not be less than 90%. During the extrusion process of the insulating layer 2, the extruded concentricity and outer diameter should be strictly controlled.

[0033] When the insulating layer 2 is formed by wrapping and sintering 1 to 3 layers of polytetrafluoroethylene turning film, the wrapping overlapping ratio should be controlled by 50-52%, or 67-69% or 75-77%, so that the insulation The layer thickness is uniform. The outer diameter of the insulating layer 2 is 1.05mm±0.03mm. During the wrapping process of the insulating layer 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com