Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Meet performance index requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

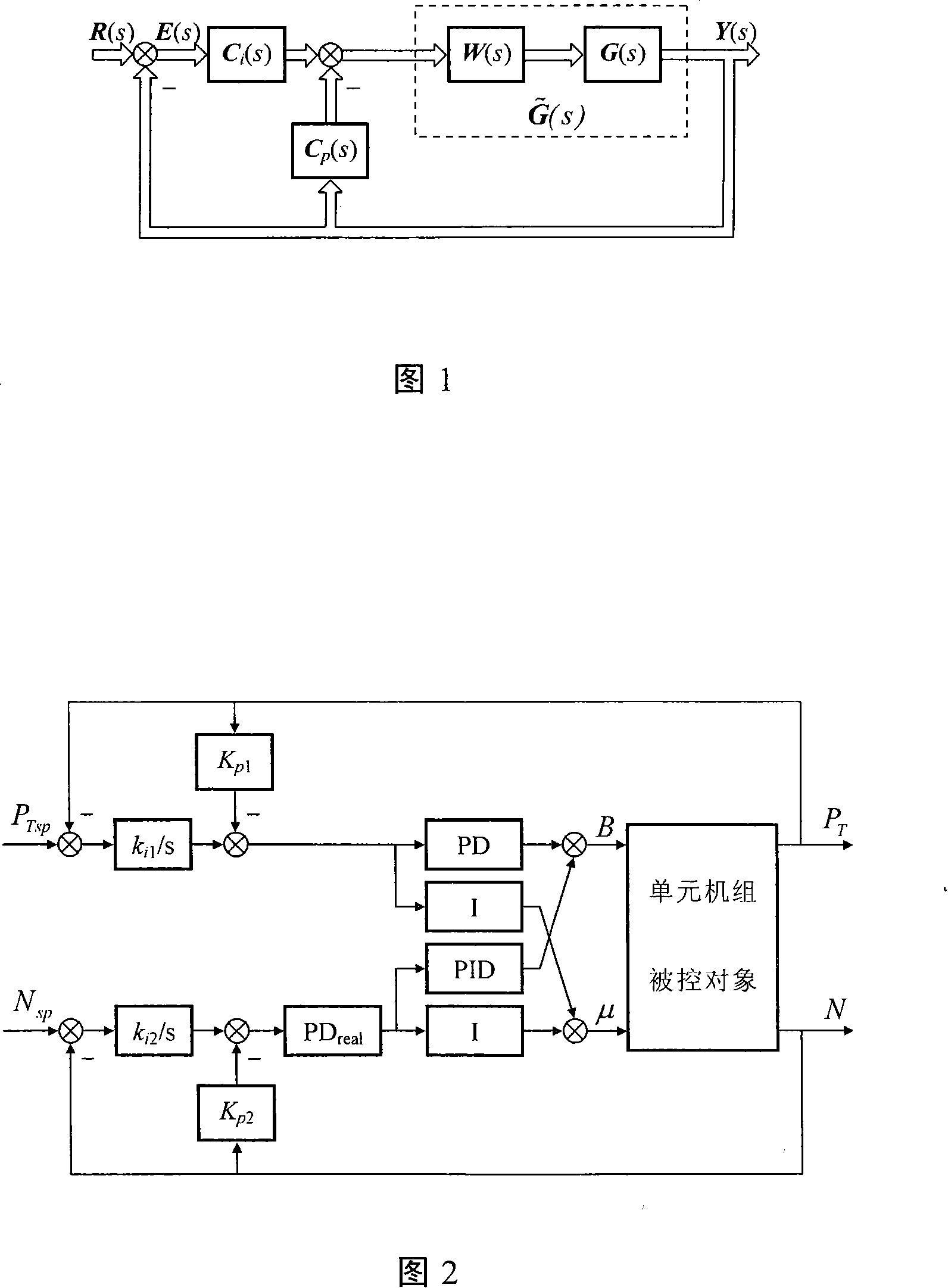

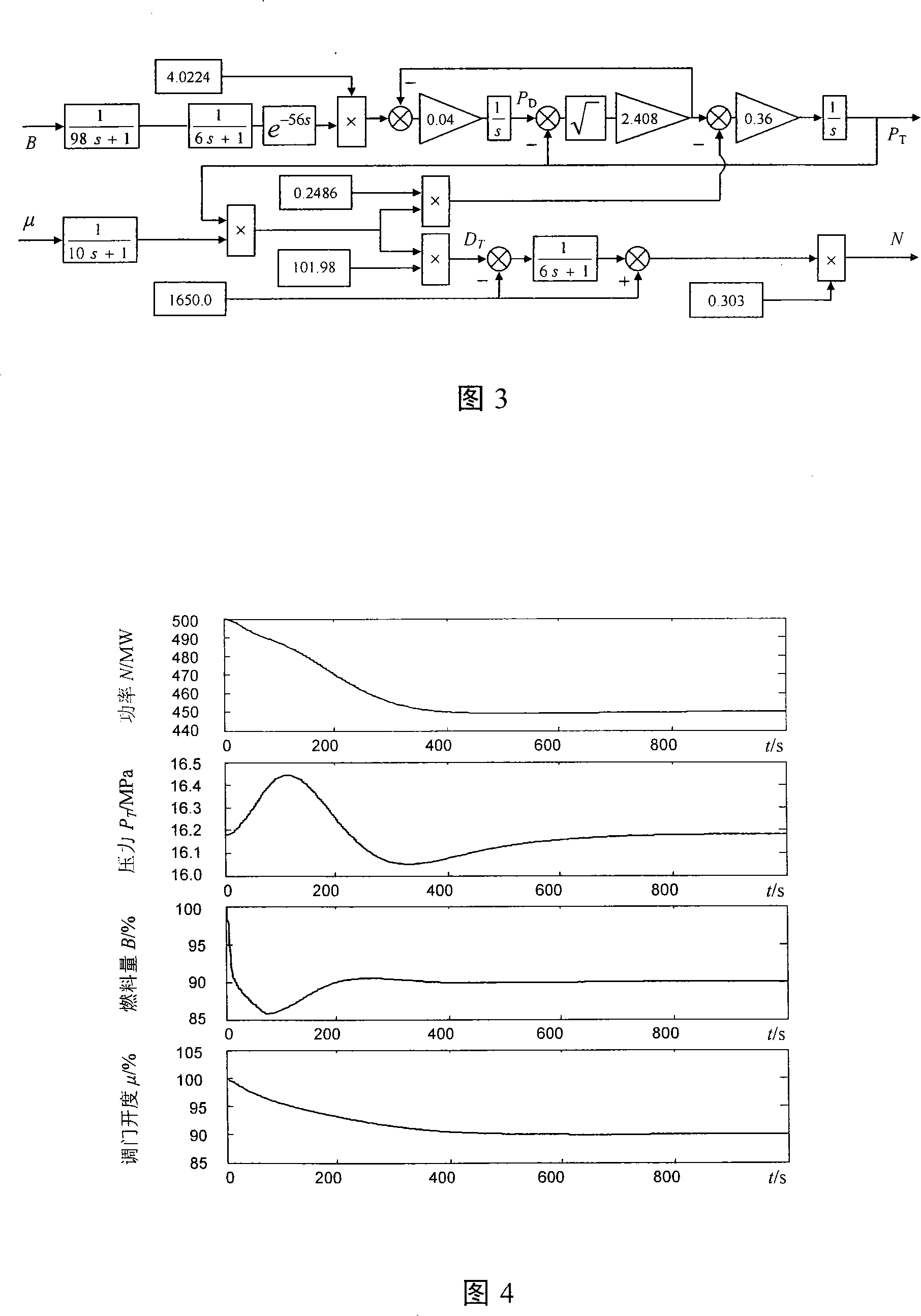

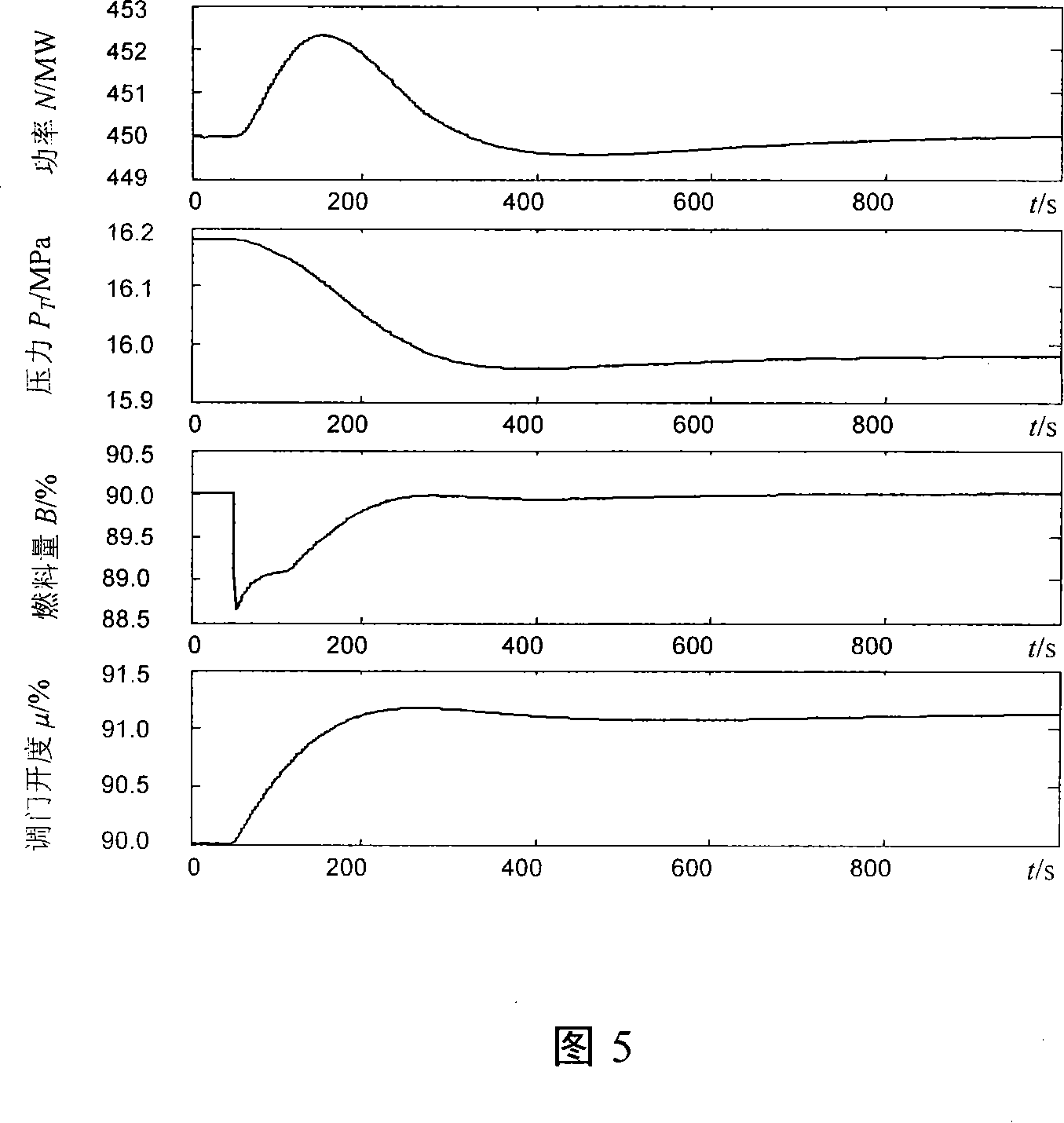

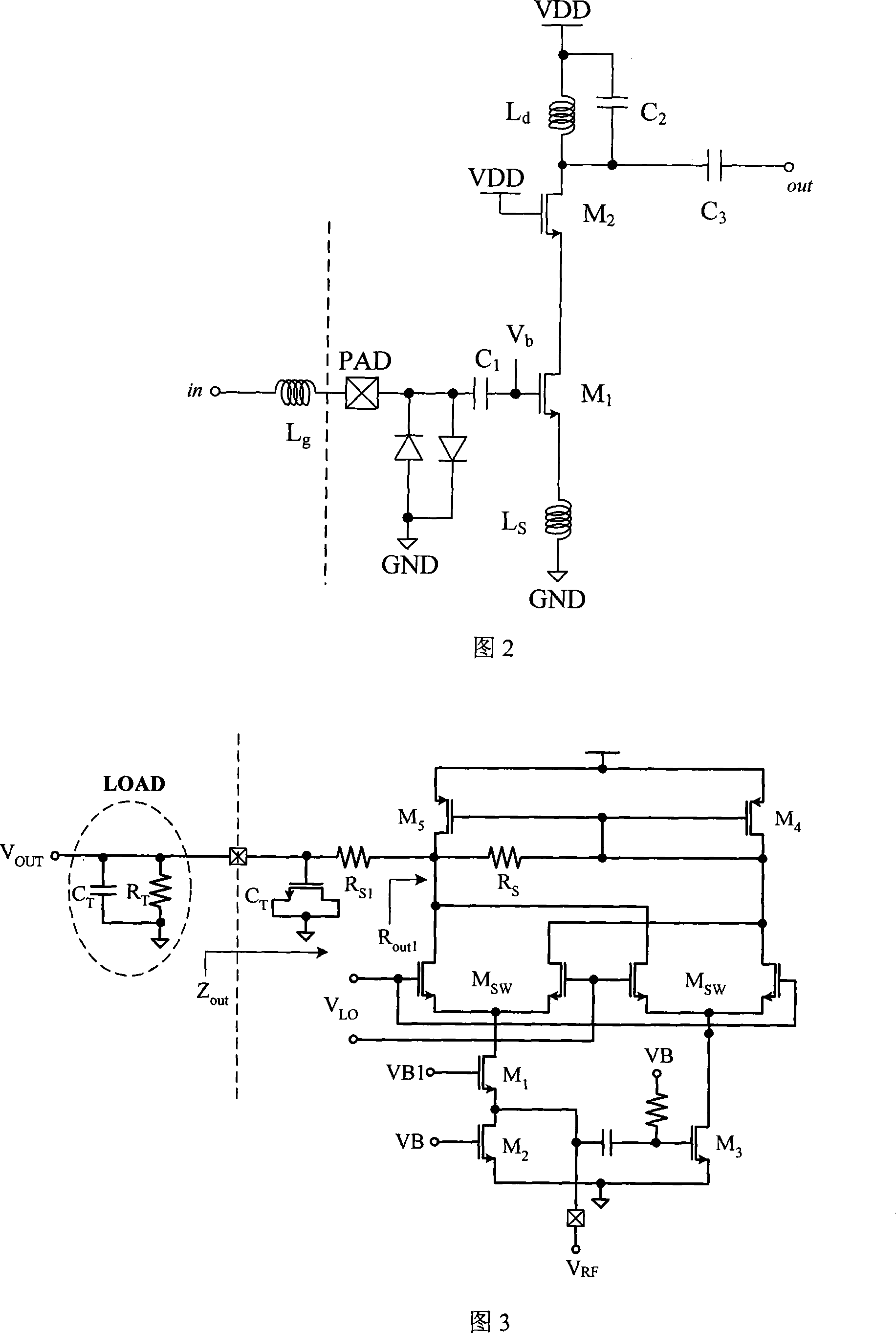

PID parameter setting method for monobloc generator group coordination and control system

InactiveCN101131571AEasy to tuneMeet performance index requirementsElectric generator controlAdaptive controlGroup coordinationMathematical model

This invention discloses a sort of method of the PID parameter setting of the coordinated control system of the cell-system generating set which belongs to this area of the control technique of the set. This method identifies the multivariable dynamic mathematic model of the unit plant according to the universal structural style. Used the series decoupling principle and the two-degree of freedom control structure the coordinated control system of the unit plant which has the PID form is thought out based this model, thereby the each setting step of the related parameter are get in this system by combining the theoretical derivation and the engineering test. This invention has this character in that the consecution is clear; the practicability is good, and it fits to engineering apply. The engineering technical personnel structures the corresponding coordinated control system expediently, and combines the engineering test aimed at the unit plant of various group, it sets out the related parameter of this system availably.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

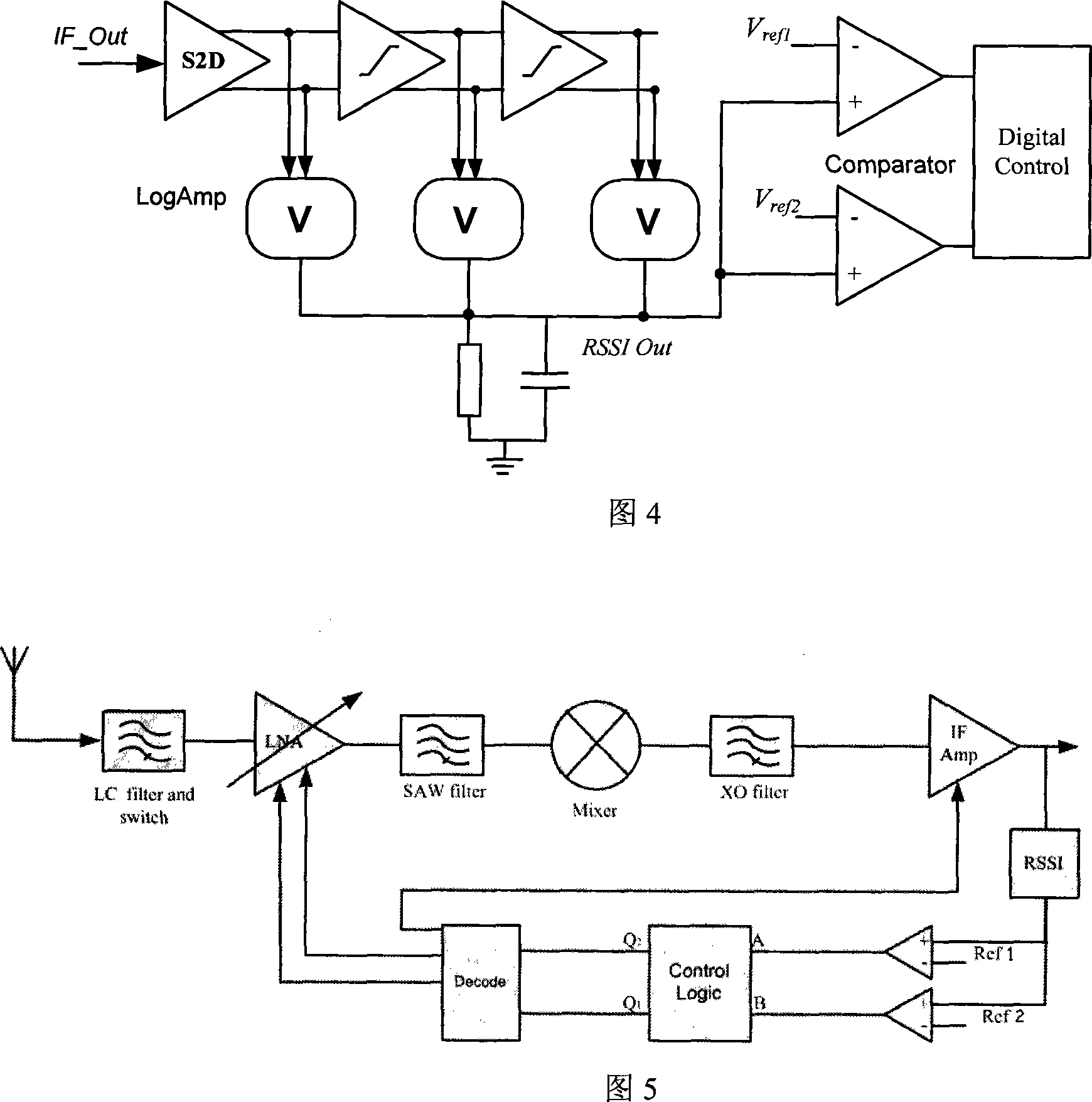

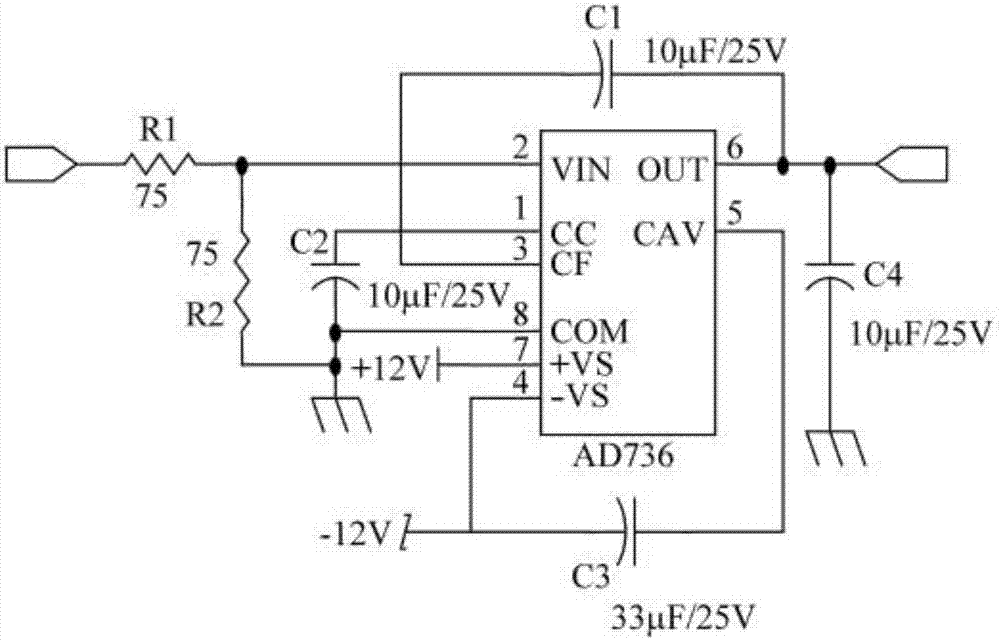

Single chip radio frequency transceiver

InactiveCN101162912AHighly integratedMeet performance index requirementsTransmissionTransceiverIntermediate frequency

A radio frequency transceiver of single chip includes a radio frequency receiving part, a radio frequency sending part, a local oscillation part, a reference voltage source and a current bias part. A low noise amplifier, a mixer and a intermediate frequency amplifier possessed by the radio frequency receiving part, an automatic gain regulator adjusting the gain of the radio frequency receiving part according to the intension of the received signal, a power adjuster and a buffer amplifier of a delivered power possessed by the radio frequency sending part, a voltage controlled oscillator, a frequency synthesizer and a crystal oscillator possessed by the local oscillation part, the reference voltage source and the current bias part are integrated to the single chip. The single chip has an input end and an output end of the received signal, which are connected with the receiving part, a filtering end connected with a filter at the outside, an input end and an output end of a signal to be emitted, which are connected with an emission part and a clock signal output end, a signal control end and an oscillation signal input end which are connected with the local oscillation part. In this way, the integration of the radio frequency transceiver is improved greatly.

Owner:上海富太克投资咨询有限公司

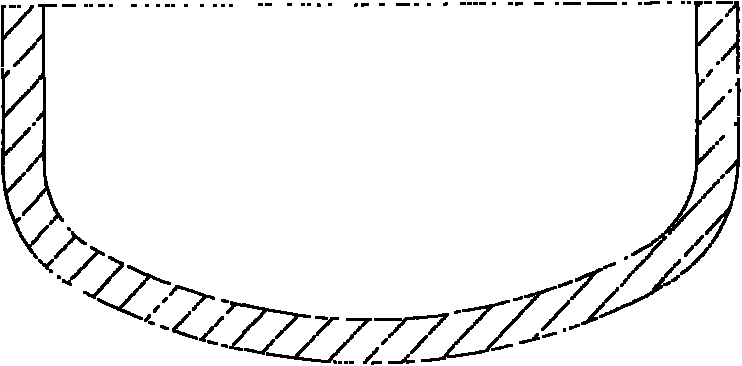

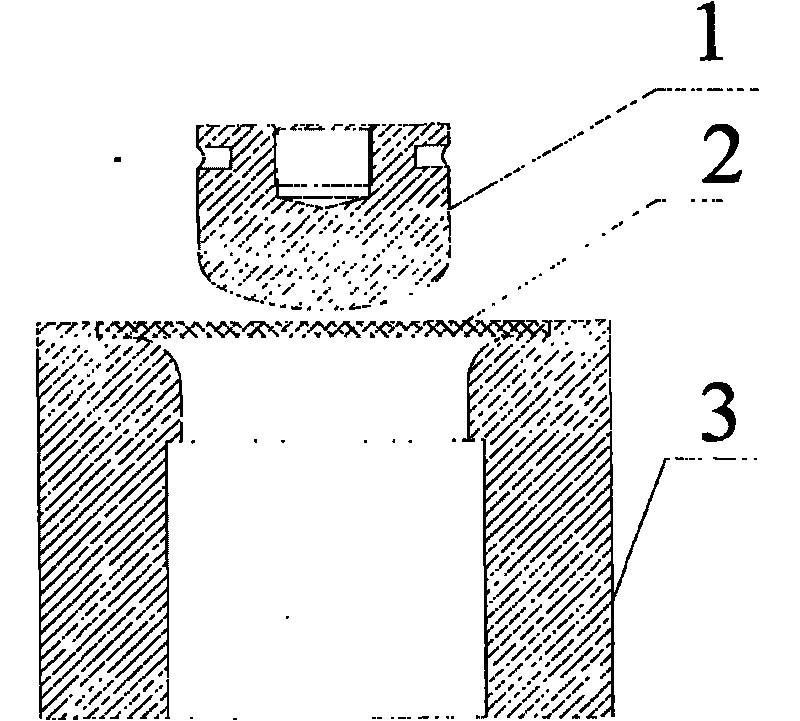

Simple forming process of seal head for titanium alloy cylinder

InactiveCN101745784AReduce productionReduce changeover processShaping toolsPlasma welding apparatusManufacturing technologyPunching

The invention relates to a machining process and a manufacture technique of metal materials, in particular to a simple forming process of a seal head for a titanium alloy cylinder. The process comprises the following steps: increasing the thickness of a blank during the design of a die, and correspondingly increasing the die clearance; blanking; preprocessing the blank, and heating to a temperature of 20-50 DEG C below a transformation point by using an electric furnace; preheating the die to 300 plus or minus 20 DEG C; ensuring the forming temperature to be within the alloy forging temperature range and avoiding overlarge temperature difference between the die and the blank; and punching by multiple heating numbers to finish the forming process. A product manufactured by adopting the process meets the technique data requirement. Compared with a common forming process with multiple heating numbers, the invention reduces the manufacture of at least one set of die, reduces a working procedure of changing tools during producing the dies, reduces the cost by more than 40 percent and shortens the production cycle by more than 50 percent.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

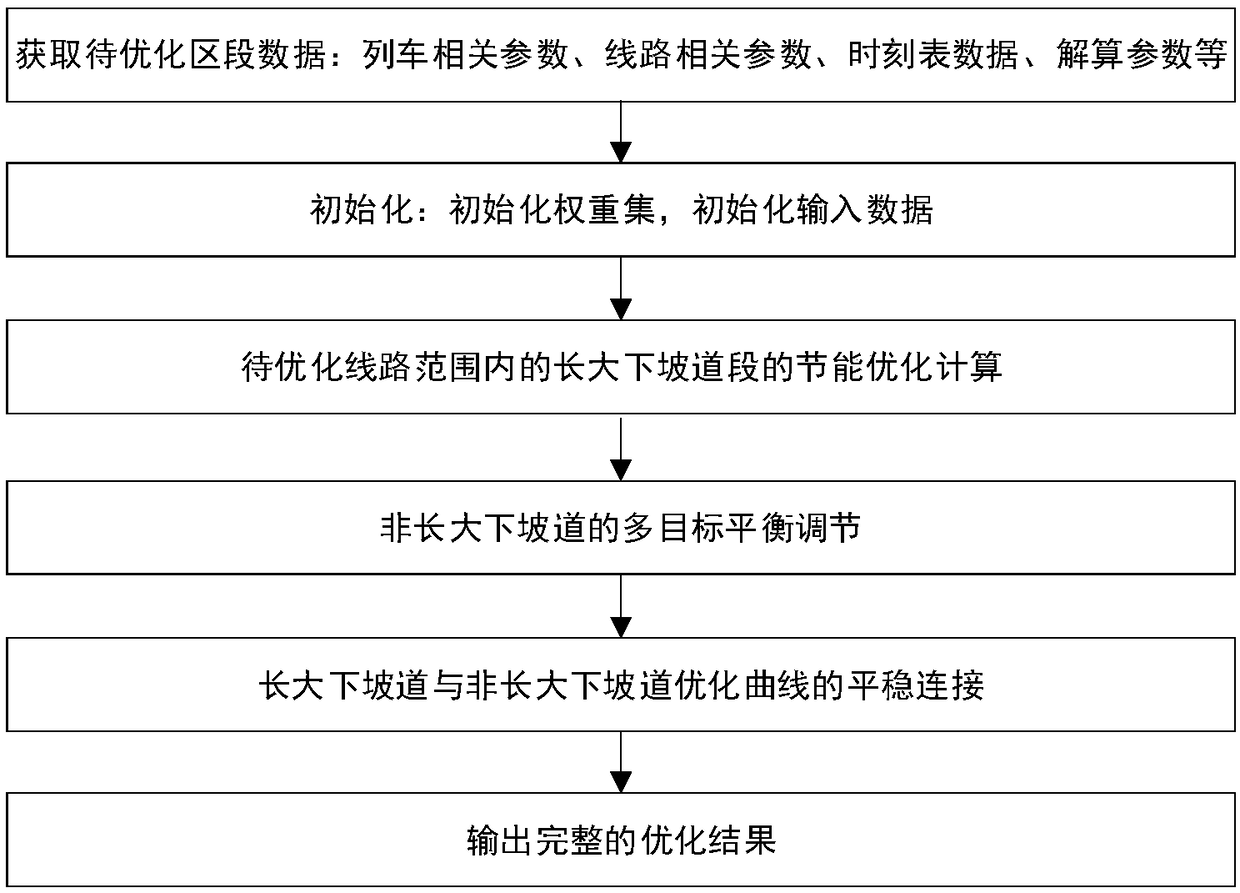

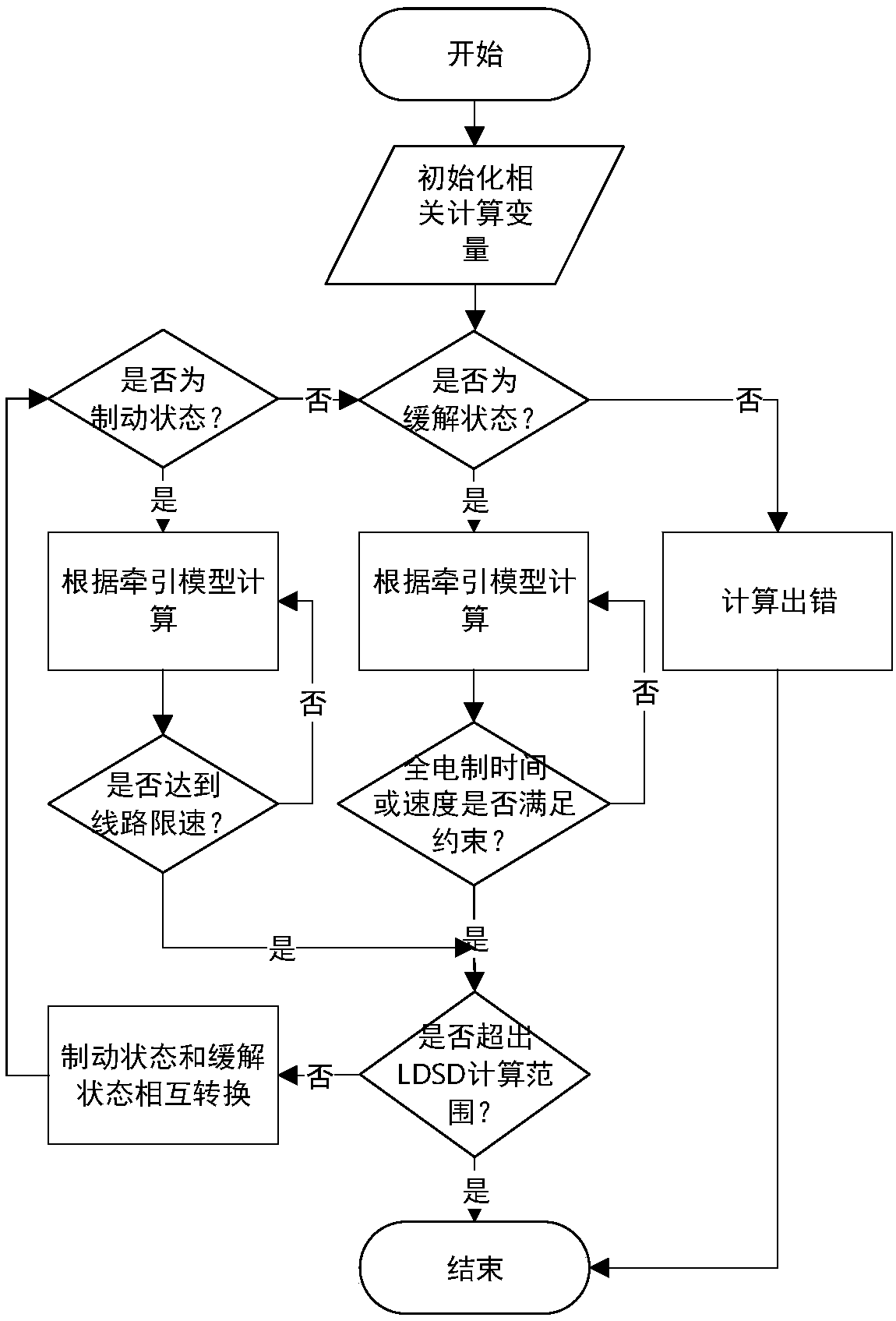

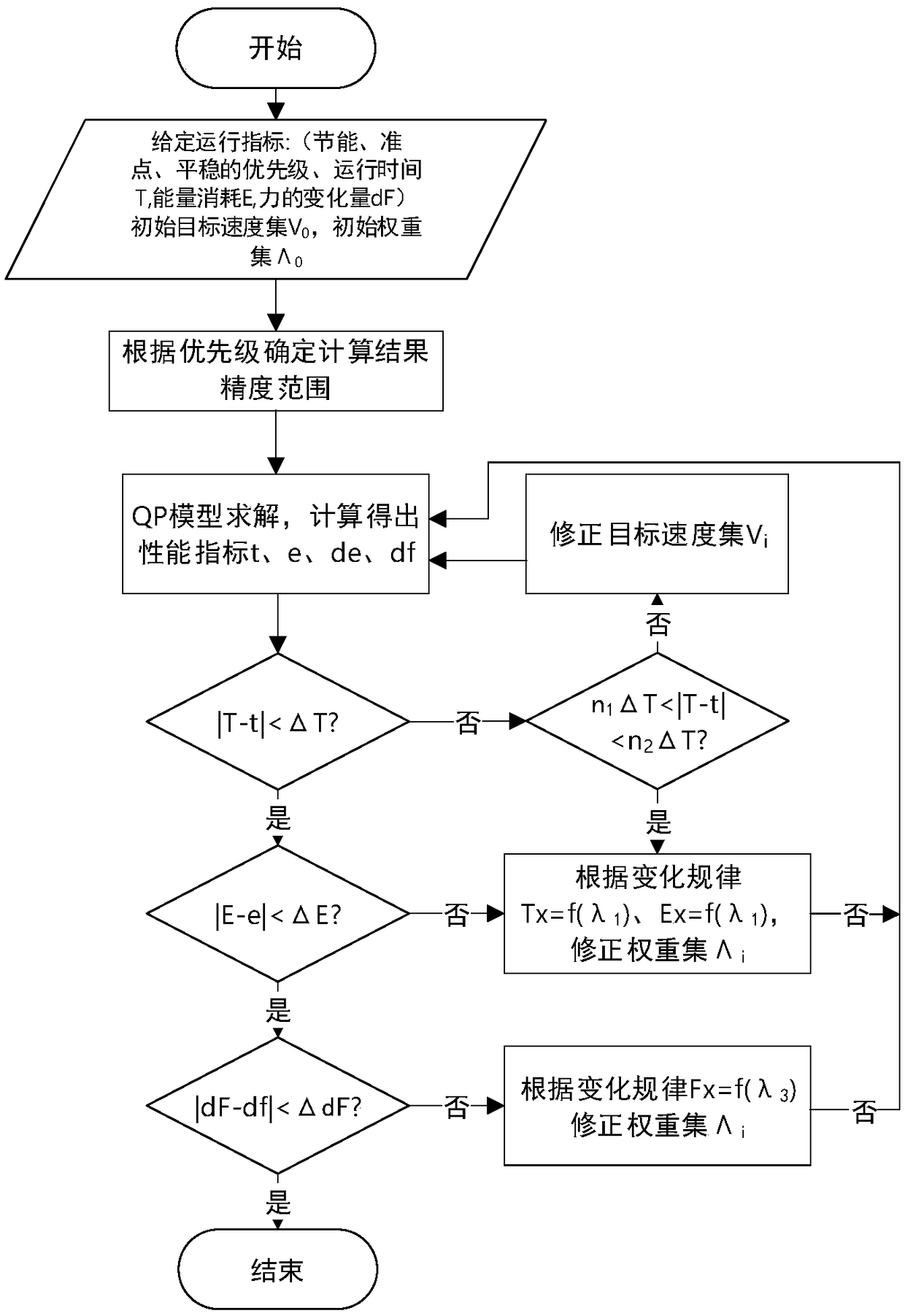

Multi-objective optimization method for operation of heavy-load train

ActiveCN108764571AMeet performance index requirementsSatisfy global optimizationForecastingRailway traffic control systemsSteep slopeGlobal optimization

The invention discloses a multi-objective optimization method for operation of a heavy-load train. The method comprises the following steps of S1, acquiring to-be-optimized section data, wherein the to-be-optimized section data includes a locomotive, vehicle information, marshalling information, line data, line speed limit, time table data and the like; S2, initializing a weight set of an objective function, and the relevant data in the step S1; S3, performing numerical solving for train operation optimization of all long and steep slope sections in a to-be-optimized line range to obtain an energy-saving optimization curve; S4, for multi-objective balance adjustment of a non-long and steep slope, comprehensively utilizing a quadratic programming model and a weight self-adaptive adjusting method, thereby obtaining a stable and energy-saving optimization curve meeting operation indexes; S5, for curve results solved in the steps S3 and S4, performing transition connection meeting the operation stability of the train; and S6, outputting a complete train speed optimization curve. The method has the advantages that on the basis of safety and on-time, stable and energy-saving operation global optimization of the heavy-load train in the whole process including the long and steep slope and the non-long and steep slope is realized.

Owner:SOUTHWEST JIAOTONG UNIV

Improved particle swarm algorithm for automatic optimization of control law parameters of unmanned aircraft

InactiveCN101551642AFaster convergence timeImprove performanceVehicle position/course/altitude controlAdaptive controlPerformance indexParticle swarm algorithm

The invention relates to an improved particle swarm algorithm for automatic optimization of control law parameters of an unmanned aircraft. The particle swarm algorithm is based on an iterative optimized algorithm; control parameters are initialized to be a group of random solutions; and optimal values are found by iteration; the improved particle swarm algorithm is characterized by comprising the following steps of: in the particle swarm algorithm, introducing a crossover operator, selecting a plurality of particles in which the optimal position value of single particle is positioned in the middle to carry out random two-two crossover; generating offspring particles with the same number; replacing parent particles with offspring particles; selecting crossover time according to convergent algebra of the standard particle swarm algorithm, namely, 17 to 20 generations for pitching and yawing channel and 7 to 10 generations for rolling channel; and selecting algebra of disturbing start as follows: starting from twelfth generation for the pitching and yawing channel and starting from fourth generation for the rolling channel. The improved particle swarm algorithm expands the range of understanding the space, has total searching capacity; the obtained parameters can meet given performance indexes; and the algorithm can save design time and has application value of engineering.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

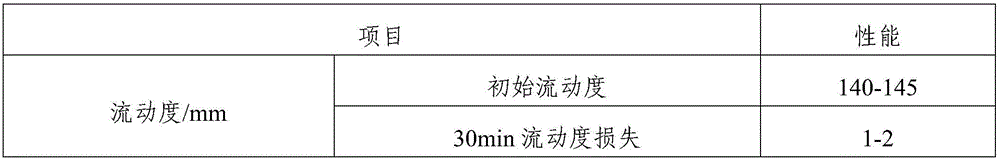

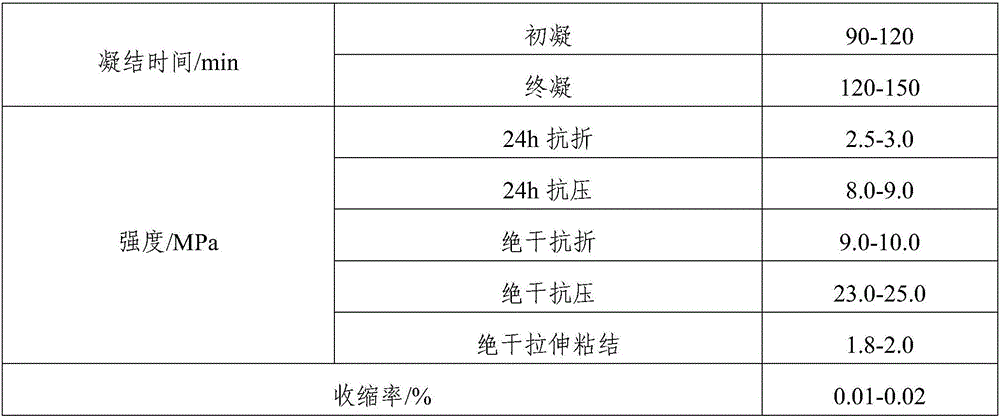

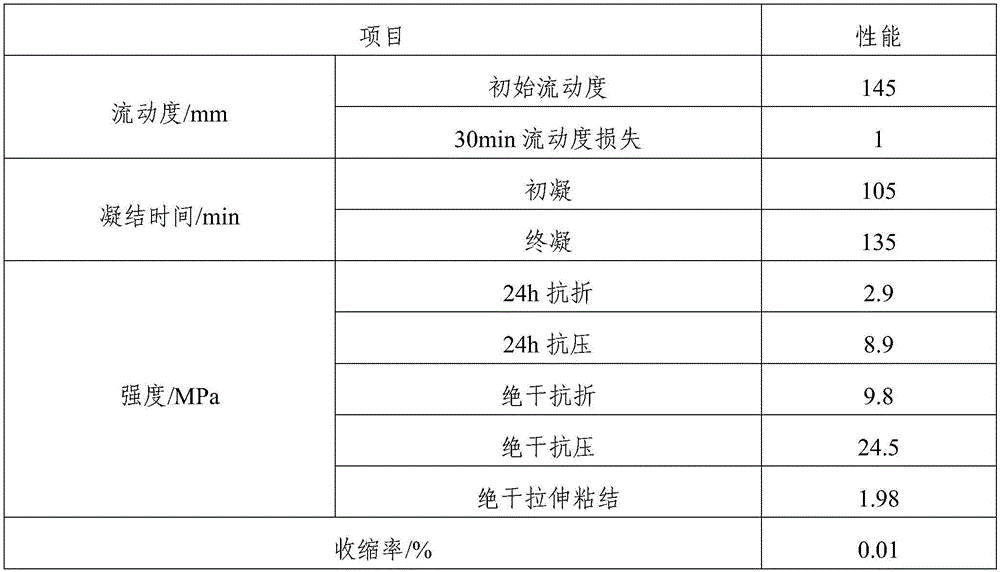

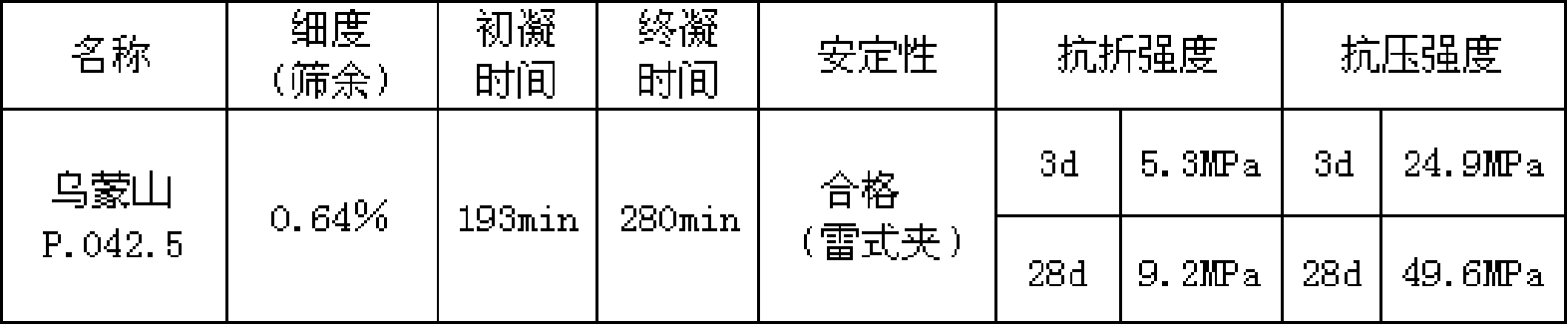

Gypsum-based self-leveling mortar prepared from fine iron tailing sand, and preparation method thereof

ActiveCN106220115AImprove microstructureReduce water consumptionSolid waste managementPerformance indexGypsum

The invention relates to a gypsum-based self-leveling mortar prepared from fine iron tailing sand and a preparation method thereof. According to the invention, the raw material fine iron tailing sand of three particle size grades, i.e., less than 0.1 mm, no less than 0.1 mm and no more than 0.3 mm, and no less than 0.3 mm and less than 0.5 mm, is compounded according to a certain proportion. The method totally replaces river sand or quartz sand with the fine iron tailing sand; the prepared gypsum-based self-leveling mortar has excellent performance and completely meets requirements on all the performance indexes prescribed in JC / T1023-2007; moreover, the gypsum-based self-leveling mortar prepared from fine iron tailing sand is obviously reduced in cost, wherein the cost of each ton of the gypsum-based self-leveling mortar is reduced by 30 yuan or above.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +2

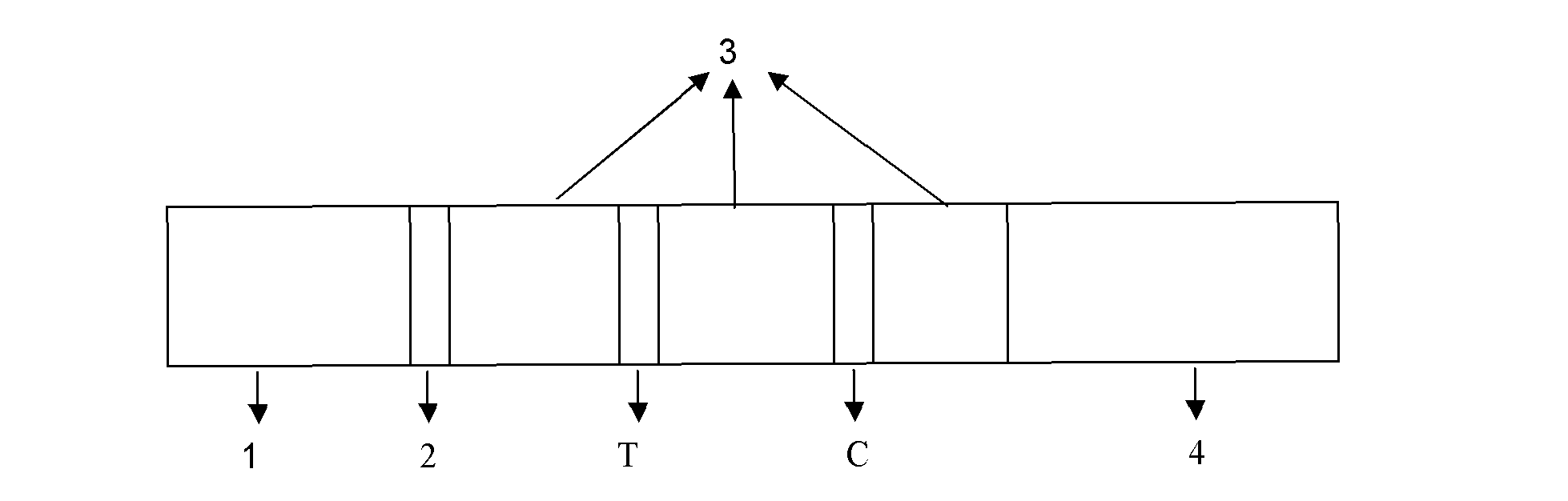

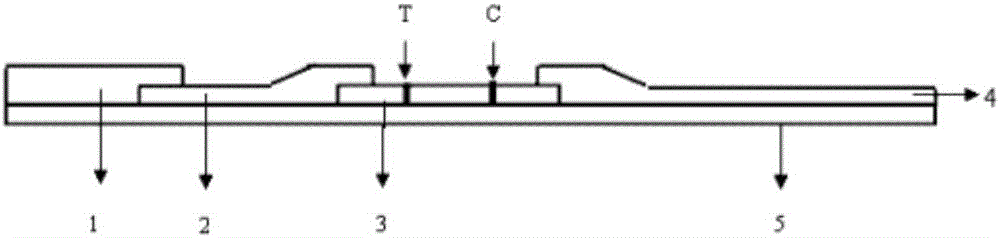

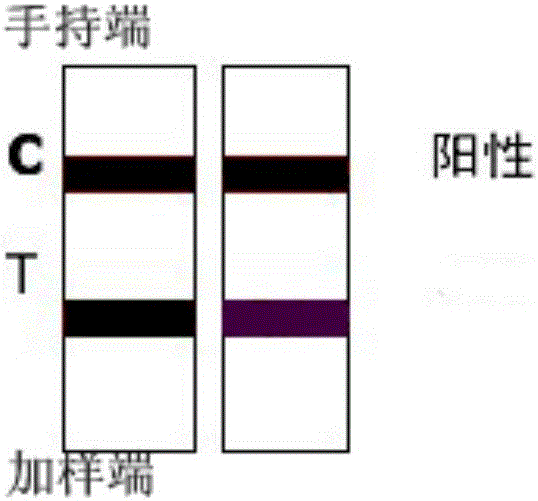

Ketamine-collaurum test paper for detection of saliva

The invention provides ketamine-collaurum test paper for detection of saliva. The ketamine-collaurum test paper comprises a reaction film and a gold mark cushion, wherein according to the reaction film, a reaction line and a quality control line are formed by respectively coating ketamine and quality-control secondary antibodies IgG (immunoglobulin G) connected with carrier protein on a nitrocellulose film (NC film); the gold mark cushion is coated with ketamine monoclonal antibodies marked with collaurum; and a film chromatography competitive inhibition method is adopted to detect the ketamine in a saliva sample. The test paper can be used for effectively monitoring the ketamine in saliva, the detection specificity is strong, the repeatability is good, the sensitivity is high, and the lowest detection quantity reaches 50ng / ml. The test paper is simple to operate, does not need special instruments and equipment, does not need professional training and has clear and obvious results, thus being suitable for field detection.

Owner:戴国华

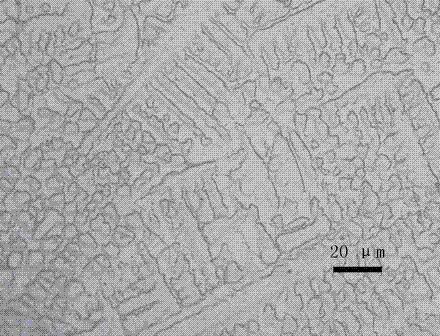

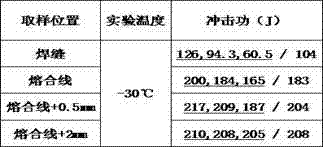

Ultrahigh-strength full-austenite stainless steel welding wire

InactiveCN102962602AHigh tensile strengthImprove toughnessWelding/cutting media/materialsSoldering mediaUltimate tensile strengthToughness

The invention provides an ultrahigh-strength full-austenite stainless steel welding wire, comprising the following chemical components in mass percentage of: 0.05-0.11% of C, 0.50-0.90% of Si, 4.0-6.0% of Mn, 16.0-19.0% of Cr, 19.0-22.0% of Ni, 5.0-6.5% of Mo, 0.25-0.35% of N, 0.15-0.30% of V, less than or equal to 0.010% of S, less than or equal to 0.015% of P and the residue of Fe. The smelting metal of the welding wire not only has the ultrahigh tensile strength, but also has good toughness; the tensile strength Rm is 735-790 MPa and KV2 reaches to 110-140 J at 20 DEG C below zero; the manufacturability is good; compared with a previously-matched manual electric welding strip, the welding efficiency of the welding wire is improved by more than 100%; and the welding without pre-heating at higher than 0 DEG C is realized and a welding process is simplified.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Continuous hot-pressing method for large-section section

InactiveCN102107454AIncrease temperatureImprove plasticityWood working apparatusFlat articlesMicrowaveSingle plate

The invention discloses a continuous hot-pressing method for a large-section section. The method comprises a pretreatment process, a continuous hot-pressing process and a post-treatment process, and is characterized in that: the continuous hot-pressing process comprises the following steps of: A, preheating and prepressing; B, hot-pressing and curing; and C, cooling to guarantee quality. In the method, a continuous blanking mode is adopted, the preheating and the prepressing are increased, and a microwave or high-frequency heating technology is adopted during hot pressing. By the method, a non-lumber small-diameter class bamboo material, a secondary material of poor quality, a single-plate residual material, saw dust and the like are machined into a high-quality material; and the method has the advantages of wide material sources, simple and convenient material manufacturing process, high utilization rate of the material, convenience of operation, low energy consumption, investment saving and the like. Meanwhile, the method can be used for machining the material with any length in a continuous pressing mode and can also be used for machining the material with the thickness of 500mm.

Owner:陈滔

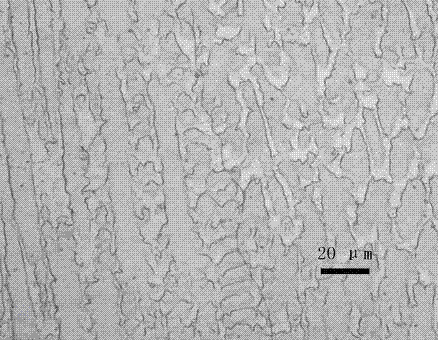

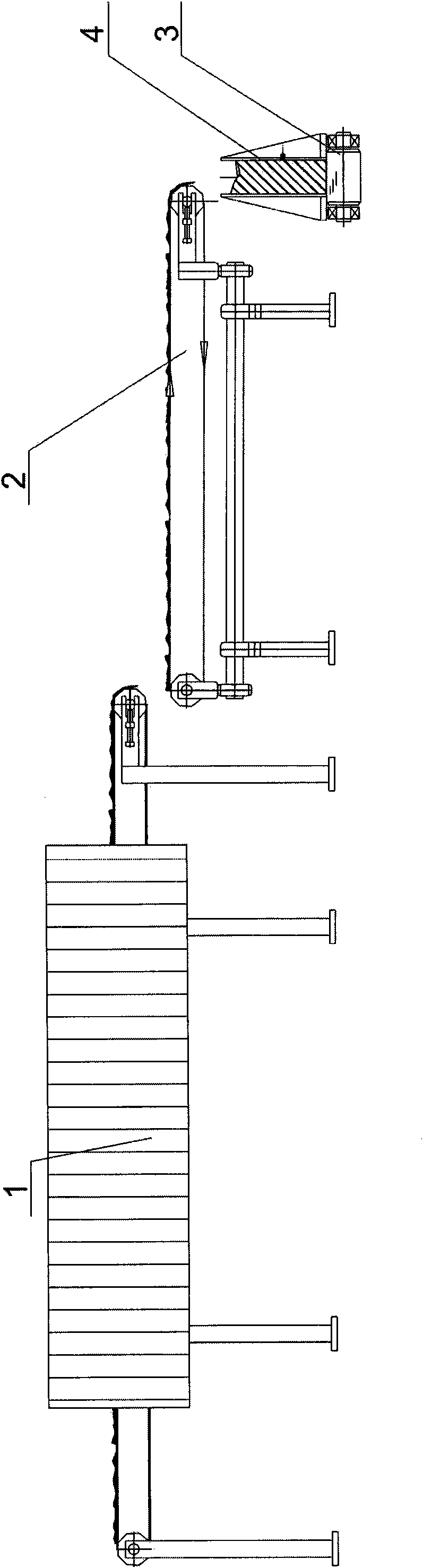

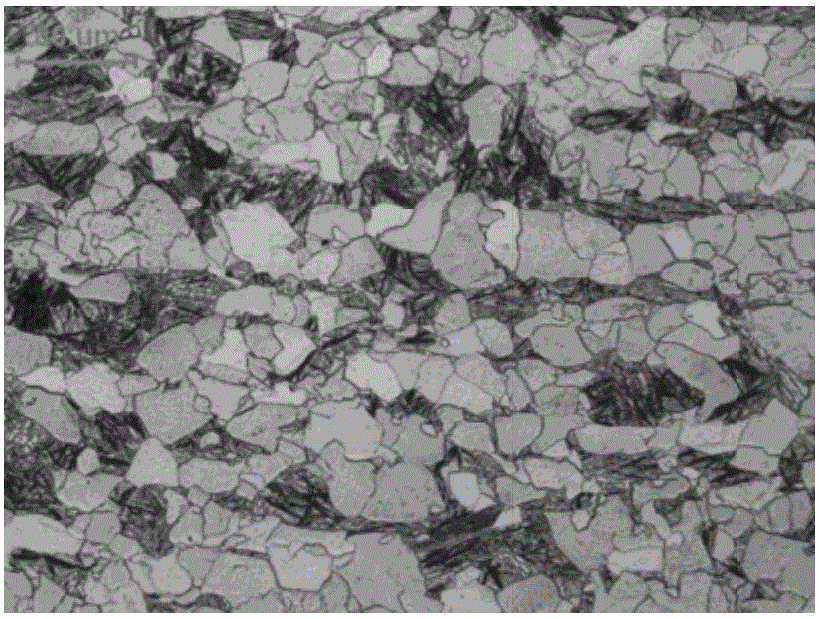

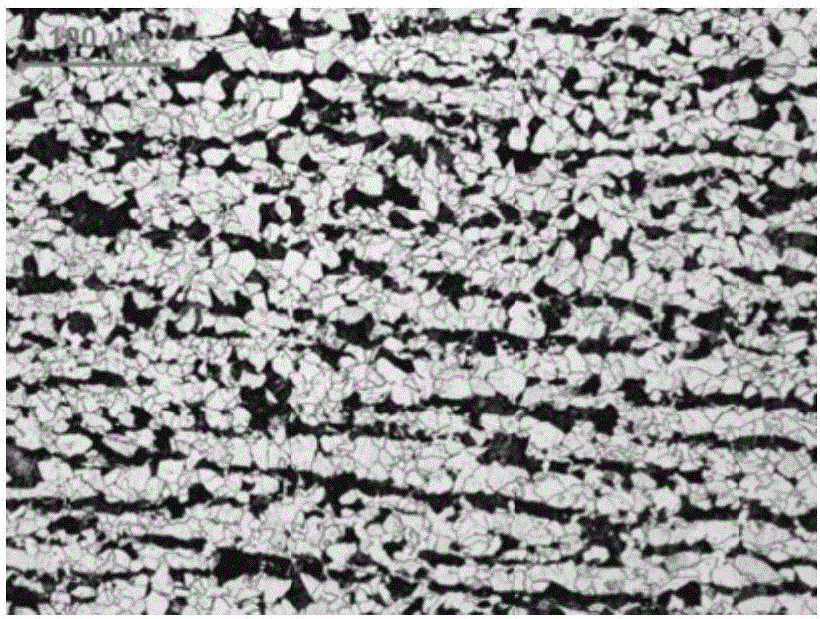

Welding process for longitudinal weld joints of submerged-arc welding for high-strength pipeline steel

ActiveCN102380694AImprove performanceImprove impact toughnessArc welding apparatusWelding/cutting media/materialsTemperature controlHeat treated

The invention belongs to the technical field of welding of high-strength pipeline steel, and relates to a welding process for longitudinal weld joints of submerged-arc welding for high-strength pipeline steel. Chemical components of high-strength pipeline steel comprise 0.04%-0.06% of C, 0.08%-0.10% of Si, 1.2%-2.0% of Mn, 0.09%-0.10% of Nb+V+Ti+Zr, 0.2%-0.4% of Mo, 0.8%-1.2% of Ni+Cr+Cu, P equal to or less than 0.004%, S equal to or less than 0.001% and the balance being Fe. Steel comprises carbon equivalent Ceq equal to or less than 0.53% and Pcm equal to or less than 0.22%. Chemical components of welding wires comprise 0.08% of C, 1.75% of Mn, 0.80% of Si, 0.003% of S, 0.010% of P, 0.138% of Cu, 0.41% of Cr, 0.53% of Mo, 2.22% of Ni, 0.011% of Al, 0.05% of Ti, 0.015% of V, 0,01% of Zr, and the balance being Fe. An X-shaped groove is utilized for the submerged-arc welding, the angle of the groove is 90 degrees, the truncated edge is 4.8mm, the heat input in welding is 21kj / cm, the welding current ranges from 450-800A, the arc voltage ranges from 32V to 38V, and the welding speed is 170cm / min. Preheating before welding, heat treatment after welding, interlayer temperature control are all eliminated, weld joints have excellent comprehensive performances, and various areas of the weld joints have fine impact ductility reserve and safety allowance.

Owner:NANJING IRON & STEEL CO LTD +1

Long pumping distance machine-made sand concrete

ActiveCN101164959AEnsure mixing qualityQuality assuranceSolid waste managementCrushed stoneWater reducer

This invention relates to a high delivery lift type machine-finished sands concrete. The raw materials are (by weight ratio): cement 400-425, machine-finished sands 780-800, broken stone (grain size=5-16mm)300-310, broken stone (16-25mm) 700-720, water 155-160, coal ash 75-80, water reducing agent 18-24. This inventive concrete has better working properties, its delivery lift can be up to 200m. It can make the equipment being at normal operation.

Owner:GUIZHOU BRIDGE CONSTR GROUP

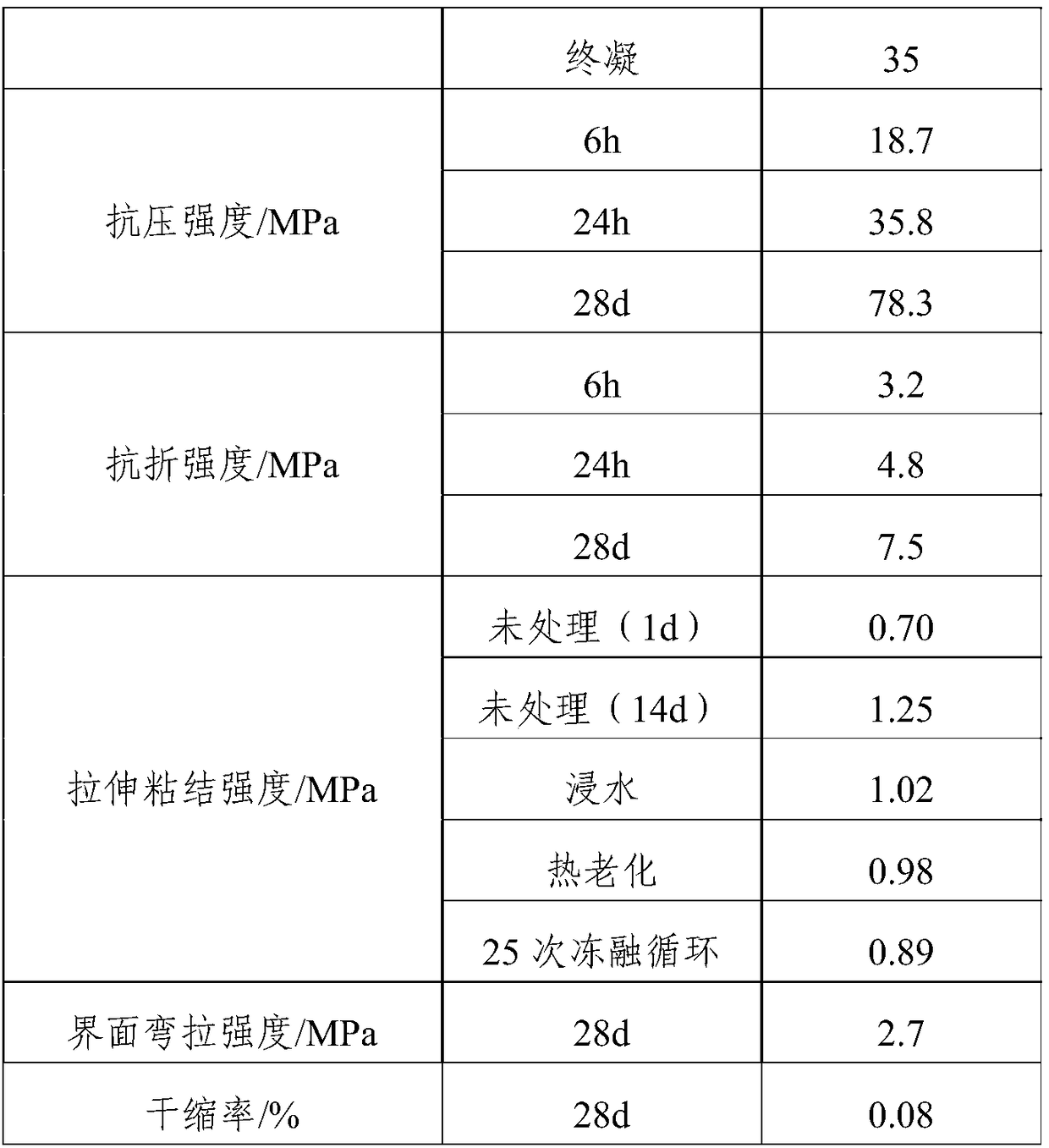

Coal ash and mineral powder-based geopolymer quick setting type rigid repair mortar and preparation method thereof

ActiveCN108585649AReduce production energy consumptionImprove performanceCement productionSolid componentChemical admixture

The invention provides quick setting type rigid repair mortar prepared from industrial byproducts such as coal ash, mineral powder and tailing fine sand as well as a preparation method of quick setting type rigid repair mortar. The coal ash and mineral powder-based geopolymer quick setting type rigid repair mortar consists of a solid component material and a liquid component liquid; the solid component material is formed by combining the coal ash, the mineral powder, the tailing fine sand and a chemical additive according to a certain proportion; the liquid component material is formed by mixing a sodium hydroxide solution with a certain concentration, waster glass and water according to a certain proportion; and the solid component material and the liquid component material are stirred completely and uniformly according to a certain proportion, and the quick setting type rigid repair mortar can be used. The coal ash and mineral powder-based geopolymer quick setting type rigid repair mortar prepared by the method has excellent performance and completely meets each perform index requirement of JC / T 2381-2016. The main raw materials of the coal ash and mineral powder-based geopolymerquick setting type rigid repair mortar are industrial byproducts such as the coal ash, the mineral powder and the tailing fine powder and belong to environment-friendly materials.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

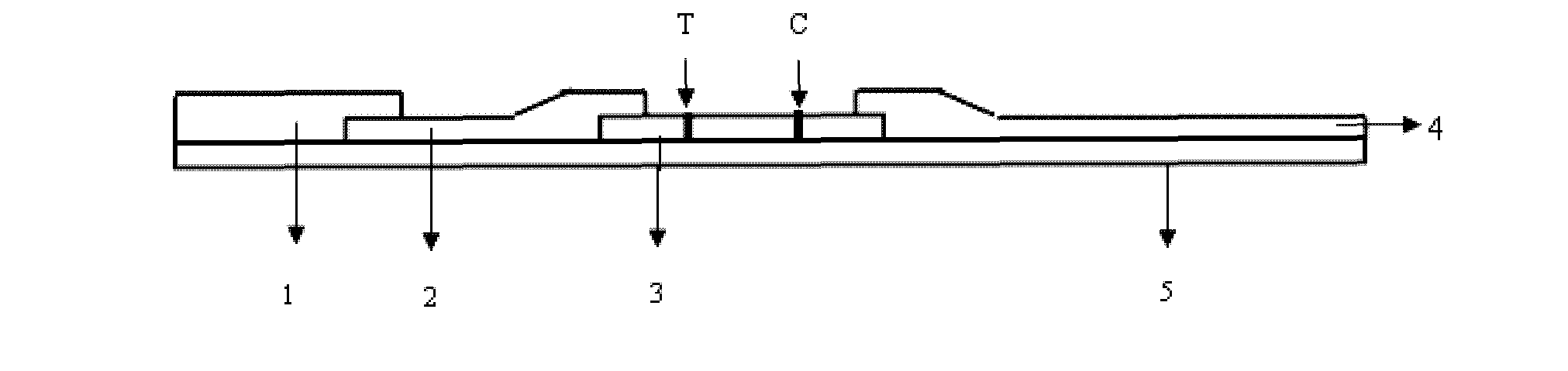

C reactive protein saliva test paper strip and preparation method thereof

ActiveCN106370861AOptimizing Process ParametersMeet performance index requirementsBiological material analysisBiological testingFiberPolyester

The invention belongs to the field of bio-detection and particularly relates to a C reactive protein saliva test paper strip and a preparation method thereof. The C reactive protein saliva test paper strip includes a reactive film and a gold marker pad. The reactive film is a nitrocellulose membrane, which has a detection line coated with a C reactive protein monoclonal antibody and a quality control line coated with goad-anti-mouse IgG. The gold marker pad is a polyester membrane that is coated with the C reactive protein monoclonal antibody marked by colloidal gold. The test paper strip, with human saliva as a detection sample, can effectively monitor the C reactive protein in saliva. The test paper strip has strong specificity and good repeatability, has high sensitivity, is 10 mg / L in lowest detection limit, is easy to operate and is free of special instruments and devices and professional training, has clear and distinguishable result and is easy to promote, and is suitable for on-site test.

Owner:BEIJING JINHUAKE BIOLOGICAL TECH

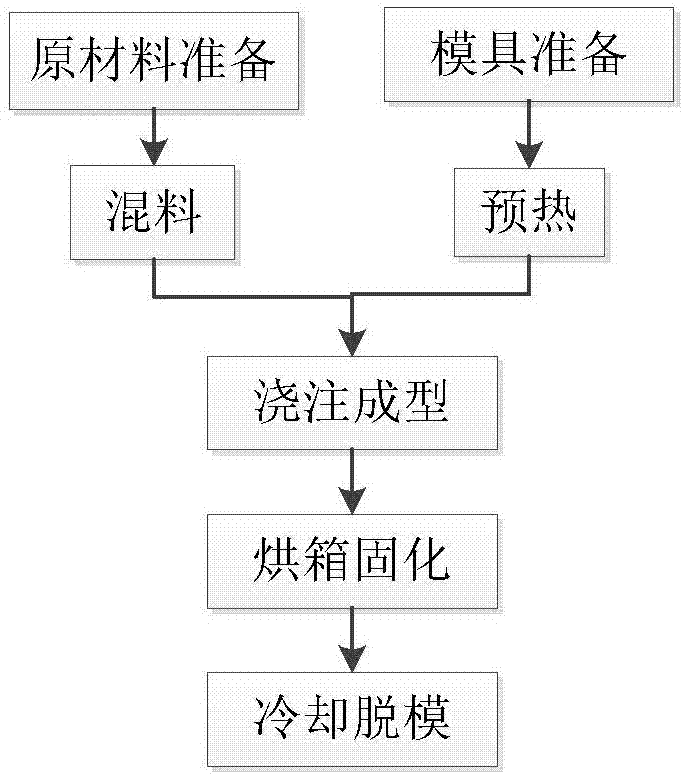

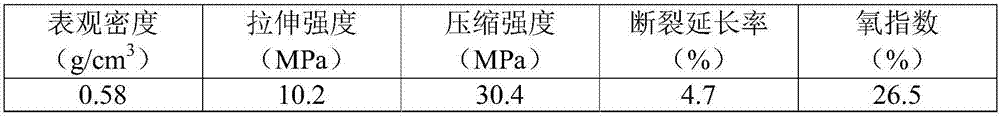

High-strength hard flame-retardant epoxy foam material and preparation method thereof

The invention relates to a high-strength hard flame-retardant epoxy foam material and a preparation method thereof. The epoxy foam material is prepared from the following ingredients in parts by weight: 100 parts of epoxy resin, 10 to 50 parts of curing agent, 0 to 40 parts of inorganic hollow filler, 1 to 5 parts of dispersing agent, 1 to 5 parts of surface active agent, 1 to 5 parts of coupling agent, 5 to 15 parts of diluent, 1 to 5 parts of antiager and 5 to 10 parts of flame retardant. In preparation, the curing agent is molten in 120 to 140 DEG C at first, the epoxy resin is added to be evenly mixed with the curing agent in a low speed, and temperature is adjusted to 30 to 50 DEG C; the dispersing agent, the surface active agent, the inorganic hollow filler, the flame retardant and the antiager are sequentially added to be stirred evenly; the diluents is quickly added into mixed materials to be stirred for 20 to 25s, and then the materials are instantly poured into a mould which is preheated to 30 to 40 DEG C to be foamed and shaped; the mould is sequentially heated to 60 to 90 DEG C, 100 to 130 DEG C and 150 to 180 DEG C and is kept warm for 1 to 2h respectively to perform curing treatment, and the high-strength hard flame-retardant epoxy foam material can be obtained after demoulding.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Method for toughening 12mm toughened glass

InactiveCN103214167AIncrease the degree of temperingReduce the chance of self-explosionGlass tempering apparatusGlass productionStress distributionPotassium nitrate

The invention discloses a method for toughening a piece of 12mm toughened glass. The method comprises the following steps of horizontally placing the glass to be processed onto a roller bed, delivering the glass to be processed into a passage type toughening furnace through the roller bed, sequentially conducting heat treatment at intervals, and cooling two surfaces of the glass through high-pressure air until the surface temperature of the glass reaches 330 to 350 DEG C; placing the glass into 10 to 15 percent potassium nitrate glycerol solution at the temperature of 150 to 160 DEG C to be cooled for 3 to 4 minutes; then placing the glass into the potassium nitrate fused salt at the temperature of 350 to 360 DEG C to be heated for 5 to 6 minutes; and taking out the glass to be naturally cooled in the air. Through the interval heating and cold treatment, the stress distribution on the surface of the glass is adjusted, and the flatness of the toughened glass is guaranteed; and through the treatment in the potassium nitrate glycerol solution and the potassium nitrate fused salt, the toughened degree of the glass surface is increased, the self cracking possibility of the glass in the cooling process can be reduced, the yield of finished products of the toughened glass can be increased, and the performance index requirement of the toughened glass can be met.

Owner:HEFEI CHENGXIN GLASS

Gypsum-based heat-insulation mortar and preparation method thereof

The invention discloses gypsum-based heat-insulation mortar and a preparation method thereof. The gypsum-based heat-insulation mortar is prepared from the following ingredients in parts by weight: 15to 25 parts of Portland cement, 30 to 40 parts of building plaster, 10 to 20 parts of glass bead, 10 to 30 parts of converter steel slag, 10 to 20 parts of coal ash, 5 to 15 parts of nano silicon dioxide powder, 15 to 25 parts of ash calcium powder, 5 to 10 parts of modified pulpified starch, 2 to 8 parts of dispersible latex powder, 5 to 15 parts of cellulose ether, 3 to 8 parts of crack-resistant fiber, 5 to 15 parts of modified talcum powder, 4 to 10 parts of binder, 0.3 to 0.7 part of air entraining agent, 0.2 to 0.6 part of water repellent, 0.1 to 0.5 part of water reducing agent and 40 to 60 parts of water. The gypsum-based heat-insulation mortar disclosed by the invention has the advantages of high strength, good heat insulation, small drying shrinkage, no easiness in cracking and the like. The gypsum-based heat-insulation mortar can meet a requirement of building industry to mortar performance indexes and can be widely applied to projects of heat insulation and the like of outer walls and inner walls of buildings.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

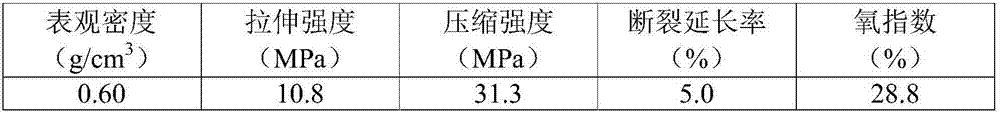

Amplifying, mixing and filtering device for GNSS (global navigation satellite system) receiving set

ActiveCN103245960AMeet performance index requirementsReduce gain requirementsSatellite radio beaconingInductive loadFrequency mixer

The invention relates to an amplifying, mixing and filtering device for a GNSS receiving set. The amplifying, mixing and filtering device comprises a high gain and gain controllable low noise amplifier, a passive orthogonal mixer assembly and a multi-phase filter which are sequentially connected. The device adopts the novel low noise amplifier which adopts a current source load, so that the gain is increased greatly, and the gain controllable function is realized. Simultaneously, compared with a conventional lower noise amplifier with an inductive load, the manufacturing cost is reduced substantially due to the fact that the low noise amplifier doesn't comprise a load inductor with a larger chip area. Due to the high gain of the low noise amplifier, the noise margin of a circuit to a post-module is increased, so that two later orthogonal demodulation mixers of the circuit can adopt the passive frequency mixer and the multi-phase filter which are free of current consumption, and the power consumption is reduced. By means of the high gain and gain adjustable function of the circuit, the design requirement of the post-module is reduced, and the overall power consumption is further reduced.

Owner:WUHAN UNIV

Inorganic calcium sulfate whisker heat retaining panel and preparation method thereof

The invention discloses an inorganic calcium sulfate whisker heat retaining panel. The inorganic calcium sulfate whisker heat retaining panel is characterized by being prepared from the following raw materials in percentage by weight: 30-50% of calcium sulfate whisker, 0.1-10% of Portland cement, 0.1-10% of silica fume, 2-5% of water-proofing agent and 30-50% of water. The invention also discloses a preparation method of the inorganic calcium sulfate whisker heat retaining panel. The inorganic calcium sulfate whisker heat retaining panel provided by the invention has the advantages of Al-grade fireproofing, light weight, high strength, excellent waterproof property, low heat conductivity coefficient and the like and is a high-quality heat retaining panel for building external walls, which has practical application value. According to the preparation method, a one-step molding method is adopted, and the technological processes comprise dry material premixing, liquid material premixing, pulping, standing still, molding, demolding, drying, high-temperature thermal treatment and the like.

Owner:SHANGHAI UNIV

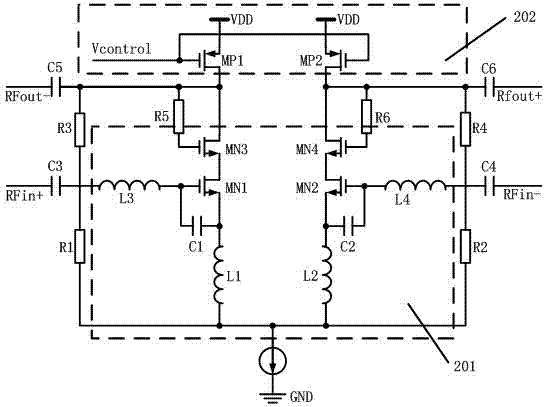

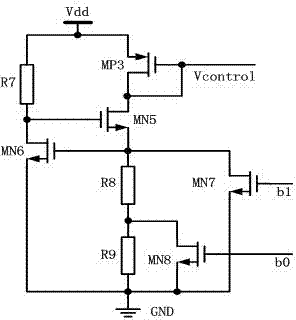

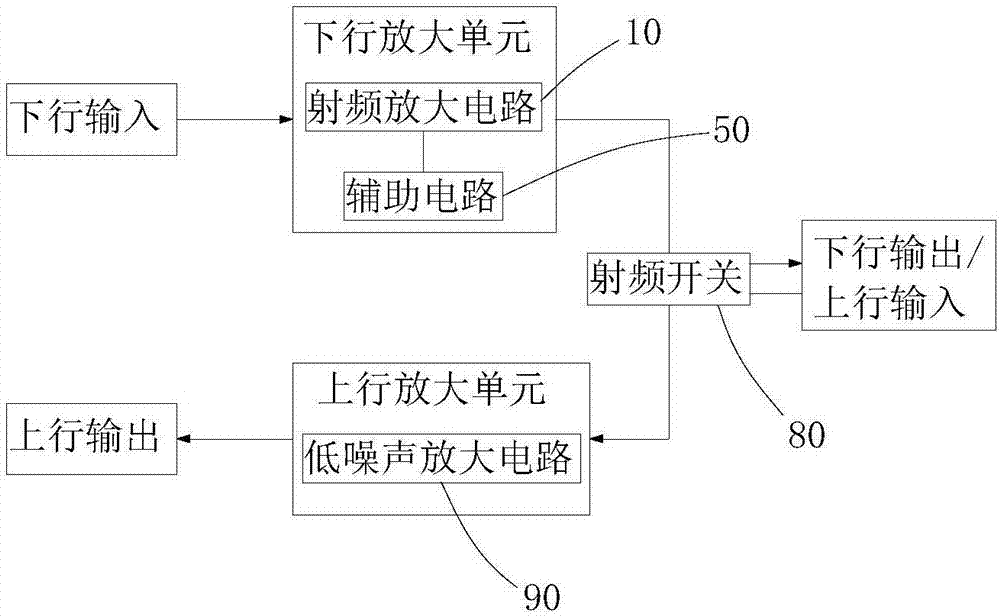

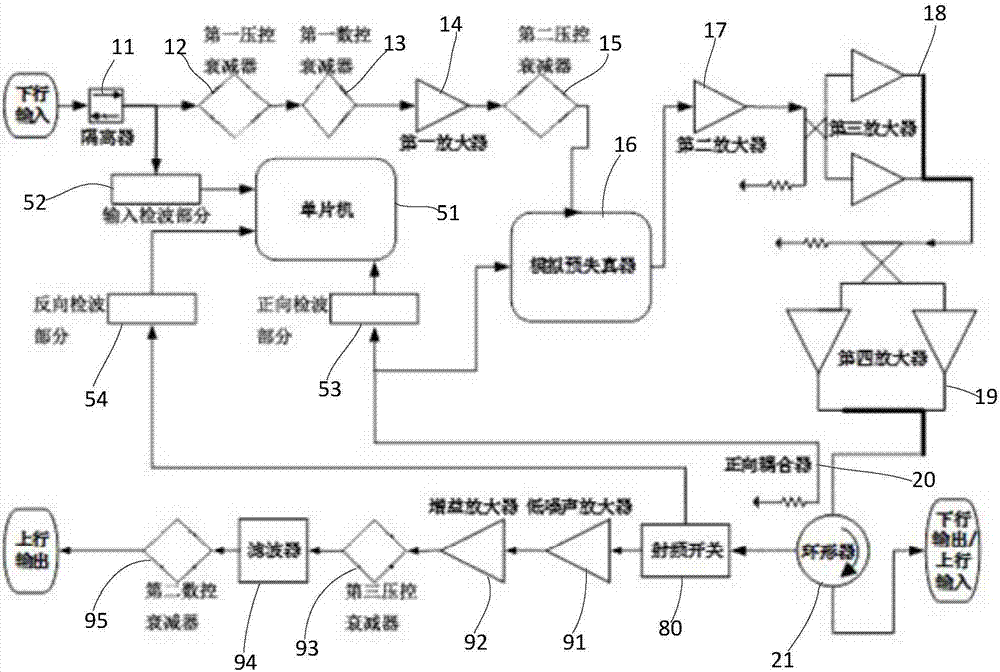

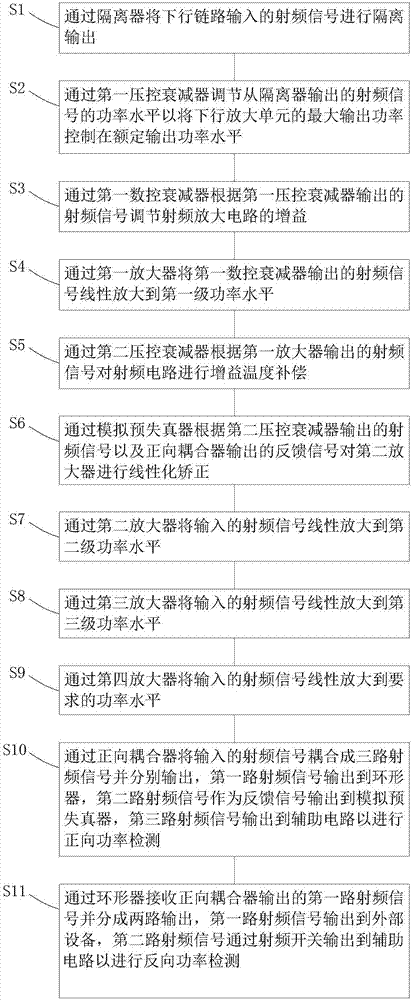

Radio frequency amplifier module and amplification method thereof

PendingCN107094029AMeet performance index requirementsHigh amplification efficiencyAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceLow noiseTime-Division Long-Term Evolution

The invention relates to a radio frequency amplifier module and an amplification method thereof. The radio frequency amplifier module comprises a downlink amplifier unit, an uplink amplifier unit and a radio frequency switch connected between the downlink amplifier unit and the uplink amplifier unit. The downlink amplifier unit comprises a radio frequency amplifier circuit which is used for carrying out power amplification processing on a radio frequency signal input by a downlink and outputting the processed signal, and an auxiliary circuit which is used for detecting input power, positive output power and negative output power of the radio frequency amplifier circuit. The uplink amplifier unit comprises a low-noise amplifier circuit which is used for carrying out low-noise amplification processing on the radio frequency signal input by an uplink and outputting the processed signal. According to the module and the method, the amplification efficiency is high, the good linearity is achieved, a performance index demand of a TD-LTE (Time Division Long Term Evolution) base station system can be satisfied, and the module and the method have relatively good application prospect.

Owner:SHENZHEN GRENTECH CORP LTD

400 Mpa-grade construction steel with excellent corrosion resistance and production method

InactiveCN106801188AMeet performance index requirementsGood corrosion performanceStrength designCorrosion resistant

The invention discloses 400 Mpa-grade construction steel with excellent corrosion resistance and a production method, and belongs to the field of production of construction corrosion steel. The steel comprises the following components by weight percent: 0.05% to 0.3% of C, 0.2% to 0.6% of Si, 1.2% to 1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 0% to 1.9% of Cr, 0.25% to 1% of Cu, 0.4% to 1% of Ni, 0.1% to 0.5% of Mo and 0.01% to 0.02% of N, and the balance being Fe. The construction steel with excellent corrosion resistance is obtained through the adoption of a vacuum smelting-low temperature rolling-controlled rolling and controlled cooling production method, optimization of selected multi-group components, and optimization of technologies. The 400 Mpa-grade construction steel has the advantages that the steel has excellent corrosion resistance, so that the steel can be utilized in concrete structures with ultrahigh strength and ultrahigh strength design requirements in severe conditions like marine environment and marshland; and the innovation point is that optimal alloy elements like chromium are optimally selected, so that the 400 Mpa-grade construction steel has excellent corrosion resistance.

Owner:SHOUGANG CORPORATION

Permanent magnet synchronous motor universal control system and control method thereof

ActiveCN108521242AMeet performance index requirementsImprove general performanceElectronic commutation motor controlAC motor controlPower inverterInterface circuits

The present invention discloses a permanent magnet synchronous motor universal control system and a control method thereof. The system comprises a control board and a driving board; the control boardcomprises a motor controller module, the driving board comprises an intelligent power module, a bus voltage detection circuit, a direct current link current detection circuit, a phase current detection circuit, an encoder, a Hall sensor and a rotary transformer interface circuit; three-phase output end of the intelligent power module is connected with a permanent magnet synchronous motor; and themotor controller module is configured to perform comprehensive processing of phase current signals and rotor position information and output three-phase and six-way PWM signals with an expected targetso as to control on-off of an inverter switching tube in the control intelligent power module and control operation of the permanent magnet synchronous motor. The permanent magnet synchronous motor universal control system and the control method thereof can support a plurality of rotor position detection modes with sensors and without sensors to ensure stable operation of the motor in various complex conditions, and employ the ideal based on the model design to establish a system simulation model and help users with improvement of development efficiency and reduction of development cost.

Owner:XI AN JIAOTONG UNIV

Glass fiber direct yarn impregnating compound as well as preparation method and application thereof

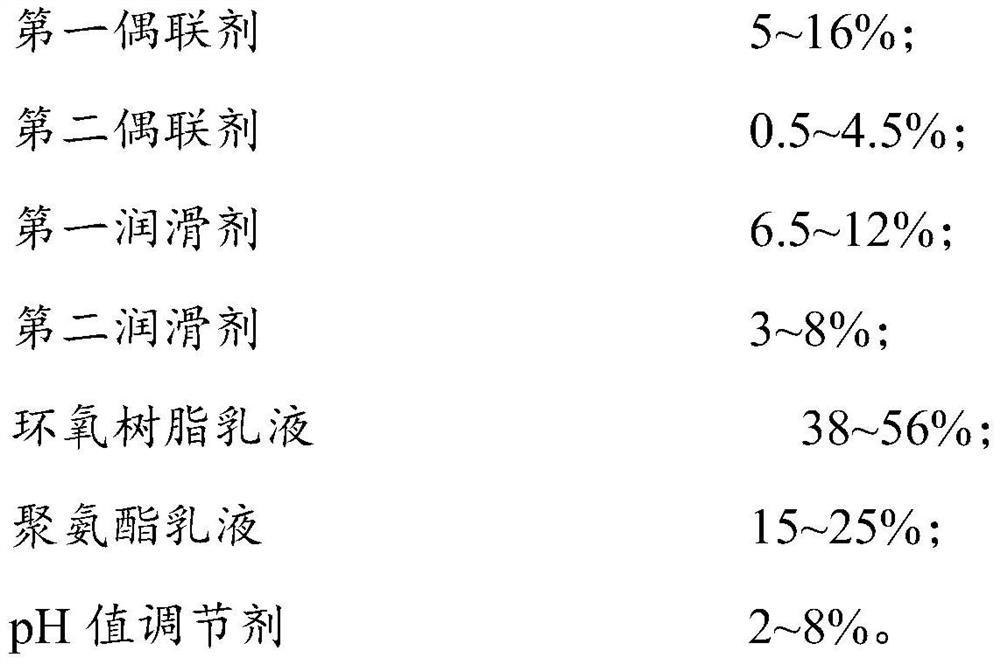

The invention discloses a glass fiber direct yarn impregnating compound which comprises the following components in percentage by mass: 5-12% of solid and the balance of water, wherein the percentageof the solid mass of each component in the impregnating compound in the solid mass of the impregnating compound is as follows: 5.5-20.5% of a coupling agent, 9-20% of a lubricant, 51-82% of a film-forming agent, and 2-8.5% of a pH value regulator, wherein the film-forming agent is a mixture of epoxy resin emulsion and polyurethane emulsion, and the mass ratio of the epoxy resin emulsion to the polyurethane emulsion is 1.42:1 to 4:1. After asphalt is coated with the impregnating compound, the strength is high, and various index requirements of the geogrid are met.

Owner:JUSHI GRP CO

Polypropylene non-woven fabric waste recovery process

InactiveCN109082775AImprove recycling ratesSimple structureFilament forming substance formingMonocomponent polypropylene artificial filamentPulp and paper industryNonwoven fabric

The invention discloses a polypropylene non-woven fabric waste recovery process. The process sequentially comprises the steps that (1), non-woven fabric waste is delivered into a forcing feeding screwrod machine on the second floor through a collecting retracting box and roller tubes; (2), the waste is winded and squeezed by the forcing feeding screw rod machine, and pulling force is generated topull the waste into the feeding machine repeatedly, and the non-woven fabric waste is delivered into a heating tube to be heated and melted after squeezing and tearing are conducted; (3), melted waste material is uniformly mixed with raw material particles according to a certain ratio, and polypropylene fibers are prepared through a spinneret device; (4) the polypropylene fibers on which spinningis conducted are prepared into fiber layer through laying passing through a receiving device, a layer of polypropylene fiber is added to the fiber layer through a conveying belt, and non-woven fabricis prepared through hot pressing rolling; (5) rolled non-woven fabric is placed on a cutting machine to cut into non-woven fabric products with specific width dimensions. By means of the process, dried body mass is improved, and product yield is greatly improved.

Owner:杭州富阳雷讯科技咨询服务有限公司

Degradable polyurethane wood-imitation material and preparing method thereof

InactiveCN105384910AMeet performance index requirementsDimensional stability Small shrinkageFoaming agentCompound (substance)

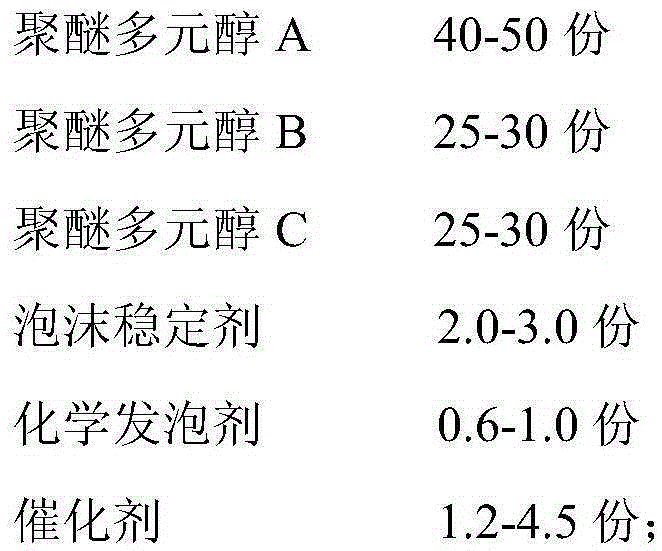

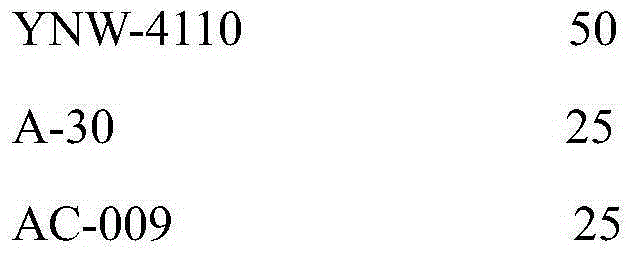

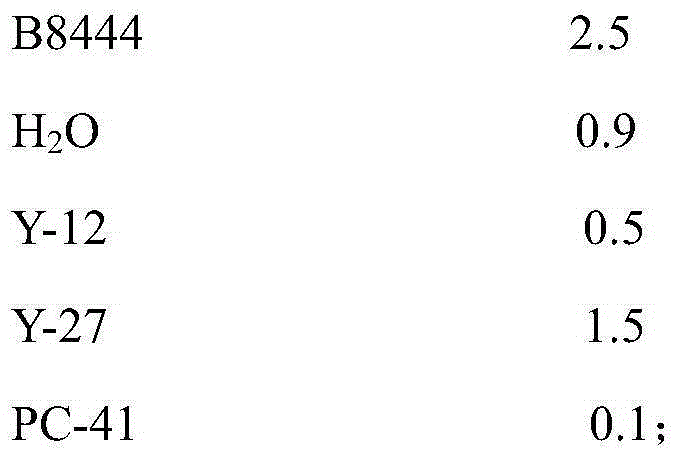

The invention belongs to the technical field of polyurethane, and particularly relates to a degradable polyurethane wood-imitation material and a preparing method thereof. The degradable polyurethane wood-imitation material is prepared from a component A and a component B, wherein the component A is prepared from polyether polyol A, polyether polyol B, polyether polyol C, a foam stabilizer, a chemical foaming agent and a catalyst, and the component B is prepared from polymethylene polyphenyl isocyanate. The multiple kinds of degradable biology-base polyether polyol are matched, and environment-friendly water is selected as the chemical foaming agent to prepare the environment-friendly degradable polyurethane wood-imitation product. The Shore hardness can be D 40 or above when the free bubble density of the product is 120-150 kg / m<3>, the dimensional stability shrinking percentage is smaller than 0.5%, the performance index requirement of the polyurethane wood-imitation material is met, and the degradable polyurethane wood-imitation material can be used for preparing wood-imitation products in complex styles.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

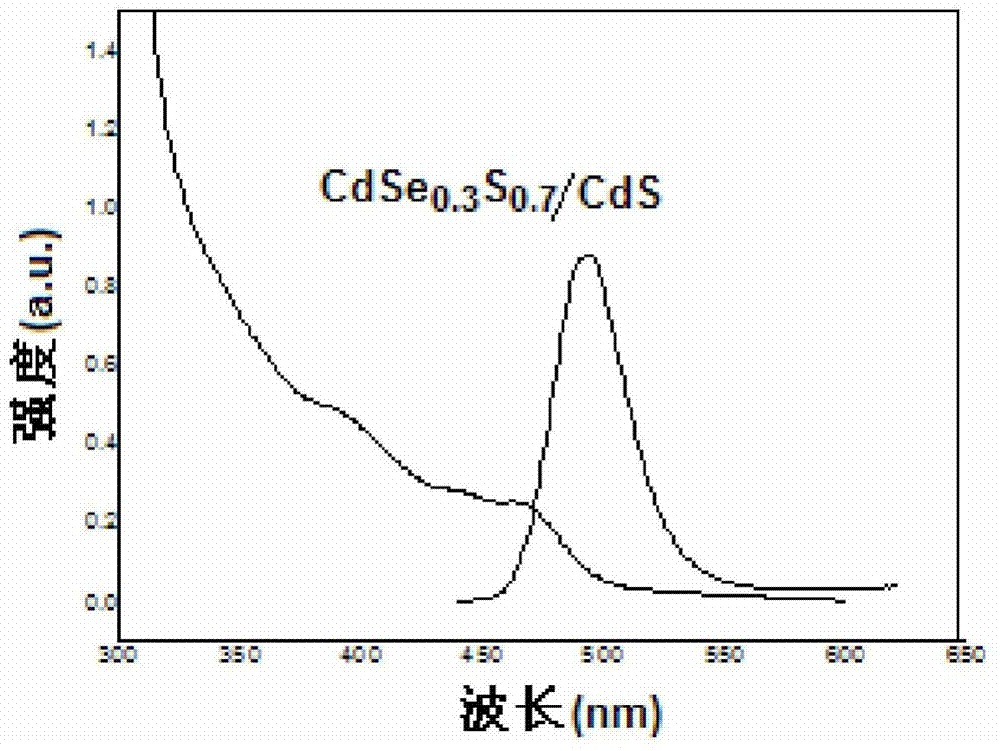

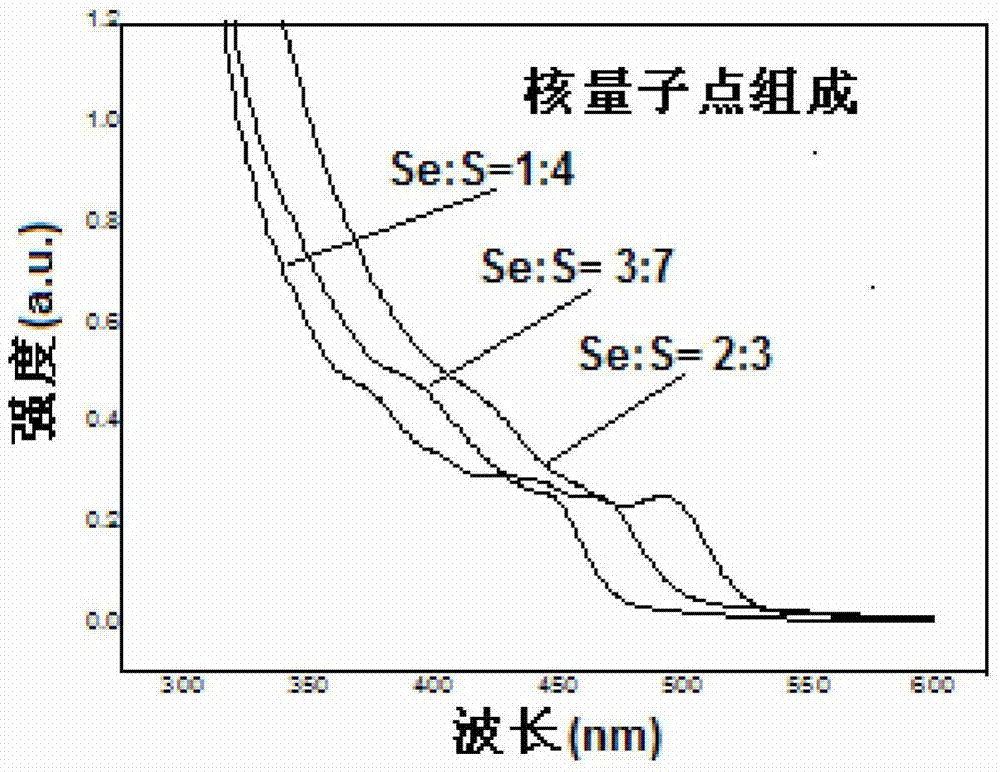

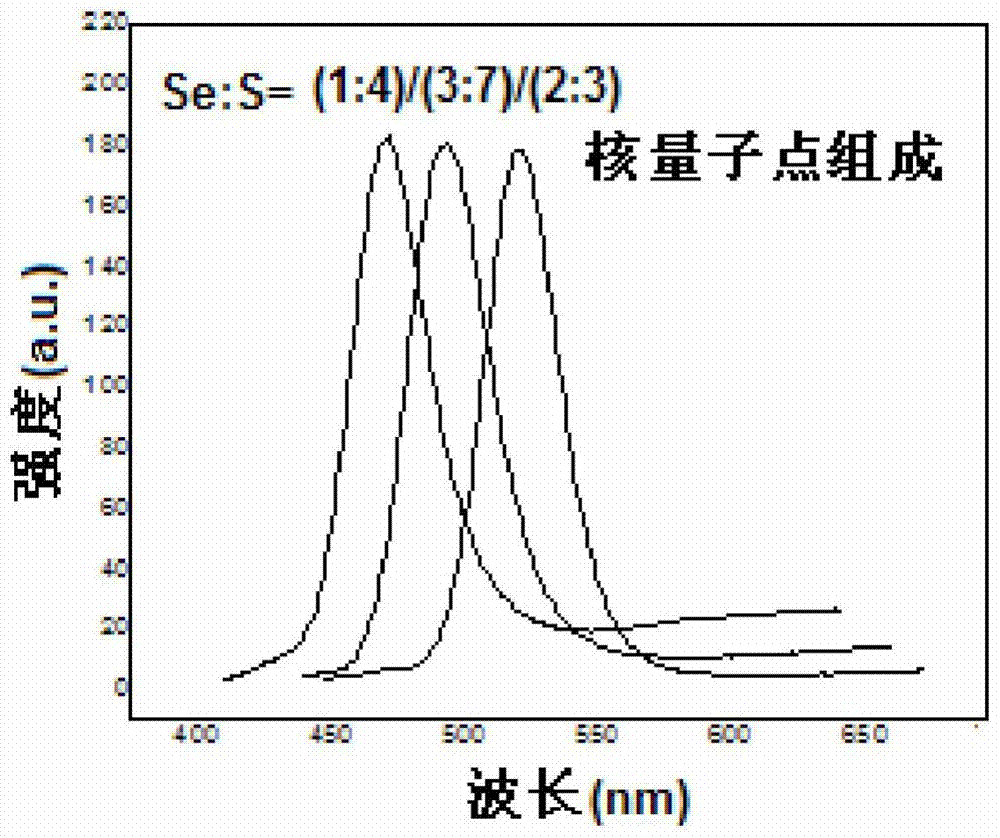

Synthetic method for core-shell quantum dot which is capable of realizing emission of blue light to green light and possesses uniformly-alloyed core

ActiveCN104498021AMeet performance index requirementsRegulatory compositionNanoopticsLuminescent compositionsCadmium selenideSulfur

The invention discloses a synthetic method for a core-shell quantum dot which is capable of realizing emission of blue light to green light and possesses a uniformly-alloyed core. The core-shell quantum dot employs uniformly-alloyed cadmium selenide sulfide CdSexS1-x as a core and employs CdS as a shell, and the composition is shortly named CdSexS1-x / CdS, wherein x=0.05-0.60. By controlling the molar ratio of a sulfur source to a selenium source, the usage amount of a cadmium source and a ligand, and the reaction temperature and time in the synthesis process of the core-shell quantum dot, the emission peak wavelength of the core-shell quantum dot is continuously adjustable in the scope of 460-530 nm. The synthetic method has green and economic characteristics, the synthesis process and the product structure and performances are highly controllable, and the method is applicable to large-scale preparation of the quantum dot.

Owner:HEFEI UNIV OF TECH

High strength light-weight concrete and preparation method thereof

InactiveCN108409226AHigh strengthHigh strength and light weightCeramicwareExpanded clay aggregateDodecylsulfonic acid

The invention discloses high strength light-weight concrete, the concrete is prepared from the following components in parts by weight: 40 to 60 parts of cement, 20 to 40 parts of ceramsite, 20 to 30parts of coal ash, 10 to 20 parts of fine sand, 5 to 15 parts of calcium carbonate, 15 to 25 parts of light calcined magnesia, 2 to 8 parts of polypropylene fiber, 5 to 15 parts of microsilica fume, 3to 8 parts of calcium monofluorophosphate, 5 to 15 parts of nano silicon dioxide, 8 to 15 parts of desulphurization gypsum, 5 to 10 parts of quartz sand, 2 to 7 parts of expanded vermiculite, 4 to 10parts of sodium dodecyl sulfate, 2 to 8 parts functional agent and 80 to 100 parts of deionized water. The high strength light-weight concrete provided by the invention has the characteristics of light weight, high strength, good weather resistance, good heat-insulating property and the like, can meet index requirements of construction industry to ceramsite concrete performance and has better application prospect.

Owner:合肥金云新材料有限公司

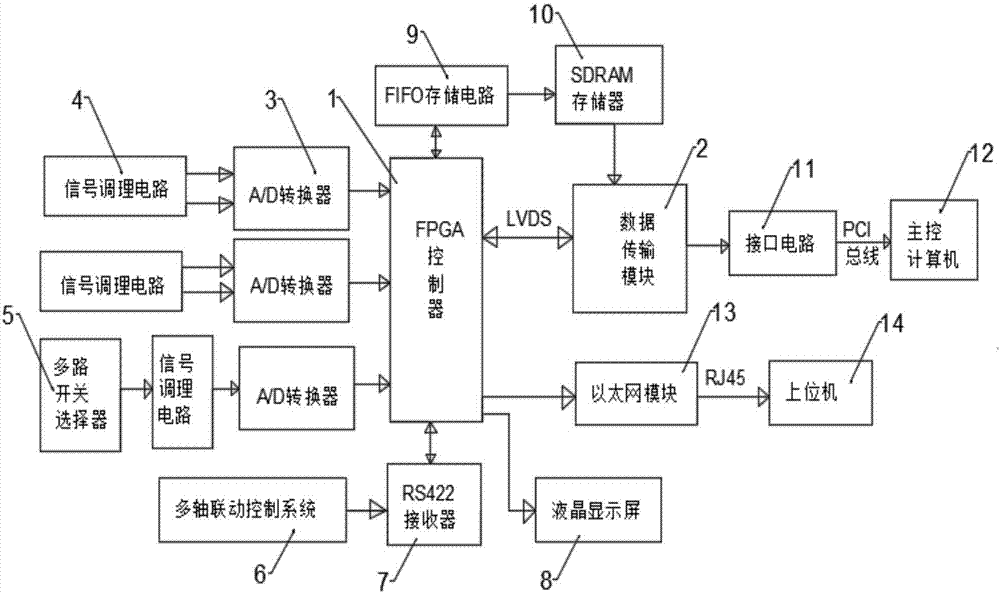

Multi-channel real-time data acquisition system

InactiveCN107367985ASave extra spaceSave hardware resourcesProgramme controlComputer controlControl signalControl line

The invention discloses a multi-channel real-time data acquisition system. The system comprises an FPGA controller and a data transmission module. A bidirectional port of the FPGA controller is electrically connected with three A / D converters through control lines. Two of the A / D converters receive control signals processed through a signal conditioning circuit, and the other A / D converter receives a switch signal processed by the signal conditioning circuit. Control signals of the channels are directly subjected to signal conditioning and then parallelly acquired at the high speed by other two A / D conversion circuits. Multiple paths of control signals of other channels are selected through multiple paths of switches, so board area is reduced and hardware resources are saved. The output end of the FPGA controller is connected with a data transmission FPGA control circuit through an LVDS high speed serial communication circuit. Data interaction is achieved for feedback data directly through an RS-422 communication and multi-shaft moving control system. The feedback data is then transmitted to a main control computer at the high speed through a PCI bus, so high-speed large-capacity data detection is achieved and data processing efficiency is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

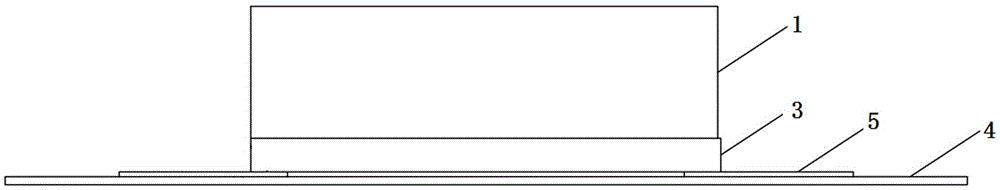

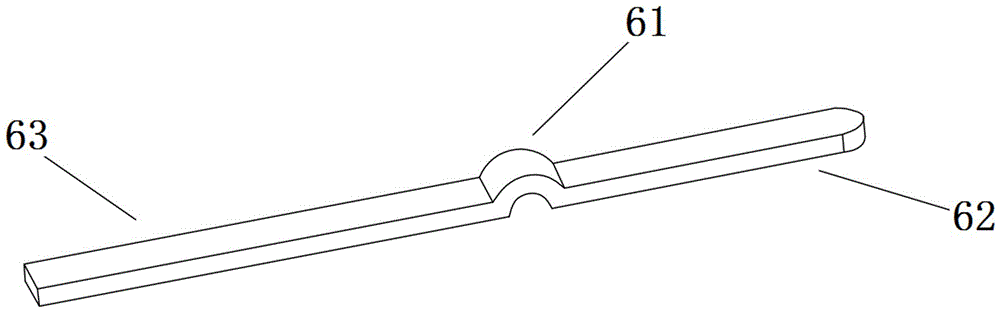

Housing lead wire used for surface-mount package of microwave device and connecting structure thereof

InactiveCN105470229AGuaranteed normal transmissionLittle interferenceSemiconductor/solid-state device detailsSolid-state devicesMicrowaveSurface mounting

The present invention relates to the field of surface mounting technology, and specially discloses a housing lead wire used for a surface-mount package of a microwave device and a connecting structure that uses the lead wire. The lead wire is flat and ribbon-shaped, is provided with a bending section that is omega-shaped and that has a radius of 0.10 mm - 0.30 mm, and the lead wire, except the bending section, is a straight line segment. The bending section is an arc that is a semicircle or greater than a semicircle. Two straight line end portions of the lead wire are a lead-in end and a lead-out end respectively; the lead-in end is used for connecting a package housing; the lead-out end is used for connecting a printed circuit board; and the bending section of the lead wire is close to the lead-out end. In the connecting structure, the distance between a bending degree and a ceramic base is 0.10 mm - 0.30 mm. According to the housing lead wire used for a surface-mount package of a microwave device and the connecting structure, a lead wire has better tensile and anti-plastic deformation performance, and also has a better microwave electric signal transmission capability; and by applying the lead wire to a microwave device, a tensile stress that the lead wire exerts on a housing when a temperature changes can be reduced or eliminated, and reliability of the device and better microwave performance can be ensured.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Tempering processing method for 8-12mm tempered glass

InactiveCN103319081AReduce the chance of self-explosionIncrease the degree of temperingGlass tempering apparatusGlass productionStress distributionPerformance index

The invention discloses a tempering processing method for 8-12mm tempered glass. The tempering processing method comprises the following steps of adding glass into dimethicone which is at a temperature of 160 DEG C to 180 DEG C and heating for 5-10 minutes, placing the glass horizontally to a roller bed, conveying the glass to a channel-type tempering furnace by the roller bed, and carrying out heat treatments at different temperature ranges sequentially. According to the fact that the tempering processing method employs different temperature ranges for heating, a preheating treatment and a final heat treatment, the stress distribution of the glass surface is adjusted, the smoothness of the tempered glass is guaranteed, the tempered degree of the glass surface is increased, the self-destruction probability in a cooling process of the glass is reduced, the yield of the tempered glass is increased, and performance index requirements of the tempered glass are satisfied.

Owner:HUAIBEI CHANGXING SAFETY ENERGY SAVING TEMPERED GLASS

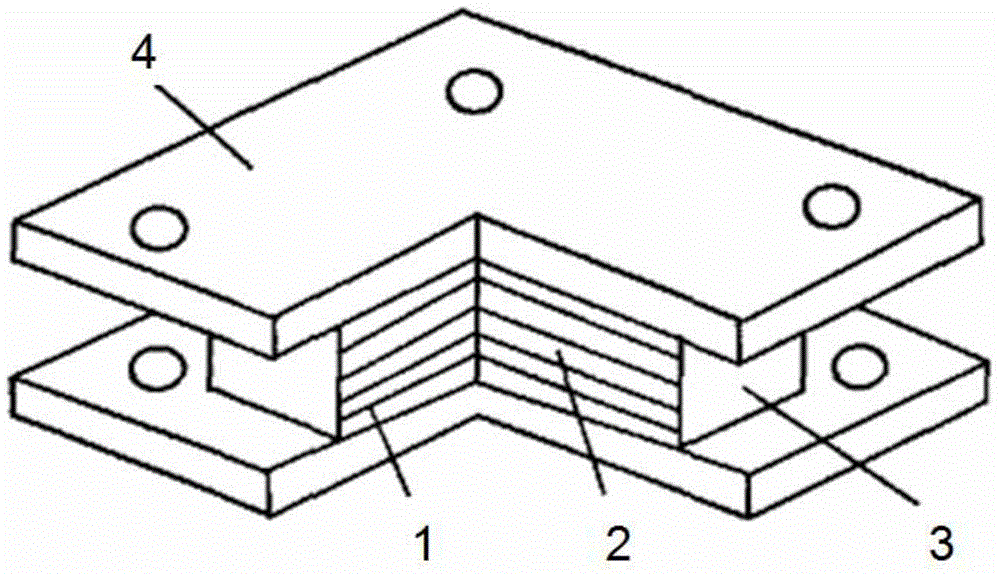

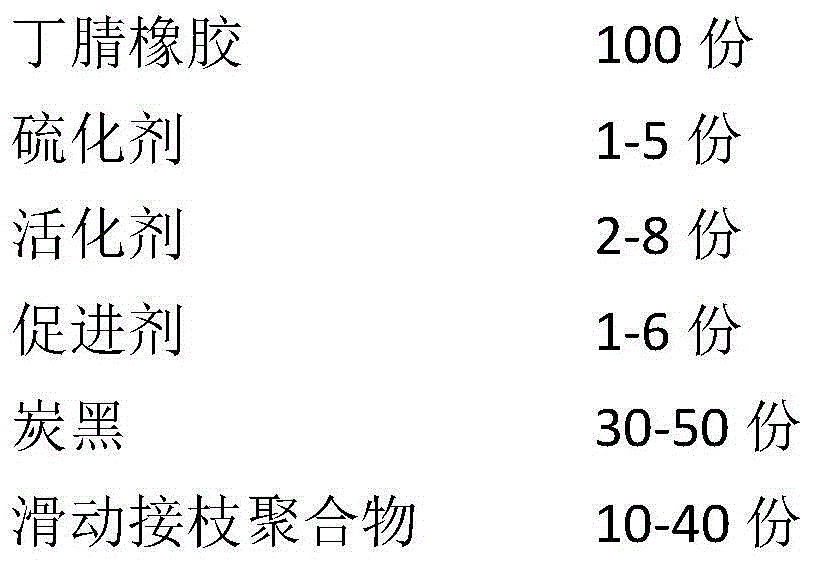

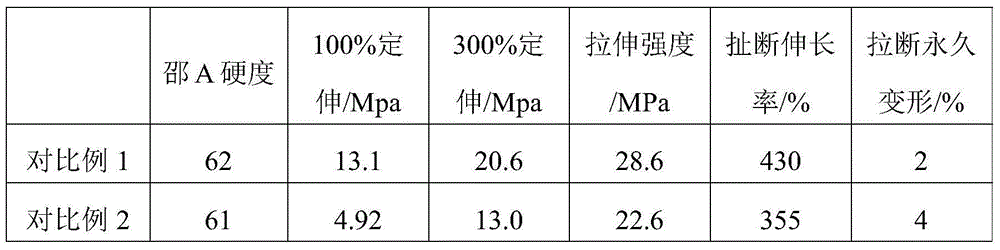

Chemigum composite material for high-damping shock-insulation support and preparation method of chemigum composite material

The invention relates to a rubber composite material for a high-damping shock-insulation support and a preparation method of the rubber composite material. According to the invention, a novel sliding graft polymer and NBR are compounded to prepare the high-damping rubber composite material, the sliding graft polymer is pre-vulcanized to form primary crosslinking, then the sliding graft polymer subjected to prevulcanization and primary crosslinking is adopted as a functional additive and mixed into a chemigum matrix and forms a hydrogen bond network structure with rubber macromolecules. The novel composite material is endowed with the advantages of high damping, high elongation at break, low stretching strength and small permanent deformation, meets the performance index requirements of the rubber composite material from the high-damping support, and has a wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com