Ultrahigh-strength full-austenite stainless steel welding wire

A fully austenitic, ultra-high-strength technology, used in welding media, welding equipment, welding/cutting media/materials, etc., to achieve excellent toughness, simplified welding process, and good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

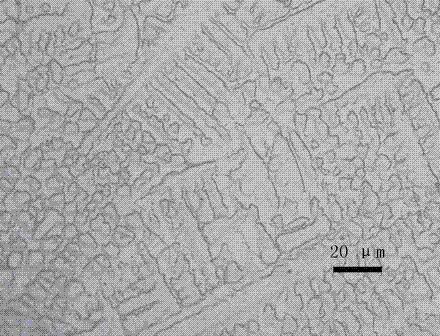

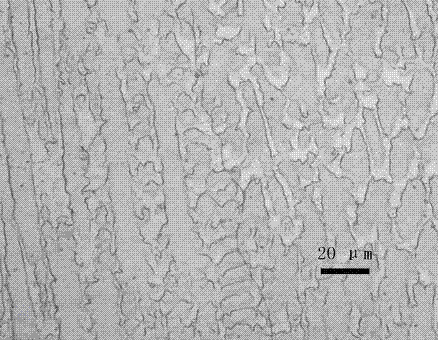

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment this patent is further explained and illustrated. But the scope of protection of this patent is not limited to the specific implementation.

[0028] The chemical composition of the welding wire used in the example is shown in Table 1, and the specification of the welding wire is φ1.0mm. The steel plate used in the test is 10CrNi5MoV steel with a thickness of 26 mm. The welding process is shown in Table 2, and 95% Ar+5% CO is used. 2 As the shielding gas, see Table 3 for the comparison data of the connection efficiency improvement.

[0029] Table 1 Chemical composition (wt%) of welding wire of the present invention

[0030] C Si mn Cr Ni Mo N V S P Fe Example 1 0.053 0.54 4.65 15.50 21.43 5.56 0.255 0.153 0.0066 0.011 margin Example 2 0.091 0.90 5.08 16.02 19.06 5.10 0.304 0.220 0.0092 0.006 margin Example 3 0.078 0.50 4.65 18.05 21.36 5.18 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com