Coal ash and mineral powder-based geopolymer quick setting type rigid repair mortar and preparation method thereof

A technology for repairing mortar and fly ash, applied in cement production and other directions, can solve the problems of low utilization rate, large output, and no high added value/high dosage utilization, etc., and achieve the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

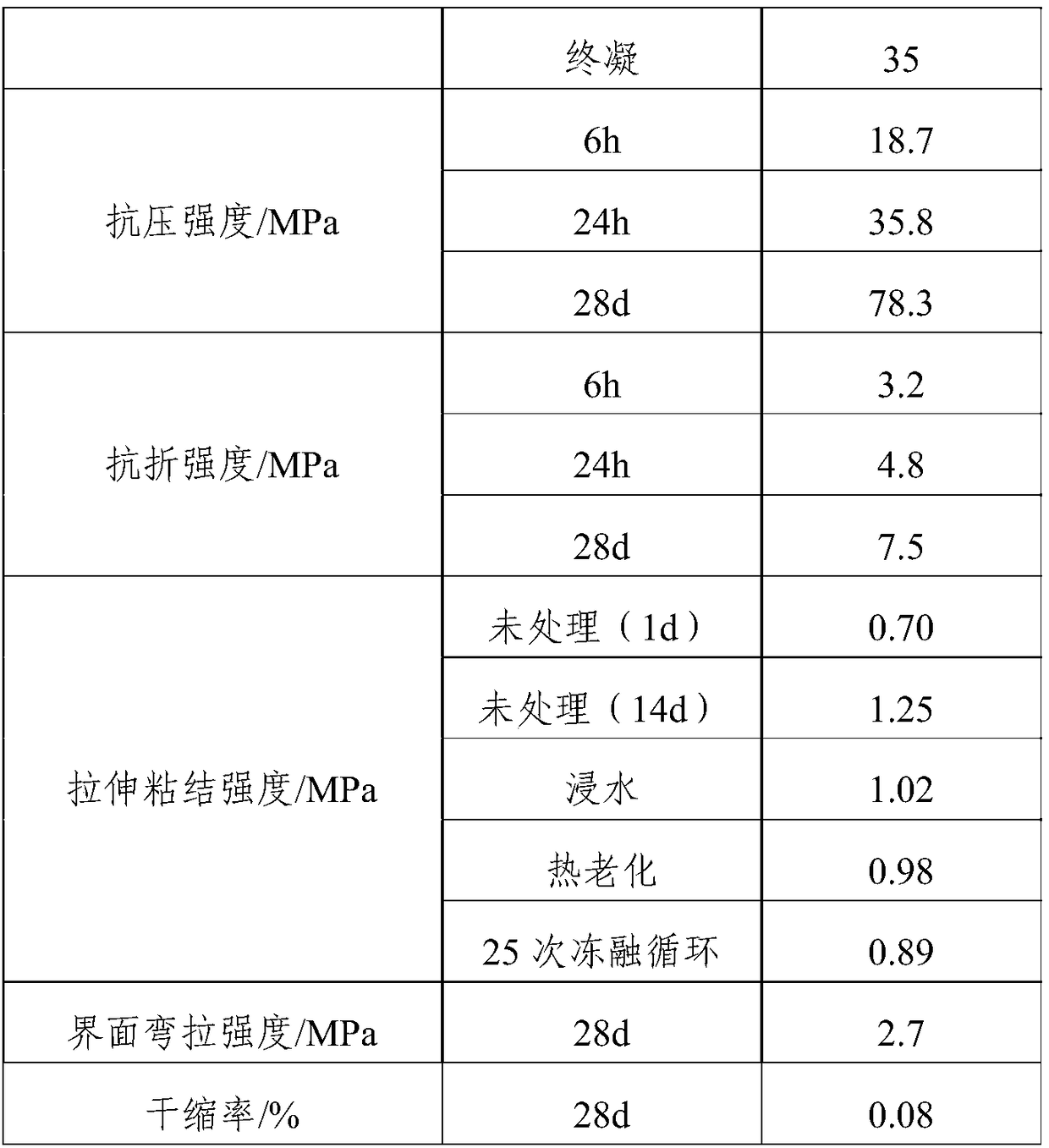

Embodiment 1

[0043] A fast-setting rigid repair mortar prepared by using industrial by-product fly ash, slag powder, and tailings fine sand, its solid component materials, in parts by weight, include:

[0044]30 parts of tailings fine sand with a particle size of 0.3-0.5mm;

[0045] 24 parts of tailings fine sand with particle size less than 0.3mm;

[0046] 13 parts of Class I fly ash;

[0047] 29.95 parts of S95 mineral powder;

[0048] Redispersible latex powder 5010 1.5 parts;

[0049] 1.3 parts of retarder sodium carbonate;

[0050] Water retaining agent HPMC 15,000 0.1 parts;

[0051] 0.15 parts of 8mm polypropylene fiber.

[0052] Its liquid component materials include the following components in parts by weight:

[0053] Mass fraction is 35 parts of sodium hydroxide solution of 34%;

[0054] Solid content is 60 parts of water glass solution of 55%;

[0055] 5 parts of water.

[0056] Mix the solid component material and the liquid component material separately, and then mix...

Embodiment 2

[0061] A fast-setting rigid repair mortar prepared by using industrial by-product fly ash, slag powder, and tailings fine sand, its solid component materials, in parts by weight, include:

[0062] 35 parts of tailings fine sand with a particle size of 0.3-0.5 mm;

[0063] 25 parts of tailings fine sand with particle size less than 0.3mm;

[0064] 10 parts of Class I fly ash;

[0065] 29.95 parts of S95 mineral powder;

[0066] Redispersible latex powder 5010 1.0 parts;

[0067] 1.0 part of retarder sodium carbonate;

[0068] 15,000 0.05 copies of water retaining agent HPMC;

[0069] 0.10 parts of 8mm polypropylene fiber.

[0070] The liquid component material includes the following components in parts by weight:

[0071] Mass fraction is 40 parts of 34% sodium hydroxide solution;

[0072] Solid content is 56 parts of water glass solutions of 55%;

[0073] 4 parts of water.

[0074] Separately mix the solid component material and the liquid component material, and then...

Embodiment 3

[0078] A fast-setting rigid repair mortar prepared by utilizing industrial by-products fly ash, slag powder and tailings fine sand, its solid component materials, in parts by weight, include:

[0079] 26 parts of tailings fine sand with a particle size of 0.3-0.5 mm;

[0080] 23 parts of tailings fine sand with particle size less than 0.3mm;

[0081] Class I fly ash 16 parts;

[0082] 29.95 parts of S95 mineral powder;

[0083] Redispersible latex powder 5010 2.0 parts;

[0084] 1.5 parts of retarder sodium carbonate;

[0085] Water retaining agent HPMC 15,000 0.1 parts;

[0086] 0.2 part of 8mm polypropylene fiber.

[0087] The liquid component material includes the following components in parts by weight:

[0088] Mass fraction is 25 parts of sodium hydroxide solution of 34%;

[0089] Solid content is 60 parts of water glass solution of 55%;

[0090] 15 parts of water.

[0091] Separately mix the solid component material and the liquid component material, and then m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com