Gypsum-based self-leveling mortar prepared from fine iron tailing sand, and preparation method thereof

A technology of self-leveling mortar and iron tailings, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of occupying large land resources, few utilization channels, safety issues, etc., and achieves low cost, Improvement of mechanical properties and durability, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A gypsum-based self-leveling mortar prepared from iron tailings fine sand, comprising the following components in parts by weight:

[0045]0.3mm≤particle size<0.5mm iron tailings fine sand: 30 parts;

[0046] 0.1≤particle size<0.3mm iron tailings fine sand: 14 parts;

[0047] Iron tailing fine sand with a particle size of <0.1mm: 6 parts;

[0048] High-strength gypsum: 44.645 parts;

[0049] 42.5 grade ordinary Portland cement: 5 parts;

[0050] High-efficiency polycarboxylate superplasticizer: 0.11 parts;

[0051] Redispersible latex powder: 0.05 parts;

[0052] Gypsum retarder: 0.035 parts;

[0053] Low viscosity cellulose ether: 0.06 parts;

[0054] Polyether defoamer: 0.10 parts.

[0055] It can be prepared by uniformly mixing the above raw materials in proportion.

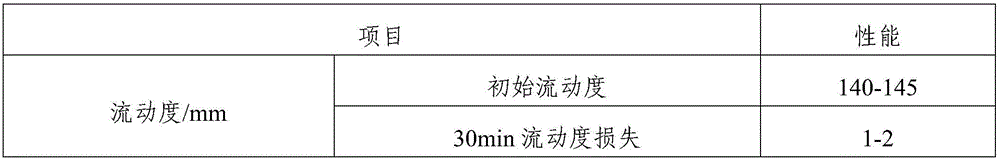

[0056] Table 2 shows the properties of the gypsum-based self-leveling mortar after adding 25% water by weight.

[0057] Table 2 Physical and mechanical properties of gypsum-based self-leveling ...

Embodiment 2

[0060] A gypsum-based self-leveling mortar prepared from iron tailings fine sand, comprising the following components in parts by weight:

[0061] 0.3mm≤particle size<0.5mm iron tailings fine sand: 35 parts;

[0062] 0.1≤particle size<0.3mm iron tailings fine sand: 15 parts;

[0063] Iron tailing fine sand with particle size <0.1mm: 10 parts;

[0064] High-strength gypsum: 35 parts;

[0065] 42.5 grade ordinary Portland cement: 5 parts;

[0066] High-efficiency polycarboxylate superplasticizer: 0.10 parts;

[0067] Redispersible latex powder: 0.10 parts;

[0068] Gypsum retarder: 0.03 parts;

[0069] Low viscosity cellulose ether: 0.05 parts;

[0070] Polyether defoamer: 0.10 parts.

[0071] It can be prepared by uniformly mixing the above raw materials in proportion.

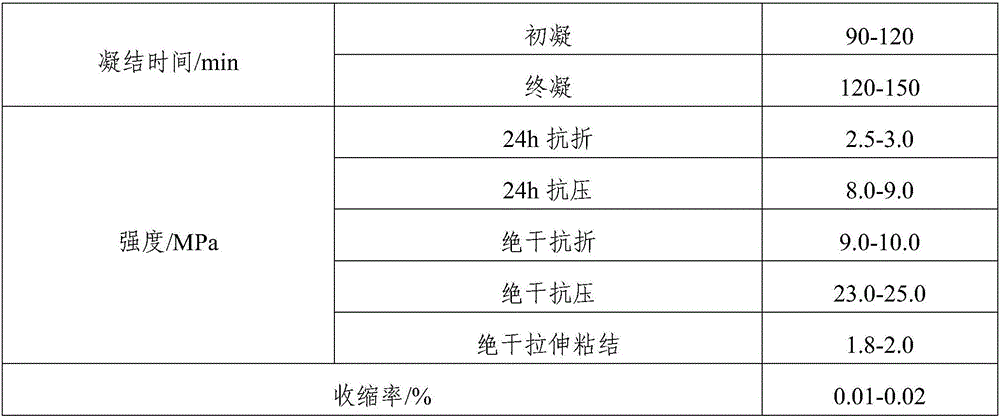

[0072] After adding 25% water by weight to the gypsum-based self-leveling mortar, its properties are shown in Table 3.

[0073] Table 3 Physical and mechanical properties of gypsum-based self-leveling ...

Embodiment 3

[0076] A gypsum-based self-leveling mortar prepared from iron tailings fine sand, comprising the following components in parts by weight:

[0077] 0.3mm≤particle size<0.5mm iron tailings fine sand: 20 parts;

[0078] 0.1≤particle size<0.3mm iron tailings fine sand: 20 parts;

[0079] Iron tailing fine sand with particle size <0.1mm: 10 parts;

[0080] High-strength gypsum: 42 parts;

[0081] 42.5 grade ordinary Portland cement: 8 parts;

[0082] High-efficiency polycarboxylate superplasticizer: 0.14 parts;

[0083] Redispersible latex powder: 0.05 parts;

[0084] Gypsum retarder: 0.042 parts;

[0085] Low viscosity cellulose ether: 0.08 parts;

[0086] Polyether defoamer: 0.18 parts.

[0087] It can be prepared by uniformly mixing the above raw materials in proportion.

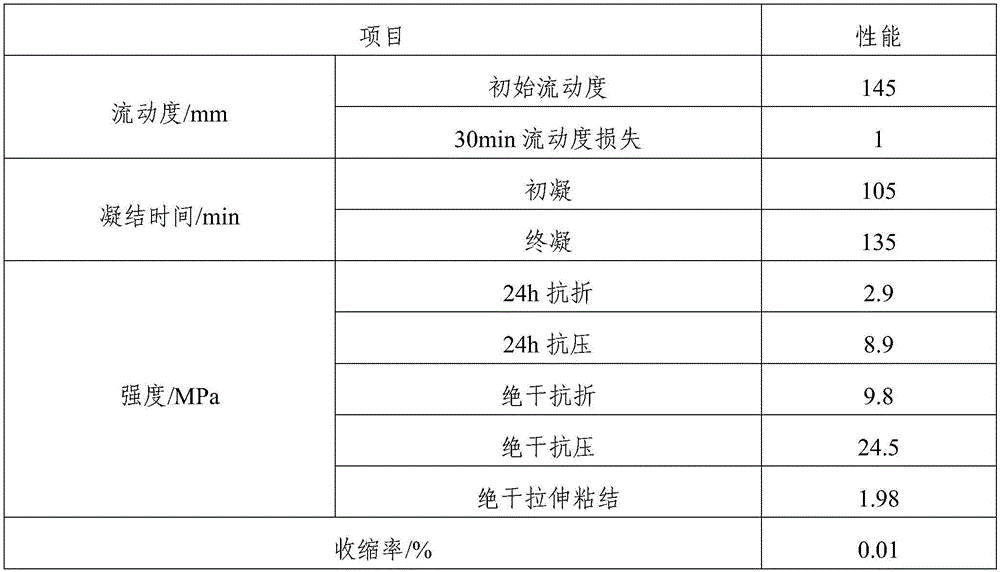

[0088] After adding 25% water by weight to the gypsum-based self-leveling mortar, its properties are shown in Table 4.

[0089] Table 4 Physical and mechanical properties of gypsum-based self-leveling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com