Continuous hot-pressing method for large-section section

A technology of large cross-section and profile, applied in the direction of wood processing appliances, household components, flat products, etc., can solve the problems of inability to solve the problem of uniformity, inability to make dimensional materials, and difficulty in feeding and discharging slabs, so as to alleviate the problems of wood. The effect of supply, increase plasticity, and easy operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

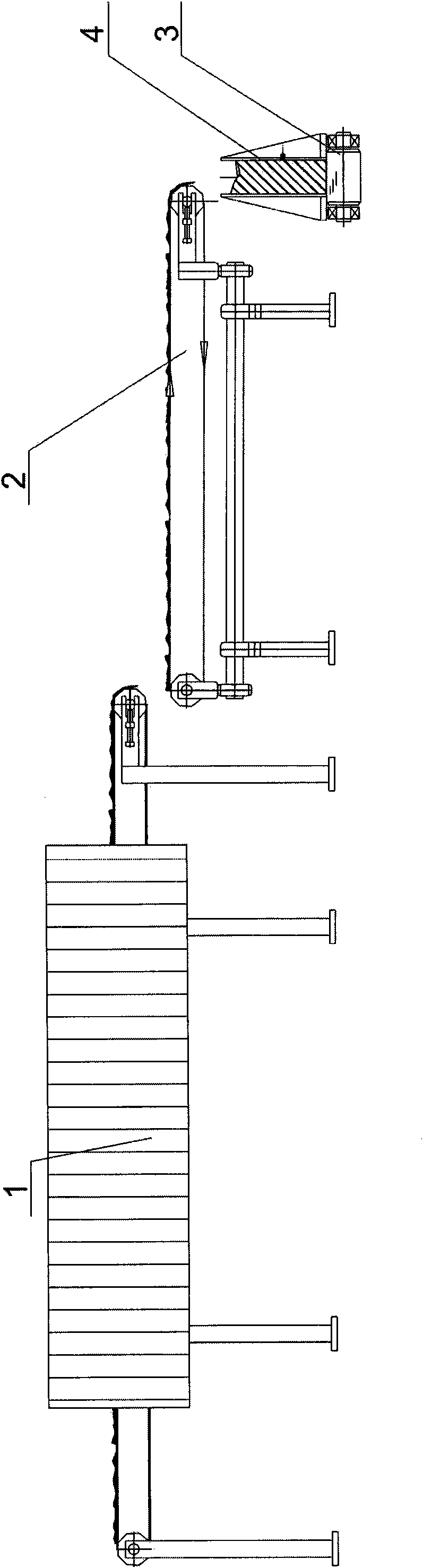

Image

Examples

Embodiment 1

[0036] Embodiment 1: (1) Sagittarius bamboo is sawed into 2.5 meters of bamboo sections, and cut into bamboo slices with a width of 40mm; (2) bamboo slices are flattened, bamboo joints are removed with a spatula, and green layer and dead yellow are removed (3) Put the unit materials into the microwave drying production line, adjust the microwave power and carry out drying treatment to a relative moisture content below 15%. The microwave generator that adjusts the microwave power carbonizes the unit material into a light bronze color; (4) Send the unit material into the dipping pool for 20 minutes to soak in glue. The dipping uses water-soluble phenolic resin diluted to a solid content of 20%. % (solid content); (5) Carry out the low-temperature continuous drying line with the glue-containing unit material, dehydrate to a moisture content of 12%, with the glue-containing unit material according to 50 kilograms of quantitative slabs, adjust the distance between the baffle plates ...

Embodiment 2

[0039] Embodiment 2: (1) the small-diameter bamboo is sawed into 0.6m bamboo sections; (2) the bamboo sections are disentangled into vertically and horizontally connected unit materials through rolling and extruding; (3) the unit materials are dried to relative moisture content 10% or less; (4) send the unit material into the glue spraying room for glue spraying treatment, using isocyanate adhesive, the glue amount is 4%; (5) drop the glue-containing unit material continuously and evenly on the reciprocating paving machine, While the paving machine is reciprocating, the belt transport auxiliary machine configured on it transports the unit material to the feeder running at a constant speed; (6) the feeder sends the continuously received unit material containing glue to the continuous hot press unit, The two sides of the continuous hot pressing unit are parallel to each other, and the baffle rollers with adjustable spacing are set in the same group. The spacing is consistent with...

Embodiment 3

[0040] Embodiment 3: (1) the thin veneer that timber is cut into 1.7mm, cut into width 200mm, the veneer strip of length 2500mm; (2) veneer strip is dried to moisture content below 10%; (3 ) dipping the veneer strips, using a phenolic resin dipping amount of 8% (the ratio of the solid glue content to the total weight of the material); (4) drying the glue-containing unit material through a mesh belt drying line to a moisture content of 14 -16%, the dried veneer according to the finished product density 0.9g / dm 3 Stacked into blanks, each blank is placed on the feeder in sequence, and the distance between the baffles of the feeder is adjusted to 200mm; (5) The feeder sends the continuously received glue-containing unit materials to the continuous hot press unit for pre-pressing Section, adjust the two sides of the continuous hot press unit to set the spacing between the parallel blocking rollers to be 200mm, and the material passes through the pre-pressing preheating section, ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com