Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Reduce preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

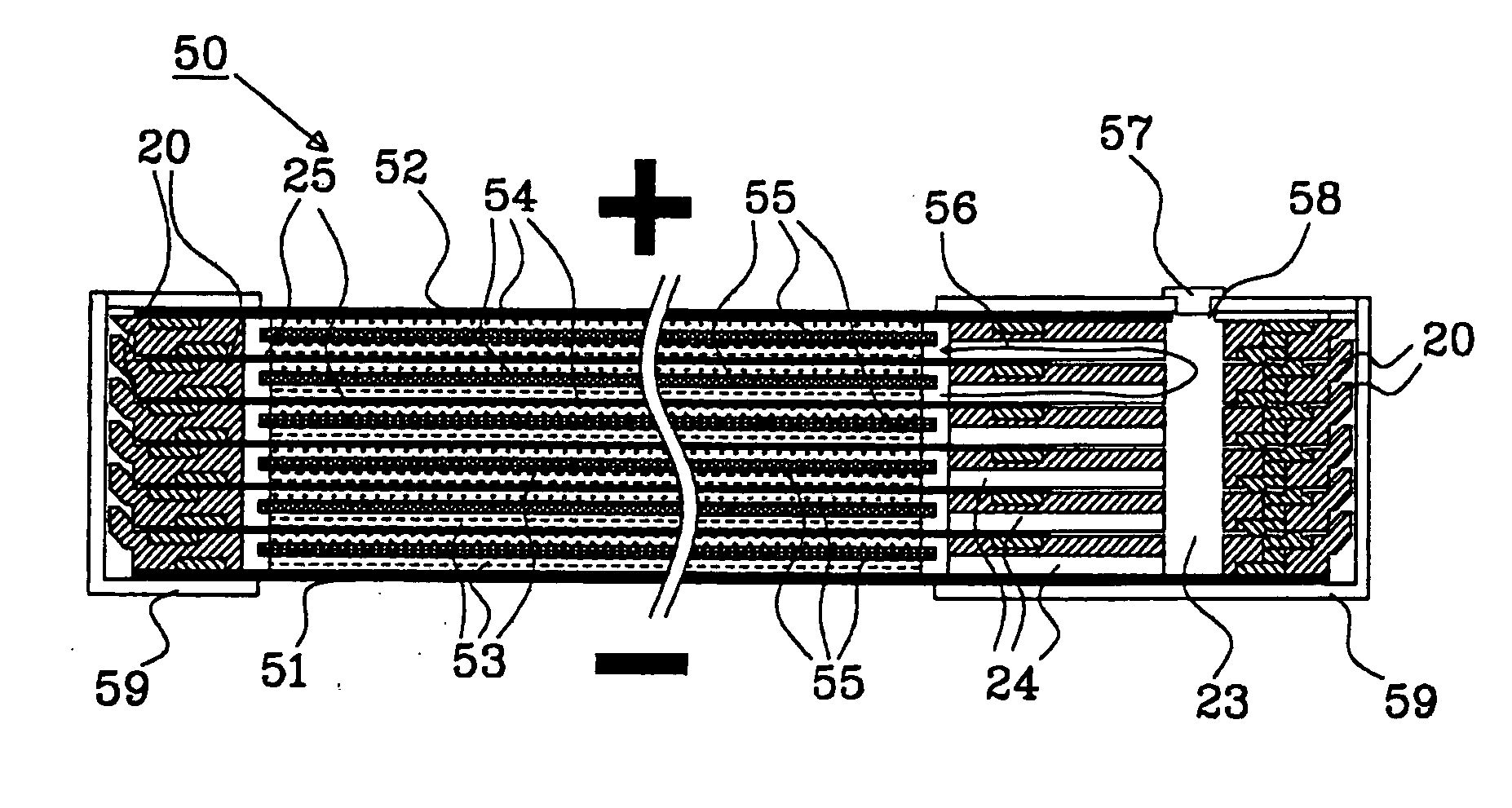

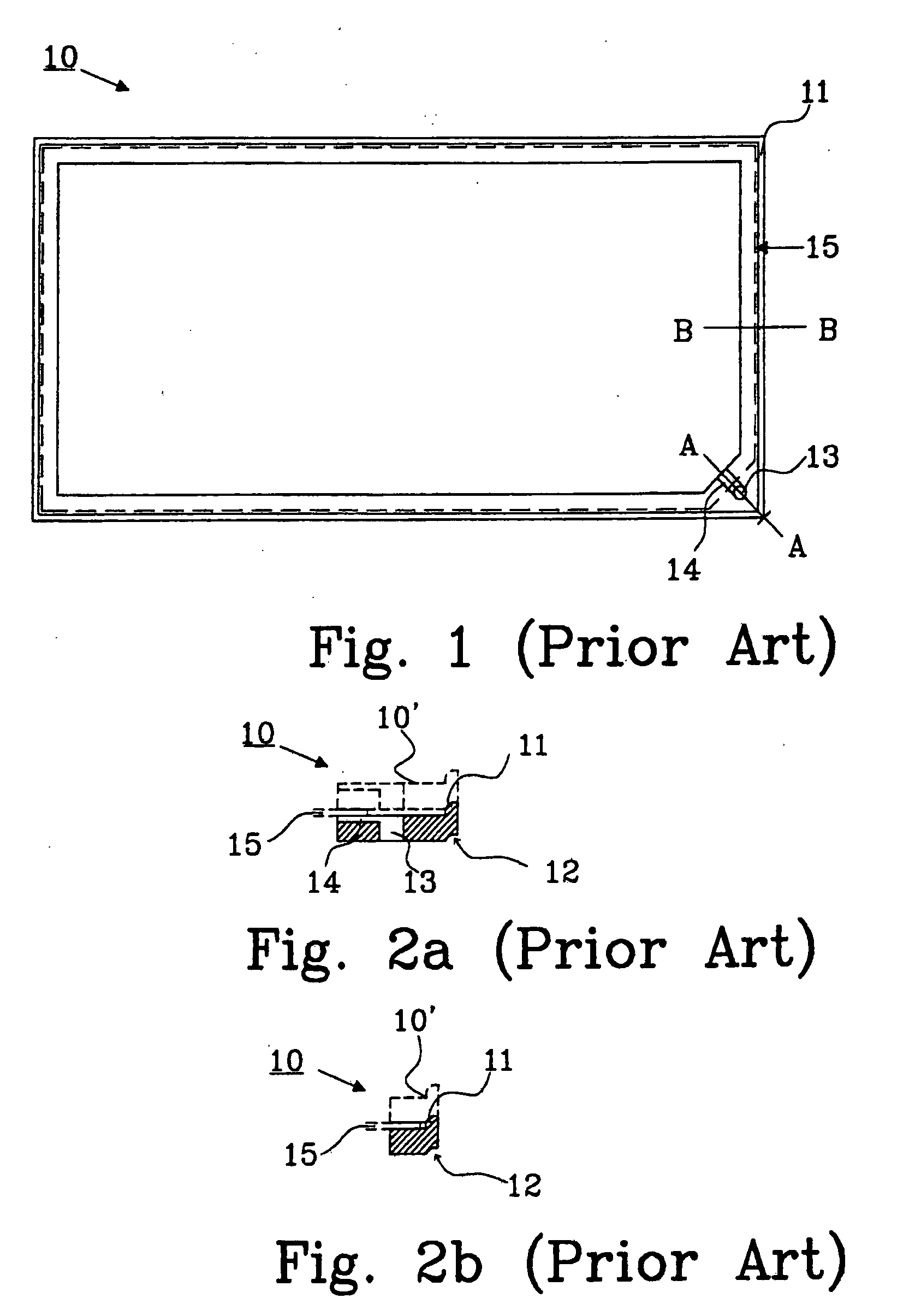

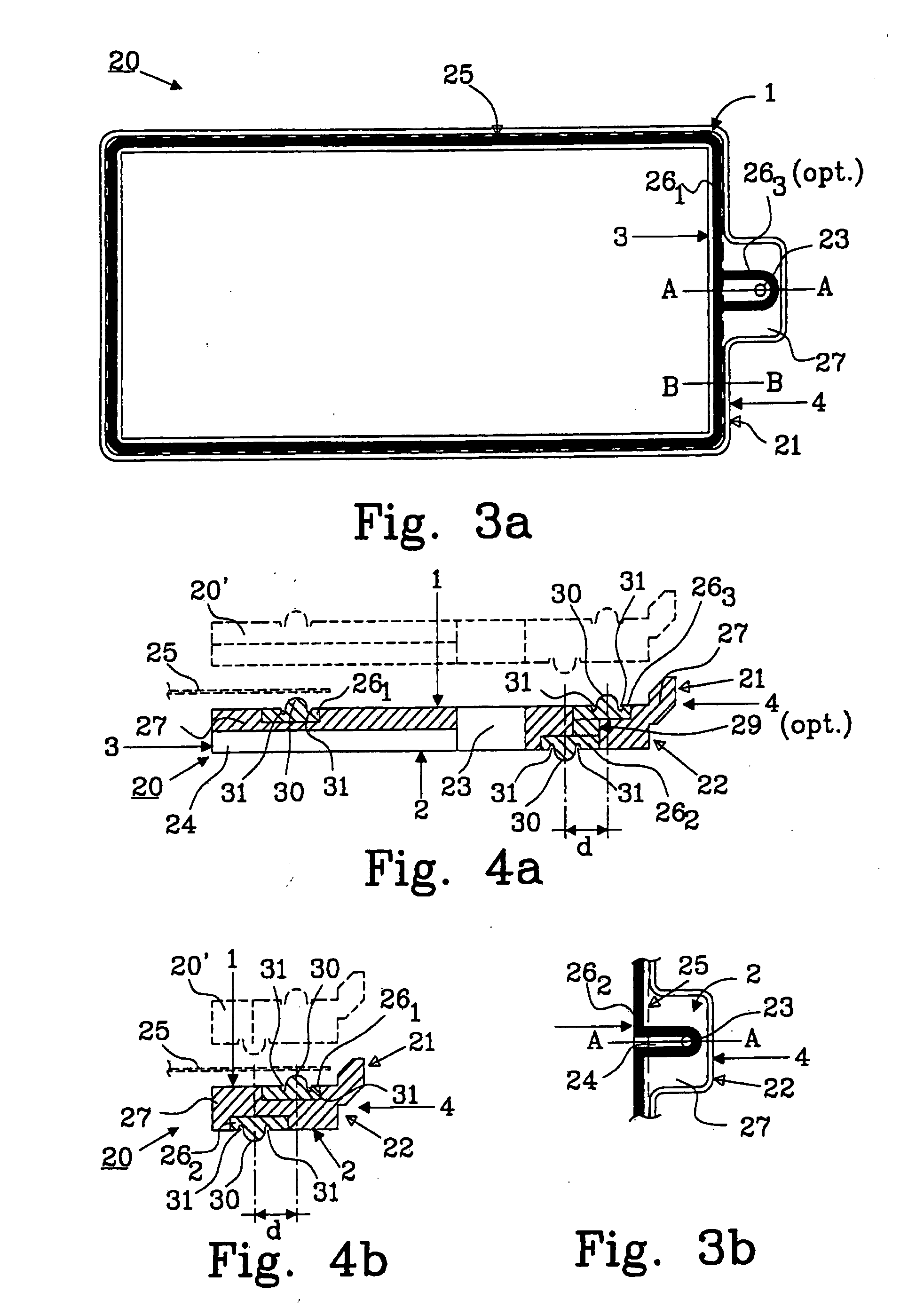

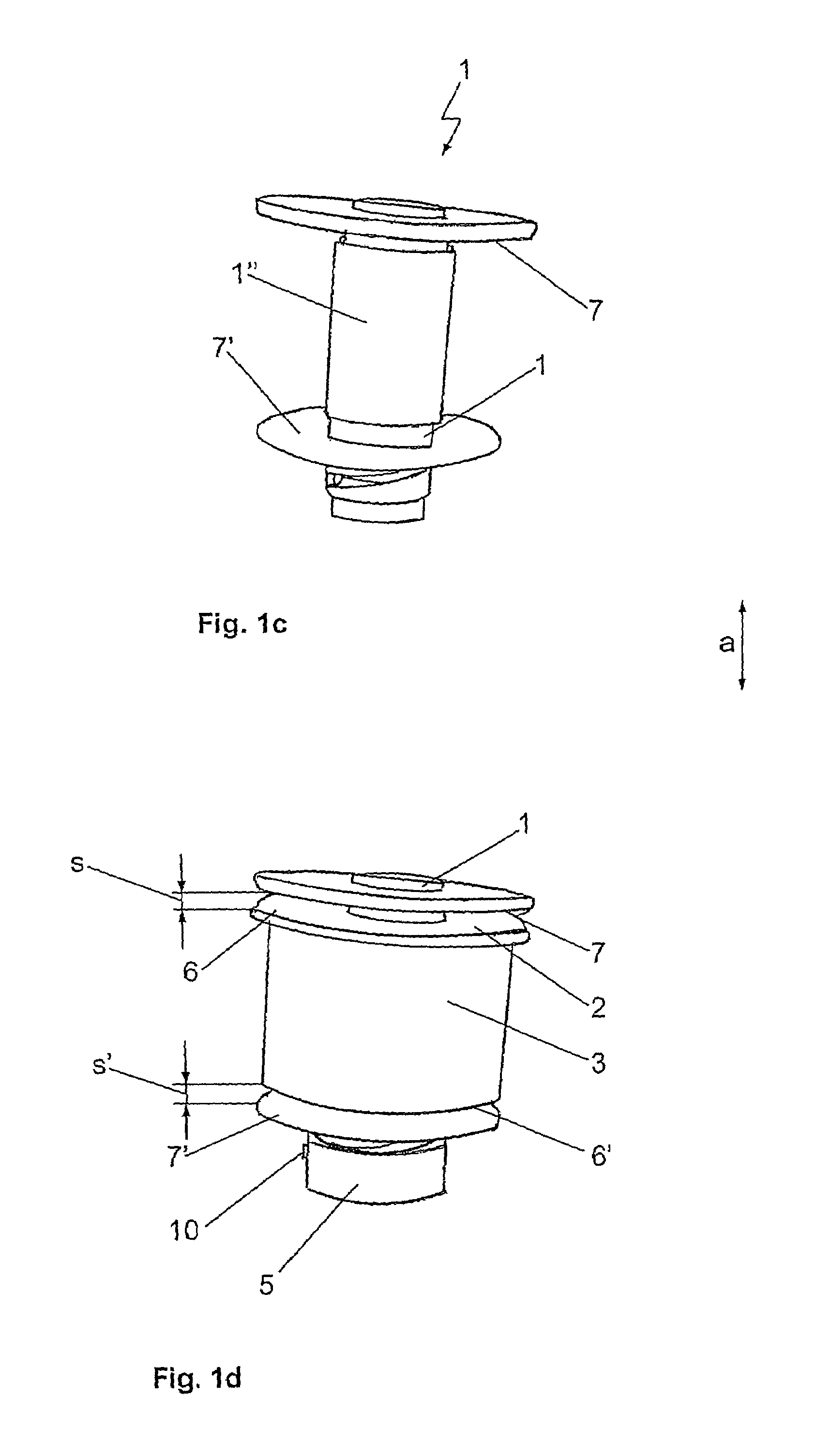

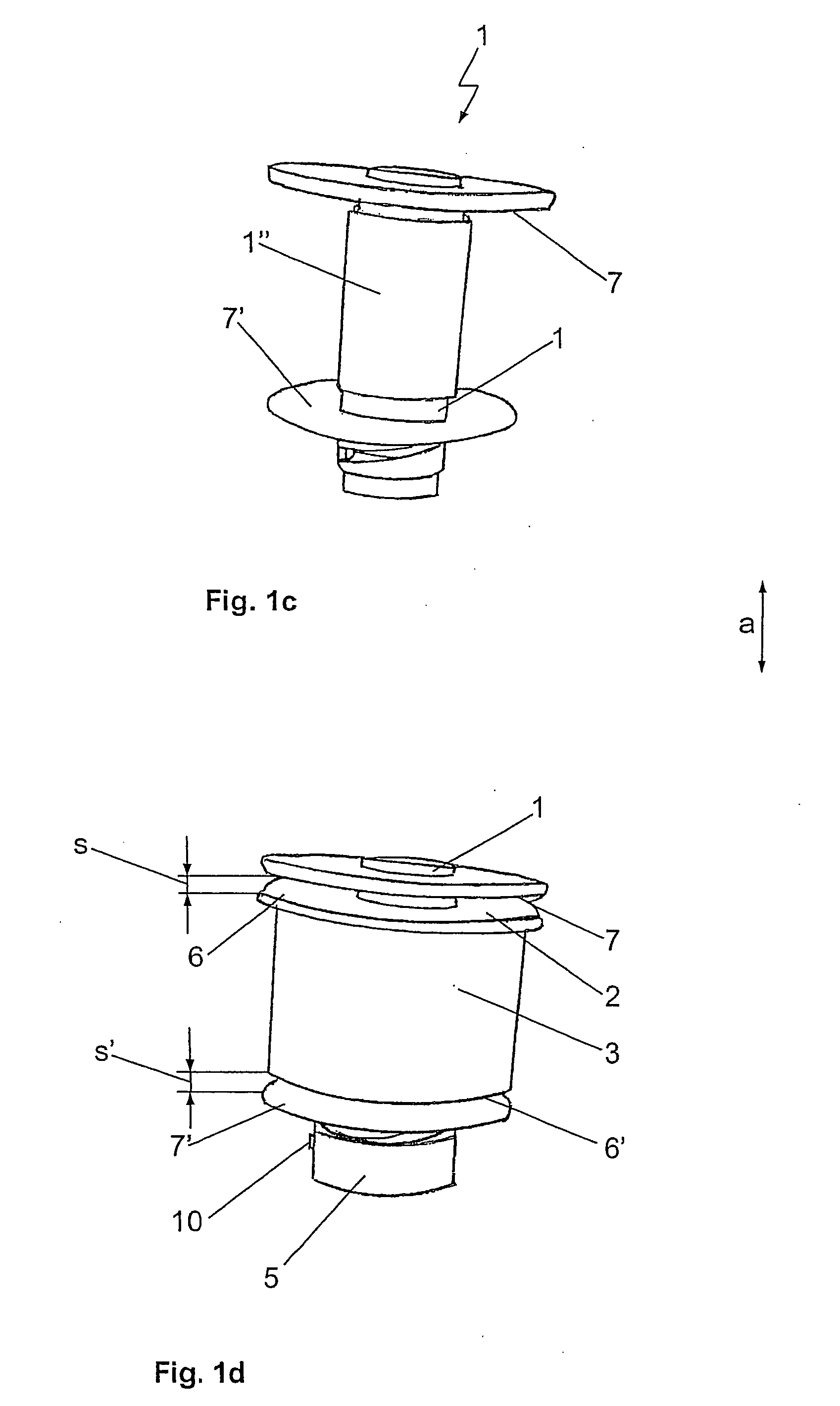

Gasket, a bipolar battery and a method for manufacturing a gasket

ActiveUS20080070106A1Reduce preloadReduce deformation areaPrimary cell to battery groupingEngine sealsClosed loopEngineering

A gasket 20; 40; 80 for use in a starved electrolyte bipolar battery comprises a structural part 27; 44; 82 in the shape of a frame having an upper surface 1 and a lower surface 2, and at least one channel 23, 24; 83, 84 to permit gas passage through the gasket. The structural part is made from a first material having hydrophobic properties. The gasket 20; 40; 80 further comprises at least a first sealing surface 30; 47; 91 arranged in a closed loop projecting from the upper surface 1, and at least a second sealing surface 30; 47; 92 arranged in a closed loop projecting from the lower surface 2. The first and the second sealing surfaces are provided on at least one sealing part 26; 41, 41; 81, are made from a second material, and the first material of the structural part 27; 44; 82 has a higher elastic modulus than an elastic modulus of the second material of the sealing parts 26; 41, 42; 81. A starved electrolyte bipolar battery and a method for manufacturing a gasket are also disclosed.

Owner:NILAR INT AB

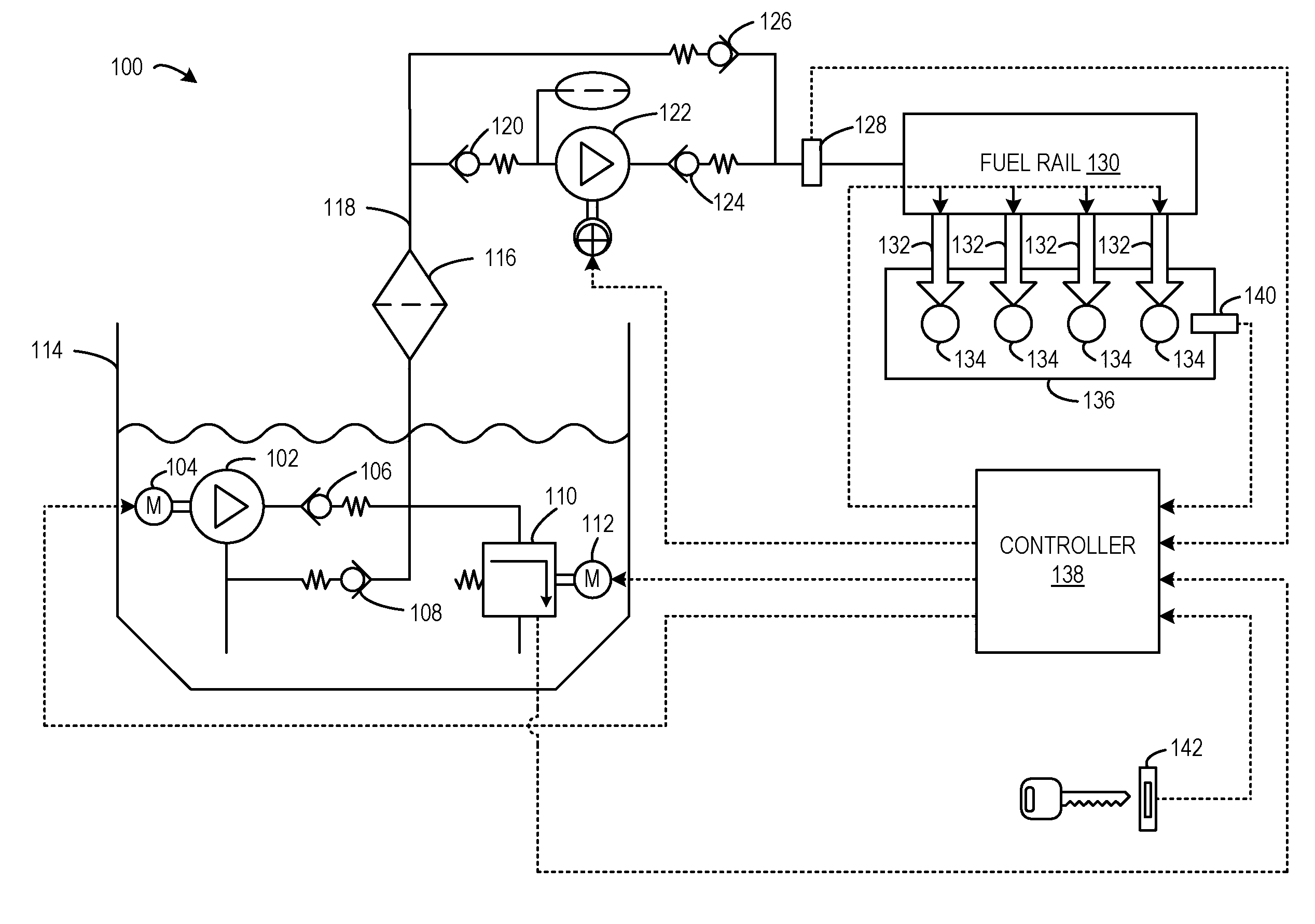

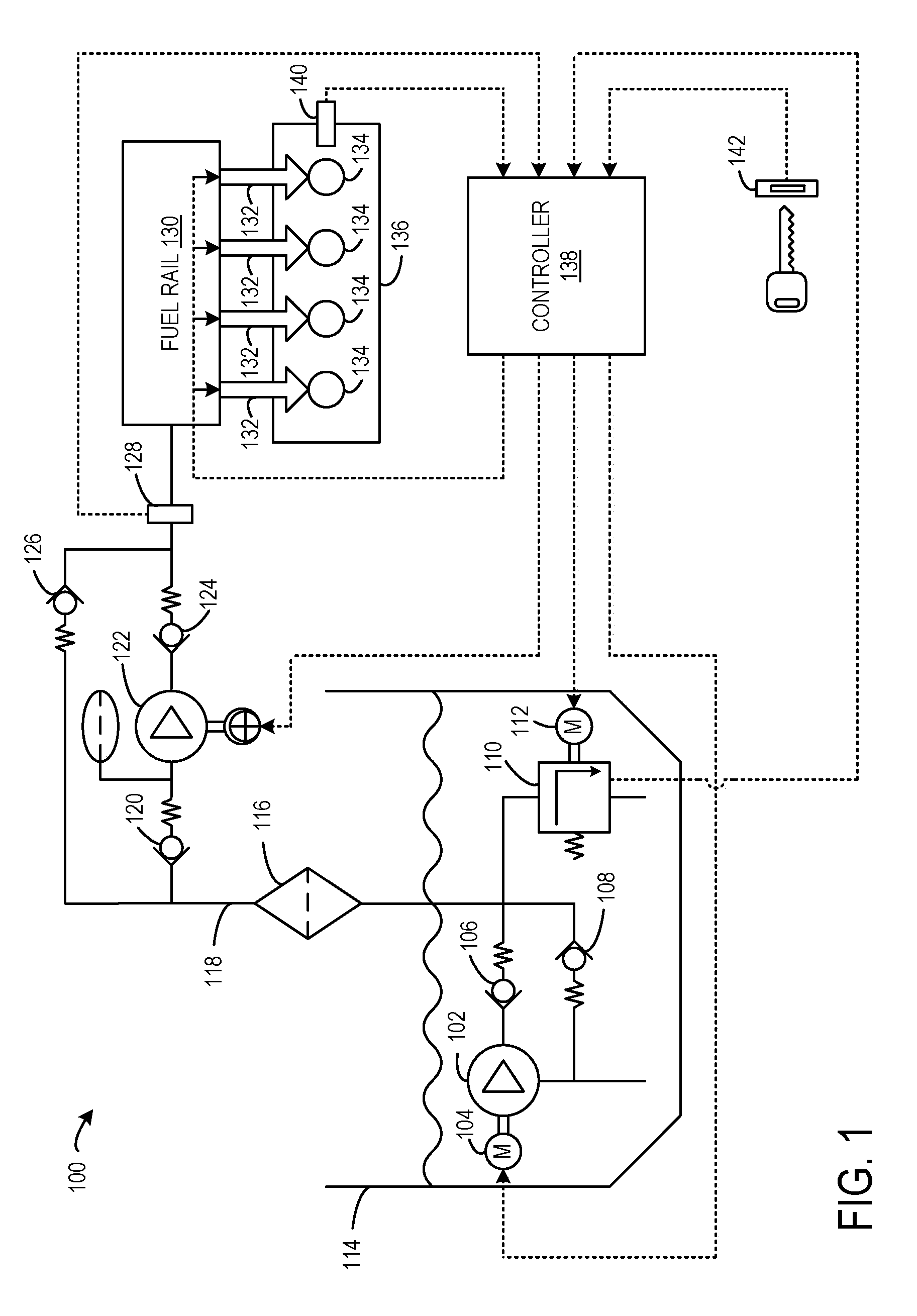

Fuel system with electrically-controllable mechanical pressure regulator

InactiveUS20110000463A1Increase power efficiency and rangeDecrease engine power and efficiencyElectrical controlExhaust apparatusAutomotive engineeringSet point

A method for operating an engine direct injection fuel system is provided. The direct injection fuel system includes a mechanical fuel pressure regulator that has a spring actuatable by an electric motor. The method includes adjusting a preload of the spring by operating the electric motor to adjust a set-point fuel pressure from a first set-point fuel pressure to a second set-point fuel pressure in response to an operating condition, and maintaining the preload of the spring mechanically when the electric motor is not operating.

Owner:FORD GLOBAL TECH LLC

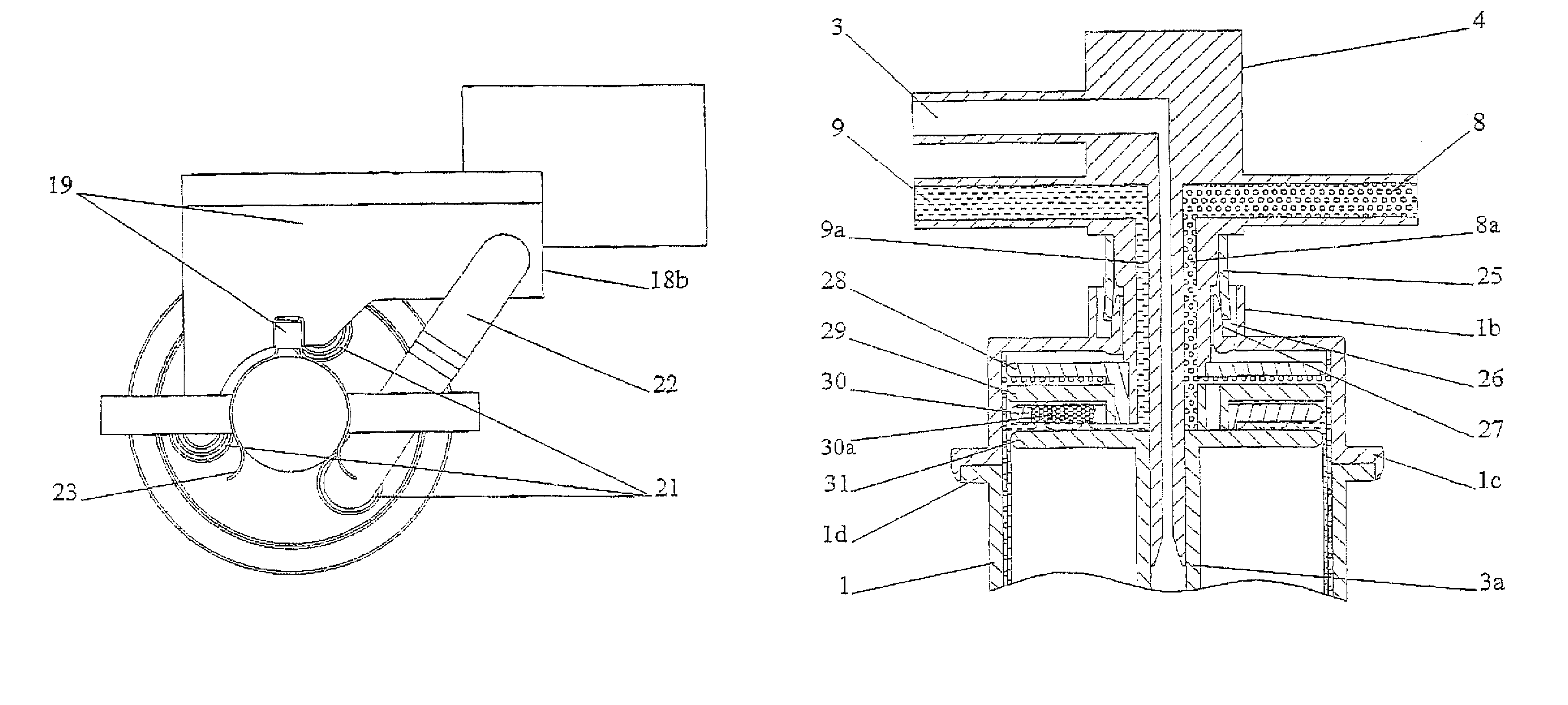

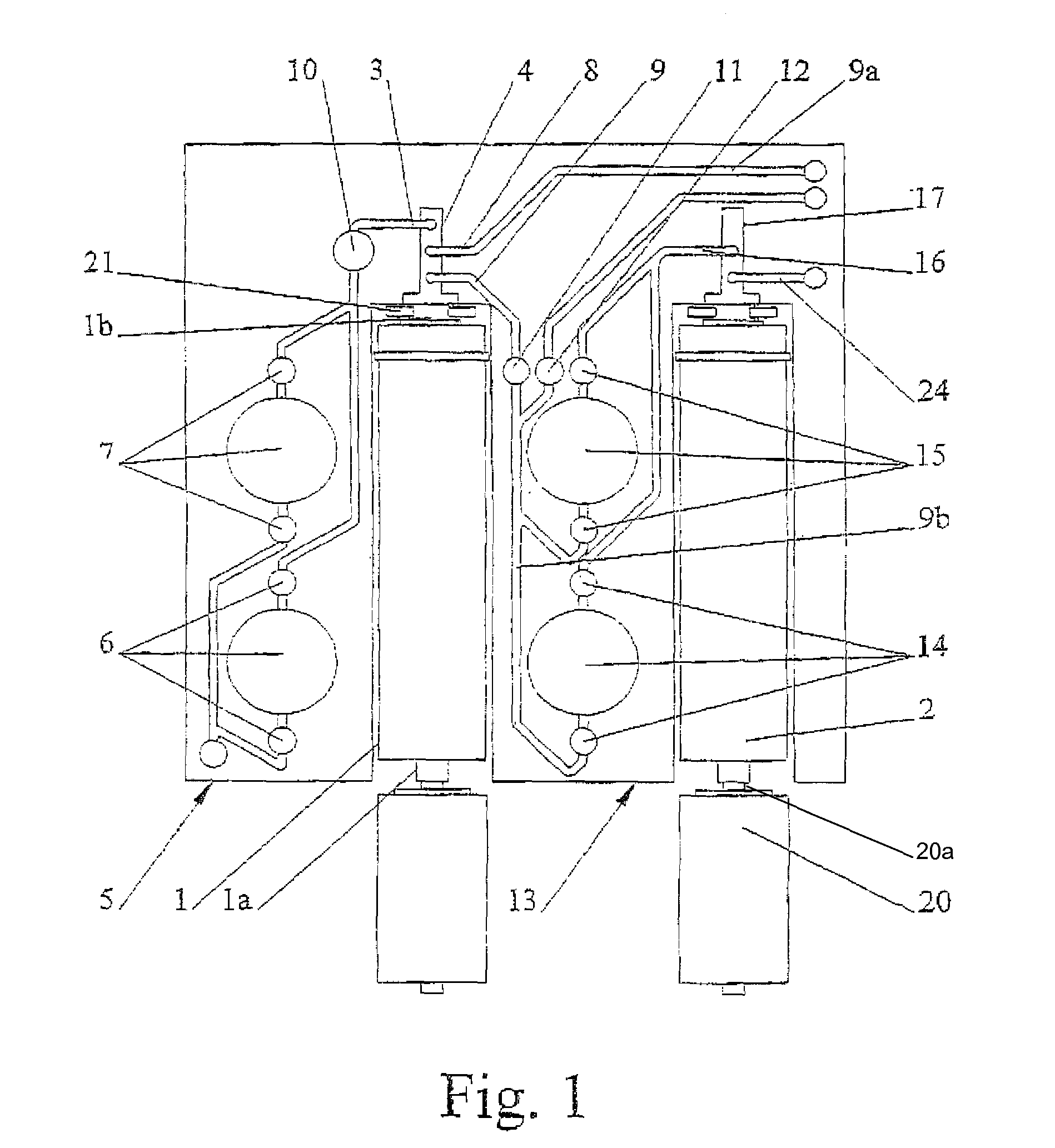

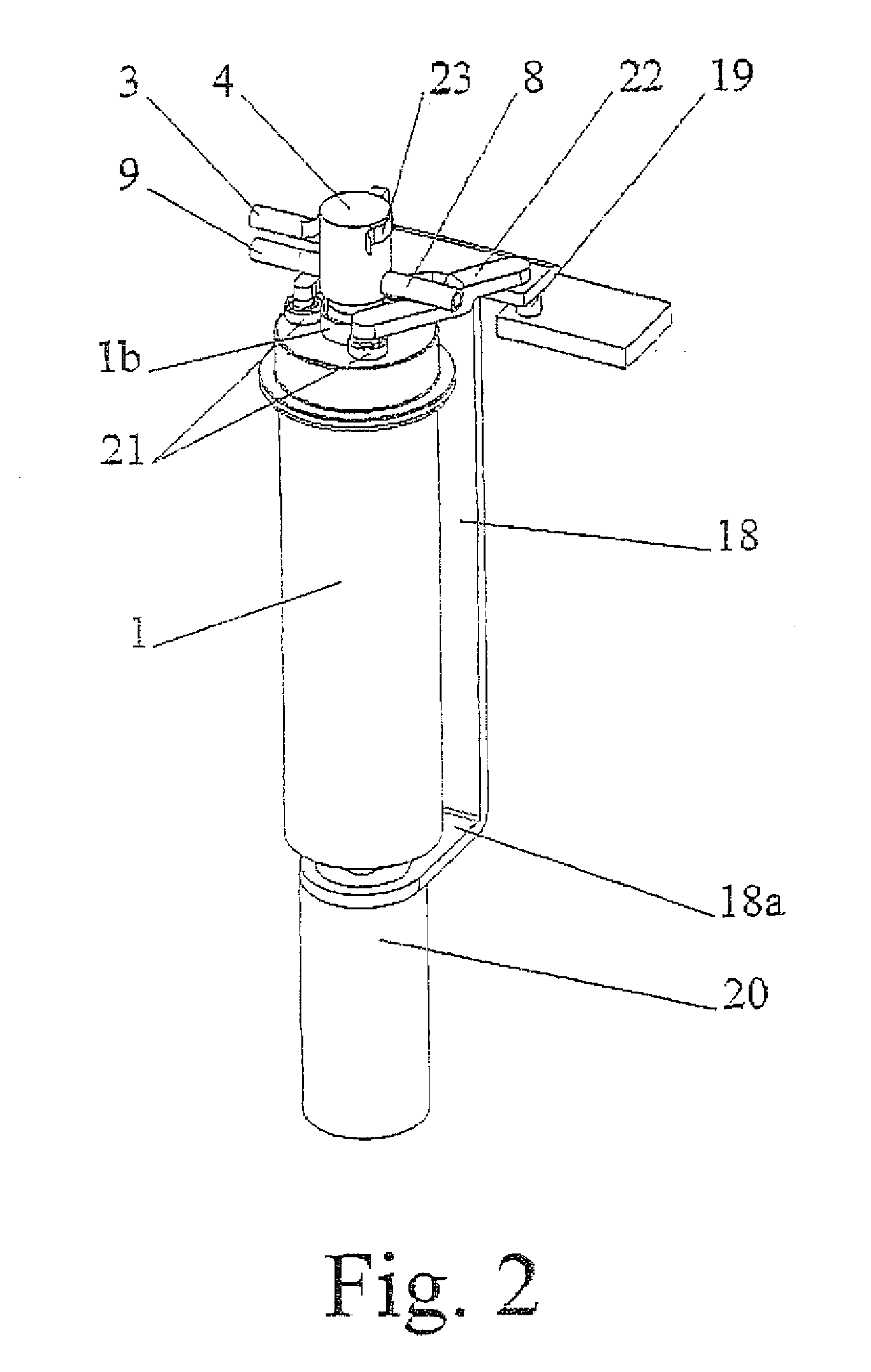

Disposable device for the continuous centrifugal separation of a physiological fluid

ActiveUS8070664B2Reduced Tolerance RequirementsReduce amount of shrinkageCentrifugesPhysiological fluidSingle-Use Device

The invention relates to disposable device for the continuous centrifugal separation of a physiological fluid. The inventive device comprises: a fixed axial element; a centrifugation chamber which is mounted such that it can rotate around the axis of said element; an inlet channel for the blood to be centrifuged, the dispensing port of which is located close to the base of the chamber; and an outlet passage for a separated constituent, the inlet port of which is located close to the other end of the chamber in a concentrated area of one of the separated constituents having the lowest mass density in order for same to be removed continuously. The above-mentioned chamber takes the form of a long tube. The fixed axial element comprises a second outlet passage for a second of the separated constituents, the inlet port of which is located close to the end of the chamber opposite the above-mentioned base in a concentrated area of said second separated constituent having the highest mass density in order for same to be removed continuously.

Owner:SORIN GRP ITAL SRL

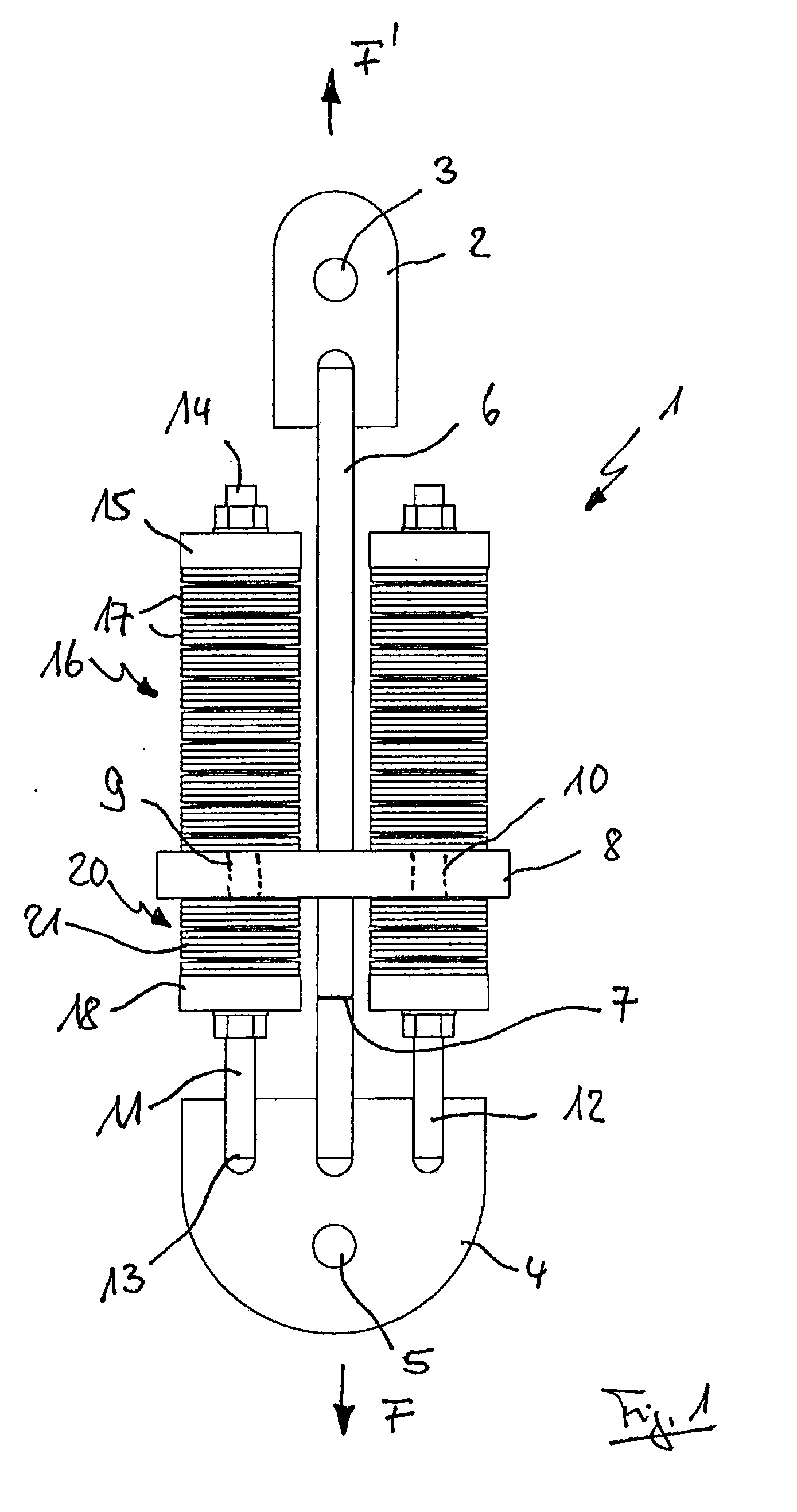

Cable end anchorage with overload protection

InactiveUS8950124B2High degree of inherent rigidity and resistanceDecouple the supporting structureWallsEngineering emergency devicesCouplingCritical load

Owner:JOSEF GARTNER & CO

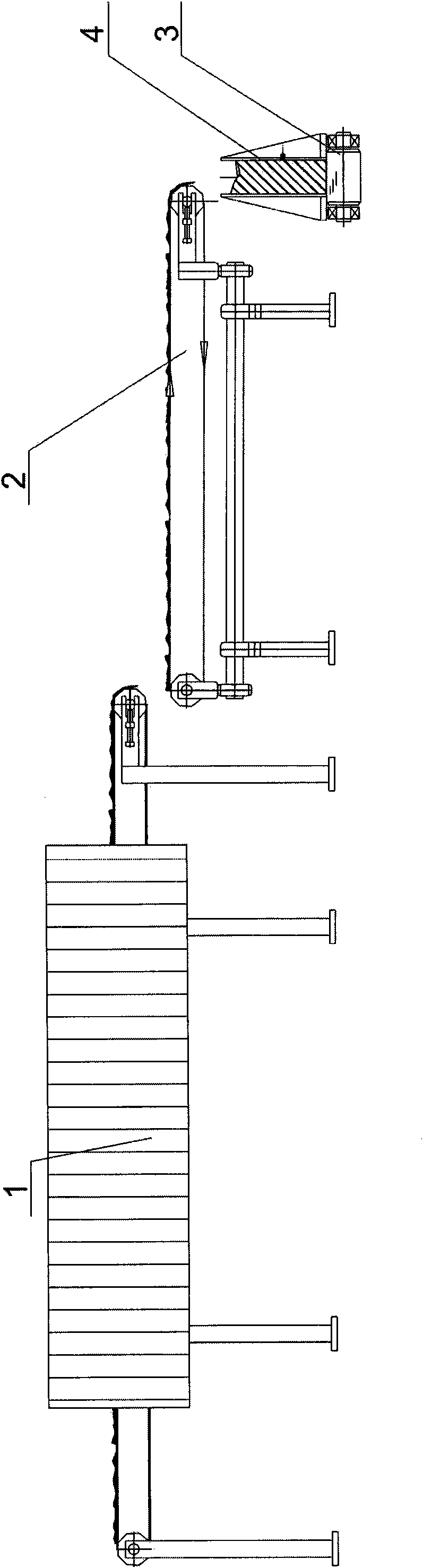

Continuous hot-pressing method for large-section section

InactiveCN102107454AIncrease temperatureImprove plasticityWood working apparatusFlat articlesMicrowaveSingle plate

The invention discloses a continuous hot-pressing method for a large-section section. The method comprises a pretreatment process, a continuous hot-pressing process and a post-treatment process, and is characterized in that: the continuous hot-pressing process comprises the following steps of: A, preheating and prepressing; B, hot-pressing and curing; and C, cooling to guarantee quality. In the method, a continuous blanking mode is adopted, the preheating and the prepressing are increased, and a microwave or high-frequency heating technology is adopted during hot pressing. By the method, a non-lumber small-diameter class bamboo material, a secondary material of poor quality, a single-plate residual material, saw dust and the like are machined into a high-quality material; and the method has the advantages of wide material sources, simple and convenient material manufacturing process, high utilization rate of the material, convenience of operation, low energy consumption, investment saving and the like. Meanwhile, the method can be used for machining the material with any length in a continuous pressing mode and can also be used for machining the material with the thickness of 500mm.

Owner:陈滔

Hydraulic steering gear

InactiveCN102328685AFit tightlyReduce frictional resistanceEngine sealsHydraulic steering gearsWear resistantEngineering

The invention relates to a hydraulic steering gear, belonging to the technical field of hydraulic transmission and control. One end of the valve body of the steering gear is fixedly connected with a stator with a cycloidal pin wheel rotor. A spool which stretches out of a front shaft and a valve pocket which can form a runner switching valve together with the spool are arranged in the valve body. A linkage shaft penetrates through the inner hole of the spool. One end of the linkage shaft is provided with outer teeth which are engaged with a spline in the rotor, and the other end of the linkage shaft is connected with the spool through a radial shifting pin. An annular sealing groove is arranged on the surface of the inner hole of the valve body which is matched with the front shaft. An annular sealing skeleton made of a lubricating wear-resistant material is installed in the sealing groove. One surface of the sealing skeleton is in fit with one sealing surface, and the other surface of the sealing skeleton is provided with a groove which can hold a sealing ring. An elastic sealing ring which is in fit with the other sealing surface is arranged in the groove. On the premise that a good sealing effect is guaranteed, the input torque for power steering is effectively reduced.

Owner:ZHENJIANG HYDRAULICS

Cable End Anchorage With Overload Protection

InactiveUS20110000155A1Increase resistanceReliable decouplingMachine supportsWallsCouplingTransverse plane

A cable end anchorage for fastening at least one cable at a supporting structure includes at least one first connecting element for connection with the supporting structure, at least one second connecting element for connection with the cable and at least one coupling element for connection of the two connecting elements in a force-transmitting manner. In the region of the coupling element, an overload device designed as a predetermined breaking point of the coupling element is provided for unfastening the connection between the two connecting elements when a critical load has been exceeded. A stop device is provided for limiting the relative motion of the connecting elements after unfastening of the connection when a critical load has been exceeded. The cable end anchorage features a transverse plate that is connected with the coupling element in a force-transmitting manner and at least one tension rod that penetrates the transverse plate in a recess with an at least slightly radial clearance, wherein one end of the tension rod is connected with one of the two connecting elements in a force-transmitting manner on one side of the transverse plate, and a terminal plate is provided at the opposite end of the tension rod on the other side of the transverse plate, the terminal plate serving as a stop on the transverse plate when a critical load has been exceeded.

Owner:JOSEF GARTNER & CO

Preload releasing fastener and release system using same

InactiveUS20120076614A1Preload be reduceReduce preloadCosmonautic vehiclesCosmonautic partsFastenerEngineering

A preload reducing fastener adapted to be fastened into a system in which includes a release system. The fastener may have an integral collar which is adapted to change shape, as in the case of a shape memory alloy. The application of heat to fastener may deform the collar such that the fastener may move axially in the load direction, thus reducing the preload previously held by the fastener. A preload reducing device including a preload reducing fastener may include an outer case adapted to center and capture a preload reducing fastener. The case may center the fastener in a desired location in a preloaded system, and may also capture the fastener after release of the system.

Owner:SPACE SYST LORAL INC

Main gear down device

InactiveCN101055018ASimple structureImprove support rigidityToothed gearingsDifferential gearingsGear wheelEngineering

The present invention provides a main decelerate device which includes a planet gear load-uniformed mechanism, a driver gear and a initiative bevel gear driven by the device, a driven bevel gear engaged with the initiative bevel gear and a speed differientiator connected to the driven bevel gear. It is characterized in that one of the sun gear in the planet gear load-uniformed mechanism is connected to the initiative bevel gear, another sun gear is connected to one of two engaged intermediate drive gears by an axle sleeve, another intermediate drive gear is connected to a secondary initiative bevel gear, the initiative bevel gear and the secondary initiative bevel gear are both connected to a driven bevel gear with double cog. The device divides the power into two parallel path powers with reverse rotate direction and equal torsion, and then combines the two powers into one power by making the main, secondary initiative bevel gears engage with the driven bevel gear with double cog, and passes the power to the speed differientiator by the driven bevel gear and output the power by an axle shaft gear, thereby complete the power output between interleaving shafts, conquers the axial direction offset of the driven bevel gear and increases the drive ability by times.

Owner:张春

Preload releasing fastener and release system using same

InactiveUS9180982B2Reduce preloadCosmonautic vehiclesCosmonautic partsShape-memory alloyBiomedical engineering

A preload reducing fastener adapted to be fastened into a system in which includes a release system. The fastener may have an integral collar which is adapted to change shape, as in the case of a shape memory alloy. The application of heat to fastener may deform the collar such that the fastener may move axially in the load direction, thus reducing the preload previously held by the fastener. A preload reducing device including a preload reducing fastener may include an outer case adapted to center and capture a preload reducing fastener. The case may center the fastener in a desired location in a preloaded system, and may also capture the fastener after release of the system.

Owner:SPACE SYST LORAL INC

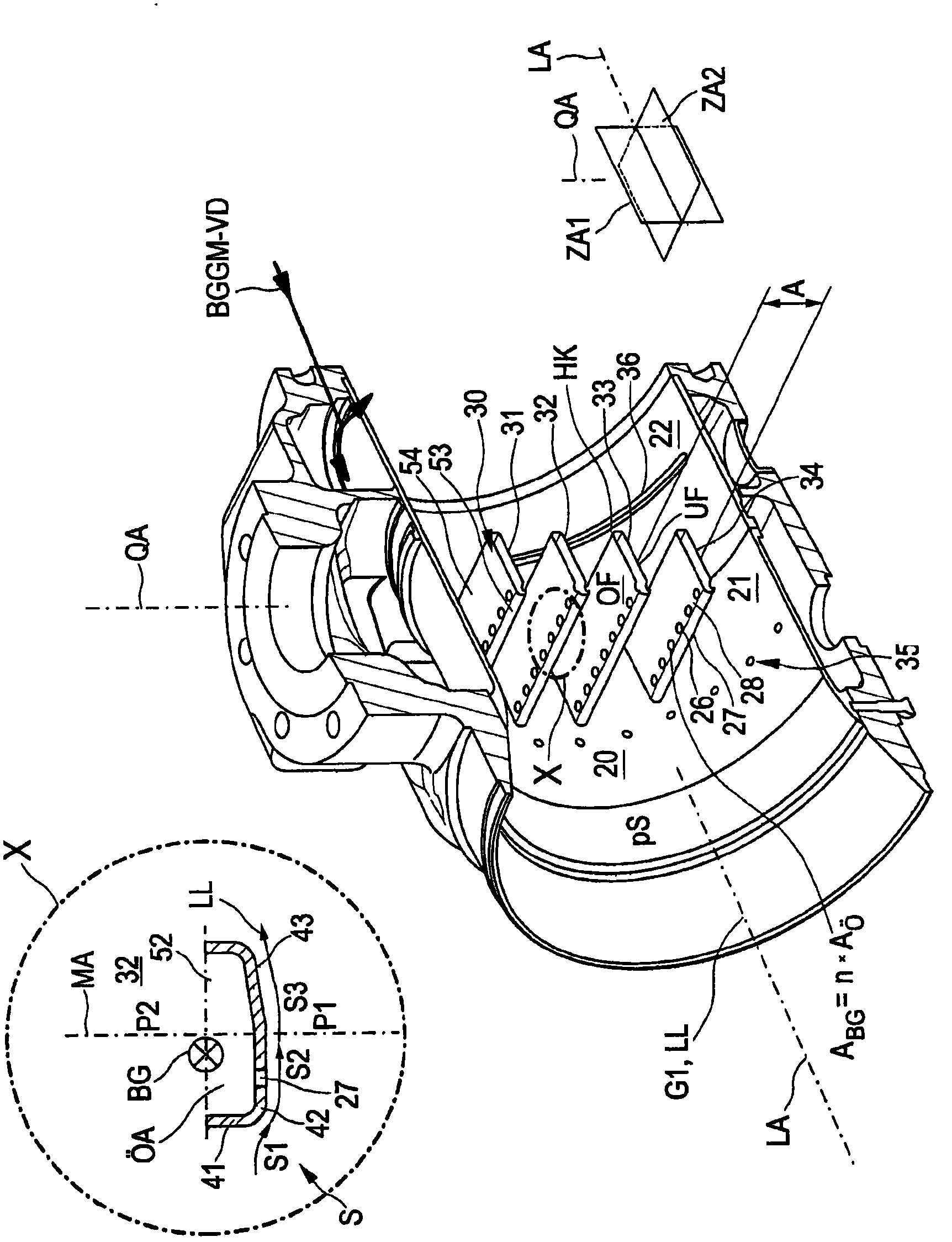

Elastomer bush bearing with axial limit stop

InactiveUS7506862B2Reduce preloadCompensation changesMachine supportsLiquid springsElastomerRelative motion

An elastomer bush bearing is disclosed with at least one axial limit stop. An elastomeric bush bearing is provided with a damping characteristic that can be adapted to the respective application and / or to changing preloads. The bearing is constructed in that a stop face formed on the bearing body and the opposing stop face, arranged on the inner sleeve or on a stop element supported by the inner sleeve, which can be rotated relative to each other in the circumferential direction of the bearing by an actuator or can be displaced relative to each other in the axial direction. The mutual separation between the stop faces determined by the gap changes simultaneously with a corresponding relative motion of the stop faces effected by a rotation of the actuator.

Owner:ZF FRIEDRICHSHAFEN AG

Bearing device for wheel

InactiveCN1886600AReduction of suppressed fit interferencePrevent creepRolling contact bearingsBearing componentsDouble rowKnuckle

To provide a bearing device for a wheel installed on a light-weight light alloy knuckle and capable of preventing preload reduction and bearing creep from occurring due to temperature rise. This bearing device for the wheel comprises a hub wheel (1) integrally having a wheel mounting flange (4) at one end and having a small diameter step part (5) axially extending from the wheel mounting flange (4) formed therein, a wheel bearing (3) formed of a double row bearing disposed in the small diameter step part (5), and the knuckle (2) forming a suspension device and formed of a light alloy. The wheel bearing (3) is press-fitted into the knuckle (2) at a specified interference, and the hub wheel (1) is rotatably pivoted on the knuckle (2). A pair of annular grooves (18) are formed in a loading area on the outer periphery of the outer ring (12) of the wheel bearing (3), and resin bands (19) formed of a heat resistant polyamide synthetic resin and having a coefficient of linear expansion of 8 to 16 x 10<-5> / DEG C are filled in the annular grooves (18) by injection molding.

Owner:NTN CORP

Elastomer bush bearing with axial limit stop

InactiveUS20060012092A1Reduce preloadCompensation changesResilient suspensionsPivoted suspension armsElastomerEngineering

An elastomer bush bearing is disclosed with at least one axial limit stop. An elastomeric bush bearing is provided with a damping characteristic that can be adapted to the respective application and / or to changing preloads. The bearing is constructed in that a stop face formed on the bearing body and the opposing stop face, arranged on the inner sleeve or on a stop element supported by the inner sleeve, which can be rotated relative to each other in the circumferential direction of the bearing by an actuator or can be displaced relative to each other in the axial direction. The mutual separation between the stop faces determined by the gap changes simultaneously with a corresponding relative motion of the stop faces effected by a rotation of the actuator.

Owner:ZF FRIEDRICHSHAFEN AG

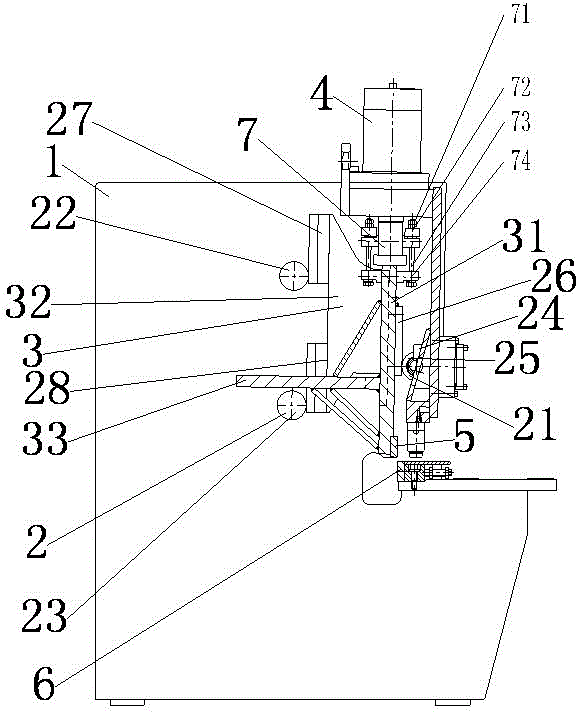

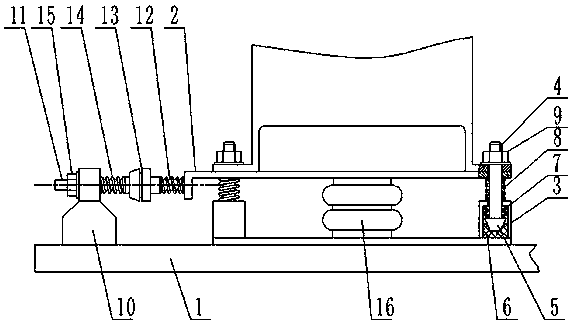

Gate type plate shearing machine

ActiveCN104526045AThere will be no gap floatingGuaranteed contactShearing machinesShearing machine accessoriesKnife bladesSupport point

The invention provides a gate type plate shearing machine which is provided with front supporting points of a small structure and has a simple overall structure and low cost. The gate type plate shearing machine comprises a machine frame, a tool rest and an oil cylinder, wherein the tool rest is arranged on the machine frame through a three-point supporting structure in a vertical sliding mode, and the oil cylinder drives the tool rest to move vertically. The tool rest comprises a tool rest vertical plate and tool rest side plates fixed to the two sides of the tool rest. An upper blade is fixed to the lower edge of the oblique tool rest vertical plate, and a lower blade is fixed to the machine frame. The three-point supporting structure comprises the front supporting points, upper rear supporting points and lower rear supporting points, and the front supporting points, the upper rear supporting points and the lower rear supporting points are arranged on the machine frame. The front supporting points are elastic supporting points tightly pressed on the front of the tool rest, and the upper portion and the rear portion of the rear of the tool rest maintain contact with the upper rear supporting points and the lower rear supporting points respectively under the action of the elastic supporting points on the tool rest. The positions, in the vertical direction, of the lower rear supporting points are flush with the cutting edge of the lower blade.

Owner:NANJING SHENGDA HEAVY IND MACHINERY

Clutch actuator and method for actuating a clutch

InactiveUS20090192016A1Reduce MechanismsImprove performanceFluid actuated clutchesGearing controlMobile vehicleDrive motor

A clutch plate (6), as well as a method for operating a clutch (3), between the drive motor and the transmission (1) of a motor vehicle. The clutch plate includes a cylinder with a piston (14) and an actuator (15), such that a clutch release bearing (4), arranged co-axially to the central axis of the clutch, may be operated to apply an axial pre-tensioning force on the clutch release bearing and conduct an operating medium into the clutch plate for axially displacing the piston and / or the clutch release bearing. To simplify a clutch plate of this type and enhance its utilization, the clutch plate is configured and used for generating the pre-tensioning force.

Owner:ZF FRIEDRICHSHAFEN AG

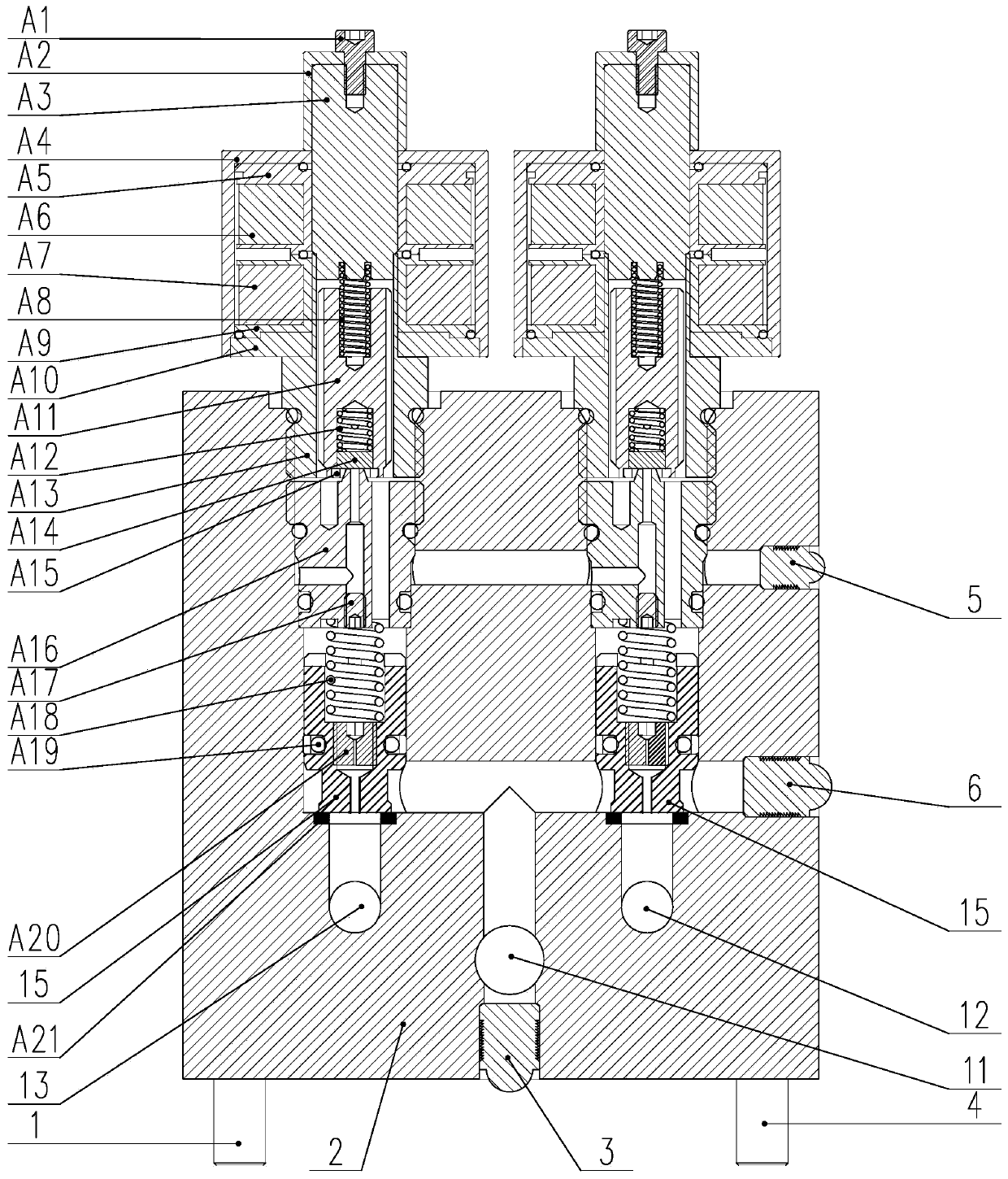

Three-position four-way water pressure proportional valve based on high-speed switch valve

PendingCN111219502AImprove anti-pollution performanceReduce preloadOperating means/releasing devices for valvesServomotor componentsEngineeringDamper

The invention belongs to the technical field of valve bodies, and relates to a three-position four-way water pressure proportional valve based on a high-speed switch valve. The three-position four-waywater pressure proportional valve comprises a valve block, four main valve core assemblies are installed on the valve block, the upper end of each main valve core assembly is provided with a pilot valve assembly in a matched mode, the upper end of each pilot valve assembly is provided with an electromagnet assembly in a matched mode, each main valve core assembly comprises a main valve core arranged in an inner hole of the valve block in a sliding sealing mode, the lower portion of an inner cavity of each main valve core is provided with a damper, main valve core pretightening springs are arranged above the dampers, and main valve core seat pads are arranged between the bottom faces of the main valve cores and the inner hole of the valve block to from soft seal. The proportional valve caneffectively meet operation environment requirements, and the valve core response speed is high.

Owner:HUST WUXI RES INST

High-performance bonded rare earth magnetostrictive material and preparation method thereof

InactiveCN106098929AReduce contentSimple processMagnetostrictive device manufacture/assemblyMagnetostrictive material selectionInfrared lampRare earth

The invention discloses a high-performance bonded rare earth magnetostrictive material and a preparation method thereof. The high-performance bonded rare earth magnetostrictive material comprises the following raw materials, in parts by weight:3-5 parts of metal terbium, 5-10 parts of metal dysprosium, 15-20 parts of metal iron, 10-15 parts of binders, 30-40 parts of acetone solution, 10-15 parts of curing agents and 10-15 parts of coupling agents. The method is characterized by blending the metal terbium, the metal dysprosium and the metal iron according to a ratio of 3:7:19 in molar mass, and placing the mixture in a vacuum non-consumable arc furnace for argon-filling melting to obtain an alloy ingot; then, under the protection of gasoline, smashing the alloy ingot through an ingot disc to obtain powder particles having required particle sizes; then, mixing the obtained powder particles with the binders, then, placing the mixture into the acetone solution, stirring the solution and meanwhile, heating the solution with an infrared lamp until the materials are uniformly blended and acetone is volatilized completely; after cooling, adding the curing agents, and after carrying out full stirring and uniform blending, keeping the obtained mixture in a certain intensity of magnetic field for a period of time; and then, carrying out compression moulding through a hydraulic press, and finally, carrying out curing processing. The tensile strength of the obtained material is enhanced, and the production cost is low.

Owner:上海归经智能科技有限公司

Cardiac Pump

ActiveUS20170128644A1Reduce preloadPreload force can be increasedPump componentsBlood pumpsMagnetic bearingEngineering

A cardiac pump includes a plain bearing assembly having a first plain bearing portion that is coupled to a cardiac pump rotor and a second plain bearing portion that is coupled to a cardiac pump housing. The plain bearing assembly is configured to rotatably support the cardiac pump rotor within the cardiac pump housing in at least an axial direction of the cardiac pump rotor. A magnetic bearing assembly includes a first magnetic bearing portion that is coupled to the cardiac pump rotor and a second magnetic bearing portion that is coupled to the cardiac pump housing. The magnetic bearing assembly is configured to rotatably support the cardiac pump rotor within the cardiac pump housing in a radial direction of the cardiac pump rotor and bias the cardiac pump rotor in the axial direction such that the magnetic bearing assembly provides a preload force to preload the plain bearing assembly.

Owner:CALON CARDIO TECH

Gas mixer and gas mixing system

InactiveCN104144740AReduce preloadInternal combustion piston enginesFlow mixersCombustible gasEngineering

A gas mixer for mixing a first gas and a second gas, having a first, outer gas housing part, having an inlet for the first gas in a longitudinal axis and an inlet for the second gas in a transverse axis, a second, interior gas housing part set into the first gas housing part to form an annular space for a second gas, having a mixing space into which the first gas and the second gas are introduced for mixing. The first and second gas housing parts and the annular space are aligned along the longitudinal axis and the mixing space is aligned cylindrically along the longitudinal axis. A mixing device having a plurality of hollow rods is arranged in the mixing space. A hollow space of a hollow rod is in fluid communication on both sides with the annular space. The number of hollow rods extends transverse to the longitudinal axis and the transverse axis and at least one hollow rod has a plurality of openings for the second gas, so that the hollow space is in fluid communication with the cylindrical mixing space.

Owner:ROLLS ROYCE SOLUTIONS GMBH

Handheld farming machine engine damping device

ActiveCN110107645APrevention of degraded vibration damping performanceReduce mid and low frequency vibrationSpringsNon-rotating vibration suppressionComputer moduleEngineering

The invention discloses a handheld farming machine engine damping device, which comprises a base. A longitudinal damping module and a transverse damping module are arranged above the base; the longitudinal damping module comprises an engine connecting plate which is horizontally arranged, and a plurality of longitudinal dampers used for supporting the engine connecting plate are arranged between the engine connecting plate and the base; the multiple longitudinal dampers are evenly arranged at intervals by taking the center line of the engine connecting plate as the center and surrounding the center; and the transverse damping module comprises a support fixedly connected to the front part of the longitudinal damping module, an elastic connecting piece is arranged between the support and theengine connecting plate, and the support and the engine connecting plate are connected through the elastic connecting piece. The handheld farming machine engine damping device is simple in structureand can consume vibration energy brought by an engine, thus vibration transmission for handles is lowered, and the discomfort feeling of an operator is relieved.

Owner:CHONGQING UNIV OF TECH

Composition of medication prepared from safflower and leaves of hawthorn

InactiveCN101049355AMeet urgent clinical needsProlonged thrombosis timeOrganic active ingredientsCardiovascular disorderDiseaseCerebral thrombosis

A Chinese medicine for treating cardiovascular and cerebrovascular diseases, such as cerebral thrombosis, coronary heart disease, angina pectoris, vasculitis, myocardiac infarction and hyperlipemia, is prepared from safflower and hawthorn leaf, or their extracts (safflower yellow and hawthorn leaf flavone).

Owner:JIANGYIN TIANJIANG PHARMA

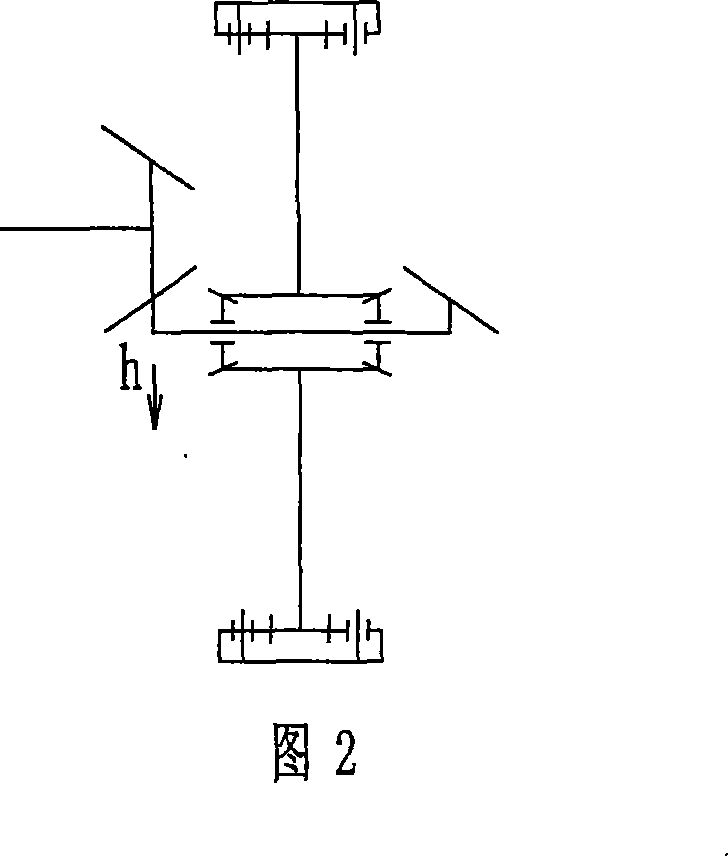

Method for adjusting the bias in a bearing assembly and bearing assembly

The invention relates to a method for adjusting the bias in a bearing assembly (1), wherein the bearing assembly (1) comprises at least one rolling bearing (2) with at least one bearing inner ring (3) and at least one bearing outer ring (4). In order to be able to adjust the bias in an easy way, the adjustment of the bearing bias according to the invention is carried out by the implementation of the following steps: a) increasing the bias in the bearing assembly (1) starting from a lower start value, or decreasing the bias in the bearing assembly (1) starting from an upper start value and simultaneously measuring the electrical resistance (RIst) between the bearing inner ring (3) and the bearing outer ring (4); b) ending the change of the bias in the bearing assembly (1) as soon as a target value (Rsoll) for the electrical resistance is reached. The invention further relates to a bearing assembly comprising a device for adjusting the bias.

Owner:AB SKF

Method for shifting gears of transmission device gear-shifting transmission capable of being switched between at least two transmission levels

ActiveCN104141780ARealize unloadingReduce manufacturing costGearing controlHydraulic motorEngineering

The invention relates to a method for shifting gears of a transmission device gear-shifting transmission capable of being switched between at least two transmission levels. A transmission device is driven by a hydrostatic transmission; in order to shift the gears of the gear-shifting transmission between the transmission levels, the method comprises the steps as follows: Step 1, unloading the gear-shifting transmission: changing the input quantity and / or the liquid inlet quantity per revolution of a hydraulic motor until the pressure difference on the hydraulic motor is lower than the preset pressure difference, or over-regulating a brake valve device to an opening position for stopping a brake valve function; Step 2, shifting the gear-shifting transmission into a neutral gear; Step 3, performing electric-hydraulic synchronization on the revolving speed of the hydraulic motor; Step 4, shifting the gear-shifting transmission into a new transmission level; Step 5, applying a load to the gear-shifting transmission.

Owner:LINDE HYDRAULICS

A multifunctional unsaturated soil consolidation instrument and testing method

InactiveCN104458430BReduce preloadVersatileMaterial strength using tensile/compressive forcesSoil scienceAxial pressure

A multifunctional unsaturated soil consolidation instrument and a testing method belong to the field of geotechnical testing instruments. The built-in methods of thrust bearings, linear bearings, self-aligning parts and axial pressure sensors are used on the loading rod of the test platform of the cementation instrument to eliminate the influence of friction during loading, and the design of rotating rigid connection components reduces the impact on the sample. The design of the self-aligning component solves the problem of eccentricity of the loading rod and the sample due to processing and installation. At the same time, the optimized design of the structure enables it to adapt to various loading platforms, ensuring that it can be tested on the existing saturated soil consolidation instrument, and can also be tested on the triaxial compression test instrument.

Owner:DALIAN UNIV OF TECH

Pharmaceutical composition of containing puerarin and leaves of hawthorn

InactiveCN101049356AMeet urgent clinical needsReduce preloadOrganic active ingredientsMetabolism disorderDiseasePuerarin

A medical composition in the form of injection or orally taken solid or liquid for treating coronary heart disease, angina pectoris, hypertension, cerebrovascular disease, hemicrania, diabetes, etc is proportionally prepared from kakonein and hawthorn leaf flavone.

Owner:JIANGYIN TIANJIANG PHARMA

Controllable centrifugal drum type high-rise descent control device

InactiveCN103316437ATo achieve the purpose of slowing downIncrease preloadBuilding rescueBrake torquePositive pressure

The invention discloses a controllable centrifugal drum type high-rise descent control device. A winding wheel is connected with an accelerator mechanism which is connected with a centrifugal drum type brake mechanism, a manual brake mechanism and an automatic descent speed control mechanism are connected onto the centrifugal drum type brake mechanism respectively, and a fireproof steel wire is wound on the winding wheel through a lead hole in a machine frame. The controllable centrifugal drum type high-rise descent control device achieves automatic uniform-speed descent through the accelerator mechanism and the centrifugal drum type brake mechanism, achieves the purpose of slow descent, and is simple and easy to use. A speed regulation knob is controlled manually, a transmission control spring group is tensioned (loosened) so as to increase (reduce) pre-tightening pressure exerted on a brake block, and the purpose of increase (reduction) of automatic descent speed is achieved. A movable handle is controlled, a part of axial force generated by the movable handle is transformed into positive pressure which is perpendicular to a shaft and is exerted on the brake block to form a braking torque so as to achieve that descent can be stopped manually at any time in the descent process, no electric power is needed, the slow descent function is completed through mechanical transmission, and the controllable centrifugal drum type high-rise descent control device is safe and reliable.

Owner:SHANGHAI JIAO TONG UNIV

Device for feeding mass flow of rod-shaped products and use of the same

InactiveCN107080283AReduce preloadSmall preloadConveyorsCigarette manufactureMechanical engineeringTobacco industry

The invention relates to a device for feeding mass flow of rod-shaped products of tobacco industry and a use of the same along a feeding section. The device comprises a feeding device which is set to be used for conveying the rod-shaped products from a delivery area to a return area along the feeding section. The feeding device passes through a guide channel along the feeding section at least in section manner, the guide channel is constructed as first and second helix arranged around a common vertical geometric axis. Furthermore, the device comprises a deflected sliding seat which is used for guiding the rod-shaped products from the first helix to the second helix. The deflected sliding seat can extendedly move along the helices for changing the length of the feeding section between the delivery area and the returen area. The guide channel comprises a sliding seat guide and a holding device, and the deflected sliding seat can be movably held on the sliding seat guide and the holding device on the guide channel.

Owner:HAUNI MASCHINENBAU AG

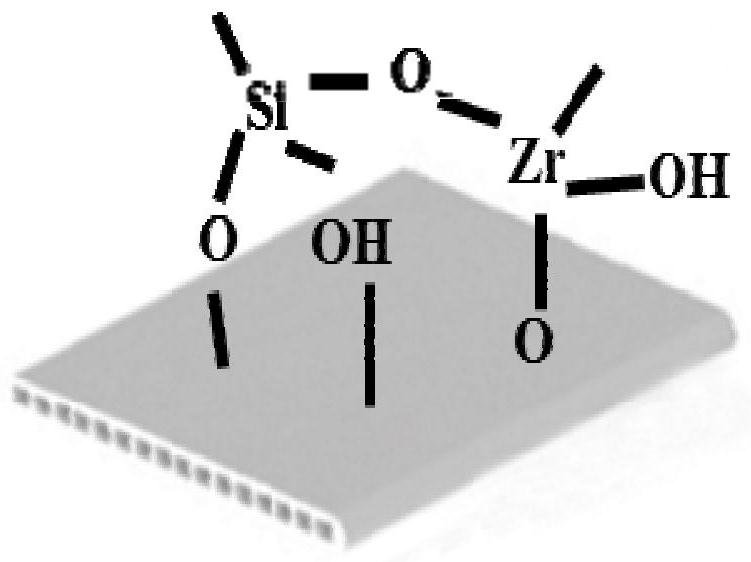

Preparation method of porous plate ceramic nanofiltration body based on silicon-zirconium sol

ActiveCN113058447AMake up for uneven defectsAvoid enteringSemi-permeable membranesPtru catalystSilicic acid

The invention belongs to the technical field of membrane separation and water treatment filter bodies, particularly relates to a preparation method of a porous plate ceramic nanofiltration body based on silicon-zirconium sol, and solves the problems that an existing inorganic nanofiltration membrane preparation process is complicated, other filter membranes are not firmly combined with a carrier, the pore diameters of filter pores in the filter membranes are not uniform and the like. According to the scheme, the preparation method comprises the following preparation process: (1) dissolving tetraethoxysilane and zirconium n-butoxide in a solvent, then adding a catalyst and water, and stirring under a variable-temperature condition to form silicon-zirconium sol; (2) pretreating the porous plate ceramic support body, and then putting the porous plate ceramic support body into a drying oven for heating; (3) dipping the support body preheated in the step (2) into the silicon-zirconium sol obtained in the step (1), taking out and drying at room temperature; (4) carrying out heat treatment roasting, taking out and cooling to room temperature; and (5) repeating the steps (3) and (4) at least once to form the porous plate ceramic nanofiltration body with the silicon-zirconium adhesive film on the surface.

Owner:常州苏南水环境研究院有限公司

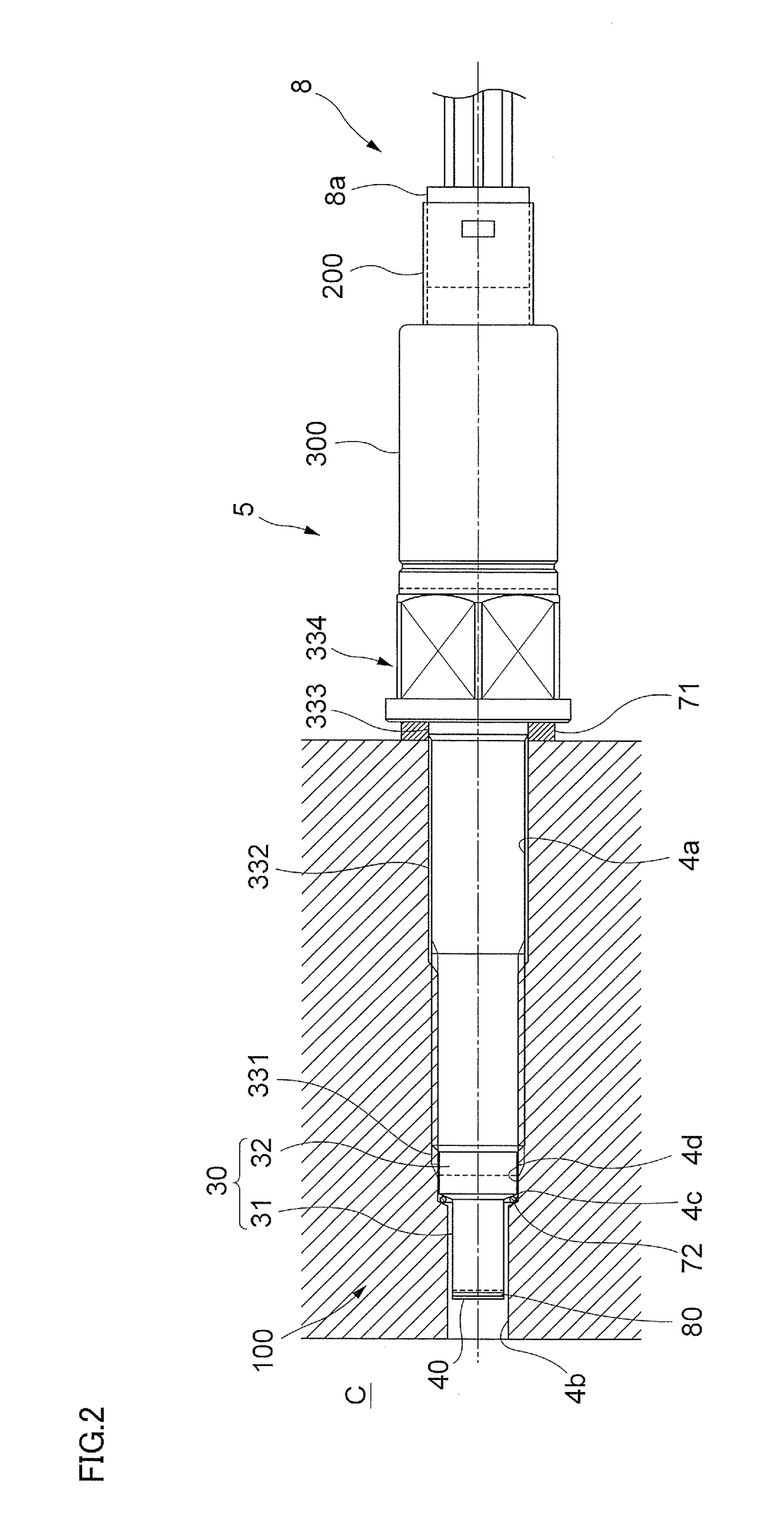

Pressure detection device, internal combustion engine equipped with the same, and method for manufacturing the same

ActiveUS20180087993A1Avoid noiseMinimize oscillationRapid change measurementElectricityElectrical conductor

A pressure detection device includes: a cylindrical body made of a conductor; a pressure receiver made of a conductor, the pressure receiver being mounted to one end side of the body and receiving pressure from the outside; a signal generator arranged inside the body, the signal generator being electrically connected to the pressure receiver and generating a signal corresponding to the pressure received by the pressure receiver; and a cover made of an insulator with a lower thermal conductivity than thermal conductivities of the body and the pressure receiver, the cover continuously covering an outer surface of the pressure receiver and a portion of an outer surface of the body, the portion being located at a side closer to the pressure receiver.

Owner:CITIZEN FINEDEVICE +2

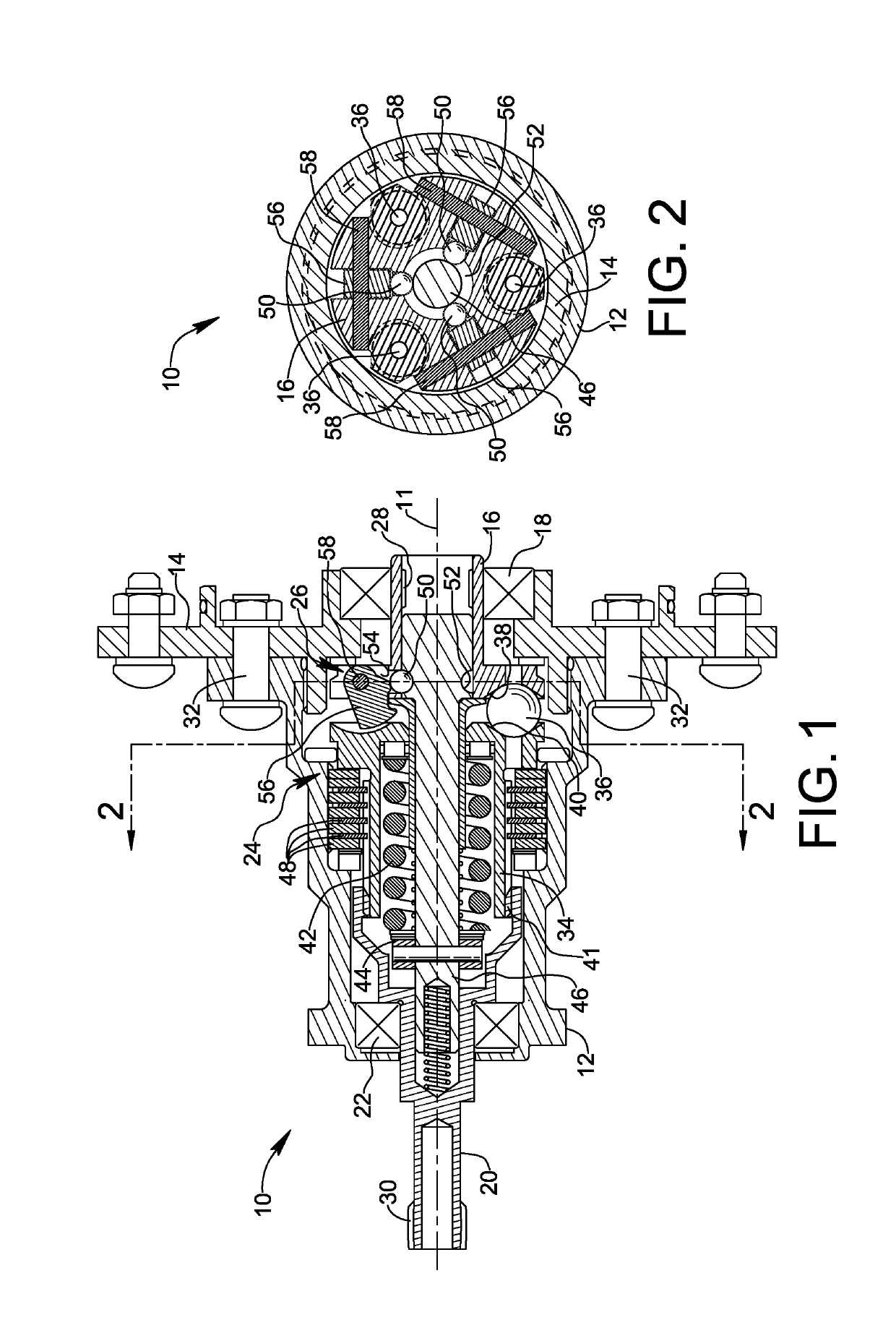

Torque limiter having over-speed protection

ActiveUS20190101169A1Reducing the torque limitReduce preloadSlip couplingAutomatic clutchesControl theoryTorque limiter

An apparatus for connecting a rotational drive member to a rotational driven member brakes rotation when either the torque transmitted between the members exceeds a predetermined torque limit or the rotational speed of the drive member exceeds a predetermined rotational speed limit. The apparatus includes a torque limiter configured to actuate a braking mechanism or disconnect transmission when the torque limit is exceeded, and an over-speed governor configured to trigger the torque limiter when the rotational speed of the input element exceeds the rotational speed limit. The over-speed governor may trigger the torque limiter by reducing the torque limit of the torque limiter, or by introducing rotational drag in the apparatus to increase transmitted torque.

Owner:MOOG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com