Three-position four-way water pressure proportional valve based on high-speed switch valve

A high-speed on-off valve, three-position four-way technology, applied in the valve operation/release device, the valve's device for absorbing fluid energy, valve details, etc., which can solve the problem of high matching requirements of the valve core and valve sleeve, and poor anti-pollution ability. , with small clearance and other problems, to achieve the effect of improving the response speed and valve output flow control accuracy, good anti-rust ability, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

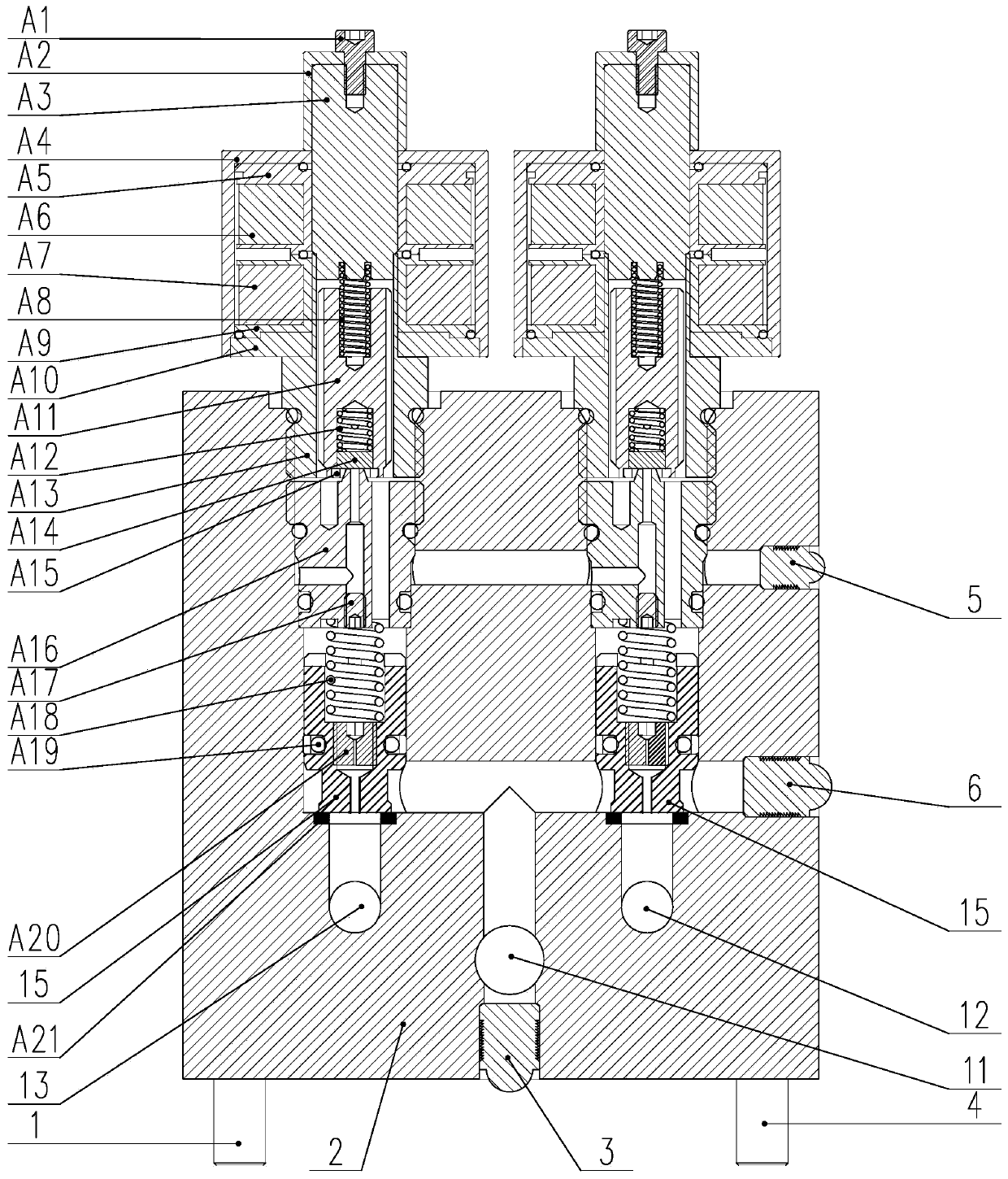

[0026] Figure 1~7 , including the first mounting screw 1, the valve block 2, the first ball expansion plug 3, the second mounting screw 4, the second ball expansion plug 5, the third ball expansion plug 6, and the fourth ball expansion plug Type plug 7, fifth ball expansion plug 8, third mounting screw 9, fourth mounting screw 10, T port 11, A port 12, B port 13, P port 14, first main spool 15, second Two main valve core 16, fastening screw A1, gland A2, pole piece A3, electromagnet shell A4, first skeleton A5, first coil A6, second coil A7, pilot valve reset spring A8, second skeleton A9, Electromagnet end cover A10, armature A11, pilot valve core sealing spring A12, pilot valve body A13, pilot valve core A14, pilot valve core gasket A15, pilot valve seat A16, pilot valve seat plug A17, main valve core preload Spring A18, gray ring A19, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com