Synthetic method for core-shell quantum dot which is capable of realizing emission of blue light to green light and possesses uniformly-alloyed core

A core-shell quantum dot and synthesis method technology, which is applied in the field of core-shell quantum dot synthesis, can solve the problems of difficult synthesis control, high energy consumption in high-temperature reactions, environmental pollution, etc., and achieve good green chemical characteristics and economical efficiency. Simplified operation procedures, easy and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

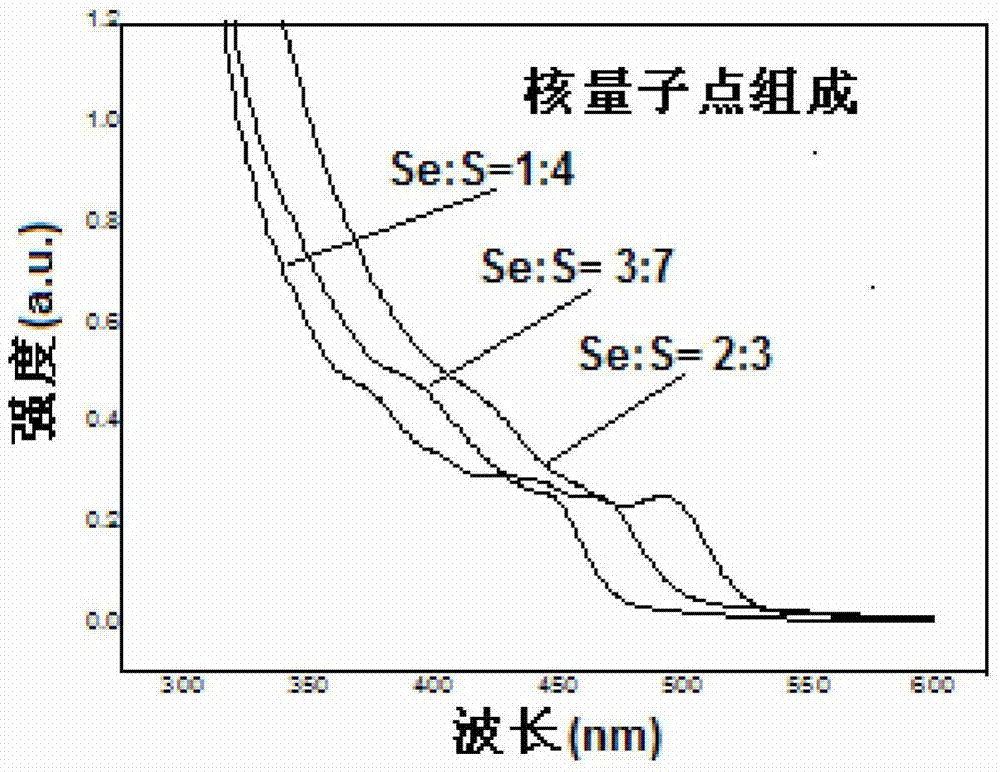

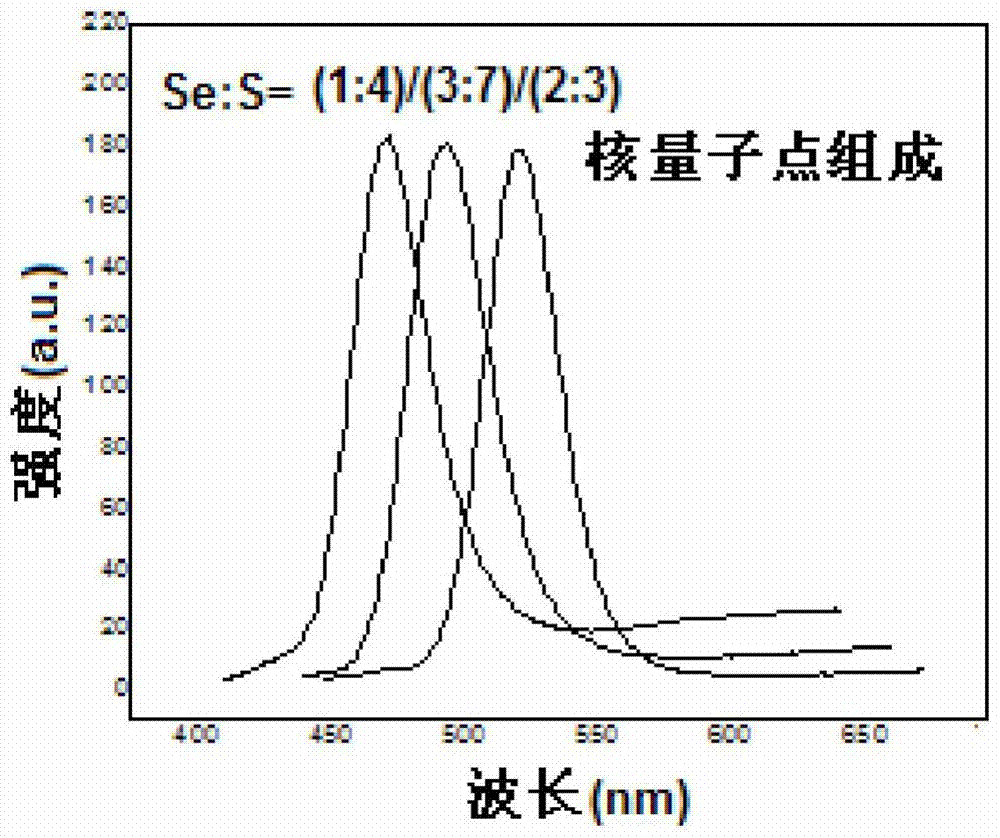

[0034] Embodiment 1: Synthesis of CdSe in octadecene medium 0.2 S 0.8 / CdS quantum dots

[0035]Add 0.200 mmol of cadmium stearate, 0.040 mmol of selenium powder, 0.160 mmol of diallyl disulfide (with S as the metering unit), 0.20 mmol of oleic acid, and 9.60 grams of octadecene into the reaction flask. Purge with argon gas at room temperature for 5 minutes, then heat to 210°C at a rate of 20°C / min, keep warm for 20 minutes, and stop heating; when the temperature of the reaction solution drops below 100°C, add 0.200 cadmium stearate to the reaction bottle mmol and diallyl disulfide 0.180mmol, heated to 195°C at a rate of 7°C / min, kept for 30min, and stopped heating. When the temperature of the reaction solution dropped below 70°C, pour the reaction solution into 50mL anhydrous In ethanol, the quantum dots were precipitated, and then using absolute ethanol as a non-solvent and cyclohexane as a solvent, the quantum dots were dissolved and precipitated three times, and CdSe was...

Embodiment 2

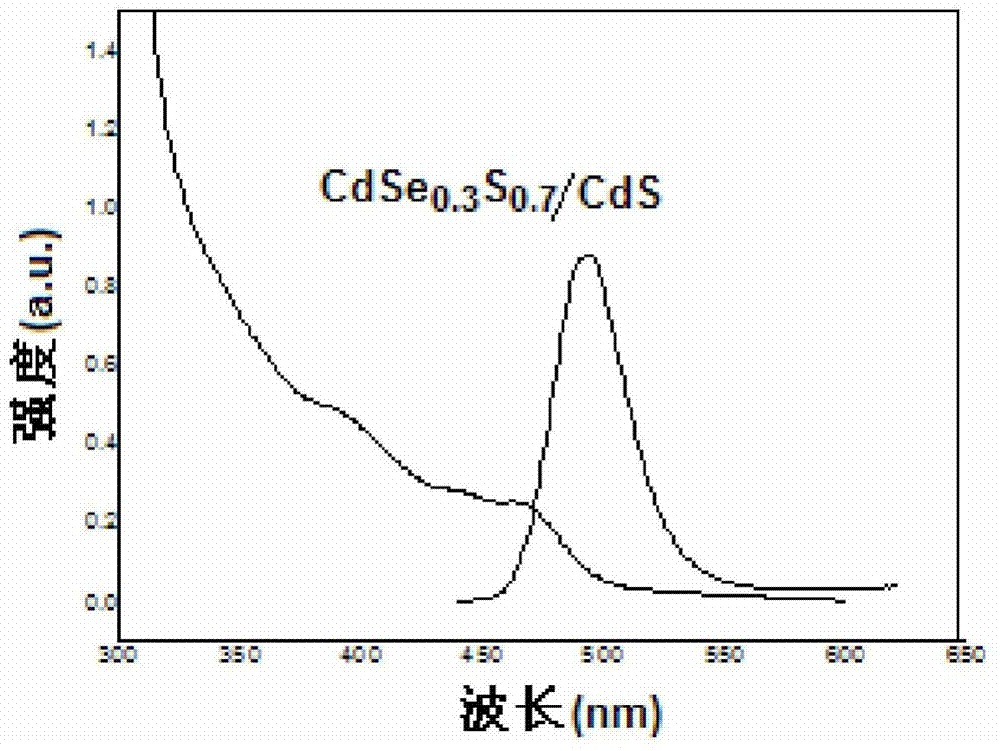

[0037] Embodiment 2: Synthesis of CdSe in liquid paraffin medium 0.3 S 0.7 / CdS quantum dots

[0038] Add 0.200 mmol of cadmium stearate, 0.060 mmol of selenium powder, 0.140 mmol of diallyl disulfide (with S as the metering unit), 0.20 mmol of oleic acid, and 9.60 grams of liquid paraffin into the reaction flask. Purge with argon gas at room temperature for 5 minutes, then heat to 210°C at a rate of 20°C / min, keep warm for 20 minutes, and stop heating; when the temperature of the reaction solution drops below 100°C, add 0.200 cadmium stearate to the reaction bottle mmol and diallyl disulfide 0.190mmol, heated to 195°C at a rate of 7°C / min, kept for 30min, and stopped heating. When the temperature of the reaction solution dropped below 70°C, pour the reaction solution into 50mL In the mixture of ethanol and acetone (volume ratio 3:1), the quantum dots were precipitated, and then using absolute ethanol as the non-solvent and cyclohexane as the solvent, the quantum dots were d...

Embodiment 3

[0040] Embodiment 3: Synthesis of CdSe in octadecene medium 0.4 S 0.6 / CdS quantum dots

[0041] Add 0.200 mmol of cadmium stearate, 0.080 mmol of selenium powder, 0.120 mmol of diallyl disulfide (with S as the metering unit), 0.20 mmol of oleic acid, and 9.60 grams of octadecene into the reaction flask. Purge with argon gas at room temperature for 5 minutes, then heat to 210°C at a rate of 20°C / min, keep warm for 20 minutes, and stop heating; when the temperature of the reaction solution drops below 100°C, add 0.200 cadmium stearate to the reaction bottle mmol and diallyl disulfide 0.190mmol, heated to 195°C at a rate of 7°C / min, kept for 30min, and stopped heating. When the temperature of the reaction solution dropped below 70°C, pour the reaction solution into 50mL In ethanol, the quantum dots were precipitated, and then using absolute ethanol as a non-solvent and cyclohexane as a solvent, the quantum dots were dissolved and precipitated three times, and CdSe was obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com