Housing lead wire used for surface-mount package of microwave device and connecting structure thereof

A microwave device, shell lead technology, applied in the direction of electric solid device, semiconductor device, semiconductor/solid state device parts, etc., can solve the problem of poor microwave electrical signal transmission effect, microwave metal ceramic surface mount shell, microwave device performance It can achieve good signal transmission, weaken stress conduction, and release stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

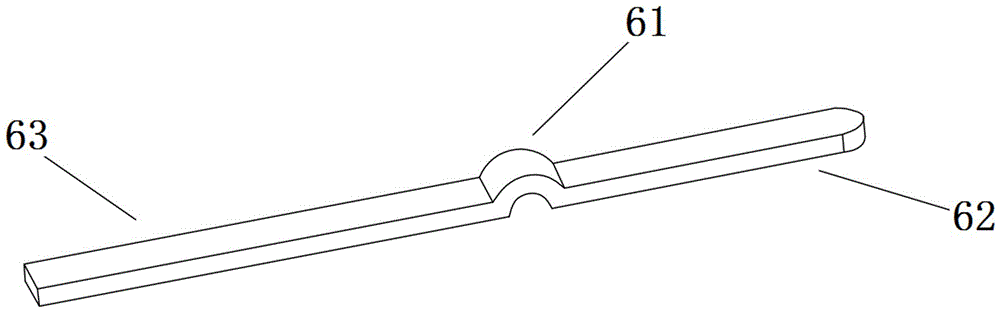

[0025] A housing lead for surface-mount packaging of microwave devices, see image 3 , the lead wire is in the shape of a flat strip, and the lead wire is provided with a bent section 61 in an Ω shape with a radius of 0.10 mm to 0.30 mm. The lead wire is a straight line section outside the bent section 61 . The selection of the radius of the bending section 61 is related to the thermal expansion coefficient of the ceramic and the PCB4 material used by the user during secondary installation. The larger the difference in thermal expansion coefficient, the larger the radius of the bending section 61 is, and the radius is controlled within the range of 0.10mm to 0.30mm. The resulting transmission inductance does not affect the transmission of microwave signals.

[0026] As a further improvement to the technical solution, the curved section 61 is a semicircle or an arc larger than a semicircle. The curved section 61 is a semicircle to facilitate processing, but if the thermal expa...

specific Embodiment approach 2

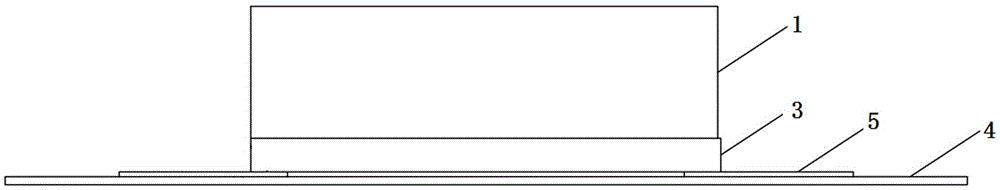

[0029] A lead wire connection structure of a microwave device surface mount package shell, see Figure 4 and Figure 5 , comprising a package shell, lead wires and PCB4, said package shell includes an upper metal wall 1 and a lower ceramic base 3; said lead wire is in the shape of a flat strip, and a bent section 61 is provided on the lead wire, which is in an Ω shape with a radius of 0.10mm~0.30mm, the lead wire is a straight line segment outside the bending section 61, the straight line segment of the lead wire is laid flat on the PCB4, the two straight line ends of the lead wire are the lead-in end 62 and the lead-out end 63 respectively, the lead-in end 62 Welded on the bottom of the ceramic base 3, the lead end 63 is welded on the printed circuit board, the bent section 61 of the lead is suspended, and the bent section 61 of the lead is located at a position 0.10 mm to 0.30 mm outside the ceramic base 3 . The material of the lead wire is Kovar alloy. The curved section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com