Welding process for longitudinal weld joints of submerged-arc welding for high-strength pipeline steel

A welding process, submerged arc welding technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., to achieve good impact toughness, excellent comprehensive mechanical properties, good forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

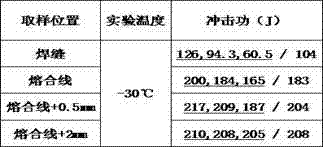

Examples

Embodiment 1

[0018] This embodiment is a welding process for submerged arc welding longitudinal welds of high-strength pipeline steel. (1) The chemical composition and weight percentage of high-strength pipeline steel are: C: 0.04%, Si: 0.08%, Mn: 1.90%, Nb+V+ Ti+Zr: 0.09%, Mo: 0.2%, Ni+Cr+Cu: 0.8%, P: 0.004%, S: 0.001%, the balance is Fe and unavoidable impurities; steel carbon equivalent Ceq: 0.53%, Pcm: 0.22%;

[0019] (2) The chemical composition and weight percentage of the welding wire used are: C: 0.08%, Mn: 1.75%, Si: 0.80%, S: 0.003%, P: 0.010%, Cu: 0.138%, Cr: 0.41%, Mo: 0.53% , Ni: 2.22%, Al: 0.011%, Ti: 0.05%, V: 0.015, Zr<0.01%, the balance is Fe and unavoidable impurities; the wire diameter is 4mm, and the selected flux grade is OK Flux 10.62; The baking system is 350℃×2h;

[0020] (3) Submerged arc welding adopts X-shaped groove, the groove angle is 90°, and the blunt edge is 4.8mm. It is welded at room temperature, without preheating, and does not control the interlayer t...

Embodiment 2

[0023] This embodiment is a welding process for submerged arc welding longitudinal welds of high-strength pipeline steel. (1) The chemical composition and weight percentage of high-strength pipeline steel are: C: 0.05%, Si: 0.09%, Mn: 1.80%, Nb+V+ Ti+Zr: 0.095%, Mo: 0.3%, Ni+Cr+Cu: 1.0%, P: 0.003%, S: 0.0009%, the balance is Fe and unavoidable impurities; steel carbon equivalent Ceq: 0.50%, Pcm: 0.21%;

[0024] (2) The chemical composition and weight percentage of the welding wire used are: C: 0.08%, Mn: 1.75%, Si: 0.80%, S: 0.003%, P: 0.010%, Cu: 0.138%, Cr: 0.41%, Mo: 0.53% , Ni: 2.22%, Al: 0.011%, Ti: 0.05%, V: 0.015, Zr<0.01%, the balance is Fe and unavoidable impurities; the wire diameter is 4mm, and the selected flux grade is OK Flux 10.62; The baking system is 350℃×2h;

[0025] (3) Submerged arc welding adopts X-shaped groove, the groove angle is 90°, and the blunt edge is 4.8mm. It is welded at room temperature, without preheating, and does not control the interlayer...

Embodiment 3

[0028] This embodiment is a welding process of high-strength pipeline steel submerged arc welding longitudinal weld. (1) The chemical composition and weight percentage of high-strength pipeline steel are: C: 0.06%, Si: 0.10%, Mn: 1.60%, Nb+V+ Ti+Zr: 0.10%, Mo: 0.4%, Ni+Cr+Cu: 1.2%, P: 0.002%, S: 0.0005%, the balance is Fe and unavoidable impurities; steel carbon equivalent Ceq: 0.51%, Pcm: 0.21%;

[0029] (2) The chemical composition and weight percentage of the welding wire used are: C: 0.08%, Mn: 1.75%, Si: 0.80%, S: 0.003%, P: 0.010%, Cu: 0.138%, Cr: 0.41%, Mo: 0.53% , Ni: 2.22%, Al: 0.011%, Ti: 0.05%, V: 0.015, Zr<0.01%, the balance is Fe and unavoidable impurities; the wire diameter is 4mm, and the selected flux grade is OK Flux 10.62; The baking system is 350℃×2h;

[0030] (3) Submerged arc welding adopts X-shaped groove, the groove angle is 90°, and the blunt edge is 4.8mm. It is welded at room temperature, without preheating, and does not control the interlayer tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com