Glass fiber direct yarn impregnating compound as well as preparation method and application thereof

A technology of glass fiber and sizing agent, which can be used in soil protection, construction, infrastructure engineering, etc., and can solve problems such as restricting technology development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

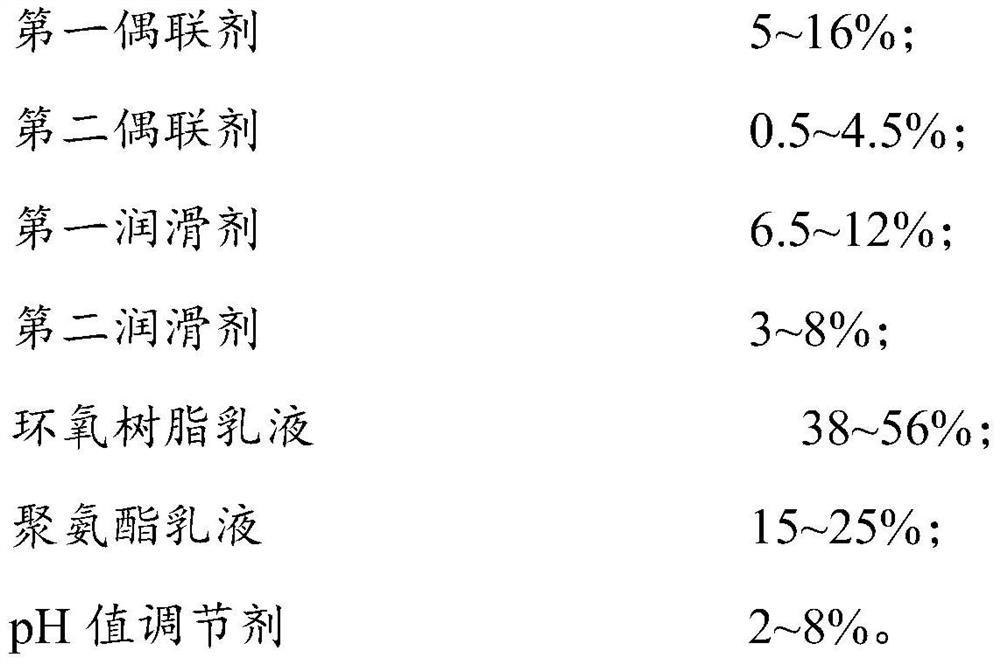

Method used

Image

Examples

preparation example Construction

[0104] The preparation method of this glass fiber direct yarn sizing agent comprises the steps:

[0105] 1S: Add 40% to 50% of the total amount of wetting agent in the container, then add the pH regulator, stir for 3 to 5 minutes, add part of the coupling agent, and stir for 20 to 30 minutes; then slowly add the remaining Coupling agent, stirring for 20 to 30 minutes, until the coupling agent is uniformly dispersed, the aqueous solution is clear, and there are no oil droplets on the surface;

[0106] 2S: Dissolve the lubricant in 5-10 times the amount of water at 40-50°C, stir and dilute it and add it to the container;

[0107] 3S: Add epoxy resin emulsion and polyurethane emulsion to the container respectively and stir evenly;

[0108] 4S: Add the remaining amount of water to the container and stir evenly.

Embodiment 1

[0111] Coupling agent: γ-aminopropyltrimethoxysilane, grade A-1110;

[0112] First lubricant: polyethylene glycol, PEG 800;

[0113] Second lubricant: simethicone;

[0114] Epoxy resin emulsion: bisphenol A epoxy resin emulsion, grade DER331;

[0115] Polyurethane emulsion: product grade 9581;

[0116] pH regulator: glacial acetic acid.

Embodiment 2

[0118] The first coupling agent: vinyltriethoxysilane, grade A-151;

[0119] The second coupling agent: γ-aminopropyltrimethoxysilane, grade A-1110;

[0120] First lubricant: polyethylene glycol, PEG 800;

[0121] Second lubricant: simethicone;

[0122] Epoxy resin emulsion: bisphenol F epoxy resin emulsion, brand YDF-162;

[0123] Polyurethane emulsion: grade 9581;

[0124] pH regulator: citric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com