High-strength hard flame-retardant epoxy foam material and preparation method thereof

An epoxy foam, high-strength technology, applied in the field of aerospace manufacturing, can solve problems such as uneven bubble structure and complex process, and achieve the effects of improving stiffness, simple process flow and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

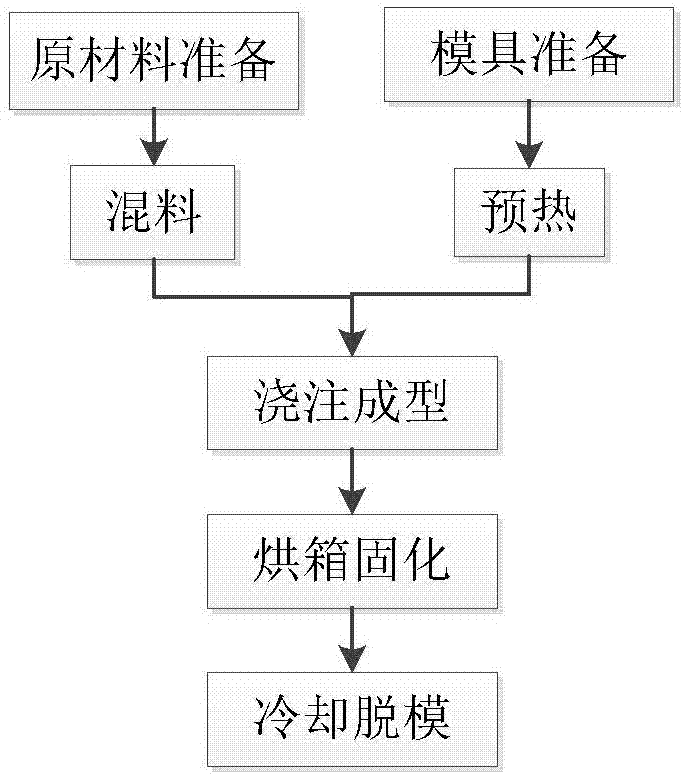

Method used

Image

Examples

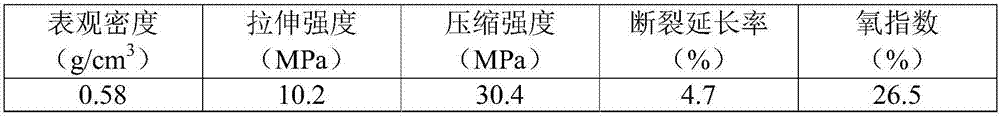

Embodiment 1

[0026] The preparation method of the high-strength rigid flame-retardant epoxy foam material of the present embodiment is as follows:

[0027] (1) Prepare materials according to the following components and parts by weight: 100 parts of epoxy resin (E-51), 25 parts of curing agent (DDM), 35 parts of glass beads (S35), 1 part of dispersant (EFKA-5044) , 1.5 parts of surfactant (Tween-20), 1.2 parts of coupling agent (KH-550), 6 parts of thinner (benzyl alcohol), 1.5 parts of anti-aging agent (2246), 3 parts of flame retardant (DMMP) .

[0028] (1) Melt the curing agent at 110°C, add bisphenol A epoxy resin, mix evenly at a low speed, and adjust the temperature to 40°C;

[0029] 3) Add dispersant, surfactant, inorganic hollow filler, flame retardant, anti-aging agent in sequence and stir evenly;

[0030] 4) Quickly add the diluent to the mixture, stir for 25 seconds, and immediately pour into a mold preheated to 40°C for foaming;

[0031] 5) Heat the mold to 90°C in turn, kee...

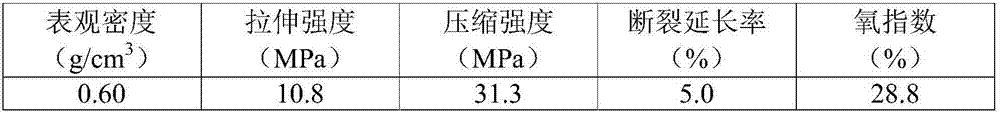

Embodiment 2

[0037] The preparation method of the high-strength rigid flame-retardant epoxy foam material of the present embodiment is as follows:

[0038] (1) Prepare materials according to the following components and parts by weight: 100 parts of epoxy resin (E-51:TDE-85=3:1 mixed), 35 parts of curing agent (DDM), 30 parts of glass microspheres (6522), 2 parts of dispersant (EFKA-5044), 5 parts of surfactant (organic silicon oil), 3 parts of coupling agent (KH-550), 8 parts of thinner (benzyl alcohol), 2 parts of anti-aging agent (2246), Fuel (DBDPE / Sb 2 o 3 ) 6 copies.

[0039] (1) Melt the curing agent at 110°C, add bisphenol A epoxy resin, mix evenly at a low speed, and adjust the temperature to 45°C;

[0040] 3) Add dispersant, surfactant, inorganic hollow filler, flame retardant, anti-aging agent in sequence and stir evenly;

[0041] 4) Quickly add the diluent to the mixture, stir for 20 seconds, and immediately pour it into a mold preheated to 40°C for foaming;

[0042] 5) He...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com