Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Meet large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

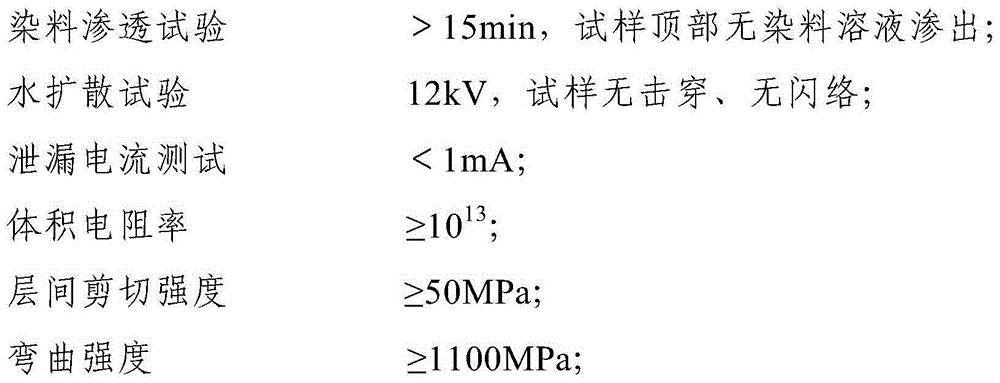

High-intensity high-hydroscopicity medical dressing containing carboxymethyl cellulose and preparation method thereof

InactiveCN103041437AReplace controllableThe degree of substitution is controllableFibre treatmentAbsorbent padsCarboxymethyl celluloseChemical adsorption

The invention provides high-intensity high-hydroscopicity medical dressing containing carboxymethyl cellulose and a preparation method thereof. The method comprises the following specific steps: preparing carboxymethyl cellulose non-woven fabric through two steps of alkali added aqueous medium process; combining the obtained carboxymethyl cellulose non-woven fabric with a non-woven fabric to form a unit through needling, so as to prepare the high-intensity high-water absorbability medical dressing containing carboxymethyl cellulose. The dressing has the advantages that the substituted ratio of the prepared carboxymethyl cellulose non-woven fabric is controlled among 0.1-.05, and the substitution is uniform; the space physical adsorption property of the carboxymethyl cellulose non-woven fabric is kept, and meanwhile, the chemical adsorption performance is improved; the obtained carboxymethyl cellulose non-woven fabric and the non-woven fabric are compounded to a unit, which improves the dryness strength of the dressing prepared by the invention, beautifies the appearance, and improves the hand feeling. Besides, the method is simple and convenient in preparation technology and lower in cost.

Owner:WUHAN TEXTILE UNIV

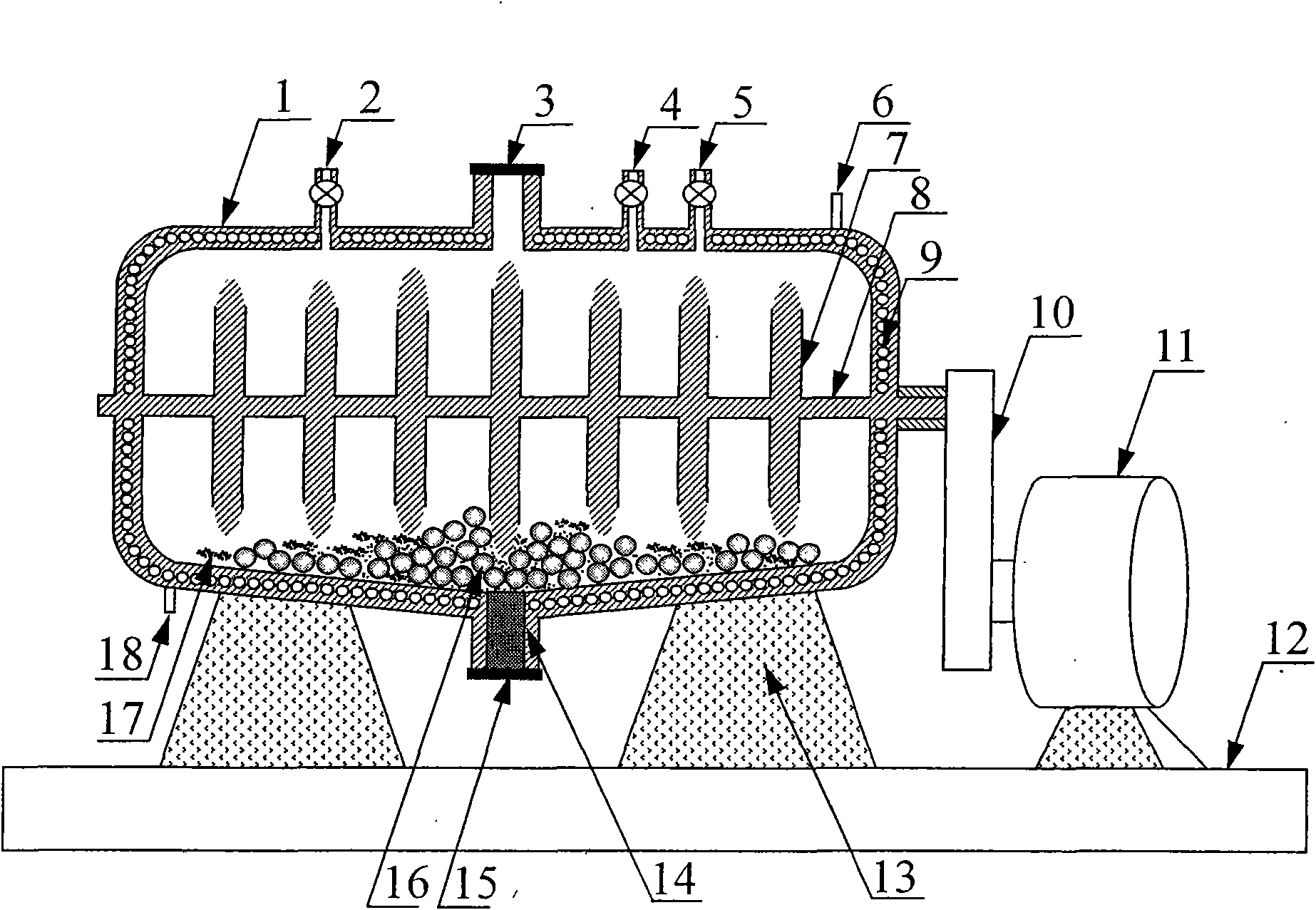

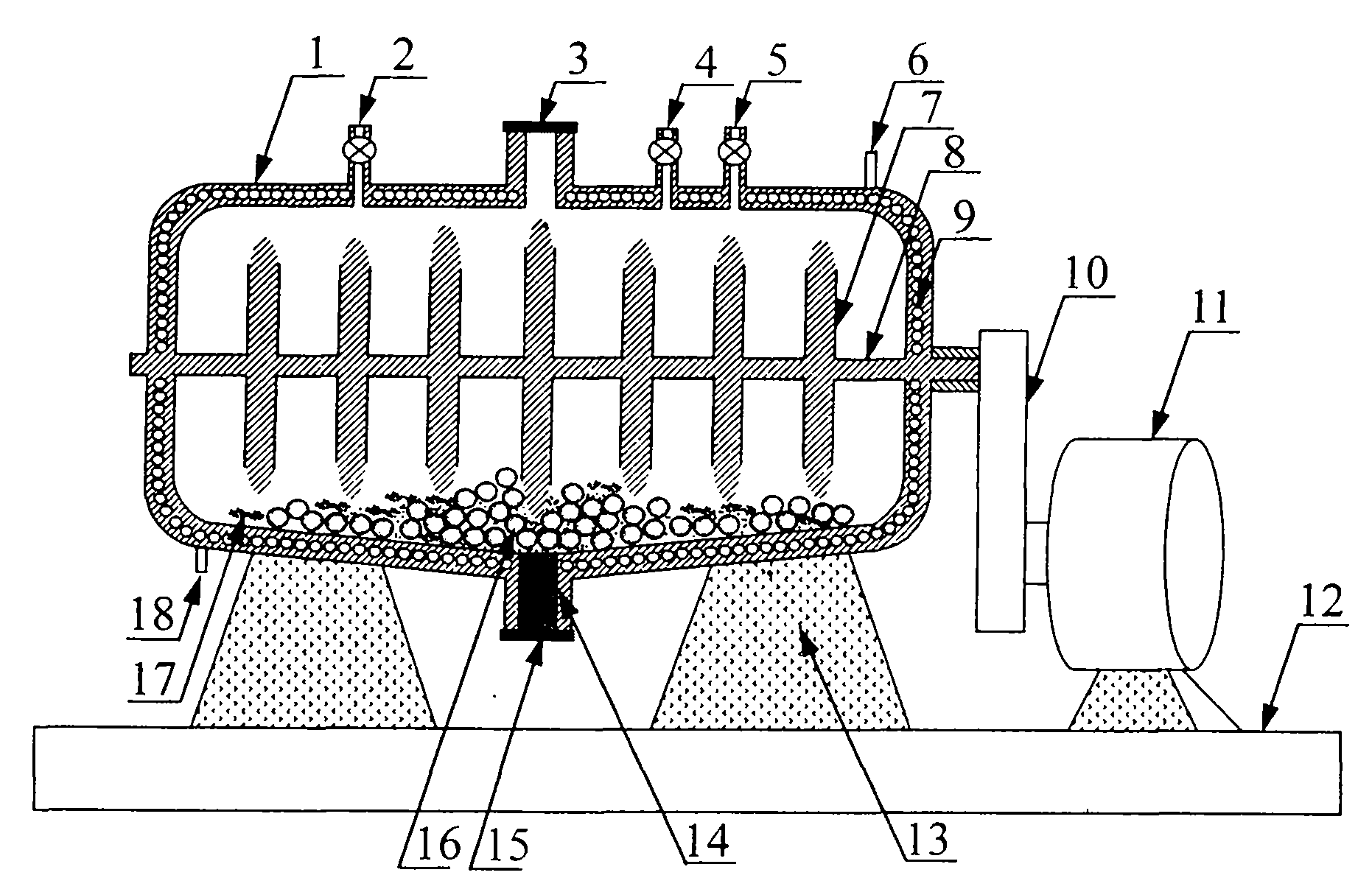

Ball grinder available for solid state reaction of powder

InactiveCN101823013AImprove mechanical energyMeeting the Energy Requirements of Solid-State Chemical ReactionsGrain treatmentsChemical reactionHigh energy

The invention relates to a ball grinder available for the solid state reaction of powder, which mainly comprises a ball grinding cylinder, an electromotor, a driving device, a grinding ball and a material inlet and outlet, wherein the horizontal type ball grinding cylinder is fixedly supported on a bracket; a jar is internally provided with the girding ball; the center of the ball grinding cylinder is provided with a rotatable main shaft; the main shaft is driven by the electromotor through the driving device to rotate; the main shaft is provided with a blade, wherein the rotating speed of the blade is 300-2000 r / min; the mechanical energy is transmitted to the grinding ball through the beating of the blade, so that the grinding ball can irregularly move with high speed; the bottom of theball grinding cylinder is in the shape of gradient with 0-30 degrees from the two ends to the center; the jar body of the ball grinding cylinder is provided with a cooling sleeve and an inlet and an outlet of cooling medium; and the jar body of the ball grinding cylinder is provided with an air exhausting opening and an air inlet. The ball grinder can lead the grinding ball to generate higher mechanical energy to provide high energy for inducing the solid state reaction among materials, thereby smashing, grinding and dispersing the materials and directly reacting to generate nanometer composite oxide.

Owner:BEIJING UNIV OF CHEM TECH

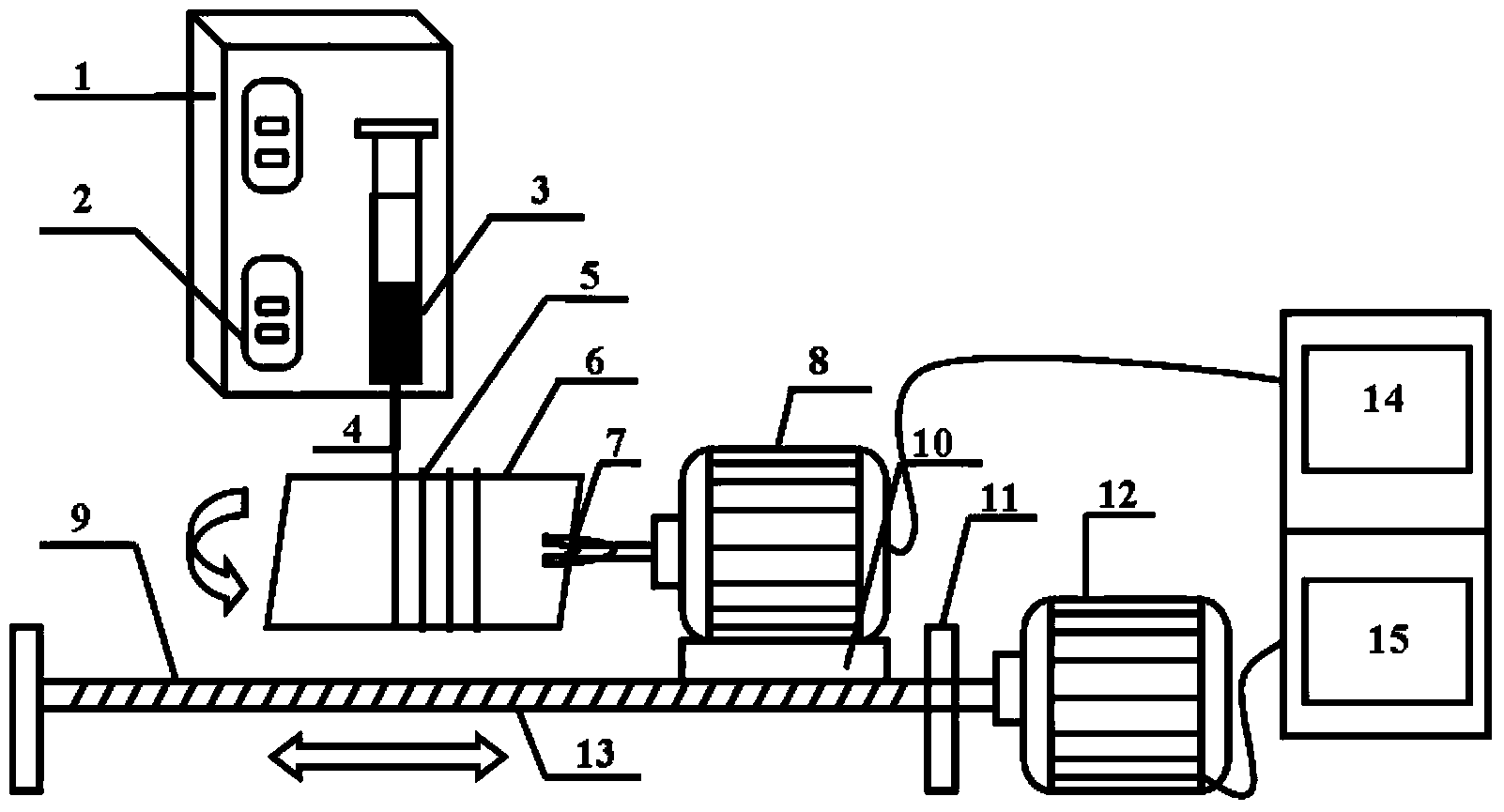

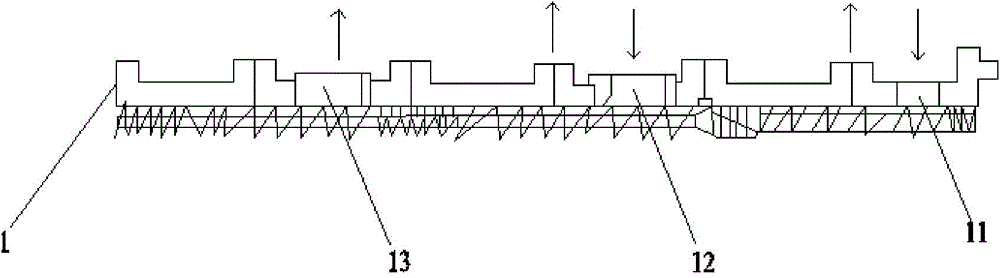

Microfluid spinning device used for preparing orderly orienting fiber

ActiveCN103757717AMeet large-scale industrial productionSimple structureFilament/thread formingFiberHigh voltage

The invention discloses a microfluid spinning device used for preparing orderly orienting fiber to realize a high-voltage-free, safe, energy-saving and rapid spinning process. The microfluid spinning device comprises a microflow pump 1, a control panel I2, an injection silk projector 3, a plate acceptor 5, an electric rotating machinery 8, a stepping motor translation platform 9, a control panel II14 and a control panel III15. The microflow pump 1 is arranged on the plate acceptor 5, the injection silk projector 3 is arranged on the microflow pump 1 and connected with a dash receiver 6 on the plate acceptor 5 via a needle point 4, the plate acceptor 5 is arranged on the electric rotating machinery 8 arranged on a base 10 of the stepping motor translation platform 9, the stepping motor translation platform 9 is provided with a translation stepping motor 12, the translation stepping motor 12 can control movement in the horizontal direction to control the gap of silk to realize quantitative control of thin silk distance, the electric rotating machinery 8 and the stepping motor translation platform 9 are connected with the control panel II14 and the control panel III15.

Owner:NANUS NEW MATERIAL

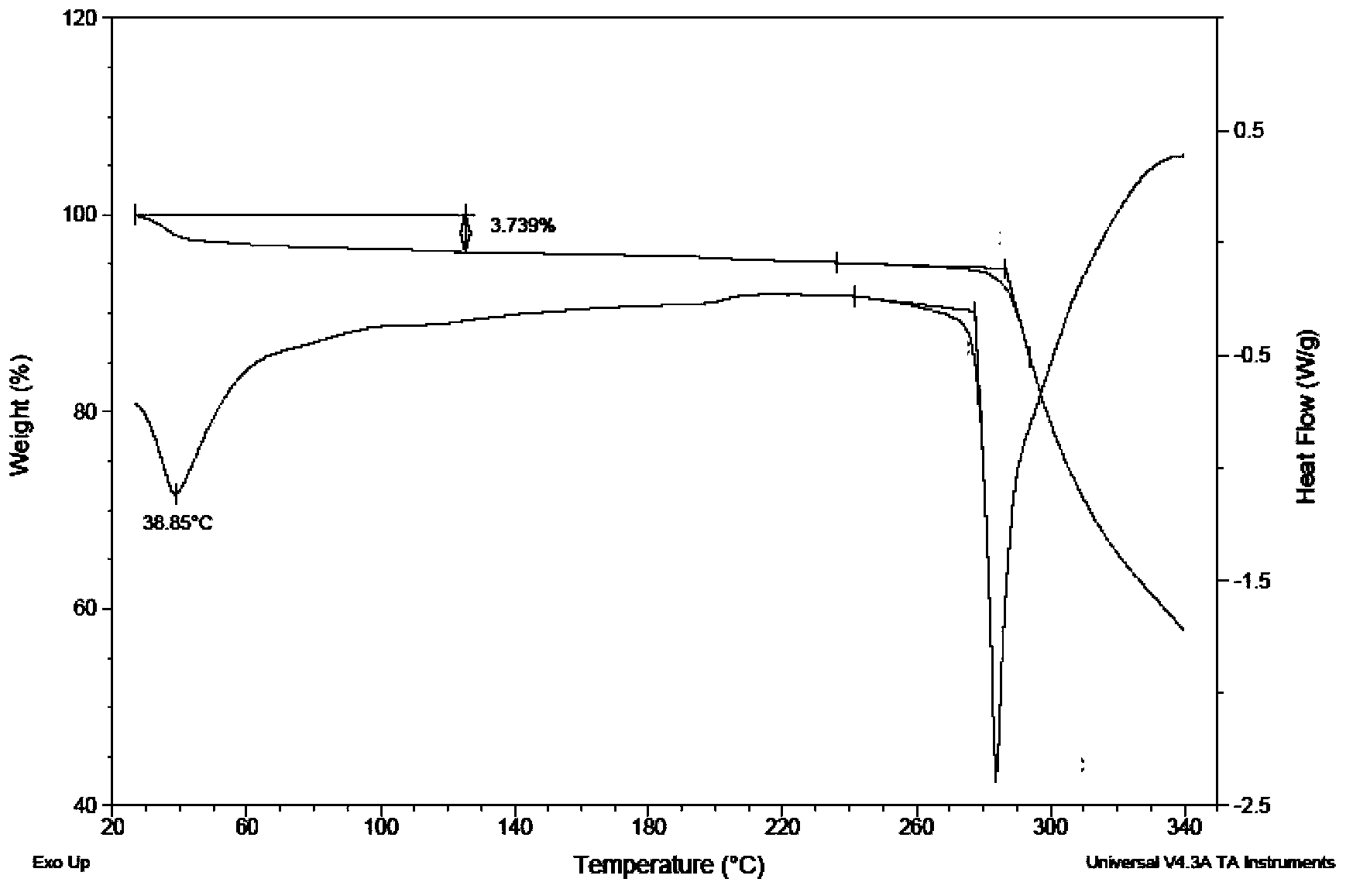

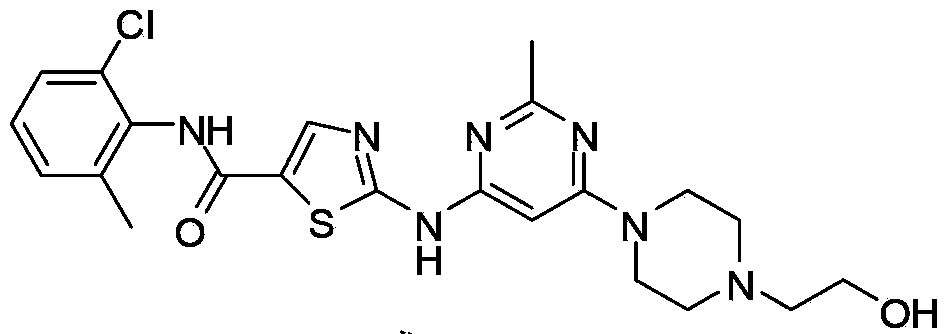

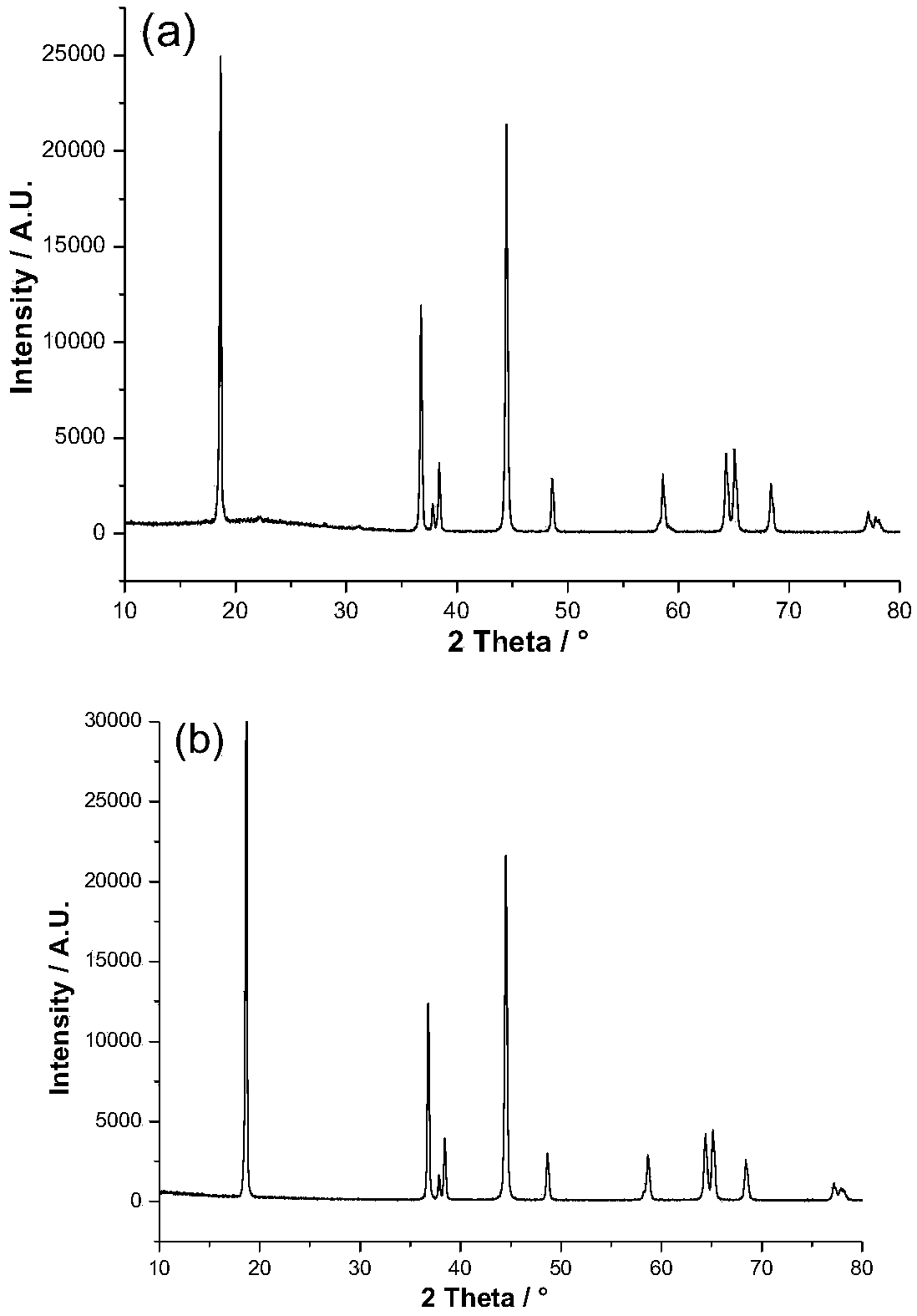

New Dasatinib crystal form and preparation method thereof

The invention relates to a new Dasatinib crystal form and a preparation method thereof. The new Dasatinib crystal form is named as a crystal form V and has characteristic peaks at 6.02 degrees, 6.91 degrees, 8.55 degrees, 12.44 degrees, 13.30 degrees, 13.84 degrees, 16.83 degrees, 24.41 degrees and 24.96 degrees (2theta) in an X ray powder diffraction spectrum obtained by means of Cu-Ka radiation detection. The invention also provides a method for preparing the new Dasatinib crystal form V. The method is simple, convenient and good in reproducibility, and the obtained new Dasatinib crystal form V is high in purity, good in stability and applicable to industrial production.

Owner:SHANGHAI SYNCORES TECH INC

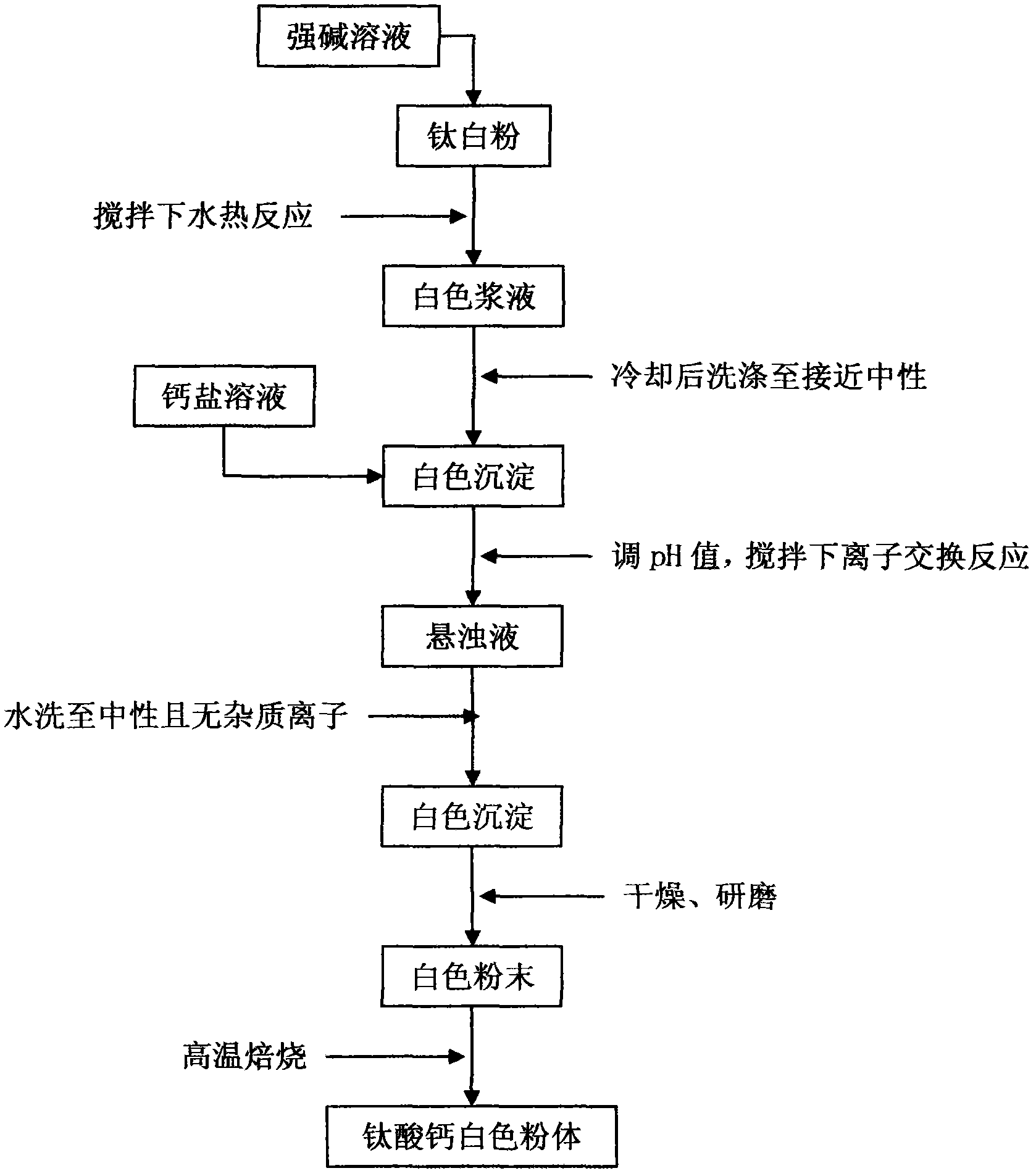

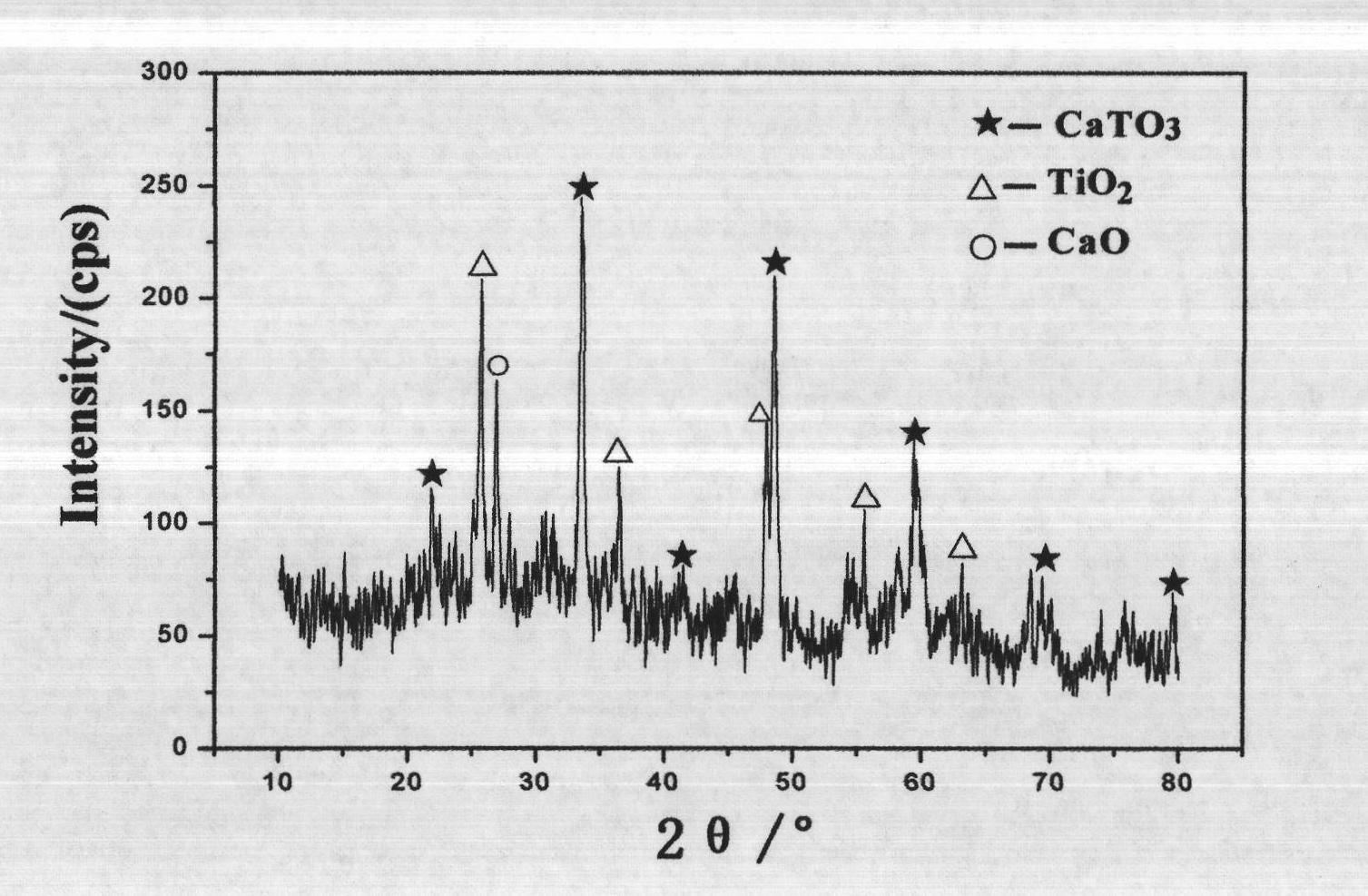

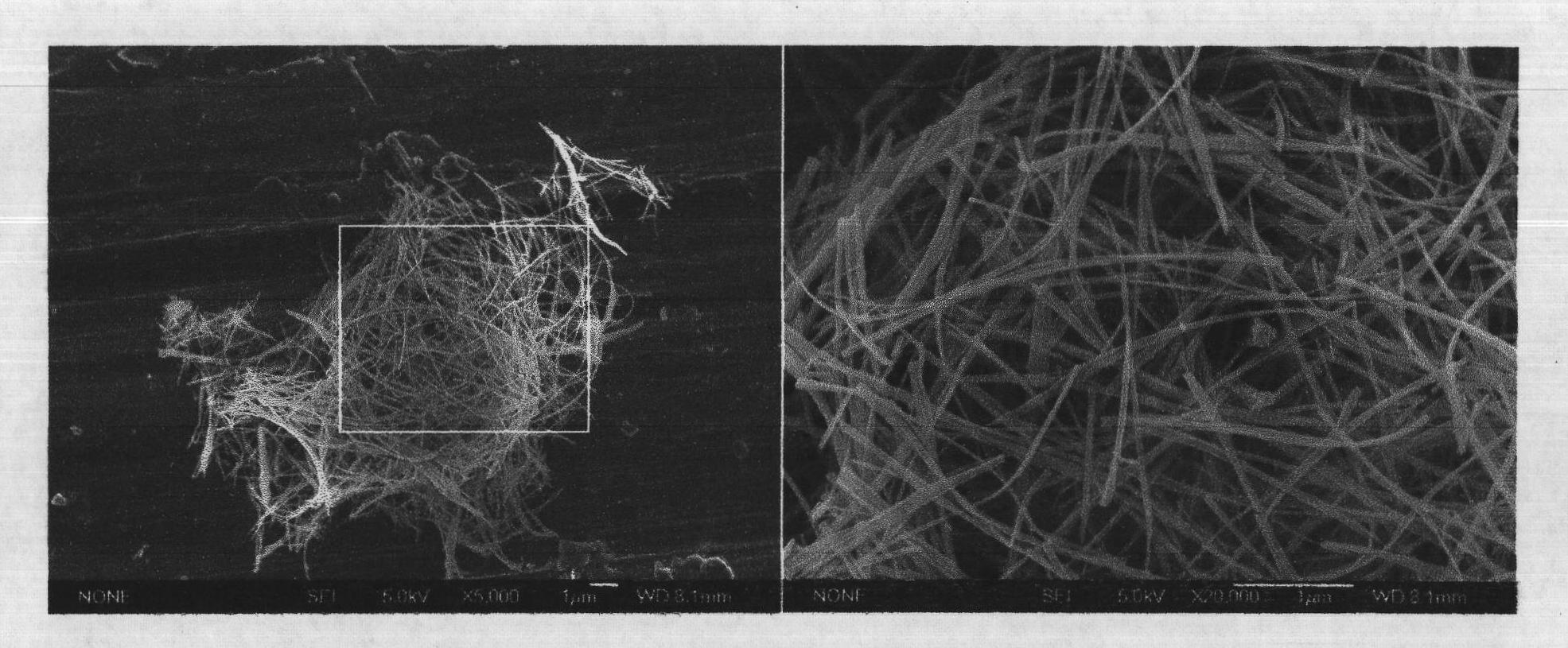

Nano linear calcium titanate and synthesis method thereof

InactiveCN102583514ALower synthesis costReduce usageNanotechnologyTitanium compoundsTissue repairSynthesis methods

The invention discloses nano linear calcium titanate and a synthesis method thereof. The synthesis method for the nano linear calcium titanate comprises the following steps of: 1) dispersing titanium dioxide in a strong alkali solution, and performing a hydro-thermal reaction with stirring to obtain a white deposit; 2) washing the white deposit by using water until the white deposit is neutral or weakly alkaline, dispersing the white deposit in a soluble calcium salt solution, controlling the temperature and the pH value of the system, and performing ion exchange reaction to obtain a calcium titanate deposit; and 3) performing centrifugal washing on the calcium titanate deposit until the calcium titanate deposit is neutral, and drying and baking the calcium titanate deposit to obtain the nano linear calcium titanate. The synthesis method for the nano linear calcium titanate is mild in reaction condition, simple in operation, rich in raw material source and low in cost, so that the synthesis method is suitable for mass production; and the synthesized nano linear calcium titanate is a solid alkali with a large specific area, has high ecological biocompatibility, and is expected to be applied in the fields of heavy metal ion contaminated waste water purification, ester exchange reaction catalysis, sclerous tissue repair and replacement and the like.

Owner:CENT SOUTH UNIV

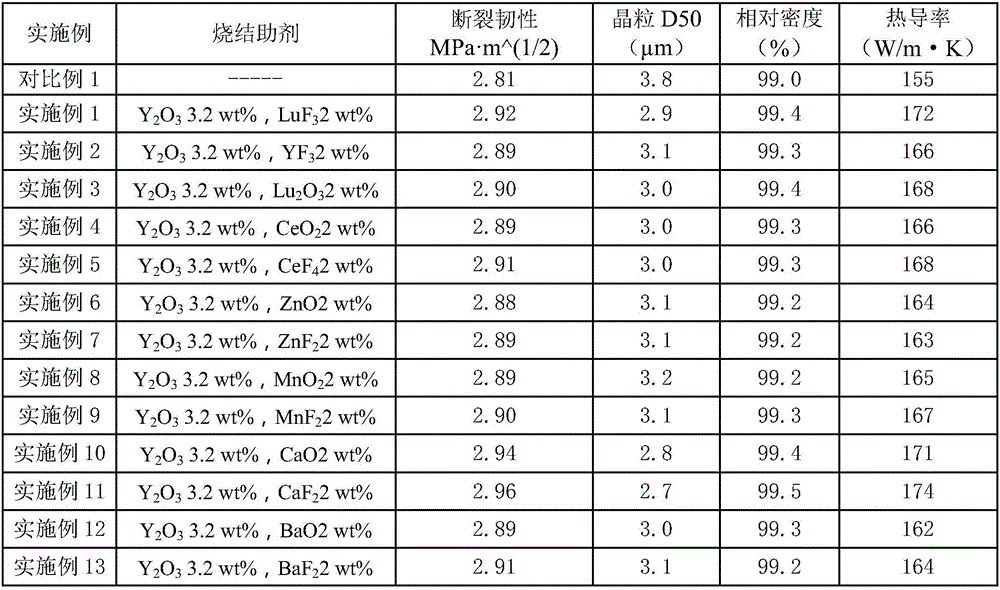

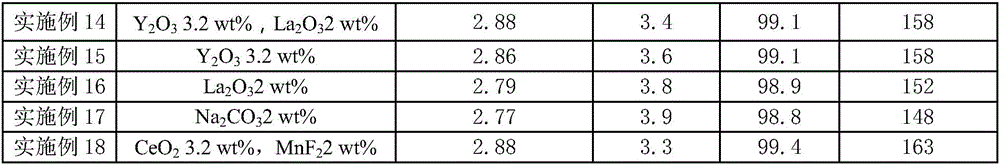

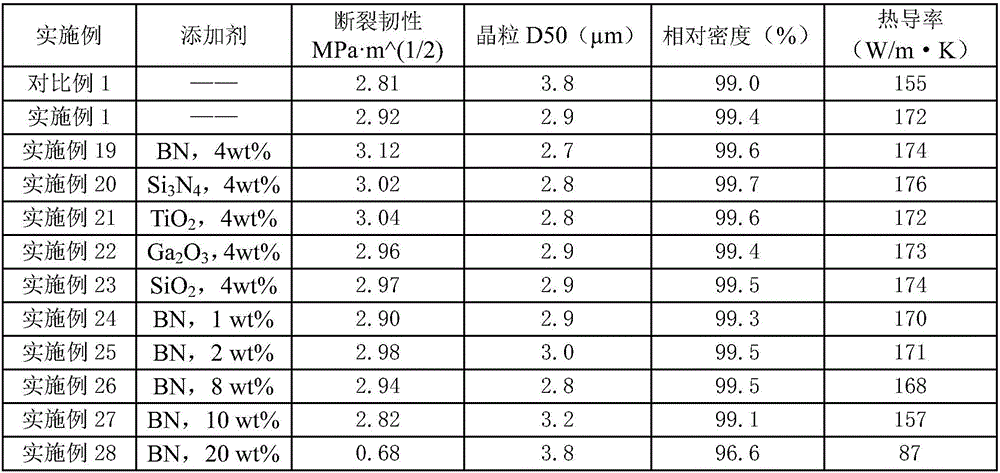

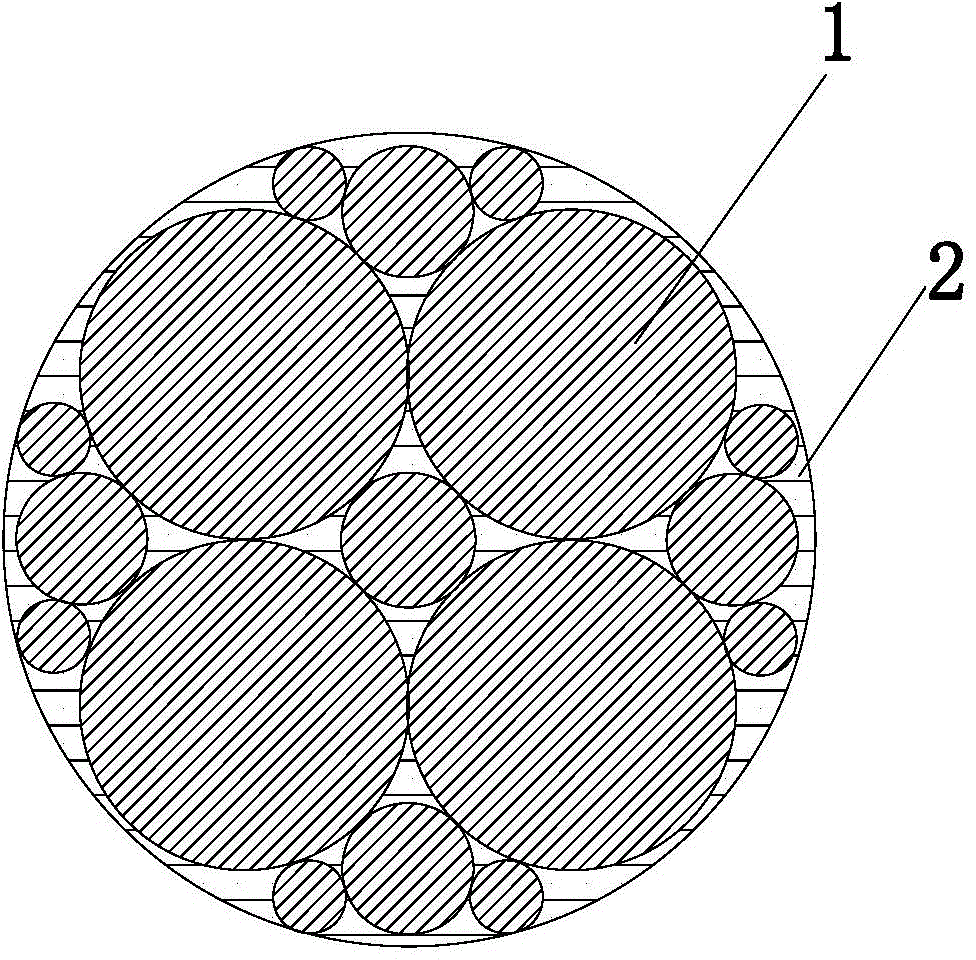

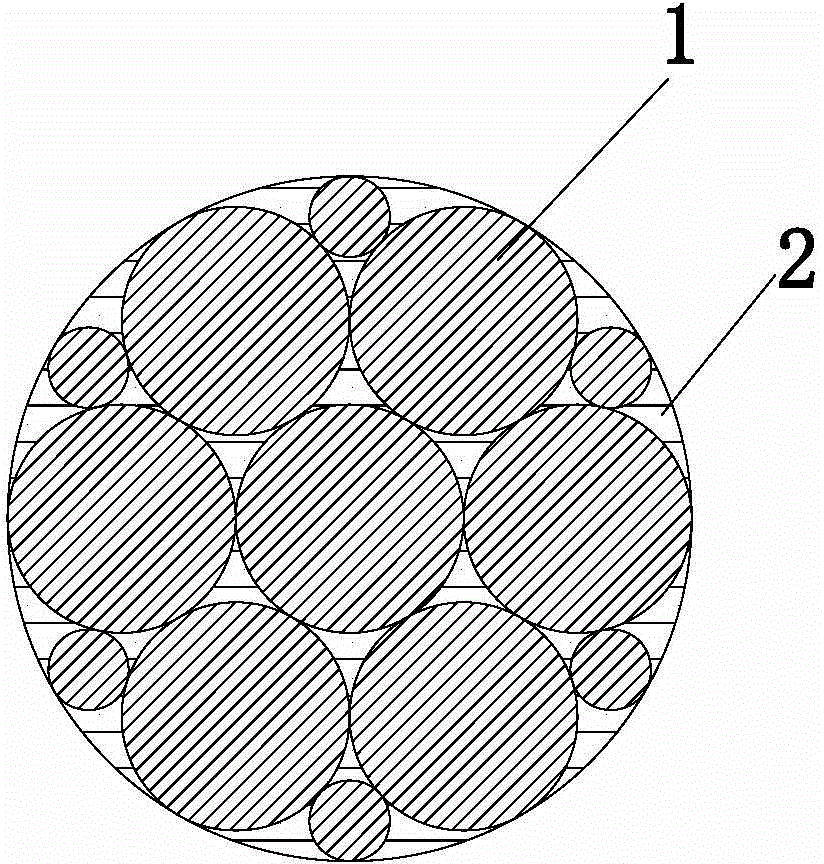

Aluminum nitride powder for aluminum nitride ceramic substrate and preparation method of aluminum nitride powder

ActiveCN106699189ASimple production processSimpler and more homogeneous mixingShock resistancePollution

The invention provides aluminum nitride powder for an aluminum nitride ceramic substrate and a preparation method of the aluminum nitride powder. The preparation method of the aluminum nitride powder comprises the following steps: (a) preparing a precursor mixture; (b) performing high temperature synthesis; (c) performing decarburization treatment; and (d) performing surface treatment. The preparation method provided by the invention is simple, low in synthetic temperature, pollution-free, and suitable for large-scale production. The invention also provides the aluminum nitride powder prepared with the method, the prepared aluminum nitride powder is good in water resistance, microelements required in a sintering process of an aluminum nitride substrate are uniformly distributed in the powder, and a more suitable powder particle size range is obtained by adjusting the usage amount of a sintering aid, thereby improving compactness, heat conductivity and shock resistance of the substrate.

Owner:HEBEI LIFU CHEM TECH

Manufacturing method of large-diameter multi-core combined core rod

InactiveCN104952565ASimple preparation processThe technology is stable and feasibleInsulatorsComposite insulatorsEngineering

The invention provides a manufacturing method of a large-diameter multi-core combined core rod. The method comprises the following steps: 1, selecting single-core core rods according to design requirements of a to-be-manufactured large-diameter multi-core combined core rod; then performing pretreatment on the selected single-core core rods; 2, preparing a glue solution; 3, loading the pretreated core rod into a mold of an injection moulding machine, preheating, then injecting the preheated glue solution into a preheated mold, and performing heat preservation so as to obtain a molded product; and 4, performing after-curing treatment on the molded product, thereby obtaining the large-diameter multi-core combined core rod. The multi-core combined core rod manufactured by the method is formed by combining multiple single-core core rods and then performing injection molding with the glue solution; the sectional diameter of the manufactured core rod is not less than 170mm, and belongs to the large diameter category; the multi-core combined core rod is excellent in performance, and meets relevant technical requirements of core rods for composite insulators.

Owner:西安高强绝缘电气有限责任公司

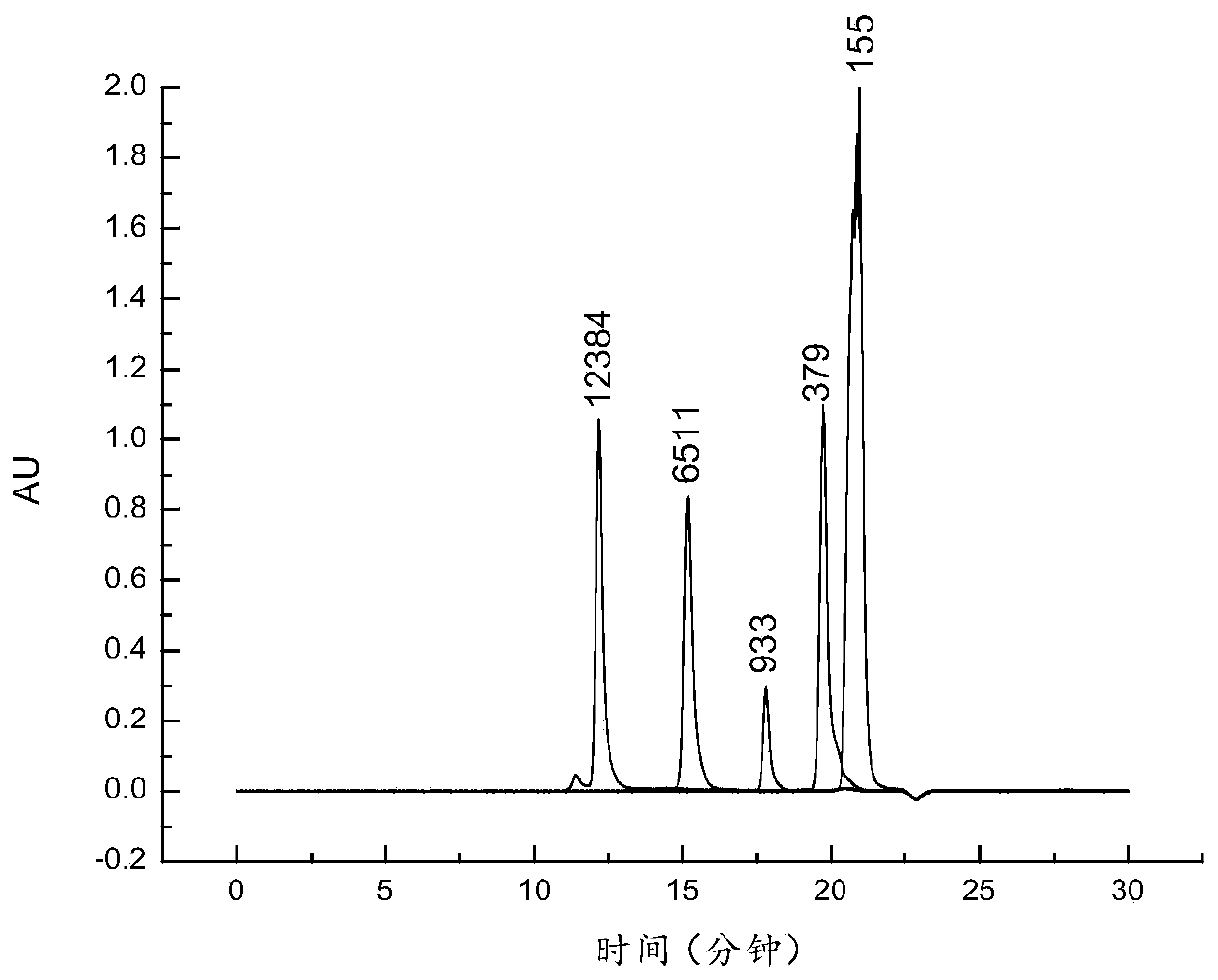

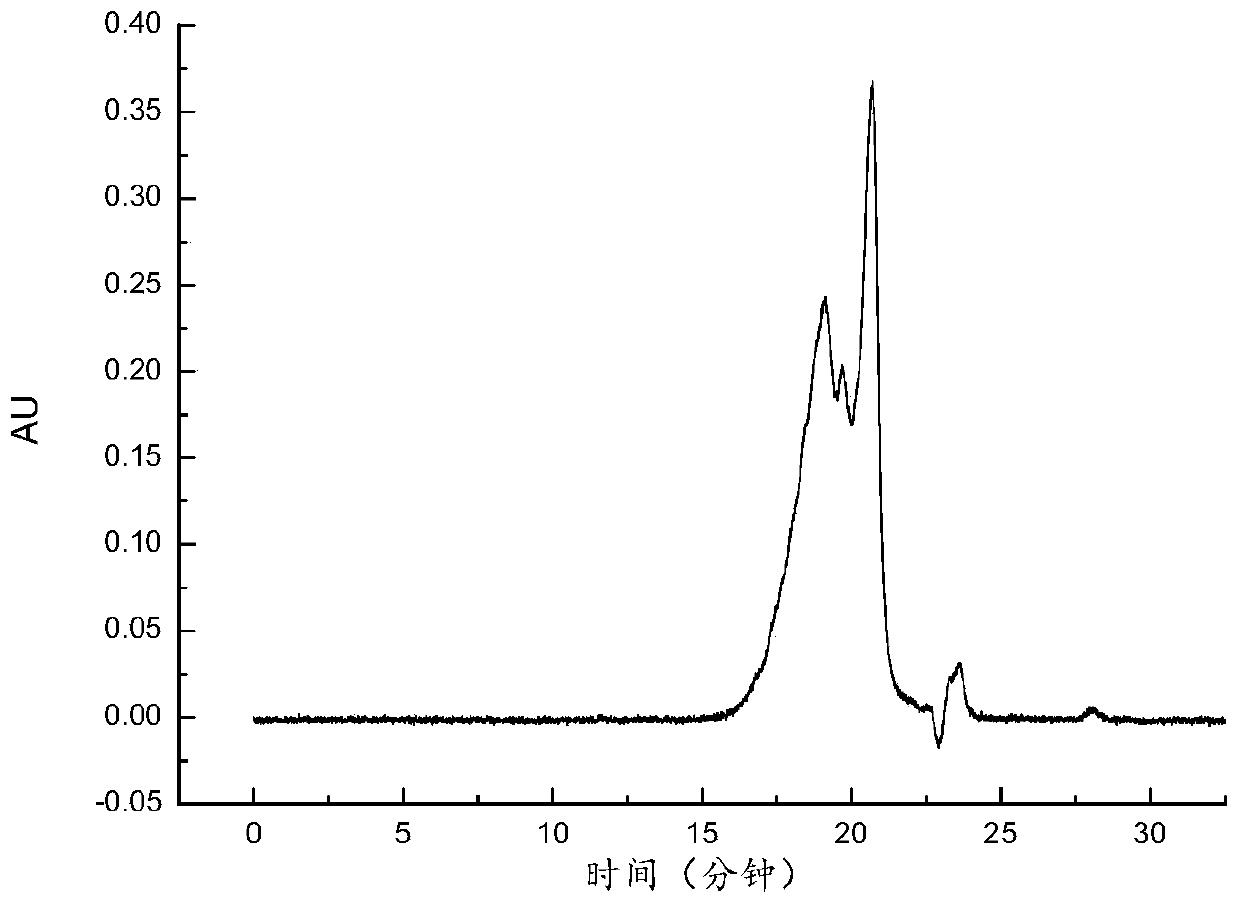

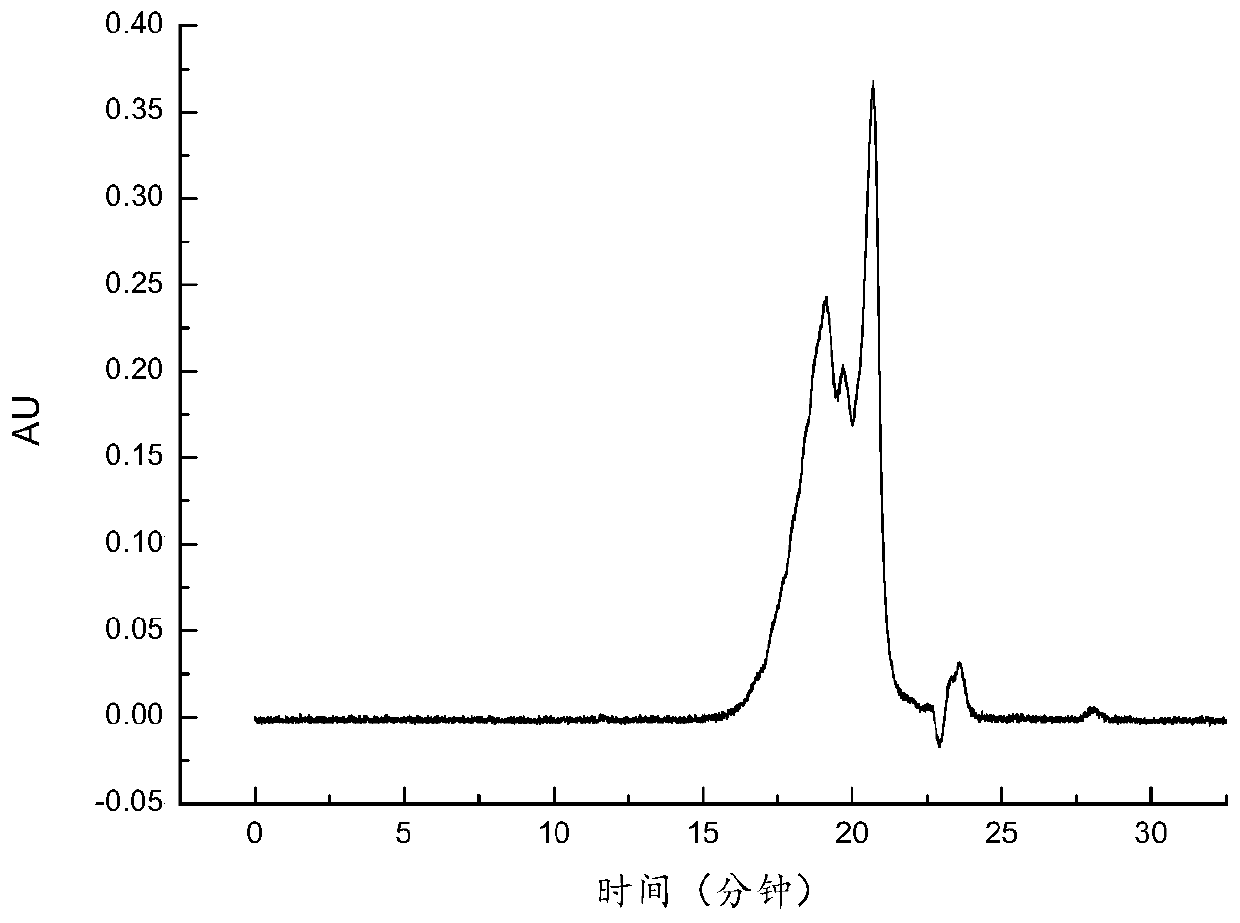

Enzymolysis preparation method of anti-coagulation peptide

The invention provides an enzymolysis preparation method of an anti-coagulation peptide, belonging to the technical field of deep processing of food-borne protein, and aiming to solve the problem that the inhibition rate of the thrombin inhibition peptide prepared from vegetable protein as a source is relatively low. The preparation method comprises the following steps: (1) dissolving isolated soybean protein in distilled water to obtain a soybean protein solution; (2) heating the soybean protein solution at 60-90 DEG C, regulating the pH value of the system according to different kinds of protease, adding the protease to carry out hydrolysis reaction, and carrying out enzyme deactivation treatment to obtain an enzymolysis solution, wherein the protease is pepsin, trypsin, alkaline protease or compound protease; (3) filtering the enzymolysis solution; (4) homogenizing; (5) sterilizing the homogenized enzymolysis solution; and (6) drying the sterilized enzymolysis solution to obtain a soybean anti-coagulation peptide. The maximum thrombin inhibition rate of the soybean anti-coagulation peptide prepared from the soybean protein as a raw material can reach 40%.

Owner:HARBIN INST OF TECH

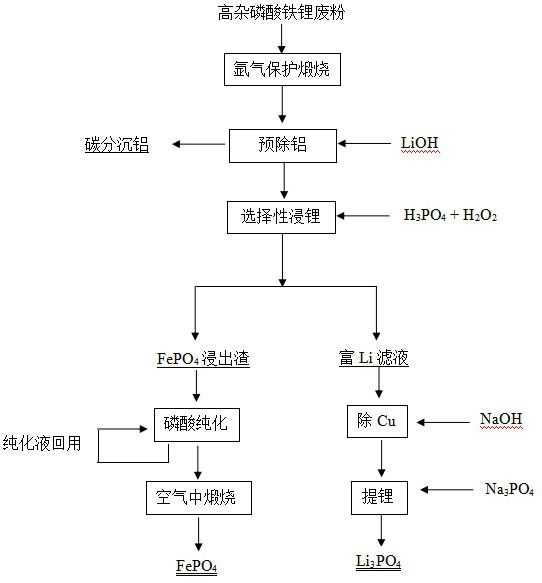

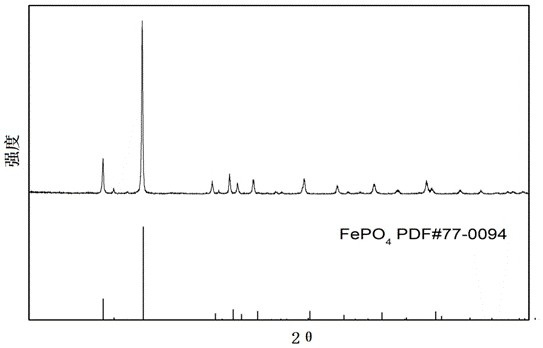

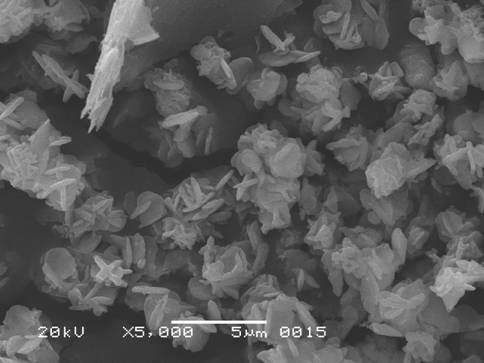

Method for treating high-impurity lithium iron phosphate waste powder by using low-consumption phosphoric acid

PendingCN113880064AReduce dosageImprove leaching ratePhosphorus compoundsBattery recyclingChemistryProcess engineering

The invention discloses a method for treating high-impurity lithium iron phosphate waste powder by using low-consumption phosphoric acid, which comprises the following steps of: pre-removing aluminum from lithium iron phosphate waste powder subjected to calcination treatment in an alkaline system, leaching aluminum-removed filter residues by using phosphoric acid and hydrogen peroxide, keeping the pH value at 2-3 all the time in the leaching process, selectively leaching Li, removing impurity copper and residual Al in the aluminum-removed filter residues to obtain FePO4 leaching residues, purifying the FePO4 leaching residues by adopting excessive phosphoric acid, supplementing a proper amount of Fe and an oxidizing agent at the same time, further removing impurities such as residual Cu, and converting hydroxyl iron phosphate generated in the selective leaching process into high-purity iron phosphate. The method is simple in process, suitable for treating high-impurity waste lithium iron phosphate powder obtained through disassembly, and capable of directly obtaining battery-grade iron phosphate and lithium phosphate. The method is easy to operate, the consumption of phosphoric acid as a leaching agent is low, the cost is low, the lithium recovery rate is high, and the iron phosphate is high in purity and meets the requirements of battery-grade iron phosphate.

Owner:ZHUZHOU SMELTER GRP

Finishing method of high water absorption hydrophilic nonwoven fabric for medical treatment

InactiveCN106906635ASoft and comfortablePromote absorptionFibre typesFilament/thread formingNonwoven fabricLow temperature plasma

The present invention provides a finishing method of a high water absorption hydrophilic nonwoven fabric for medical treatment. The finishing method comprises: (1) low temperature plasma treatment: taking a nonwoven fabric base cloth, and carrying out low temperature plasma treatment on at least one surface of the nonwoven fabric base cloth, wherein the low temperature plasma treatment comprises: carrying out low temperature plasma treatment on the nonwoven fabric base cloth under a normal pressure by using N2, Ar or He gas as a working gas by using a ceramic electrode through dielectric barrier discharge; (2) online liquid injection: coating a fatty acid ester finishing liquid on the surface of the nonwoven fabric base cloth, and carrying out high temperature drying; and (3) cutting and packaging. According to the present invention, the method does not require the vacuum condition, can directly achieve the online liquid injection, and can directly perform the low temperature plasma treatment under the normal pressure without other additional equipment conditions; and the produced non-woven has characteristics of soft handfeeling and comfort, and can especially meet the high water absorption requirement in the medical industry, and the method can well meet the large-scale industrial production.

Owner:CHTC JIAHUA NONWOVEN CO LTD

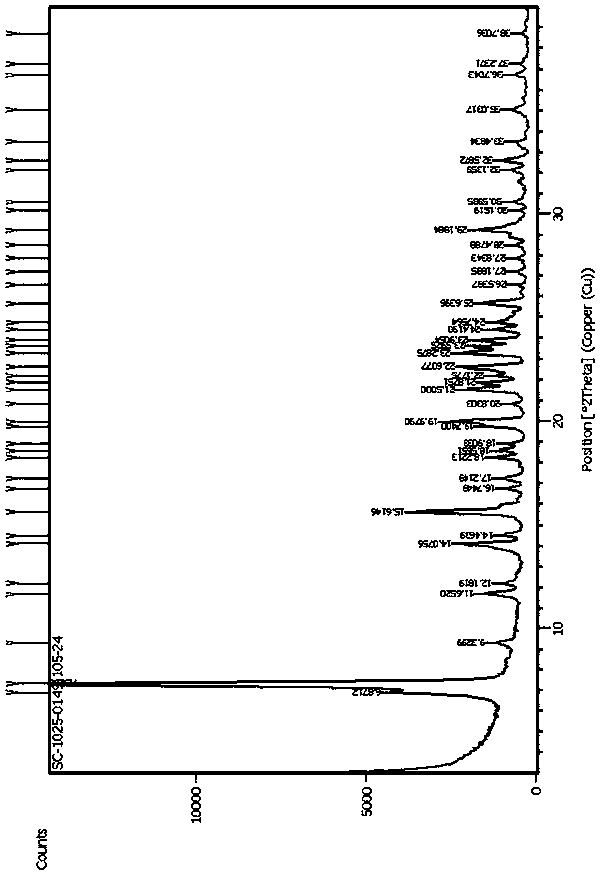

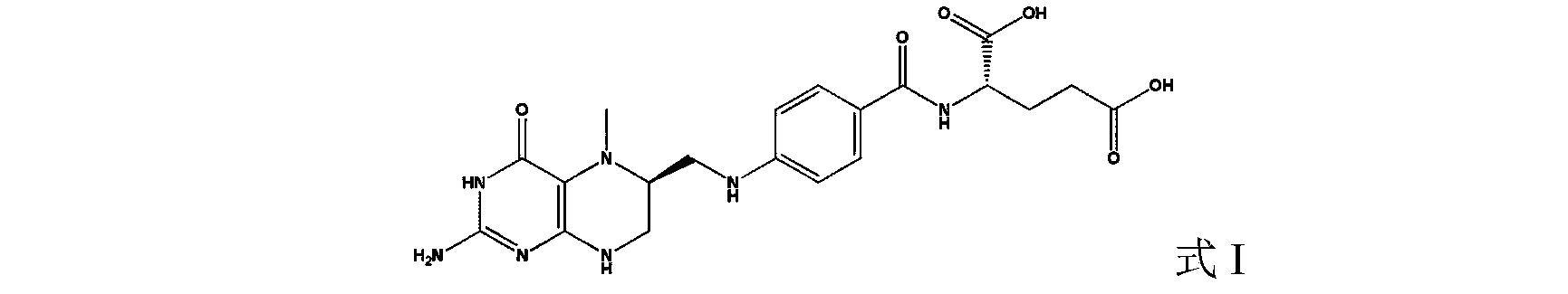

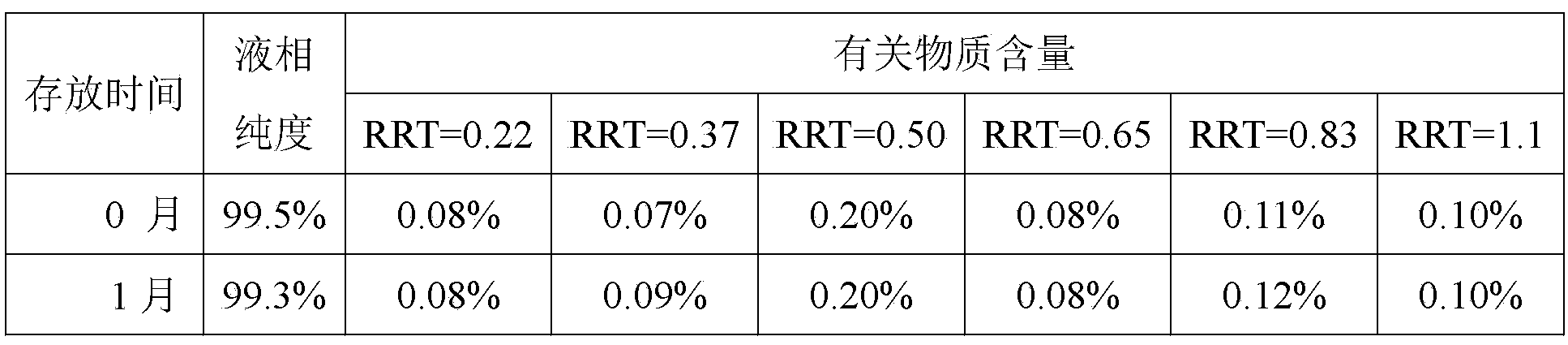

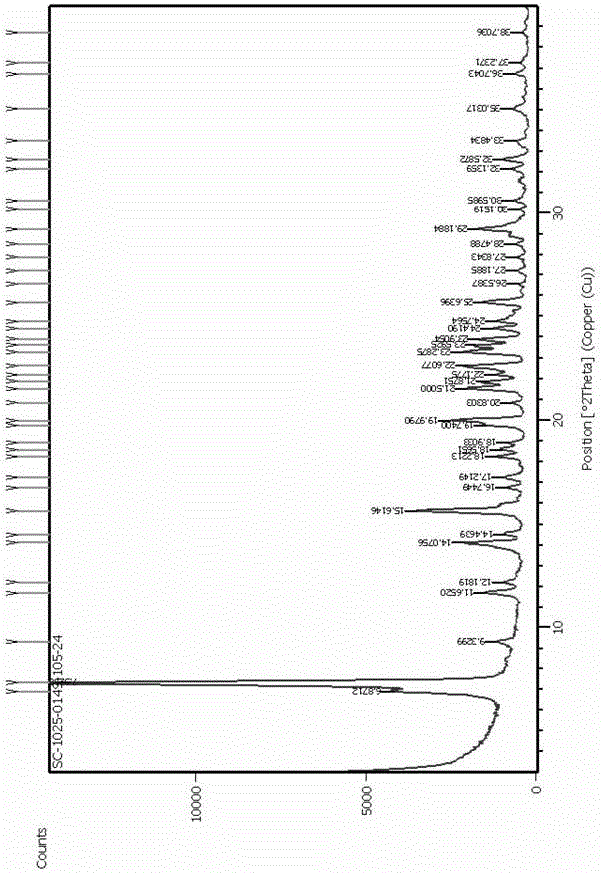

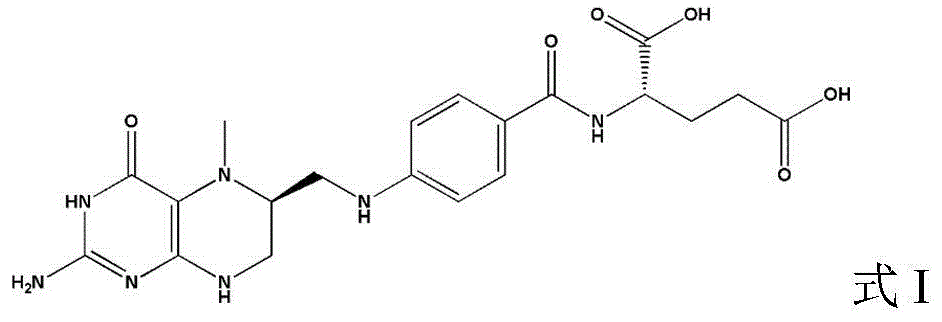

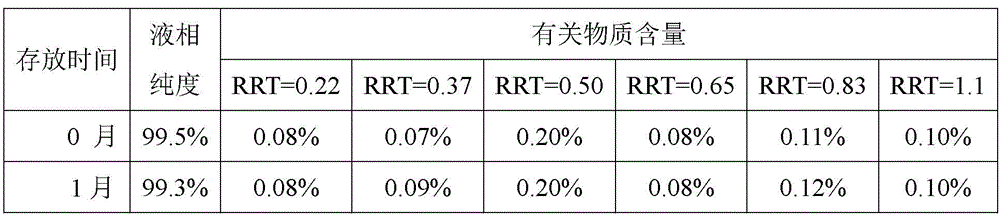

Crystal form A of 5-methyl-(6S)-tetrahydrofolic acid and preparation method thereof

The invention relates to a crystal form A of 5-methyl-(6S)-tetrahydrofolic acid and a preparation method thereof. The crystal form A of the 5-methyl-(6S)-tetrahydrofolic acid has characteristic peaks at about 7.3, 9.3, 11.6, 12.1, 14.0, 14.4, 15.6, 16.7, 17.2, 18.2, 18.5, 18.9, 19.9, 20.8, 21.5, 21.8, 22.1, 22.6, 23.2, 23.5, 23.9, 24.4, 24.7, 25.6, 26.5, 27.1, 27.8, 28.4 and 29.1 in X-ray powder diffraction expressed by 2[theta] by utilization of Cu-K[alpha] radiation. The crystal form A of the 5-methyl-(6S)-tetrahydrofolic acid is good in stability, high in purity, good in reproducibility and good in dissolvability. The preparation method is simple and is suitable for industrial production.

Owner:SHANGHAI SYNCORES TECH INC

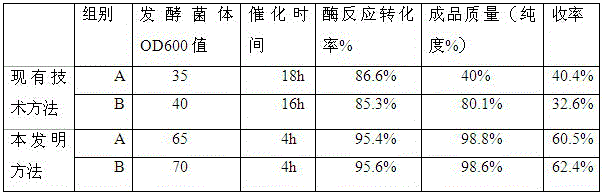

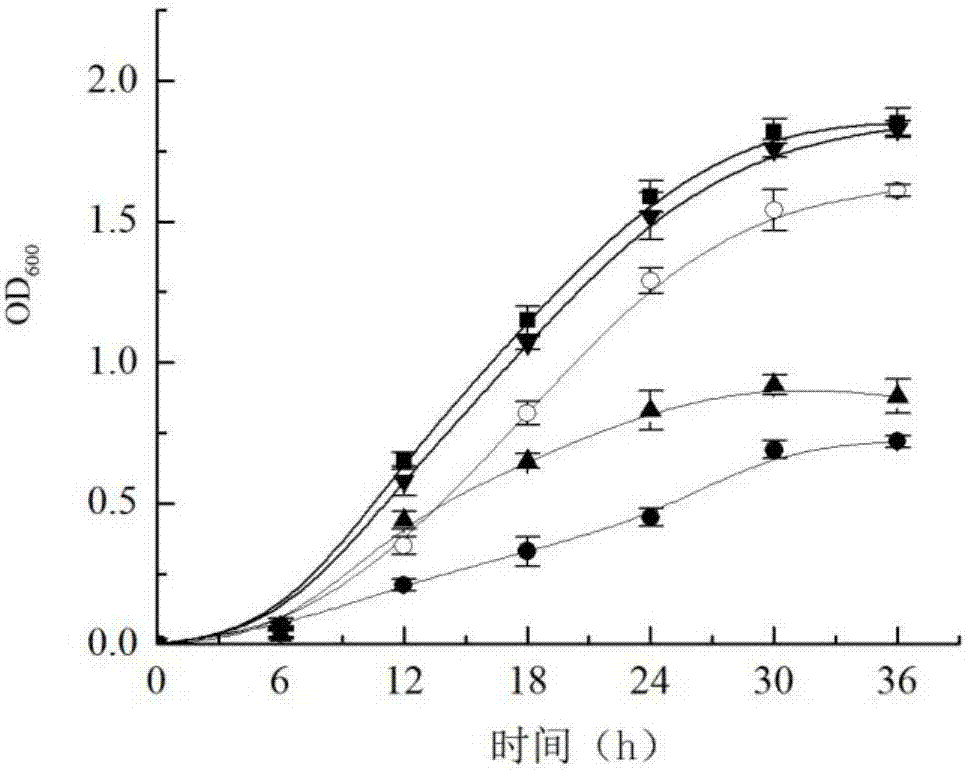

Method for producing L-4-hydroxyisoleucine by microbial enzyme conversion method

ActiveCN105779522AIncrease production capacityImprove efficiencyMicroorganism based processesFermentationEscherichia coliUltrafiltration

The invention relates to a method for producing L-4-hydroxyisoleucine by a microbial enzyme conversion method. The method comprises the following steps: 1, culturing a mature bacterial strain; 2, grafting mature escherichia coli recombinant bacteria which are capable of inducing production of L-4-hydroxyisoleucine into a fermentation tank, and carrying out fermentation culture, wherein the temperature of the fermentation process is controlled in two stages, i.e., 4 to 36 DEG C in the earlier stage and 30 to 32 DEG C in the later stage; 3, collecting thallus after fermentation, adding phosphate buffer and washing, then adding alpha-oxoglutarate, isoleucine, ferrous sulfate, magnesium sulfate and ascorbic acid, and carrying out forced ventilation for catalysis; 4, removing bacteria from the catalytic liquid with a ceramic membrane, filtering with an ultrafiltration membrane, decoloring with activated carbon, desalting with faintly acid cation exchange resin, adsorbing effluent with 732 cation exchange resin and eluting with ammonia water, carrying out evaporation concentration and recrystallization to obtain the L-4-hydroxyisoleucine. The preparation method disclosed by the invention is simple and efficient in reaction system and simple and feasible in extraction process. The conversion rate is up to over 95.4 percent, and the purity of the product can reach over 98 percent.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD +1

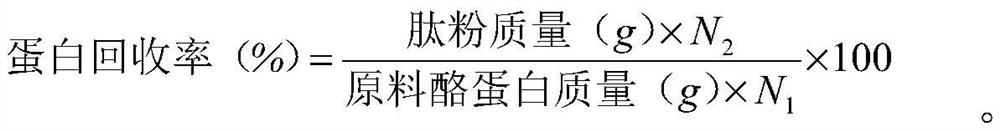

Bioactive peptide and preparation method thereof

InactiveCN107163133AHigh inhibition rateAbundant raw materialsPeptide/protein ingredientsPeptide preparation methodsFreeze-dryingReverse osmosis

The invention discloses a bioactive peptide and a preparation method thereof. The preparation method comprises the following steps: using milk or casein as a raw material, selecting an appropriate protease, carrying out enzymatic hydrolysis under certain conditions, carrying out concentration by adopting a membrane technology, desalting the obtained concentrate in a reverse osmosis manner, and drying the desalted concentrate by adopting a vacuum freeze-drying technique or a low-temperature spray drying technique in order to prepare polypeptide powder rich in bioactive peptides; and screening the polypeptides having anticoagulation activity through molecular fishing, sequencing the screened polypeptides to obtain an amino acid sequence, and synthesizing the final highly-pure polypeptide product in a solid phase synthesis manner. An identification result shows that the angiotensin converting enzyme inhibition rate and the thrombin inhibiting peptide inhibition rate of the peptide disclosed in the invention are high, the angiotensin converting enzyme inhibition rate of 1 mg of antithrombotic peptide dry powder is 30-80%, and the thrombin inhibition rate of 1 mg of the antithrombotic peptide dry powder is 70-98%. The method for preparing the bioactive peptide from the milk or casein has the advantages of richness in the raw material, low price, and meeting of large-scale industrial production.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Preparation method and application of cod protein peptide with high digestion and absorption characteristics

PendingCN110521849APromote digestionPromote absorptionProtein composition from fishMilk preparationAlkaline proteaseFiltration

The invention discloses a preparation method of cod protein peptide with high digestion and absorption characteristics. The method comprises the following steps: using cod meat as a raw material, carrying out pulping and alkaline protease enzymolysis, and carrying out membrane filtration and drying to obtain cod protein peptide powder. In the cod protein peptide powder prepared by the method, peptides with the molecular weight of 1000Da or below account for 90% or above of the protein content, are easy to digest and absorb by a human body and rich in nutrients and has various biological activities. The peptide with good digestion and absorption characteristics is developed by taking crushed cod meat as a raw material, cod processing byproducts are utilized, the price is low, more commercial values can be created, the method is simple and safe, and large-scale industrial production can be met. The prepared cod protein peptide has important significance in development and utilization offunctional foods, health foods or medicines.

Owner:DALIAN POLYTECHNIC UNIVERSITY

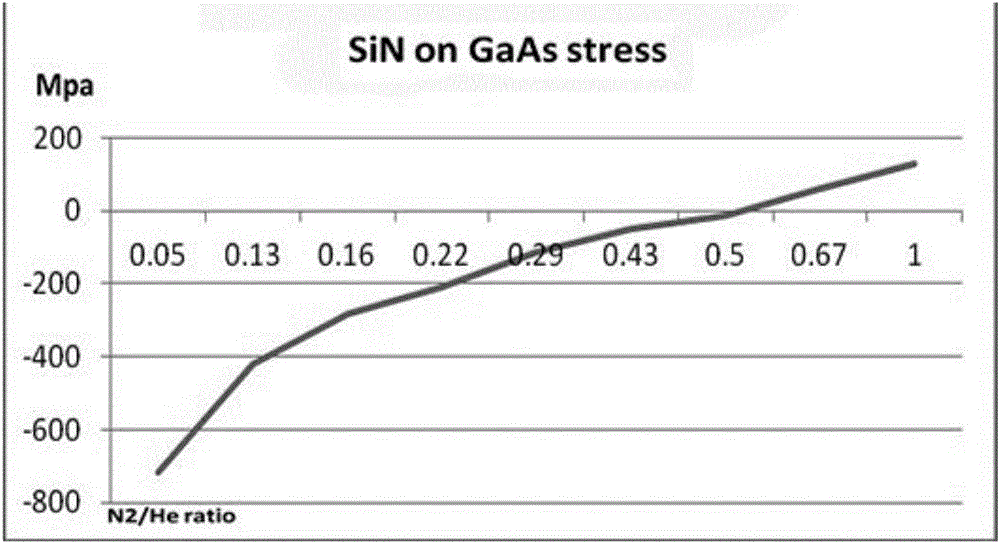

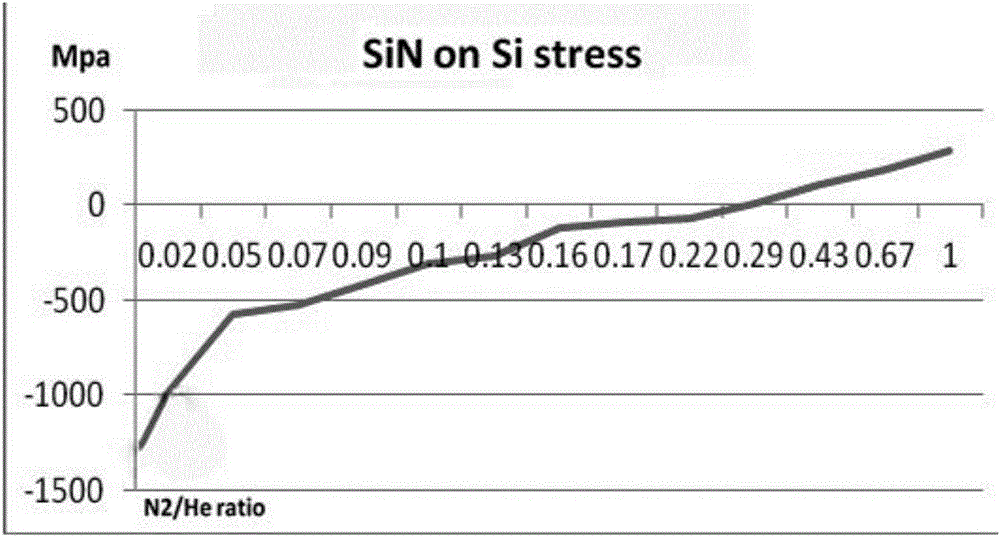

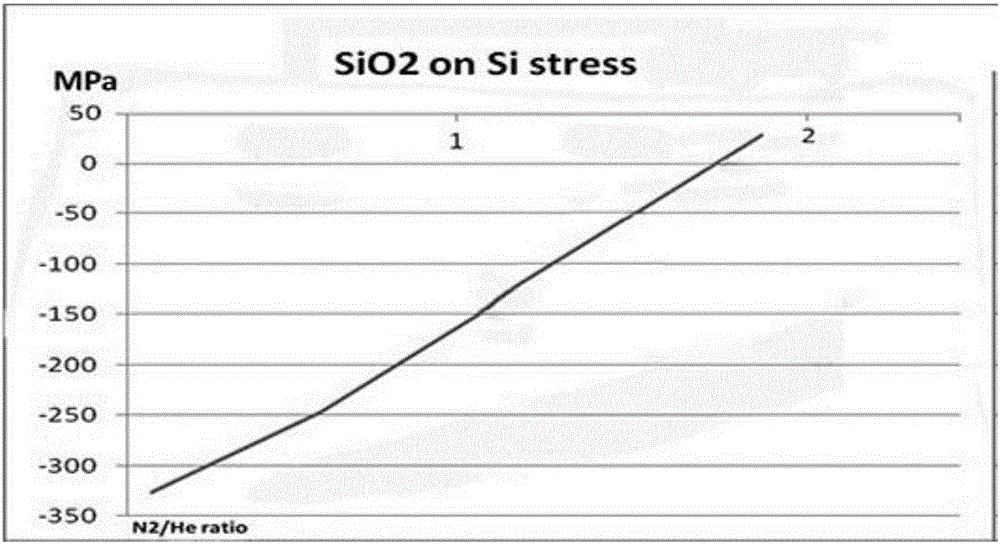

Preparation method of stress controllable silicon-based thin film

InactiveCN106169414AStress controllableLow costSemiconductor/solid-state device manufacturingTension stressChemical vapor deposition

The invention discloses a preparation method of a stress controllable silicon-based thin film. The preparation method comprises a step of enabling raw gas to deposit and grow on a substrate material through a chemical vapor deposition method by using single-frequency PECVD equipment so as to obtain the silicon-based thin film. During the preparation, He and N2 are imported into the raw gas. The preparation method is simple in process and high in controllability, and can be used for preparing the silicon-based thin film which can be adjusted between pressure stress and tension stress in a large range and which is good in uniformity, high in compactness and low in cost in PECVD equipment of a single-frequency radio source.

Owner:CHENGDU HIWAFER SEMICON CO LTD

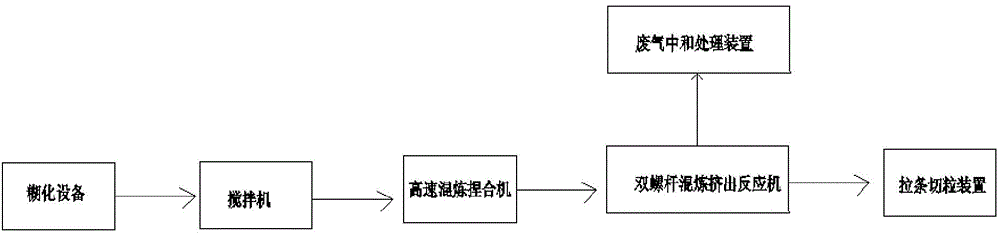

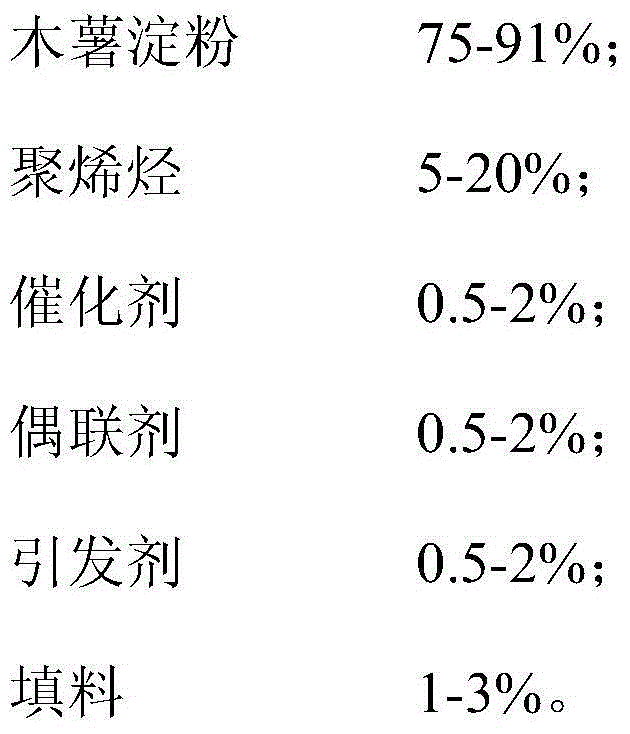

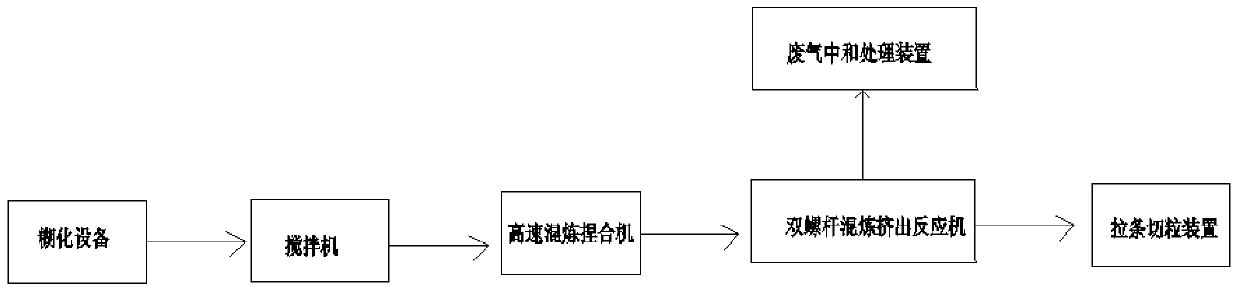

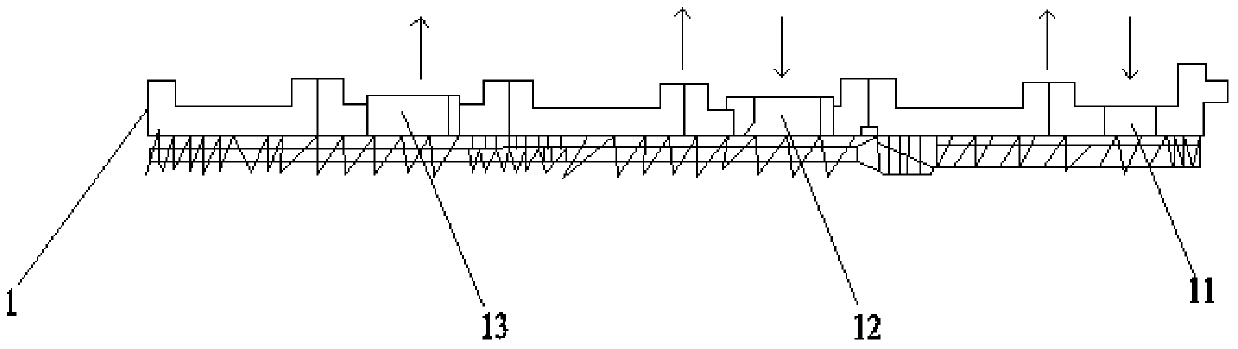

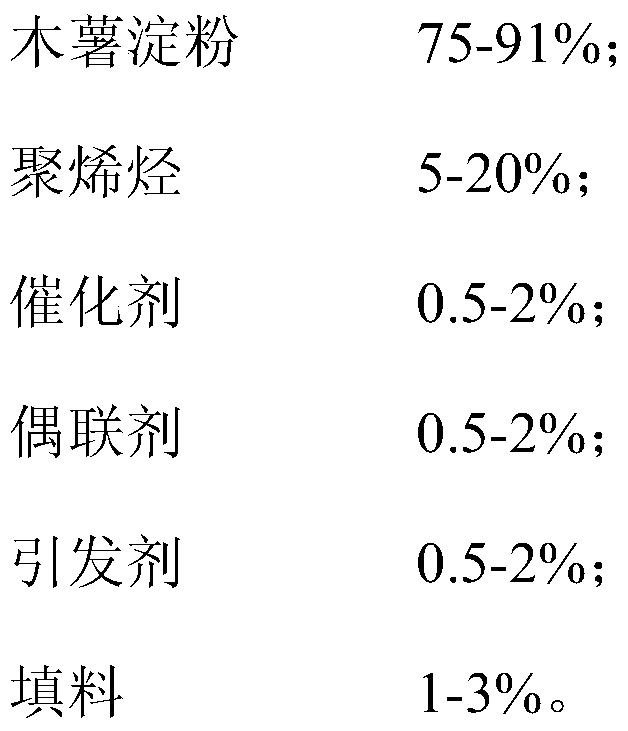

Cassava degradable plastic as well as production process and production equipment thereof

The invention relates to the technical field of cassava degradable plastic as well as a process and equipment thereof, and in particular relates to a cassava degradable plastic as well as a production process and production equipment thereof. The cassava degradable plastic consists of the following components in percentage by weight: 75-91% of cassava starch, 5-20% of polyolefin, 0.5-2% of a catalyst, 0.5-2% of a coupling agent, 0.5-2% of an initiator and 1-3% of filler. The production process comprises the following steps: carrying out gelatinizing pretreatment, carrying drying pretreatment, then mixing and kneading powder at a high speed, reacting and extruding in a twin-screw extrusion reacting machine, and finally bracing, dicing, drying and sub-packaging to obtain the cassava degradable plastic. The cassava degradable plastic production equipment comprises a sieving machine for sieving the filler and a stirrer for mixing materials, and further comprises gelatinizing equipment for gelatinizing the cassava starch, a high-speed mixing and kneading machine, a twin-screw melting-extrusion reacting machine and a bracing and dicing device; the stirrer is connected to the high-speed mixing and kneading machine; the high-speed mixing and kneading machine is connected to the twin-screw melting-extrusion reacting machine; and the twin-screw melting-extrusion reacting machine is connected to the bracing and dicing device. The degradation rate can reach more than 85%.

Owner:DONGGUAN FANGZHONG SPORT PROD

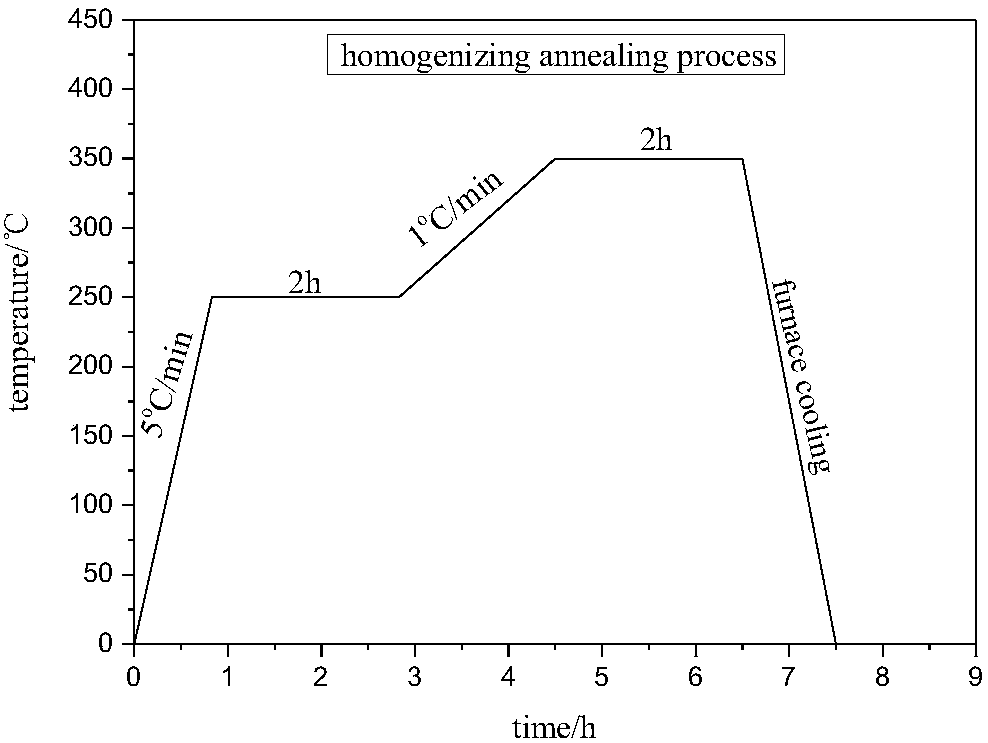

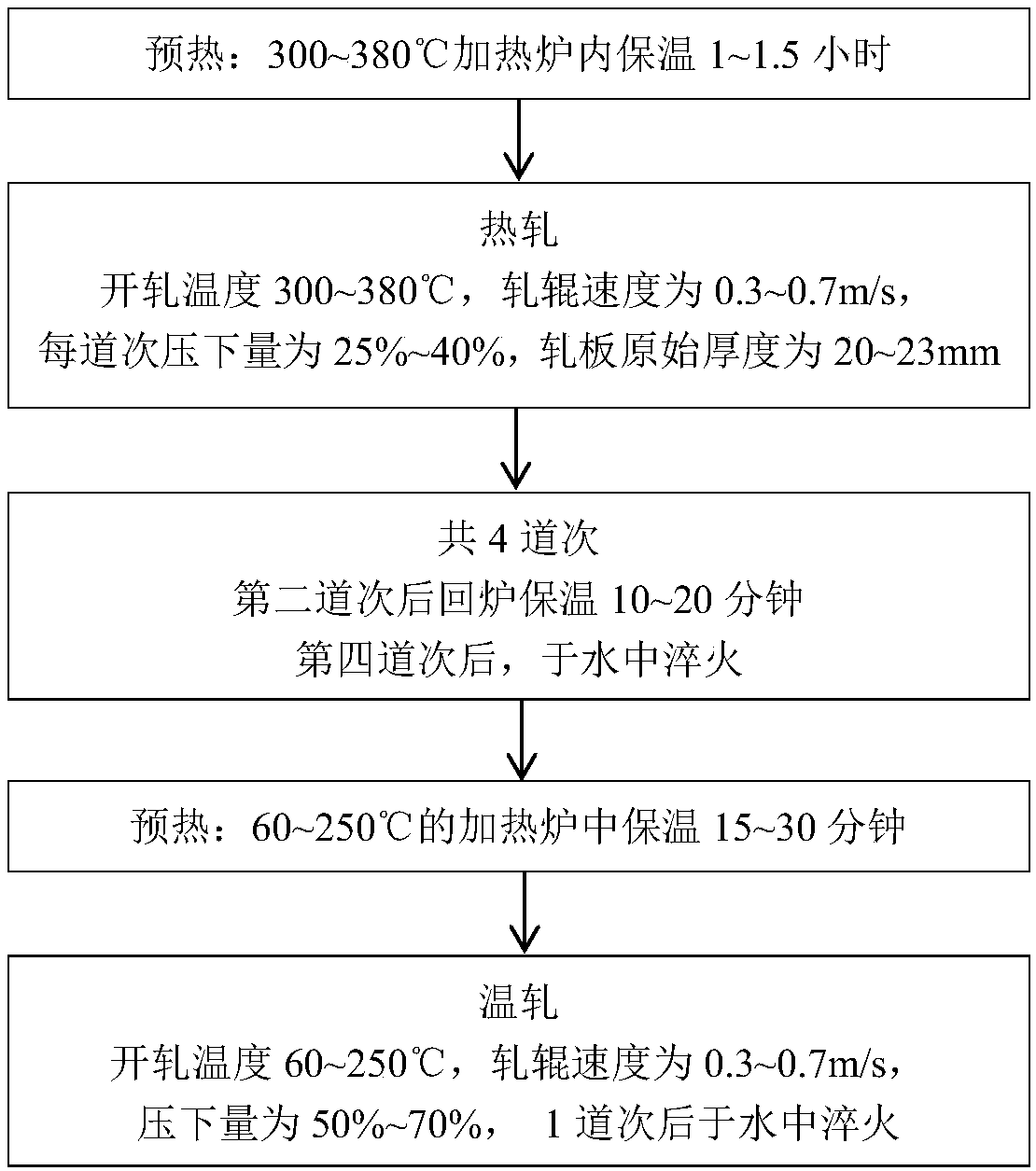

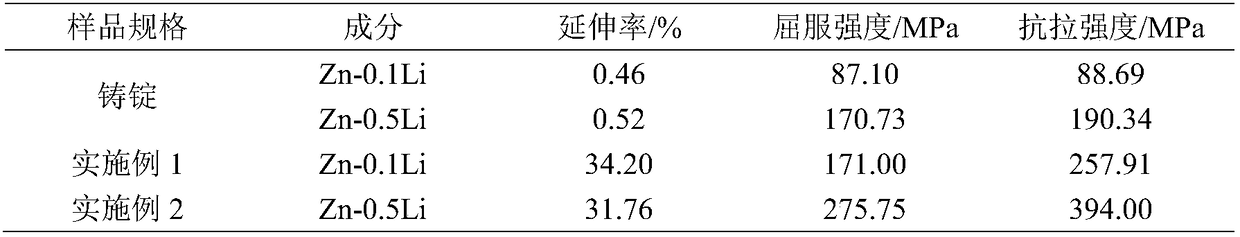

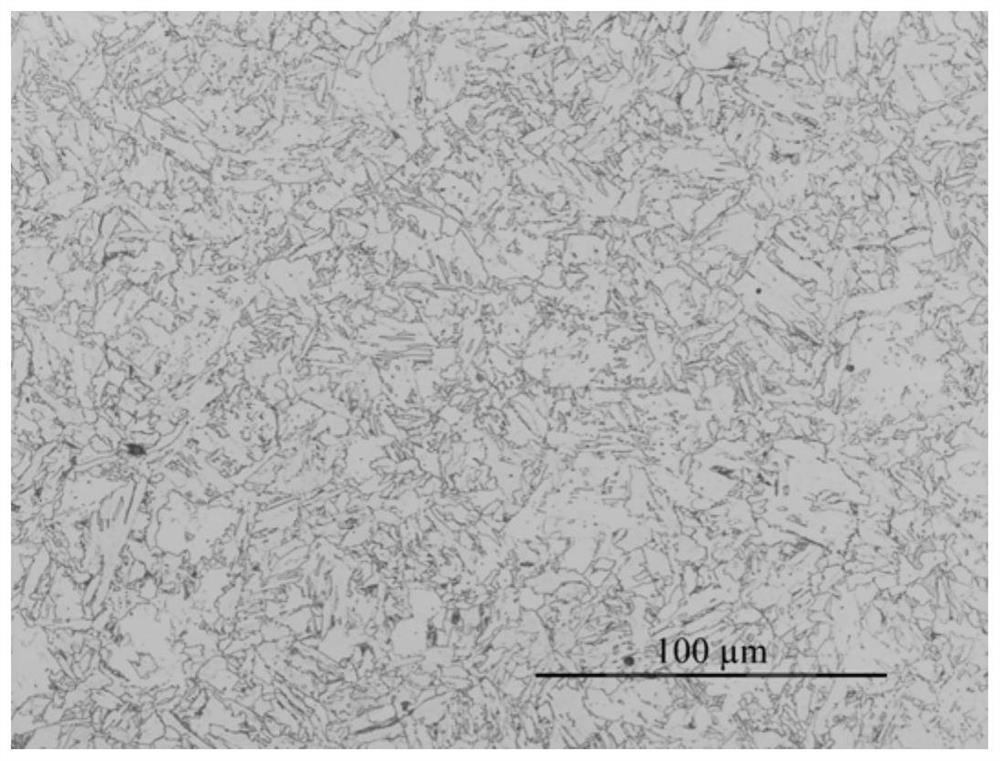

Rolling method of biodegradable medical Zn-Li alloy

ActiveCN108372203ASuitable degradabilityGood biocompatibilityTemperature control deviceMetal rolling arrangementsIngot castingUltimate tensile strength

The invention discloses a rolling method of a biodegradable medical Zn-Li alloy and belongs to the technical field of biodegradable medical materials and metal rolling. The method includes: homogenizing alloy ingots: rising temperature to 200-280 DEG C at a speed of 2-6 DEG C per min, holding the temperature for 1-2h, rising the temperature to 300-380 DEG C at a speed of 0.5-1 DEG C per min, holding the temperature for 1-2h, and cooling along with a furnace; after alloy is preheated, hot rolling: putting the alloy back into the furnace and holding the temperature for 10-20min after the secondtime of rolling, and quenching in water after the fourth time of rolling, wherein rolling start temperature is 300-380 Deg C, press-down amount of each time of rolling is 25-40%, and rolling is performed for four times in total; warm rolling: rolling once, and quenching in water, wherein rolling start temperature is 60-250 DEG C, and press-down amount is 50-70%. Through a simple rolling process, the biodegradable Zn-Li alloy with high strength and high plasticity is obtained, the problem of low section plasticity caused by common plastic processing methods is avoided, and material using requirements of various human implantation devices are met. The method is low in cost and easy for large-scale production in factories, thereby having extremely high popularization value and extensive application prospect in the field of medical materials.

Owner:北京尚宁科智医疗器械有限公司

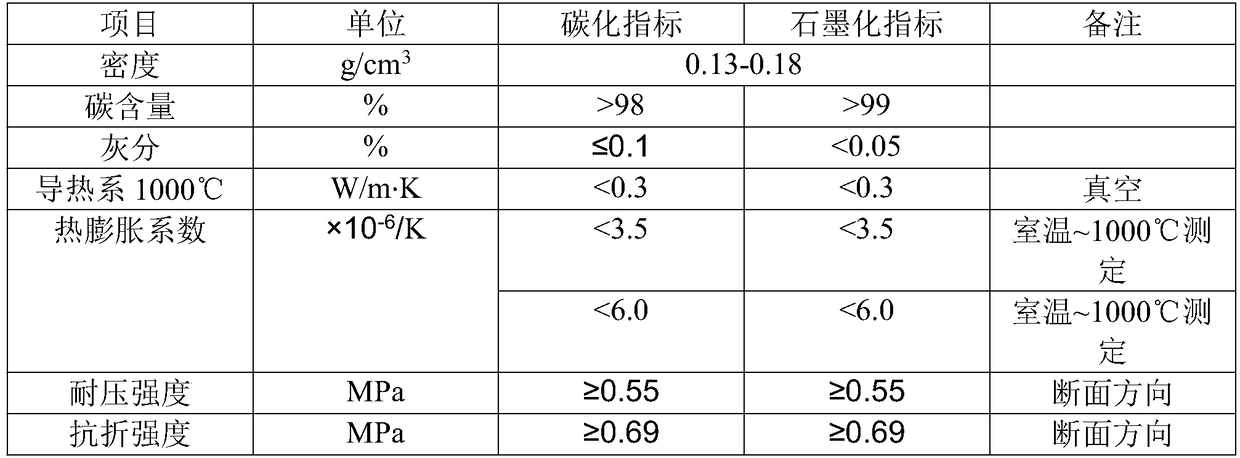

High-efficiency energy-saving cured carbon felt, and preparation method thereof

InactiveCN108625185ANo pollutionIncrease effective spaceNon-woven fabricsThermal insulationCarbon felt

The invention discloses a high-efficiency energy-saving cured carbon felt, and a preparation method thereof. The high-efficiency energy-saving cured carbon felt is prepared from, by weight, 650 to 720parts of soft felt, 30 to 40 parts of a dilluent, 50 to 100 parts of a curing agent, 200 to 300 parts of a resin, and 25 to 35 parts of an inorganic filing material. The preparation method comprisesfollowing steps: 1, felt cutting; 2, rubber preparation; 3, rubber coating; 4, manufacturing and moulding; 5, high temperature oven drying; 6, machining; 7, coating; 8 high temperature calcining; and9, detection. The high-efficiency energy-saving cured carbon felt is low in thermal conductivity, excellent in thermal insulation performance, uniform in density, low in heat storage capacity, quick in degassing, low in outgassing amount in vacuum, possesses heat impact resistance; product pollution or hearth pollution is not caused; furnace body effective space is enlarged; installation and maintenance are convenient; thermal insulation requirements of various monocrystalline growth furnaces and polysilicon ingot furnaces are satisfied. The preparation method is simple, is suitable for largescale industrialized production, and is promising in application prospect.

Owner:NINGJIN JINGXING ELECTRONICS MATERIAL

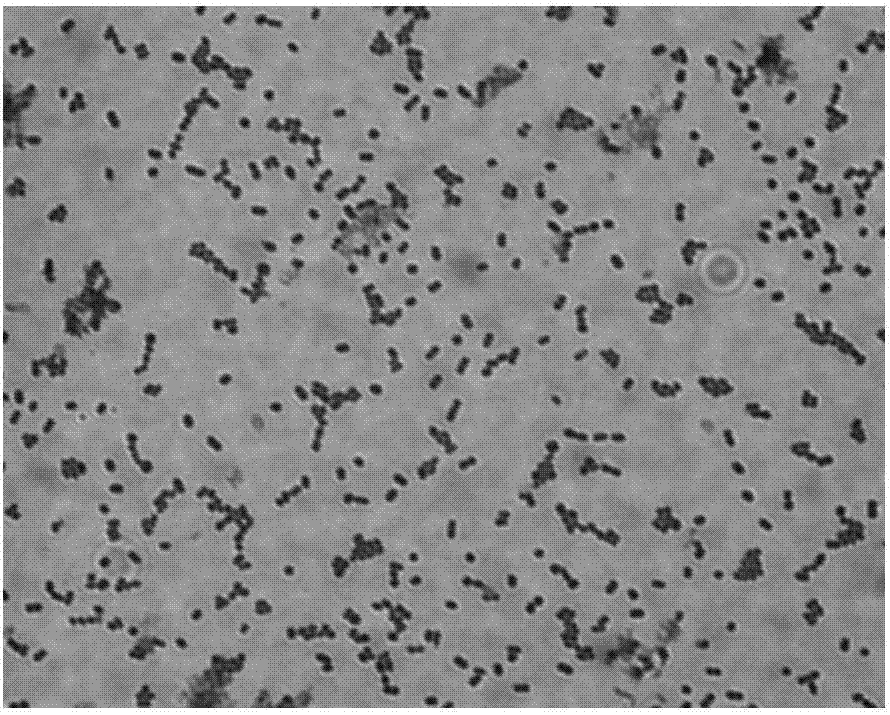

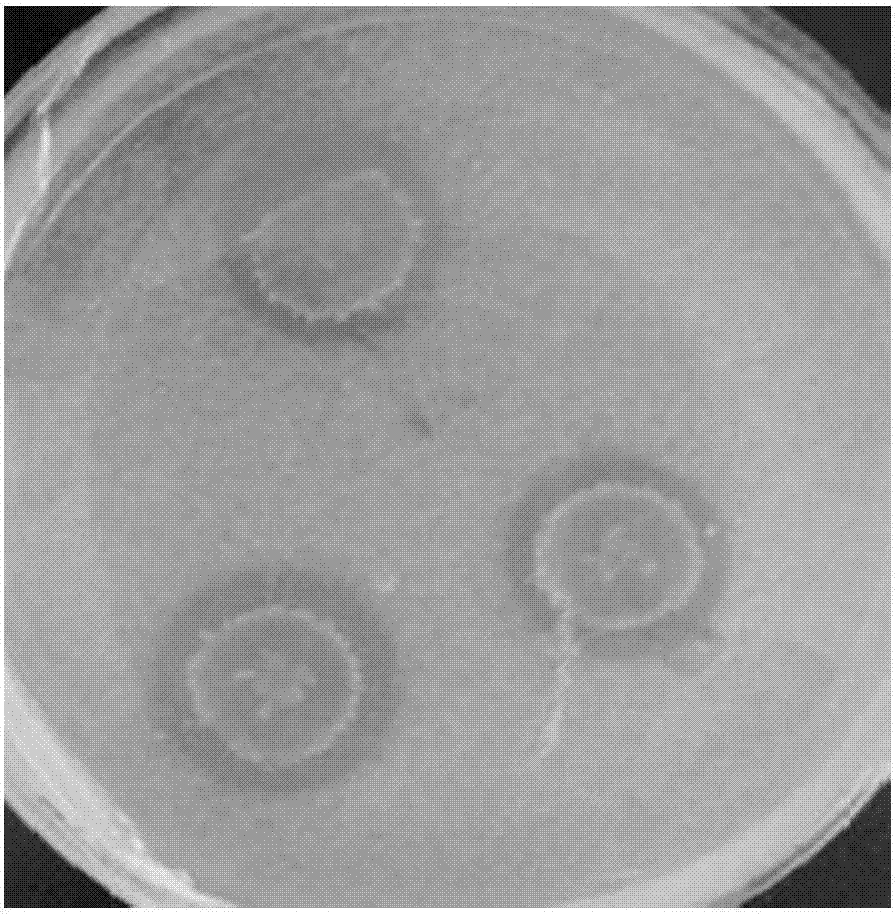

Acinetobacter schindleri MCDA 01 and method for preparing chitin deacetylase from Acinetobacter schindleri MCDA 01

The invention discloses Acinetobacter schindleri MCDA 01 from the sea. The Acinetobacter schindleri MCDA 01 was preserved in the China General Microbiological Culture Collection Center with the preservation number of CGMCC NO.13538. The strain is gram-negative brevibacterium, and has characteristics of no spore, white and nontransparent bacterial colony, smooth and moist surface with slight bulges and serrulateserrulated edge of bacterial colony. According to the strain, optimum growth temperature is 30 DEG C, optimum growth pH is 8.0, optimum growth NaCl concentration is 4%, and optimum fermentation pH of chitin deacetylase produced from the MCDA01 strain is 8.0 and the optimum temperature is 30 DEG C. The prepared chitin deacetylase has high activity at low temperature and helps save energy and cost in industrial application. Chitosan by utilization of enzymatic preparation has high degree of deacetylation, the biological enzyme method is green and environment-friendly, and green production of chitosan is realized. The invention has great economic benefits.

Owner:HUAIHAI INST OF TECH +1

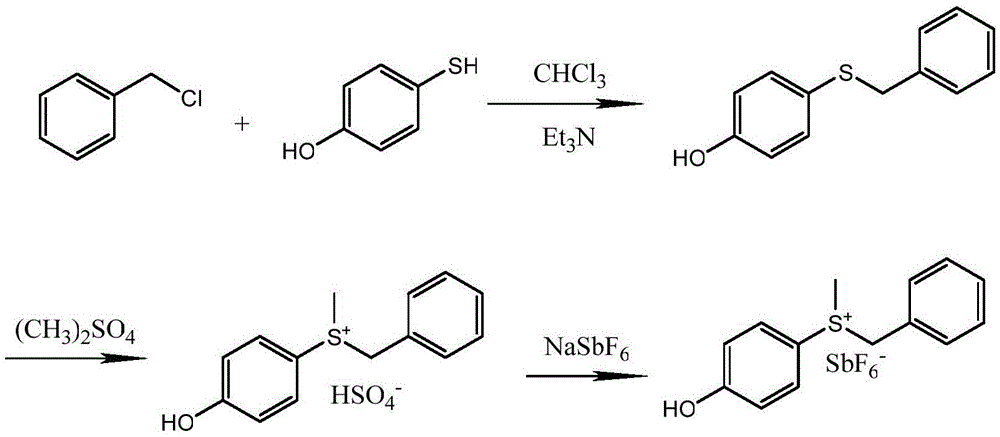

Method for synthesizing (4-hydroxyphenyl) methyl benzyl sulfonium hexafluoroantimonate

InactiveCN105541686AHigh purityMeet large-scale industrial productionSulfide preparationPotassium iodinePotassium carbonate

The invention relates to a method for synthesizing (4-hydroxyphenyl) methyl benzyl sulfonium hexafluoroantimonate. The method includes the following steps that in a solvent, 4-mercaptophenol or benzyl chloride or benzyl bromide serves as a raw material, and 4-(benzylthio) phenol is prepared under the action of triethylamine or potassium carbonate or sodium carbonate; in a toluene or cyclohexane or chloroform or dichloroethane solution, 4-(benzylthio) phenol and dimethyl sulfate or potassium iodide are methylated to obtain (4-hydroxyphenyl) methyl benzyl sulfonium sulfate or (4-hydroxyphenyl) methyl benzyl sulfonium iodate; in a methanol or alcohol or isopropanol solution, (4-hydroxyphenyl) methyl benzyl sulfonium sulfate and sodium hexafluoroantimonate are subjected to ion exchange to obtain the target product (4-hydroxyphenyl) methyl benzyl sulfonium hexafluoroantimonate. The method has the advantages that the raw materials are easy to obtain, the technology is simple, the prepared 4-(benzylthio) phenol is high in purity and does not need to be refined, and the requirement for large-scale industrial production of (4-hydroxyphenyl) methyl benzyl sulfonium hexafluoroantimonate can be met.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

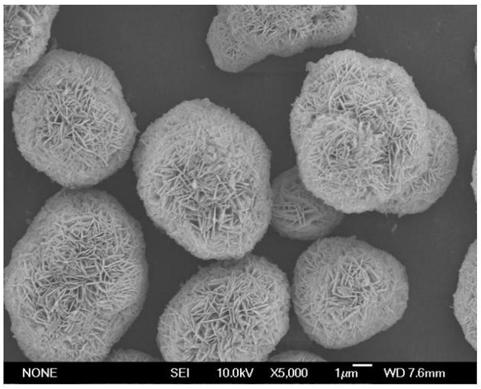

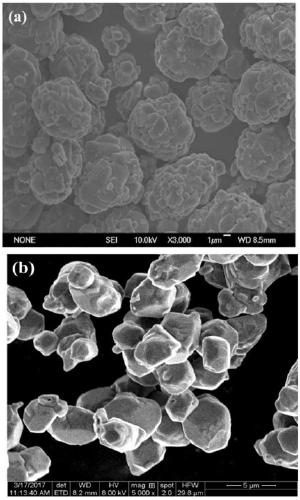

Improved preparation method of large single crystal layered positive electrode material for lithium ion battery

ActiveCN107311242BHigh tap densityIncrease compaction densitySecondary cellsPositive electrodesElectrical batteryManganese

Owner:UNIV OF JINAN

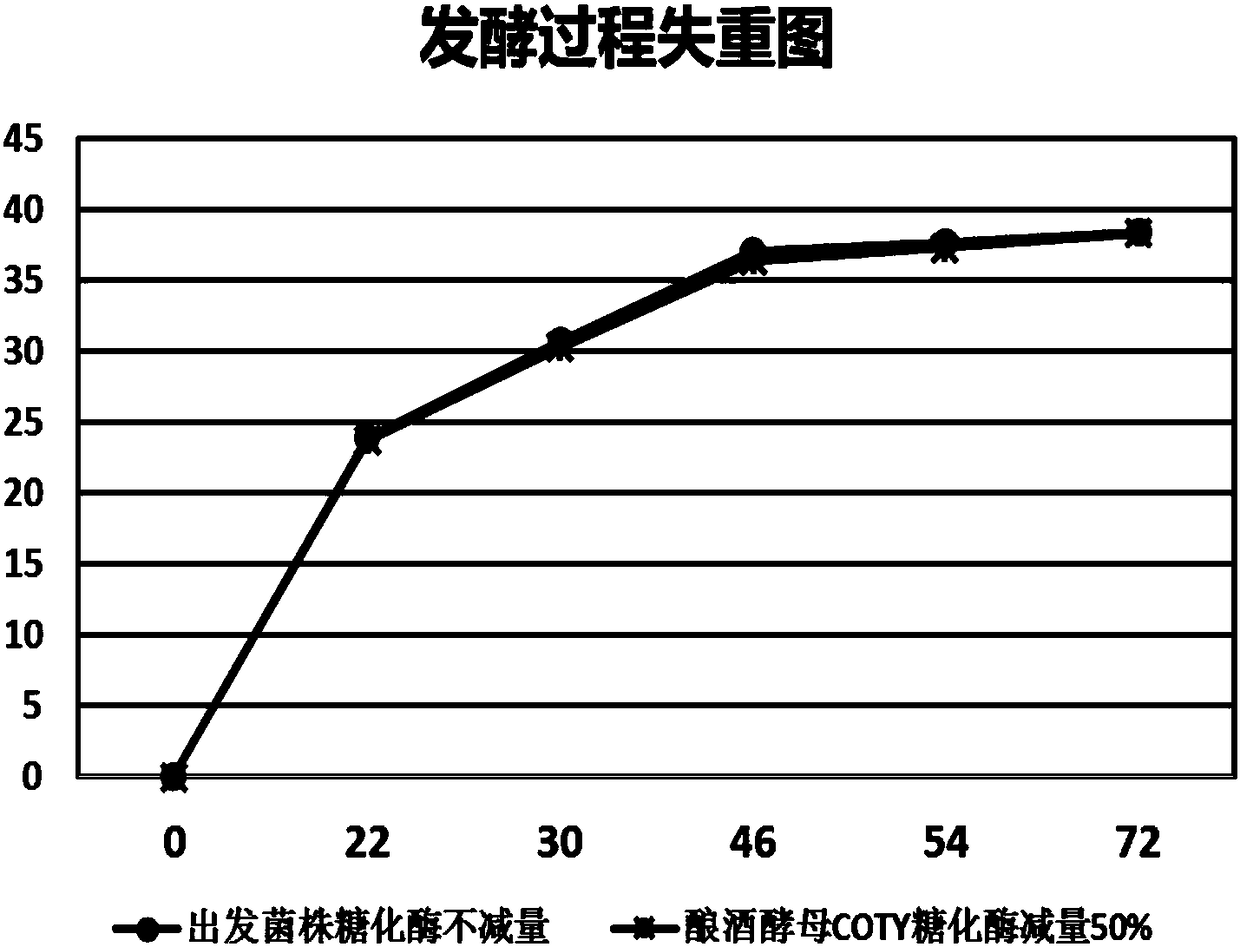

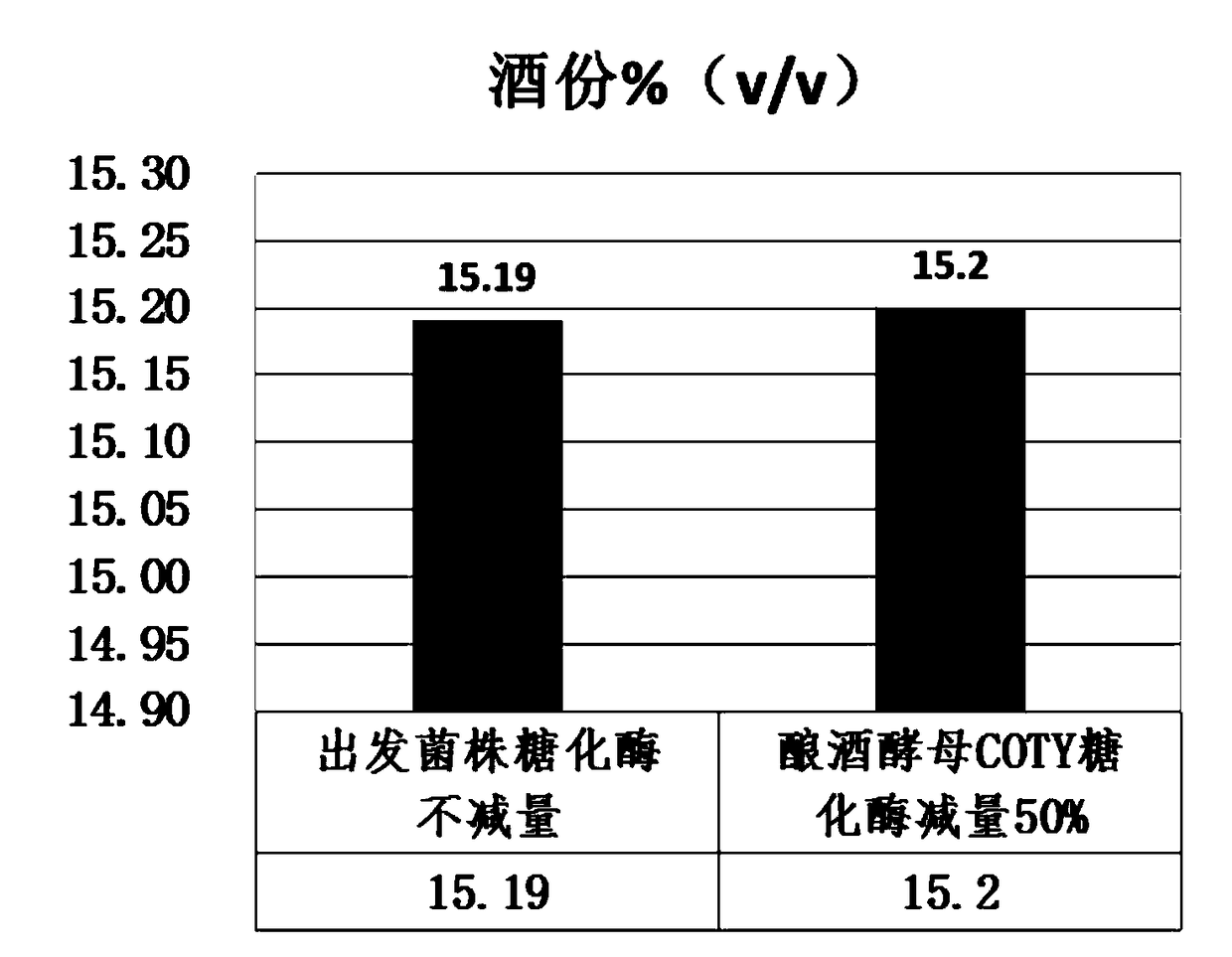

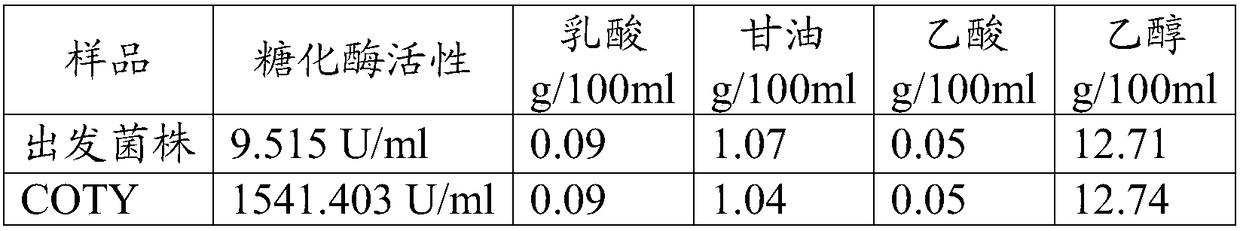

Saccharomyces cerevisiae strain and applications

ActiveCN109251868AHas glucoamylase activityExcellent fermentation performanceFungiBiofuelsMicroorganismAlcohol

The invention belongs to the field of microbiology, relates to a saccharomyces cerevisiae strain and applications, and in particular relates to a saccharomyces cerevisiae strain with the efficient saccharifying enzyme function and good fermenting property, and applications of the saccharomyces cerevisiae strain in producing bioethanol. The saccharomyces cerevisiae with the accession number of CGMCC No.13506 has the saccharifying enzyme activity and good fermenting property, and has the enzyme activities of various enzymes relevant to amylolysis, in the fermentation industry of bioethanol, thecoupling of starch saccharification with saccharomyces cerevisiae growth and alcohol fermentation is realized, the adding of 30-50 % of exogenous saccharifying enzyme can be effectively replaced, thusthe fermentation process is simplified, the production cost of alcohol is reduced, and the large-scale industrial production of alcohol is satisfied.

Owner:JILIN COFCO BIOCHEM +2

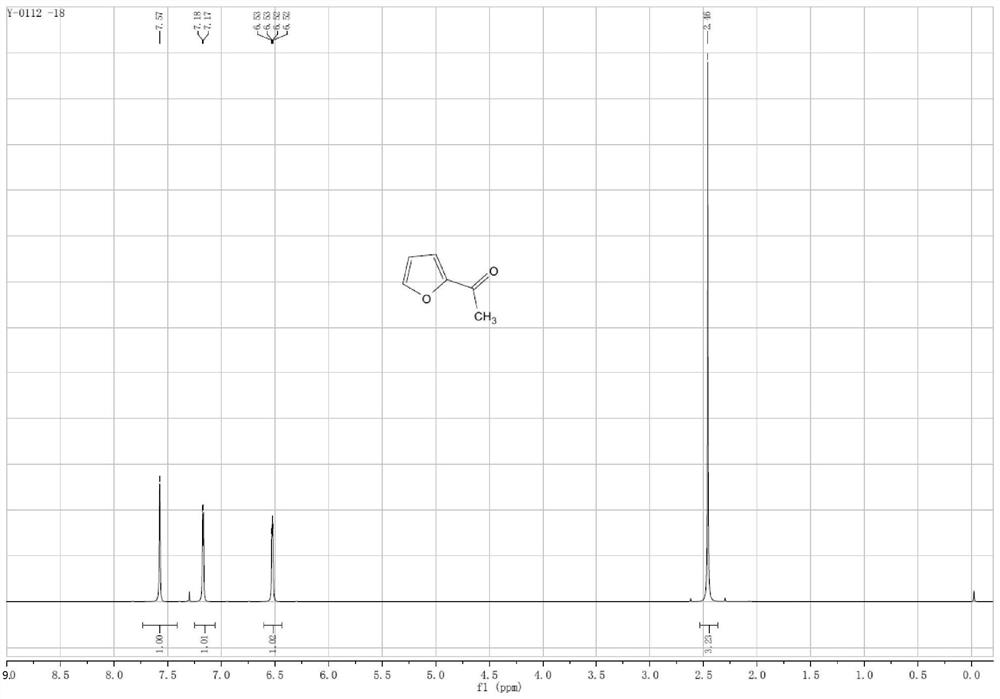

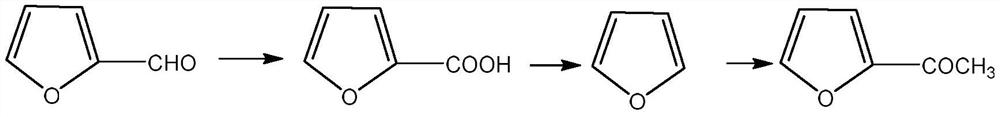

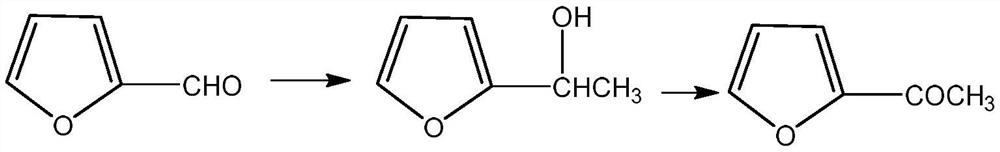

Preparation method of 2-acetylfuran

ActiveCN113004229ASimple processCatalyst simpleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsGrignard reactionFuran

The invention discloses a preparation method of 2-acetylfuran, which comprises the following steps: taking furfural as a raw material, carrying out Grignard reaction to obtain furfuryl alcohol, and carrying out oxidation reaction on furfuryl alcohol in the presence of a catalyst in an oxygen-containing atmosphere to obtain 2-acetylfuran, wherein the catalyst is a 4-hydroxy-2, 2, 6, 6-tetramethylpyridine oxide (Temp) and potassium bromide. The method is simple in process, simple in catalyst and suitable for large-scale industrial production, the stability meets the market requirements of products, the product cost is lower than that of existing industrial production, and the product quality is better.

Owner:长沙启晟合研医药科技有限公司

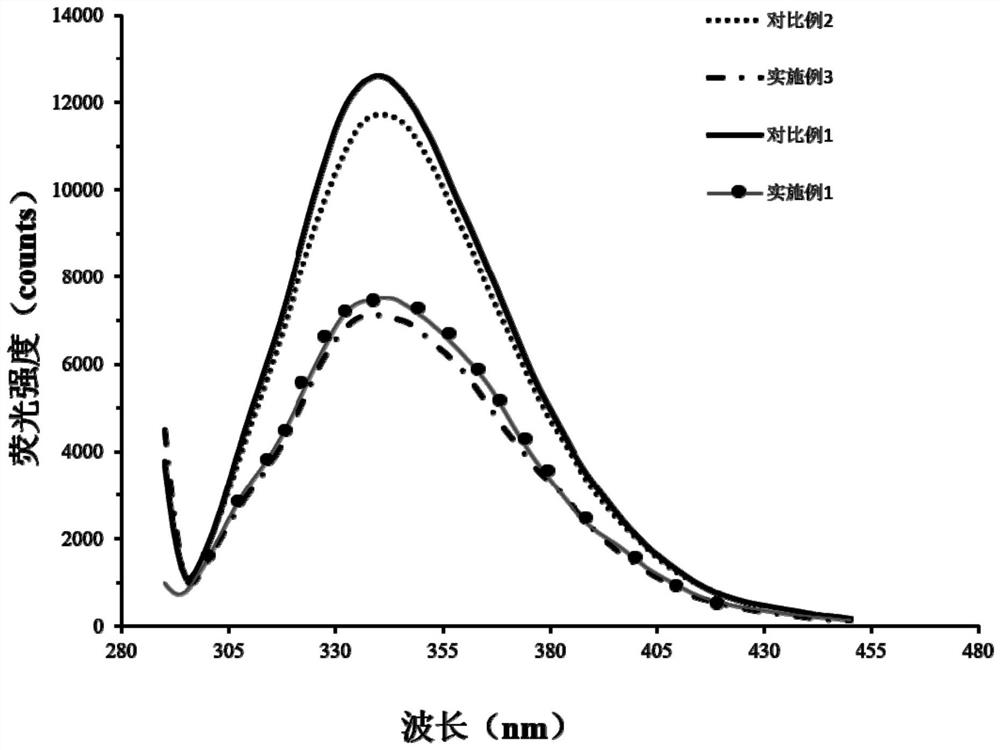

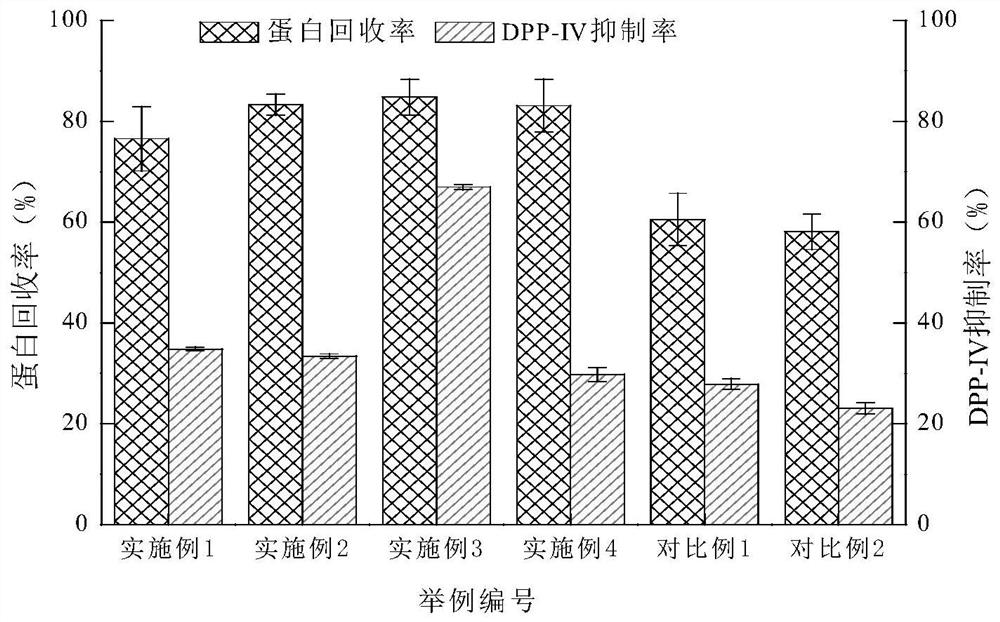

A kind of casein hypoglycemic peptide and its preparation method

ActiveCN110511274BGood hypoglycemic activityAbundant raw materialsMetabolism disorderProtein composition from milkDipeptidyl peptidaseEnzymatic hydrolysis

Owner:SOUTH CHINA UNIV OF TECH +1

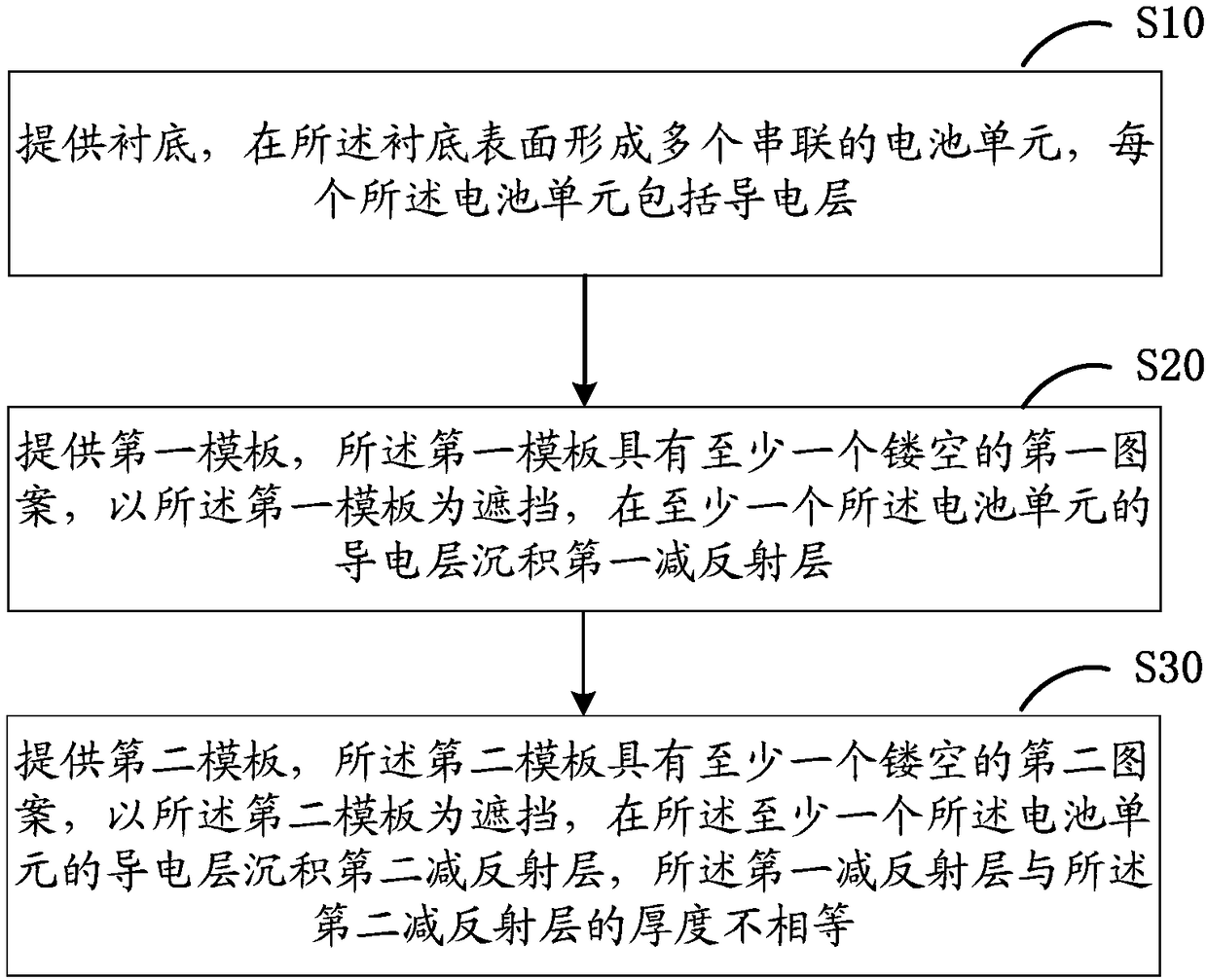

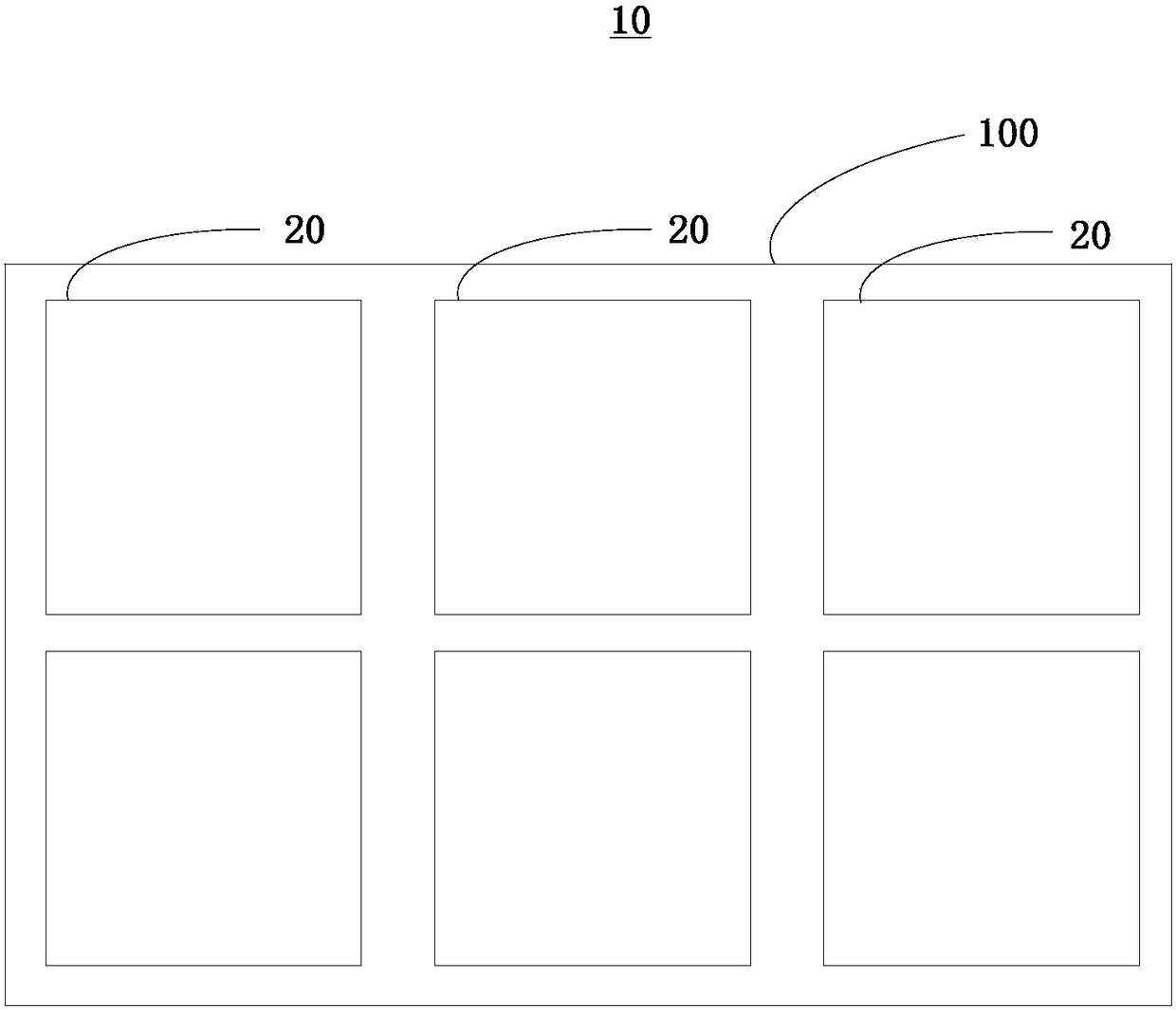

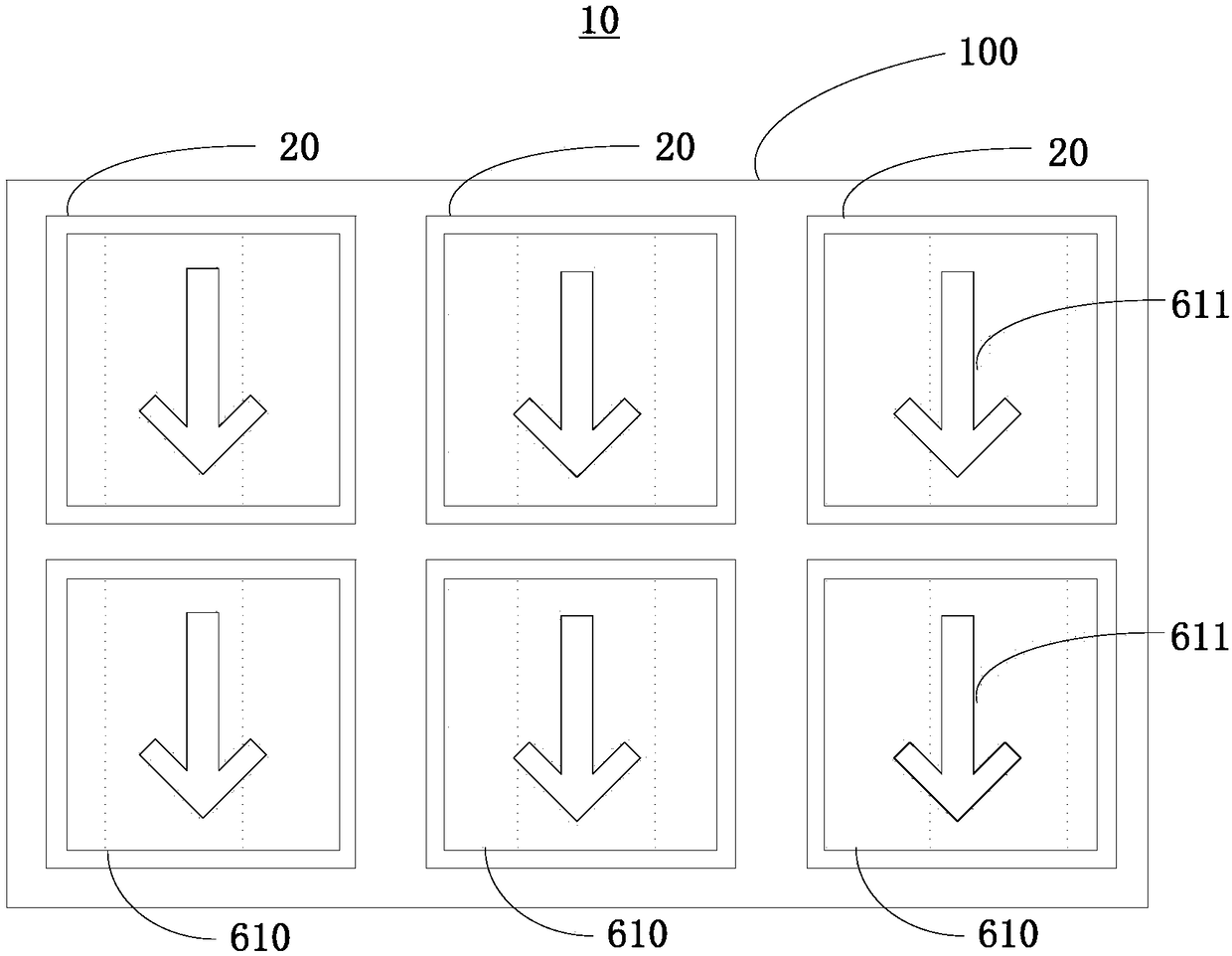

Color solar cell and preparation method thereof

InactiveCN108258068AAchieve color pattern effectRealize large-scale industrial productionPhotovoltaic energy generationSemiconductor devicesSolar cellComputer science

The invention relates to a color solar cell and a preparation method thereof. The cell is provided with several serial cell units. Each cell unit includes a conducting layer. A first template is provided. The first template includes at least one hollow first pattern. Shielding from the first template, a first anti-reflection layer is deposited on the conductive layer of at least one of the cell units. A second template is provided. The second template includes at least one hollow second pattern. Shielding from second template, a second anti-reflection layer is deposited on the conductive layerof at least one of the cell units. The thicknesses of the first anti-reflection layer and the second anti-reflection layer are not equal. The color solar cell has the advantages of simple process steps, convenient operation, good repeatability and high reliability can be industrially produced on a large scale. Customized production can be realized.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

A cassava degradable plastic and its production process and production equipment

The invention relates to the technical field of cassava degradable plastic as well as a process and equipment thereof, and in particular relates to a cassava degradable plastic as well as a production process and production equipment thereof. The cassava degradable plastic consists of the following components in percentage by weight: 75-91% of cassava starch, 5-20% of polyolefin, 0.5-2% of a catalyst, 0.5-2% of a coupling agent, 0.5-2% of an initiator and 1-3% of filler. The production process comprises the following steps: carrying out gelatinizing pretreatment, carrying drying pretreatment, then mixing and kneading powder at a high speed, reacting and extruding in a twin-screw extrusion reacting machine, and finally bracing, dicing, drying and sub-packaging to obtain the cassava degradable plastic. The cassava degradable plastic production equipment comprises a sieving machine for sieving the filler and a stirrer for mixing materials, and further comprises gelatinizing equipment for gelatinizing the cassava starch, a high-speed mixing and kneading machine, a twin-screw melting-extrusion reacting machine and a bracing and dicing device; the stirrer is connected to the high-speed mixing and kneading machine; the high-speed mixing and kneading machine is connected to the twin-screw melting-extrusion reacting machine; and the twin-screw melting-extrusion reacting machine is connected to the bracing and dicing device. The degradation rate can reach more than 85%.

Owner:DONGGUAN FANGZHONG SPORT PROD

A 5-methyl-(6s)-tetrahydrofolate crystal form a and its preparation method

The invention relates to a crystal form A of 5-methyl-(6S)-tetrahydrofolic acid and a preparation method thereof. The crystal form A of the 5-methyl-(6S)-tetrahydrofolic acid has characteristic peaks at about 7.3, 9.3, 11.6, 12.1, 14.0, 14.4, 15.6, 16.7, 17.2, 18.2, 18.5, 18.9, 19.9, 20.8, 21.5, 21.8, 22.1, 22.6, 23.2, 23.5, 23.9, 24.4, 24.7, 25.6, 26.5, 27.1, 27.8, 28.4 and 29.1 in X-ray powder diffraction expressed by 2[theta] by utilization of Cu-K[alpha] radiation. The crystal form A of the 5-methyl-(6S)-tetrahydrofolic acid is good in stability, high in purity, good in reproducibility and good in dissolvability. The preparation method is simple and is suitable for industrial production.

Owner:SHANGHAI SYNCORES TECH INC

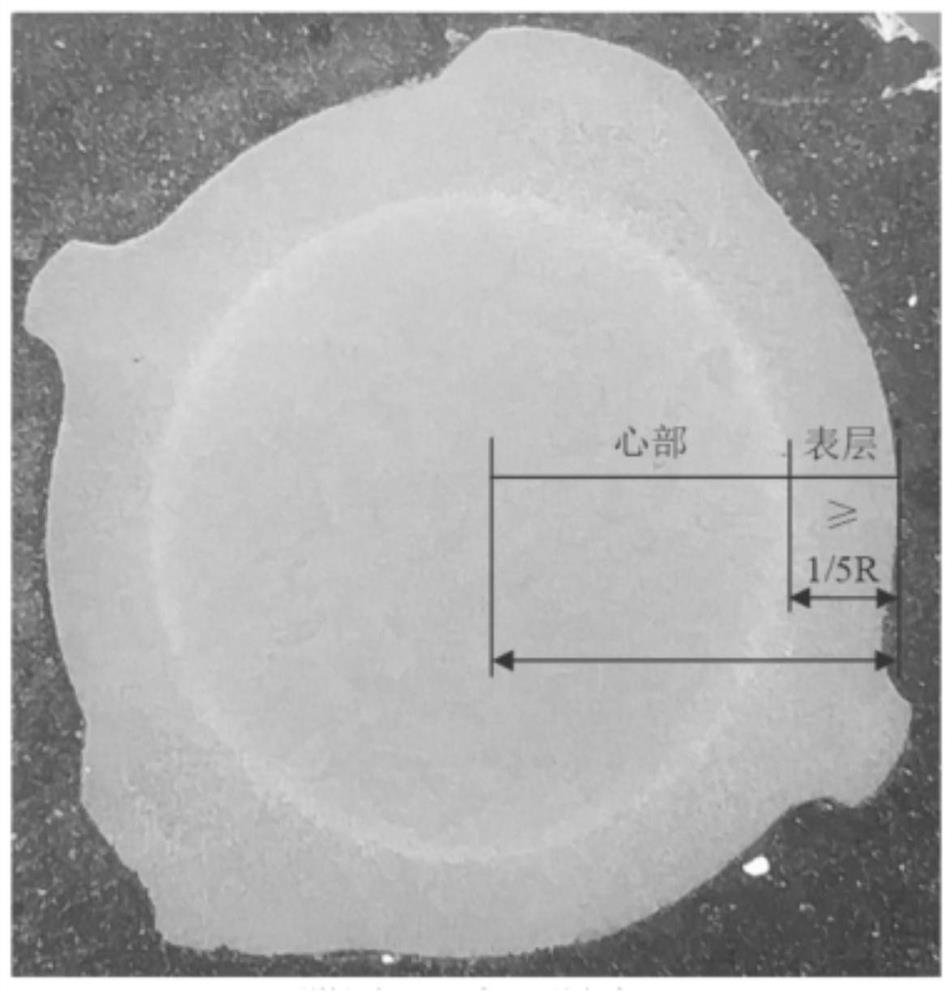

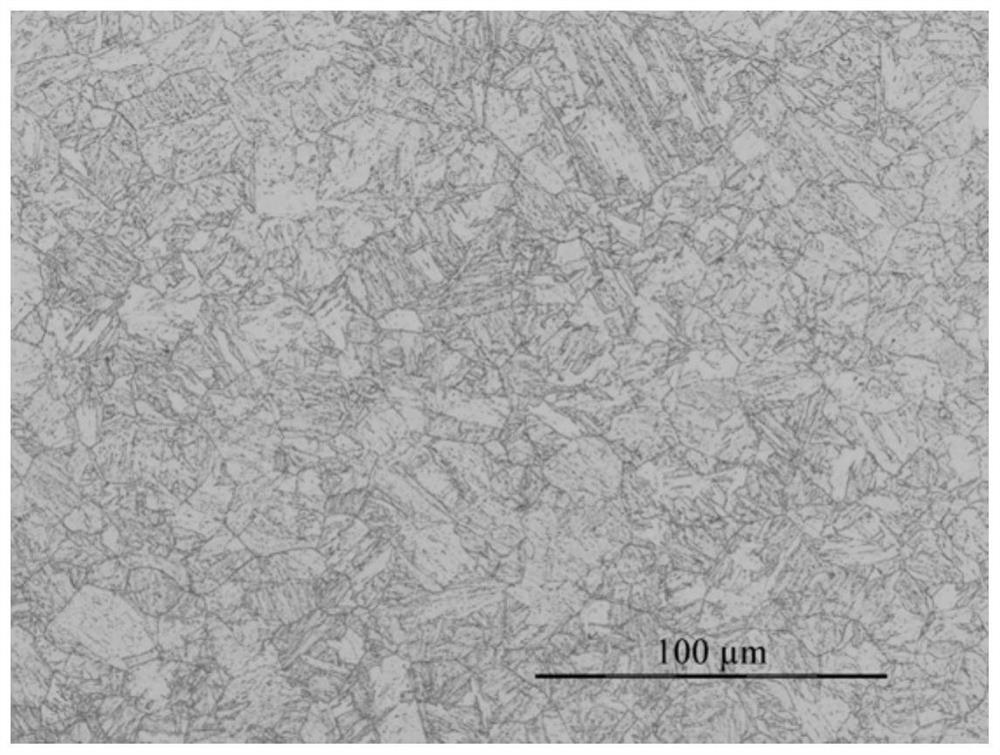

A kind of vanadium microalloying 600mpa grade low temperature steel bar and its production method

ActiveCN110923413BImprove toughnessRealize large-scale industrial productionFurnace typesHeat treatment furnacesSteelmakingRebar

The invention provides a vanadium microalloyed steel for 600MPa grade low-temperature reinforcement and a production method thereof, the components C: 0.04-0.10%, Si: 0.20-0.40%, Mn: 1.30-1.80%, P≤0.008%, S ≤0.008%, Ni: 1.00~2.50%, V: 0.15~0.25%, Als: 0.020~0.040%, [H]≤0.00015%, T.O≤0.0020%, and the rest are Fe and unavoidable impurity elements. Compared with the prior art, the present invention adopts vanadium microalloying, electric furnace steelmaking, LF furnace refining, RH vacuum degassing, full protection casting, bar mill on-line quenching self-tempering process, and the surface layer of the produced steel bar is tempered wire The core is granular bainite, and the depth of tempered sorbite on the surface is ≥ 1 / 5 of the radius. This multiphase structure makes the steel bar have good strength and toughness.

Owner:MAANSHAN IRON & STEEL CO LTD

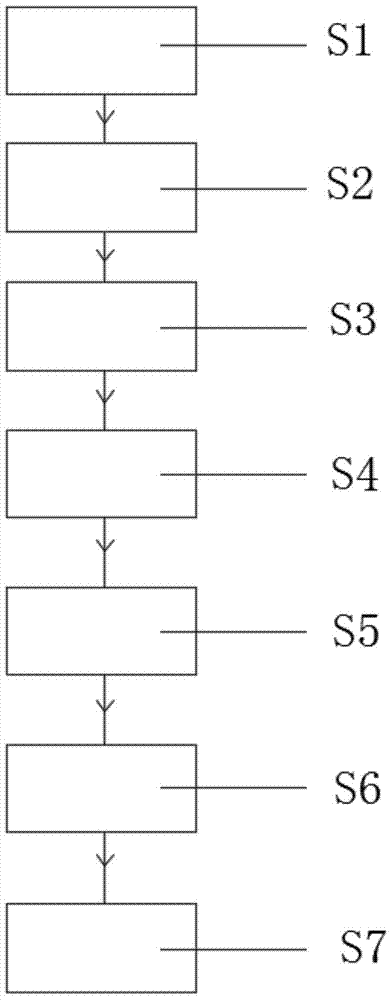

A kind of method of making sponge titanium and zirconium electrodes by explosion

The invention relates to a method for manufacturing a sponge titanium and zirconium electrode through an explosion. The method for manufacturing the sponge titanium and zirconium electrode through the explosion comprises the following steps of S1, material mixing, S2, mold assembly, S3, charging, S4, mold combination, S5, laying of explosives, S6, explosion and pressurization, and S7, material taking. According to the method for manufacturing the sponge titanium and zirconium electrode through the explosion, the electrode is formed at a time through the explosion, the procedures of pressing and assembly-welding of electrode blocks are omitted, and the electrode production efficiency is improved.

Owner:南京宝泰特种材料股份有限公司

A kind of iron-copper based powder metallurgy anti-friction material and preparation method thereof

ActiveCN104384503BImprove wear resistanceReduce coefficient of frictionCarbon monofluorideMechanical property

The invention discloses a ferrum- and copper-based powder metallurgy antifriction material and a preparation method thereof. The material is prepared from the following raw materials in part by weight: 72 to 75 parts of mixed powder, 5 to 8 parts of alumina powder, 3 to 7 parts of zinc oxide, 2 to 5 parts of barium oxide, 4 to 8 parts of carbon monofluoride, 4 to 8 parts of micronized wax, 3 to 7 parts of nickel oxide powder, 10 to 14 parts of tin powder, 2 to 5 parts of zirconium dioxide powder and 3 to 6 parts of carborundum powder. The preparation method comprises the following steps of mixing, pressing, sintering, shaping and impregnating oil. The antifriction material is excellent in wear-resisting property, low in friction coefficient, low in running noise, high in mechanical property, large in bearable load, wide in application range and low in price, and meets the requirement on environment friendliness as components do not contain harmful lead; moreover, the preparation process is simple, parameters are easy to control, the production process is safe and environment-friendly, and the antifriction material is suitable for large-scale industrial production.

Owner:仪征市瑞福投资发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com