Method for producing L-4-hydroxyisoleucine by microbial enzyme conversion method

A technology of hydroxyisoleucine and microbial enzymes, applied in the field of microbial enzyme conversion to produce L-4-hydroxyisoleucine, can solve the problem that the production of L-4-hydroxyisoleucine cannot meet domestic and foreign trade exports Demand, large demand for raw materials, difficulty in separation and purification, etc., to achieve the effect of reducing the specific growth rate of bacteria, facilitating protein expression, and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

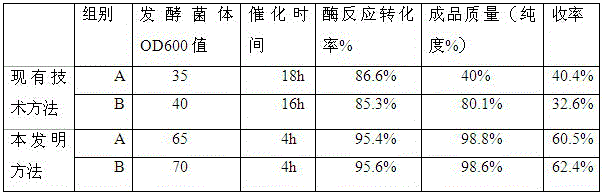

Image

Examples

Embodiment 1

[0039] A method for producing L-4-hydroxyisoleucine by a microbial enzyme conversion method, comprising the following steps:

[0040] (1) Introduce recombinant Escherichia coli bacteria capable of inducing the production of L-4-hydroxyisoleucine into a seed tank equipped with a seed tank culture medium, at a temperature of 36°C, pH 7.0, and dissolved oxygen at 25% Cultivate under the above conditions until the OD600 value of the bacterial solution is 14, that is, a mature Escherichia coli recombinant bacterium capable of inducing the production of L-4-hydroxyisoleucine is obtained;

[0041] In this embodiment, the Escherichia coli recombinant bacteria that can induce the production of L-4-hydroxyisoleucine are obtained through purchase; the construction method is to clone the gene whose gene sequence is shown in SEQNO.1; construct the gene into a plasmid pET28a, to obtain a recombinant plasmid, and then introduce the recombinant plasmid into Escherichia coli BL21 to obtain an ...

Embodiment 2

[0048] A method for producing L-4-hydroxyisoleucine by a microbial enzyme conversion method, comprising the following steps:

[0049] (1) Introduce recombinant Escherichia coli bacteria capable of inducing the production of L-4-hydroxyisoleucine into a seed tank with a seed tank culture medium, at a temperature of 37°C, pH 6.5, and control of dissolved oxygen at 25% Cultivate under the above conditions until the OD600 value of the bacterial solution is 12: obtain a mature Escherichia coli recombinant bacterium that can induce the production of L-4-hydroxyisoleucine;

[0050] Seed tank medium formula: glucose 20g / L, yeast powder 10g / L, peptone 5g / L, ammonium sulfate 2g / L, potassium dihydrogen phosphate 2g / L, magnesium sulfate 1g / L, VB110mg / L, VH0.5mg / L L, ferrous sulfate 20mg / L, manganese sulfate 20mg / L, defoamer 0.4ml / L, and the rest is water.

[0051] (2) Put the mature strains into the fermenter, and cultivate them under the following conditions: ferment through liquid deep...

Embodiment 3

[0056] A method for producing L-4-hydroxyisoleucine by a microbial enzyme conversion method, comprising the following steps:

[0057] (1) Introduce recombinant Escherichia coli bacteria capable of inducing the production of L-4-hydroxyisoleucine into a seed tank equipped with a seed tank culture medium, at a temperature of 36°C, pH 6.8, and control of dissolved oxygen at 25% Cultivate under the above conditions until the OD600 value of the bacterial solution is 13: obtain a mature Escherichia coli recombinant bacterium that can induce the production of L-4-hydroxyisoleucine;

[0058] Seed tank medium formula: glucose 10g / L, yeast powder 8g / L, peptone 3g / L, ammonium sulfate 4g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate 2g / L, VB115mg / L, VH5mg / L, Ferrous sulfate 30mg / L, manganese sulfate 30mg / L, defoamer 0.4ml / L, and the rest is water.

[0059] (2) Put the mature strains into the fermenter, and cultivate them under the following conditions: ferment through liquid de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com