Improved preparation method of large single crystal layered positive electrode material for lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of low volume energy density and achieve high phase purity, improved structural order, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method comprises the following steps:

[0032] The first step: preparing a Co-Mn precursor according to the molar ratio of the transition metal element shown in the general formula of the large single crystal layered positive electrode material;

[0033] There are many methods for preparing Co-Mn precursors in the prior art. From the perspective of synthesis effect, the present invention adopts the co-precipitation method to synthesize Co-Mn precursors. The types of the precursors include [Co 1-x mn x ](OH) 2 、[Co 1-x mn x ]CO 3 、[Co 1-x mn x ]C 2 o 4 or [Co 1-x mn x ]O y , can be prepared by conventional methods in the prior art, for example, by one or more of hydroxide, carbonate or oxalate co-precipitation methods.

[0034] The second step: Mix the Co-Mn precursor obtained in the above step with the lithium source evenly, wherein the molar ratio of lithium element to transition metal element is set to 0

Embodiment 1

[0049] Embodiment 1 prepares precursor [Co1 / 2 mn 1 / 2 ](OH) 2

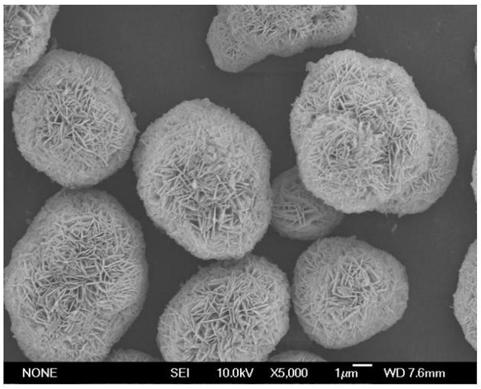

[0050] Weigh 11.246Kg CoSO 4 ·7H 2 O and 6.76Kg MnSO 4 ·H 2 O preparation concentration is 20L of 2M salt solution. Add the above salt solution to 1L h -1 Add it dropwise into the continuously stirring reactor at a speed of 200rpm, and at the same time control the pH value in the kettle at about 11.0 with a mixed solution of 10M NaOH solution and 1M ammonia solution, until the salt solution is completely consumed, centrifuge, wash, and Dry to obtain the precursor [Co 1 / 2 mn 1 / 2 ](OH) 2 ,Such as figure 1 shown.

Embodiment 2

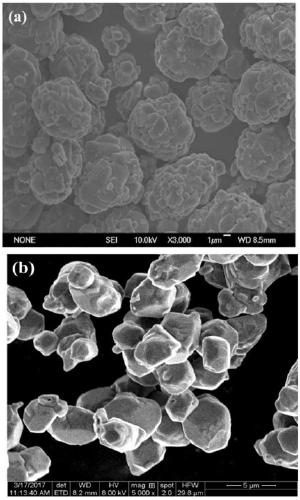

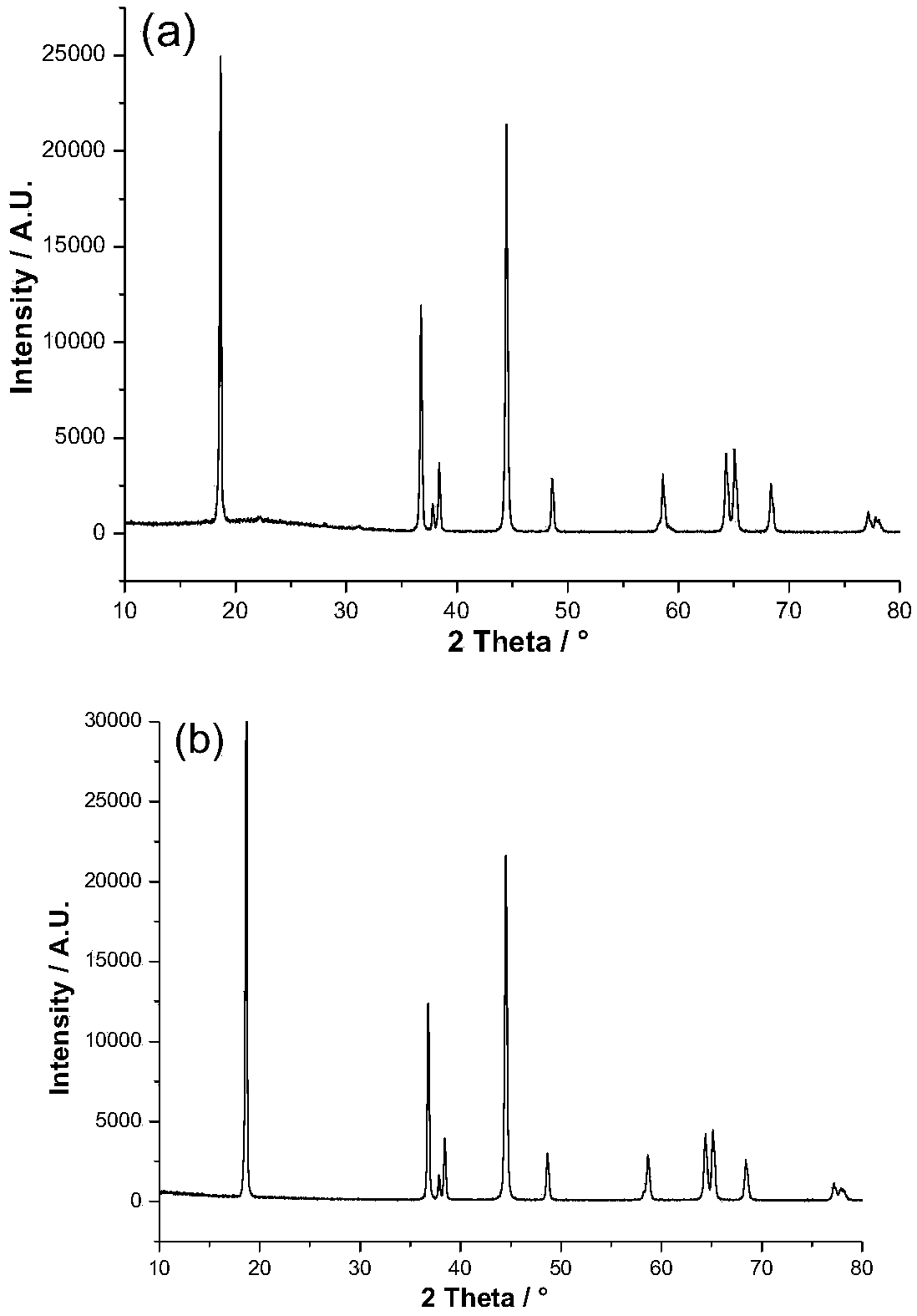

[0052] Take the precursor prepared by 90.94g embodiment 1 [Co 1 / 2 mn 1 / 2 ](OH) 2 with 18.47g battery-grade Li 2 CO 3 (Li / Co-Mn=0.5) was evenly mixed, and the mixture was placed in a muffle furnace and sintered in an air atmosphere at 950°C for 8h. Since the molar ratio Li / Co-Mn4 , since the spinel phase is easier to grow than the layered phase, micron-sized grains are obtained, and 46.35g of nano-sized Ni(OH) is further added to the micron-sized grains 2 and 38.61g battery-grade Li 2 CO 3 , so that Li / Ni-Co-Mn = 1.03, it was placed in a muffle furnace and sintered in an air atmosphere at 900°C for 12 hours to obtain a large single-crystal layered cathode material Li[Ni 1 / 3 co 1 / 3 mn 1 / 3 ]O 2 , its SEM and XRD such as figure 2 (b) and image 3 As shown in (b), the first-cycle charge-discharge curves and cycle stability of the electrodes prepared with large single-crystal layered cathode materials are as follows: Figure 4 shown.

[0053] From figure 2 In (a), it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com