High-efficiency energy-saving cured carbon felt, and preparation method thereof

A high-efficiency, energy-saving, carbon felt technology, used in textiles, papermaking, non-woven fabrics, etc., can solve the problems of environmental operator hazards, high waste liquid treatment costs, uneven carbon felt density, etc. Fast, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

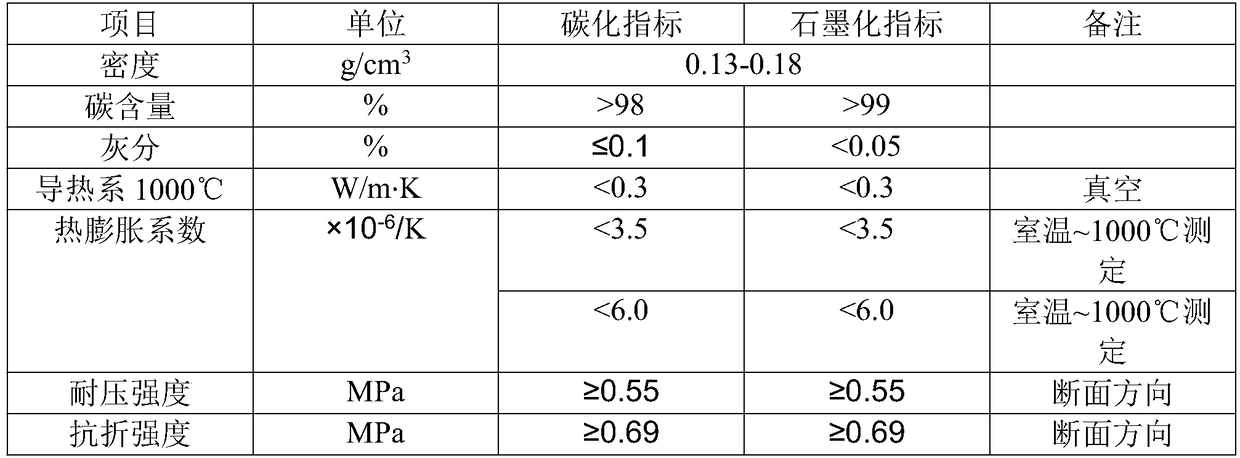

Image

Examples

Embodiment 1

[0023] High-efficiency energy-saving curing carbon felt, which is made from the following raw materials: soft felt 720 grams, ethanol 35 grams, boric acid 75 grams, epoxy resin 65 grams, phenolic resin 180 grams, graphite 30 grams, graphite particle size is 400 mesh, refraction Rate 2.4.

[0024] The preparation method of the above-mentioned high-efficiency energy-saving solidified carbon felt comprises the following steps:

[0025] (1) Cut felt: cut soft felt into required shape and size;

[0026] (2) Glue compounding: mix the above-mentioned soft felt, ethanol, boric acid, epoxy resin, phenolic resin and graphite evenly to make a colloid;

[0027] (3) glue brushing: the colloid described in step (2) is coated on the soft felt surface described in step (1), and coating thickness is 0.5mm;

[0028] (4) Forming: after the glue brushing is completed, air dry and shape naturally;

[0029] (5) High-temperature oven: use a high-temperature oven to fire at 500°C for 13 hours for ...

Embodiment 2

[0035] High-efficiency energy-saving solidified carbon felt, which is made from the following raw materials: 650 grams of soft felt, 32 grams of methanol, 75 grams of boric acid, 210 grams of phenolic resin, and 26 grams of graphite. The graphite particle size is 300 mesh and the refractive index is 2.4.

[0036] The preparation method of the above-mentioned high-efficiency energy-saving solidified carbon felt comprises the following steps:

[0037] (1) Cut felt: cut soft felt into required shape and size;

[0038] (2) Glue compounding: mix the above-mentioned soft felt, methanol, boric acid, phenolic resin, and graphite to make a colloid;

[0039] (3) glue brushing: the colloid described in step (2) is coated on the soft felt surface described in step (1), and coating thickness is 0.5mm;

[0040] (4) Forming: after the glue brushing is completed, air dry and shape naturally;

[0041] (5) High-temperature oven: use a high-temperature oven to fire at 400°C for 11 hours for de...

Embodiment 3

[0047] The invention provides a high-efficiency energy-saving solidified carbon felt, which is made from the following raw materials: 710 grams of soft felt, 30 grams of methanol, 75 grams of boric acid, 210 grams of epoxy resin, and 26 grams of graphite. Rate 2.4.

[0048] The preparation method of the above-mentioned high-efficiency energy-saving solidified carbon felt comprises the following steps:

[0049] (1) Cut felt: cut soft felt into required shape and size;

[0050] (2) Glue compounding: mix the above-mentioned soft felt, methanol, boric acid, epoxy resin and graphite evenly to make a colloid;

[0051] (3) Glue brushing: the colloid described in step (2) is coated on the soft felt surface described in step (1), and the coating thickness is 0.6mm;

[0052] (4) Forming: after the glue brushing is completed, air dry and shape naturally;

[0053] (5) High-temperature oven: use a high-temperature oven to fire at 500°C for 12 hours for degumming and shaping;

[0054] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com