Aluminum nitride powder for aluminum nitride ceramic substrate and preparation method of aluminum nitride powder

A technology of aluminum nitride ceramics and aluminum nitride, which is applied in the field of material science, can solve problems such as difficulty in mixing aluminum nitride powder and sintering aids uniformly, unsatisfactory shock resistance of the substrate, thermal conductivity and compactness, etc. Achieve the effects of inhibiting excessive growth of particles, simple and easy preparation method, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Commercially available superfine alumina powder, carbon black and sintering aid (Y 2 o 3 3.2wt%, LuF 3 2wt%), put it into an ethanol medium ball mill tank, mill it for 10 hours, then dry it at 80°C for 4 hours, and pass it through a 200-mesh sieve to obtain a precursor mixture, then put it into an alumina ark crucible, and put it into a horizontal corundum tube furnace, sintered at 1600°C for 4h, and then put the obtained powder in an alumina crucible, and decarburized it in a box furnace at 700°C for 2h in an air atmosphere. Soak in diphosphoric acid solution for 2h, filter, dry, and sieve. Then press the obtained powder into a graphite grinding tool, set the pressure at 5MPa, lay graphite paper on the contact area between the grinding tool and graphite, coat the surface of the graphite paper with BN release agent, and sinter at 1800°C for 4 hours under a nitrogen atmosphere, and the nitrogen pressure is 9.8Mpa, after the sintering is completed, cool to room tempera...

Embodiment 2-18

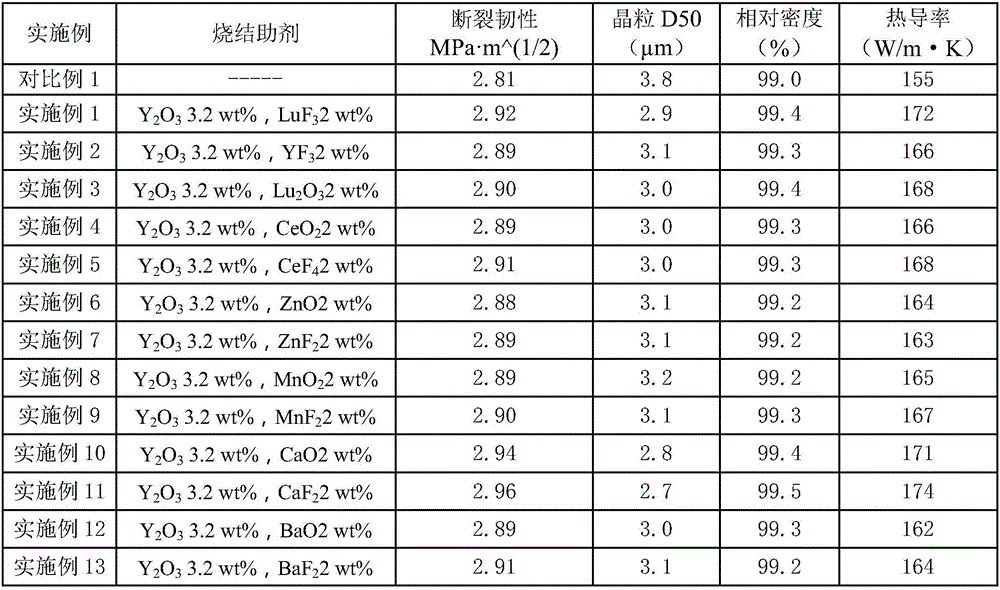

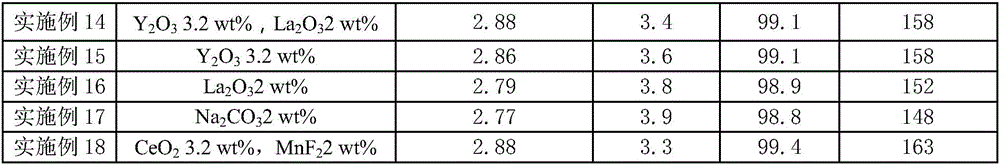

[0031]The type and corresponding amount of sintering aids were changed (see Table 1 for details), and other raw materials and methods were the same as in Example 1. The relevant performance tests were carried out on the final sintered aluminum nitride blank, and the results are shown in Table 1.

[0032] Table 1:

[0033]

[0034]

[0035] It can be seen from Table 1 that the addition of an appropriate amount of the sintering aid provided by the present invention can effectively improve the performance of the aluminum nitride billet sintered by the aluminum nitride powder, and its overall performance is better than that of Comparative Example 1. The sintering aid of the present invention The alkali or carbonate compounds in the compound will be converted into the corresponding oxides at high temperature, so it can have the same effect; the present invention optimizes the composition of the trace elements required for the synthesis of aluminum nitride substrates, and the i...

Embodiment 19-28

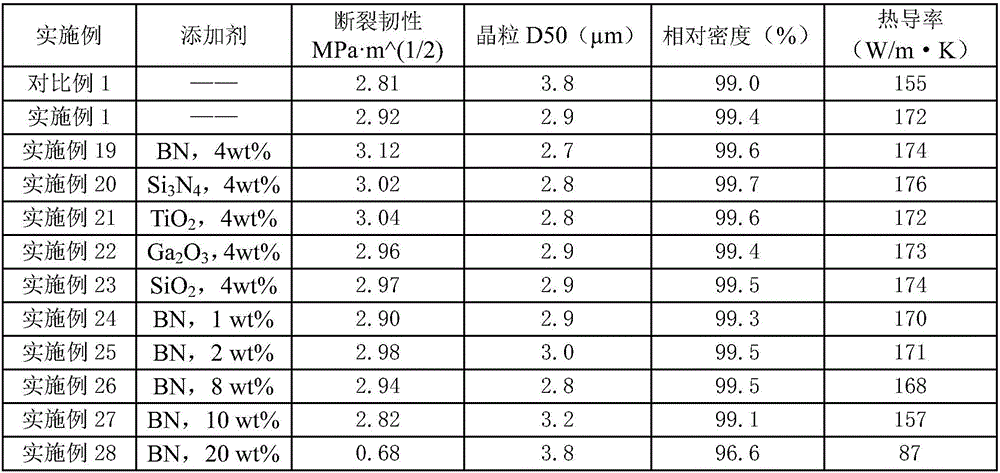

[0038] When preparing the precursor mixture, different types and amounts of additives were added (see Table 2 for details), and other raw materials and methods were the same as in Example 1. The relevant performance tests were carried out on the final sintered aluminum nitride billets, and the results are shown in Table 2.

[0039] Table 2:

[0040]

[0041] It can be seen from Table 2 that the proper use of additives makes the performance of the prepared aluminum nitride billet better, and the covalent bond of Al and other multi-covalent bond elements form a complex combination, which reduces the aluminum nitride grains and grains. The voids between them improve the compactness of the corresponding aluminum nitride billet, thereby improving its fracture toughness. Among them, BN, Si 3 N 4 、TiO 2 The effect of using is the most prominent. In addition, the effect of using too little additive is not obvious compared with no addition, while too much addition will change th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com