Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Maintain flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

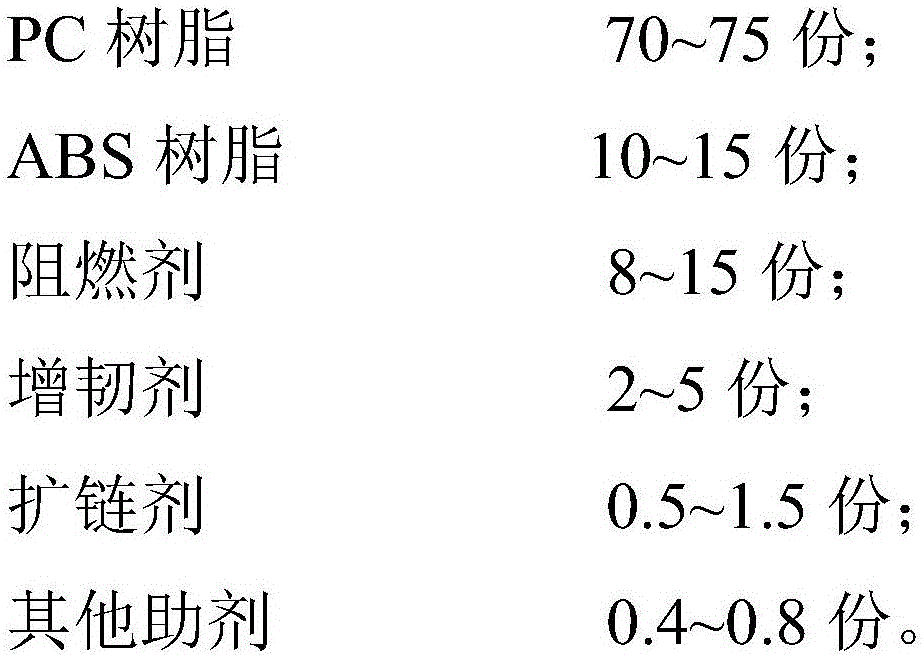

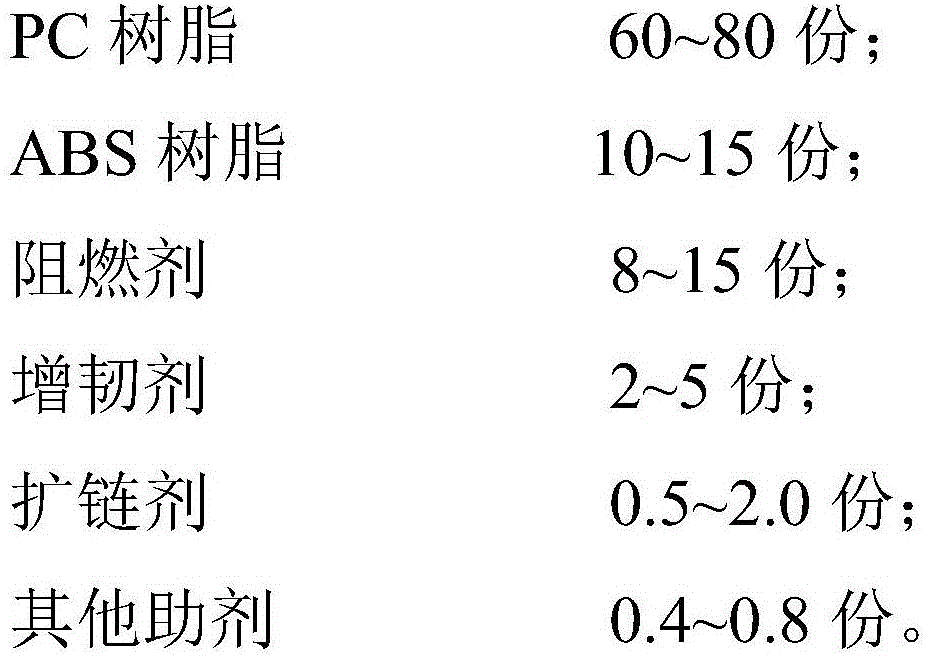

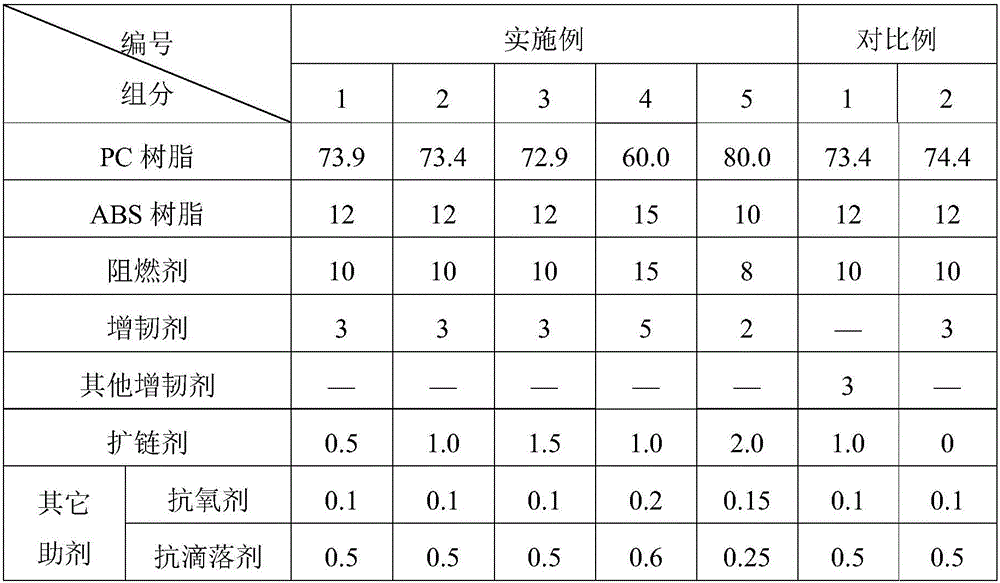

Flame-retardant PC/ABS composite material with high hydrolysis resistance and preparation method thereof

InactiveCN106317821AReduce hydrolysisRetention of mechanical properties and flame retardant propertiesEpoxideFire retardant

The invention discloses a flame-retardant PC / ABS composite material with high hydrolysis resistance and a preparation method thereof. The composite material comprises PC resin, ABS resin, a fire retardant, a flexibilizer, a chain extender and other auxiliaries. According to the composite material, the flexibilizer with specific number-average particle size and specific molecular structure and the chain extender with high epoxide equivalent are selected, the hydrolysis resistance of the flame-retardant PC / ABS composite material can be improved by optimizing the raw materials, and the flame-retardant PC / ABS composite material can have relatively ideal flame retardance and mechanical property after being subjected to long-time high temperature and high humidity treatment and is particularly suitable for the occasions with relatively high requirements for the use environments.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

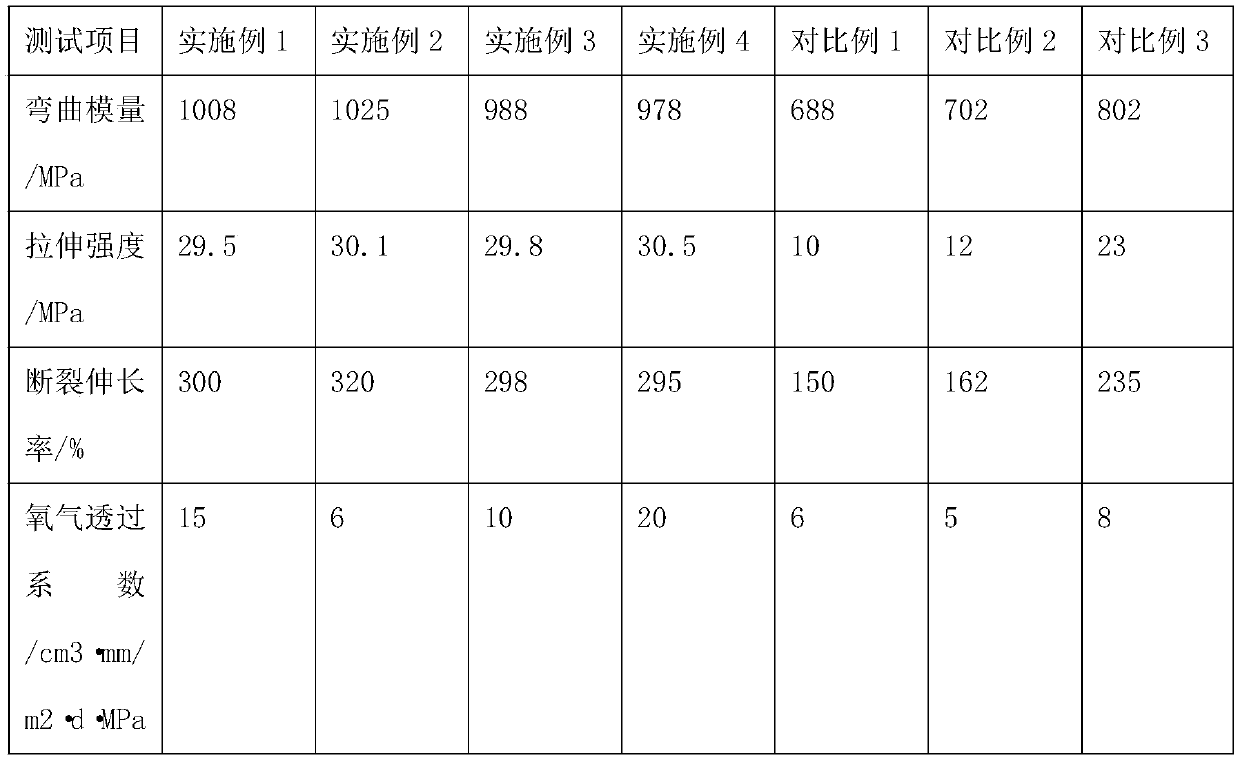

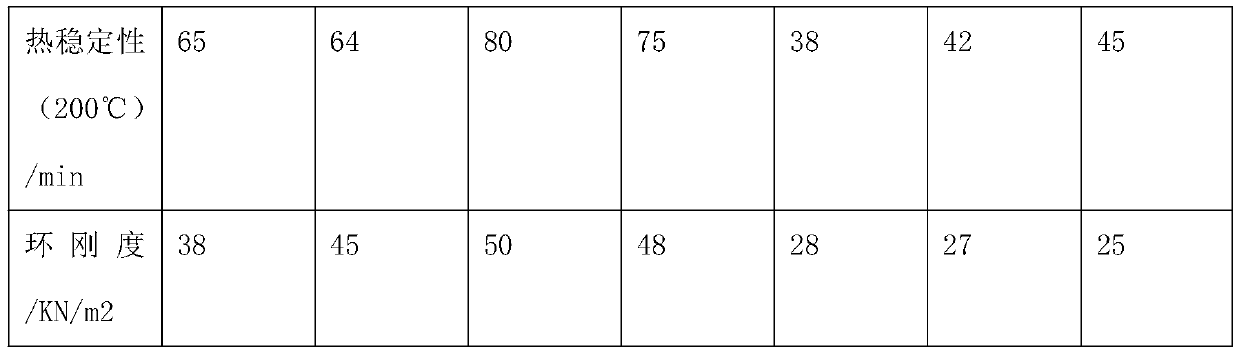

Oil-proof anti-static polyvinyl chloride pipe

The invention discloses an oil-proof anti-static polyvinyl chloride pipe. The polyvinyl chloride pipe comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 10-30 parts of chloride polyethylene, 1-10 parts of ethylene-propylene-diene monomer, 1-3.5 parts of zinc oxide modified graphene oxide, 2-10 parts of zinc borate, 3-10 parts of aluminium hydroxide, 2-5 parts of coupling agent modified diatomite, 0.5-1.5 parts of antimony pent(iso-octyl thioglycollate), 1-2.5 parts of N-isopropyl-N'-phenyl p-phenylenediamine, 1-3 parts of calcium stearate, 1-2.5 parts of lanthanum stearate, 1-5 parts of epoxy soybean oil, 5-10 parts of polyethylene wax, 5-15 parts of poly-4-methyl-1-pentene, 0.5-2 parts of trioctyl trimellitate, and 1-5 parts of 2,4-bis(1,1-dimethylethyl)-pheno phosphite. The oil-proof anti-static polyvinyl chloride pipe disclosed by the invention has excellent oil resistance and static resistance, and is low in cost and good in processing property.

Owner:ANHUI LANTONG TECH CO LTD

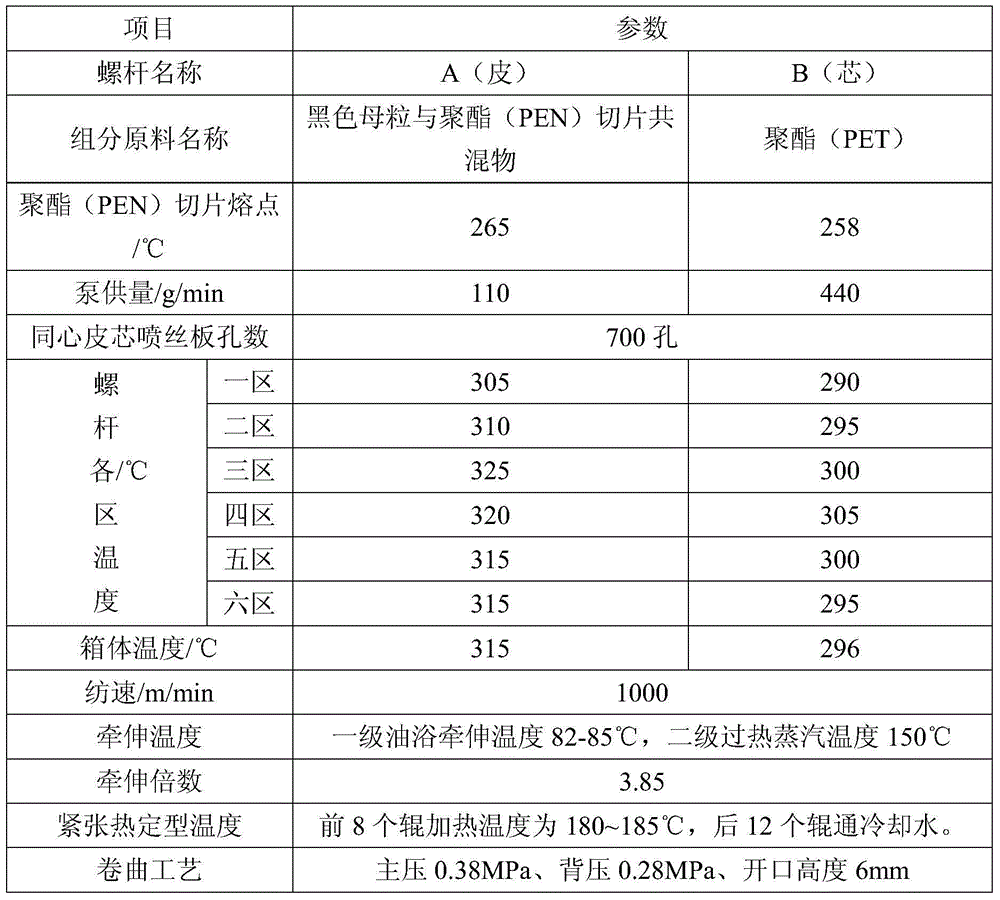

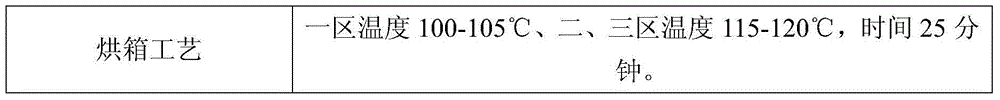

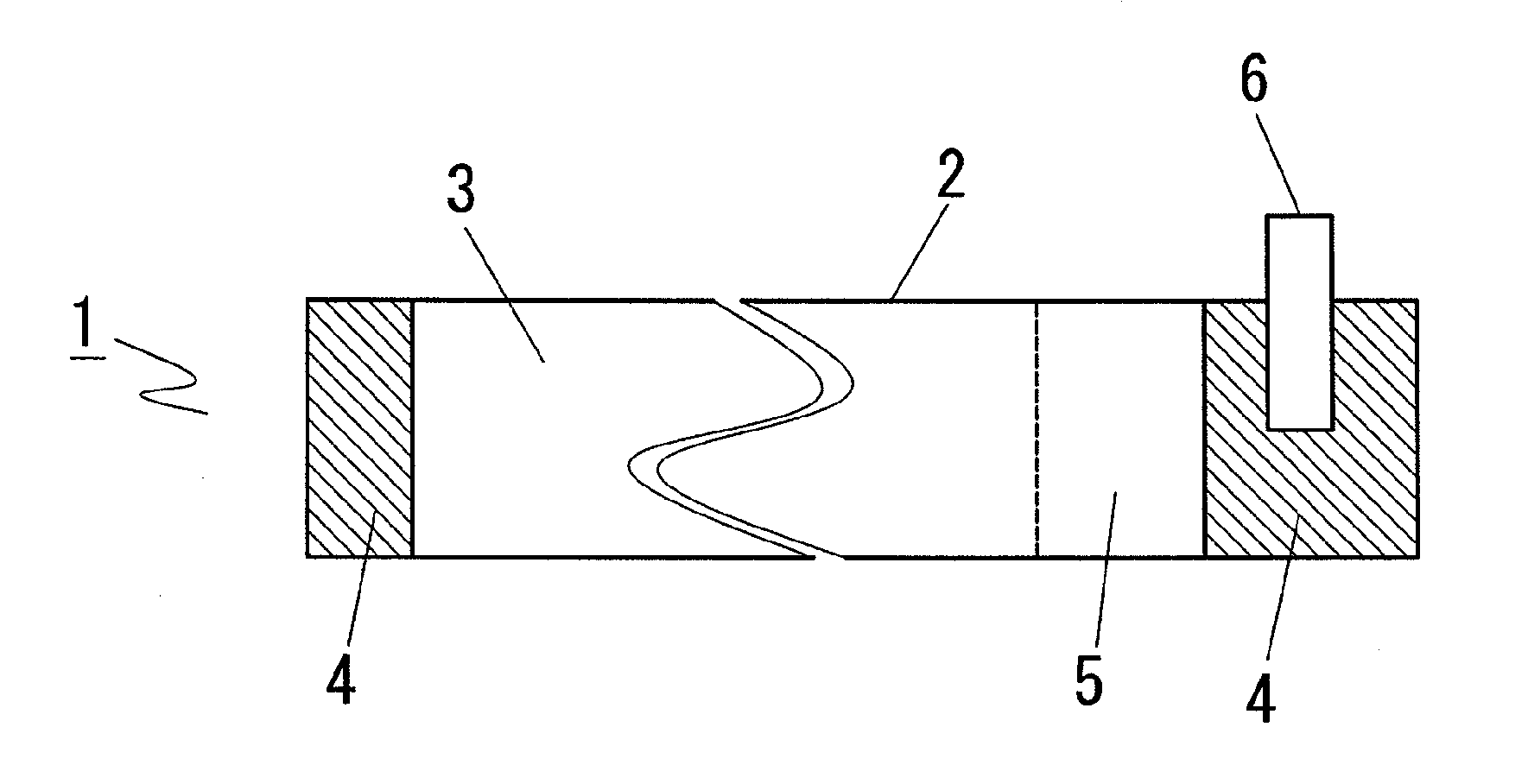

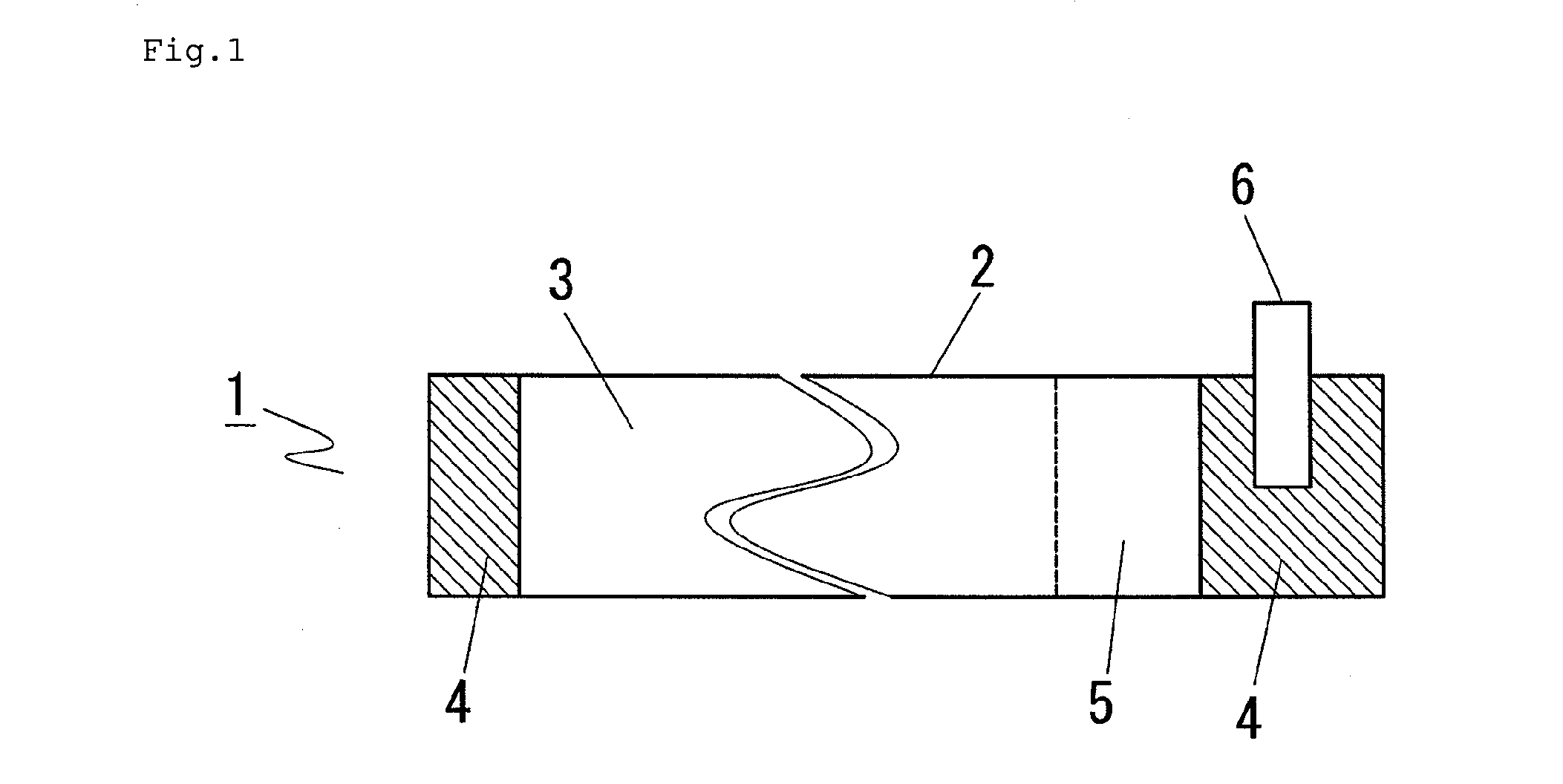

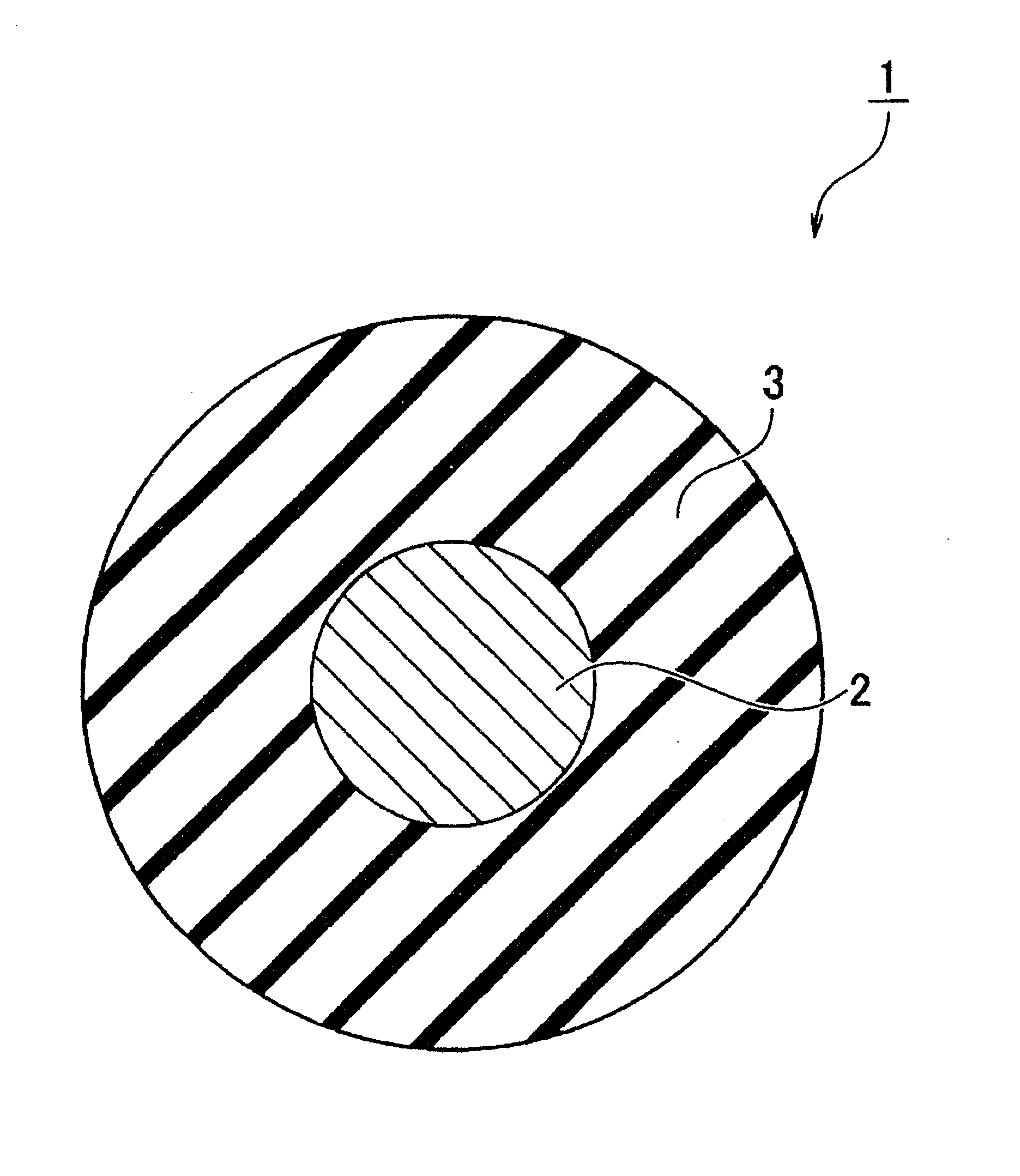

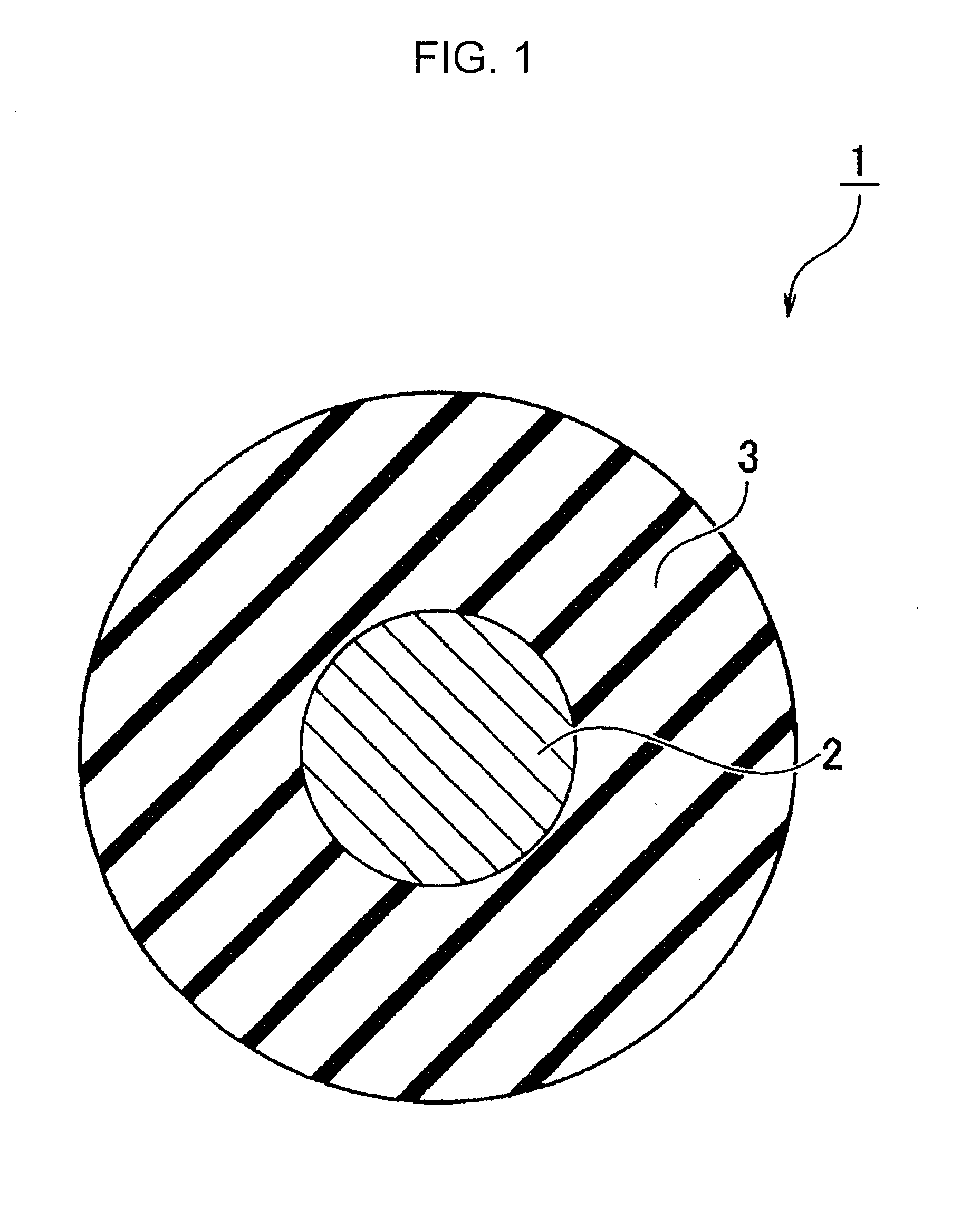

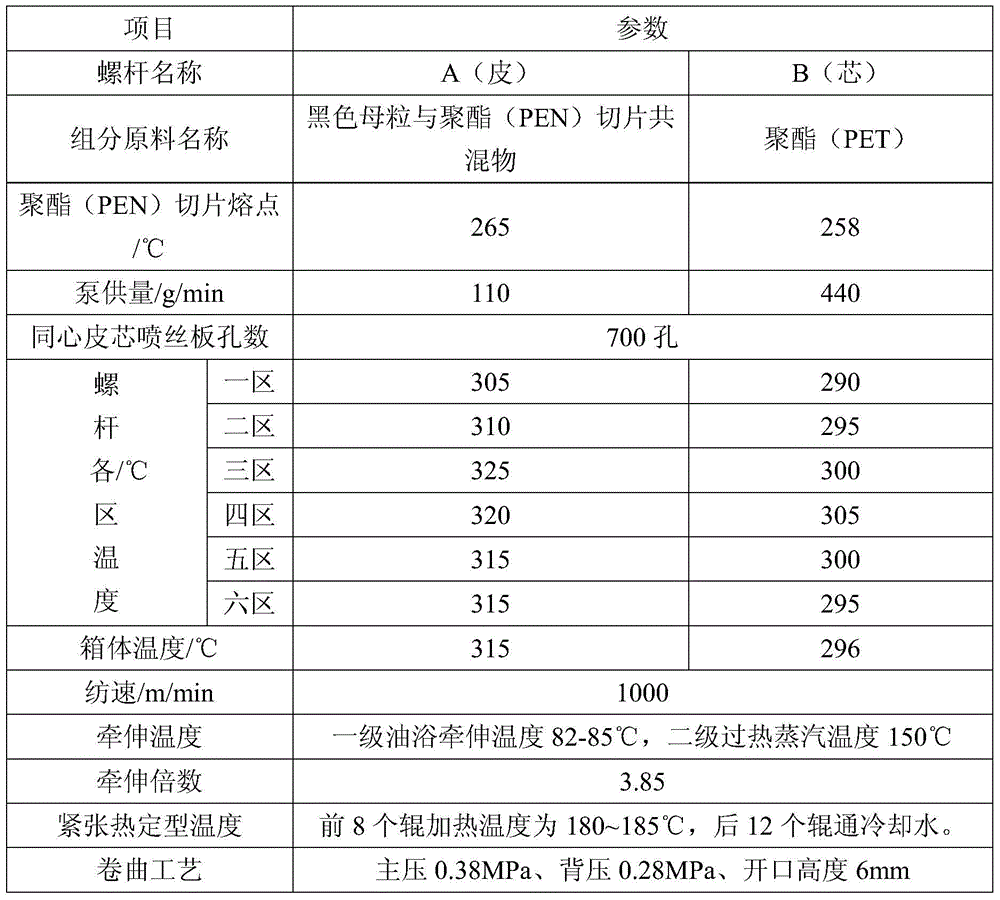

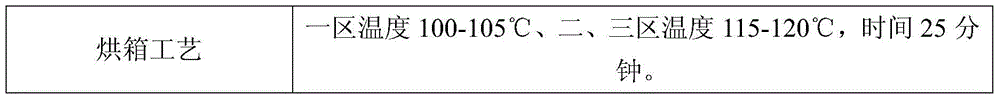

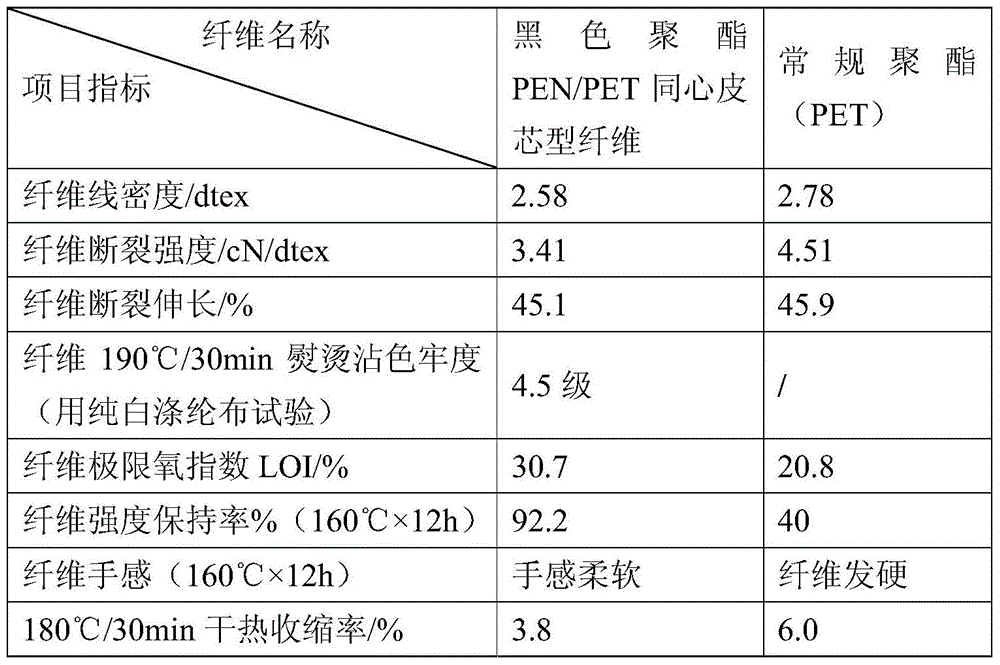

Colored polyester concentric sheath-core composite fiber and manufacturing method thereof

ActiveCN104532399AGuaranteed chemical stabilityMaintain gas barrier propertiesMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention provides a colored PEN / PET concentric sheath-core composite fiber. The sheath layer comprises a colored master batch and PEN, wherein the weight ratio of the colored master batch to the PEN is 5-15:95-85, and the colored master batch comprises colored powder and PEN, and the weight ratio of the colored powder to the PEN is 25-35:75-65. The core layer comprises PET. The weight ratio of the sheath layer components to the core layer component is 15-25:85-75. The defect that PEN fiber forming and dyeing are difficult is overcome, and the fiber keeps the unique chemical stability, gas barrier property, flame retardance, heat resistance and the like of the PEN fiber. The PET economical efficiency and favorable PEN fiber properties are organically combined, the PEN using cost is greatly reduced, the application range of the PEN in the fiber field is enlarged, and meanwhile the application range of the PET fiber in the industrial field can be broadened further.

Owner:SHANGHAI DEFULUN CHEM FIBER

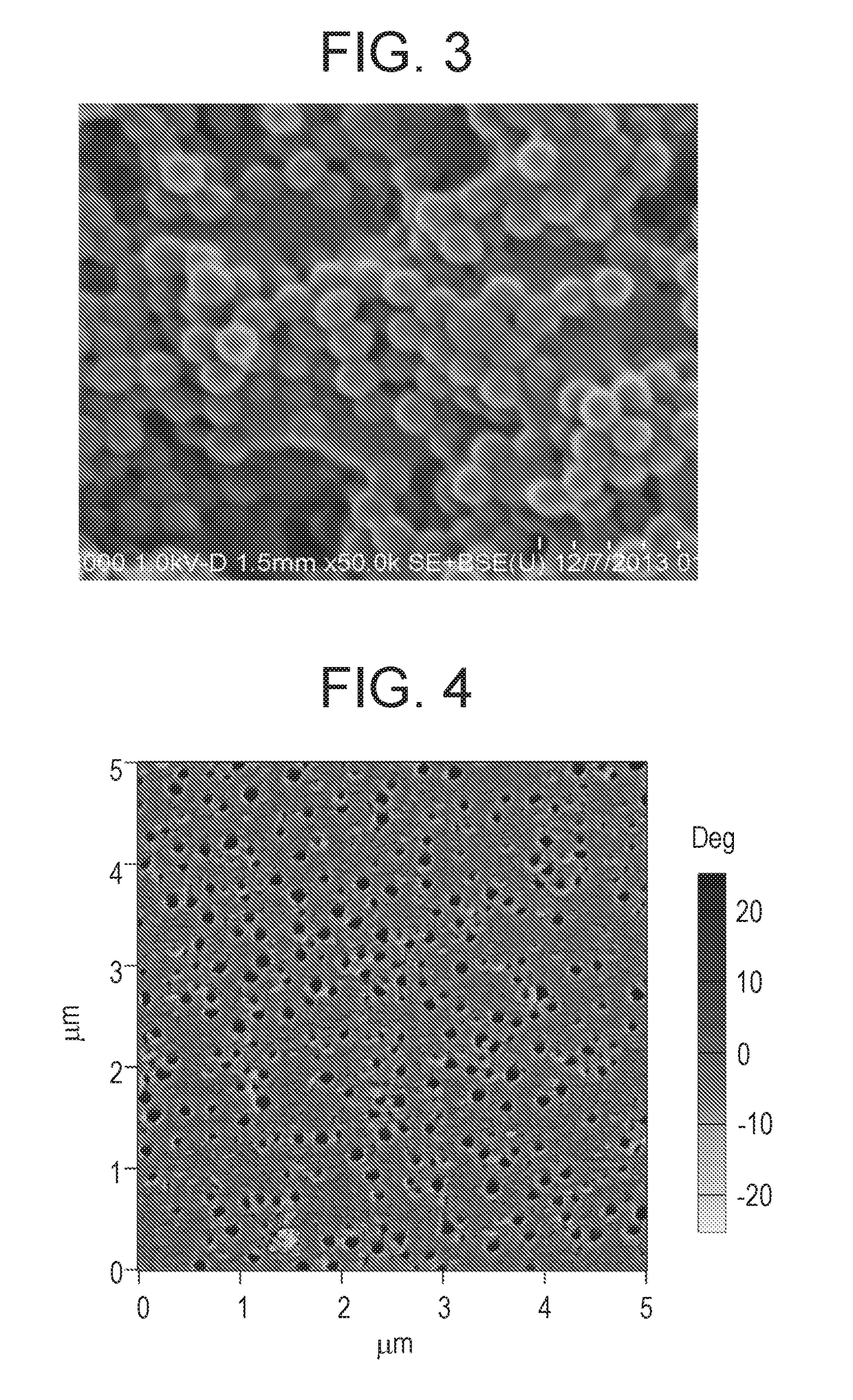

Lithium ion battery

InactiveUS20120315546A1Suppress reduction/decomposition activityFacilitate intercalationCell electrodesNon-aqueous electrolyte cellsAluminium-ion batteryDecomposition

To provide high energy density, good cycle properties and rate characteristics and long-term safety of a lithium ion battery containing at least an ionic liquid and a lithium salt. The above problems are solved by suppressing reduction and decomposition of the ionic liquid on an anode by using a graphite coated with an amorphous carbon or onto which an amorphous carbon is deposited as an anode active material.

Owner:TOKIN CORP

Aging-resistant PPO (Polyphenylene Oxide) - PPS (Polyphenylene Sulfite) plastic alloy

The invention discloses an aging-resistant PPO-PPS plastic alloy, which is composed of the following components in weight part: 100 parts of PPO, 40-60 parts of PPS, 4-8 parts of compatibilizer and 0.5-1.5 parts of age resister. The aging-resistant PPO-PPS plastic alloy disclosed by the invention is an alloy material with excellent overall performances, mostly retains the advantages of PPS in respects of mechanical property, thermal tolerance, flame retardance and the like, and integrates excellent electrical performances of PPO. The aging-resistant PPO-PPS plastic alloy is suitable for fields of electric appliances such as thermotolerant breaker frameworks and electric appliance connectors.

Owner:浙江丞达新材料科技有限公司

Flame retardant polypropylene resin composition

InactiveUS7067576B2Improve flame retardant performanceGood weather resistancePlastic/resin/waxes insulatorsSpecial tyresPolypropyleneMechanical property

The present invention provides a polypropylene resin composition including a polypropylene resin having a melt flow rate of 4-18 g / 10 minutes, a flame retardant additive having a low melting point, an antimony oxide, a UV stabilizer, a silane coupling agent, and titanium dioxide as a light-blocking agent. The resin composition of the invention produces products exhibiting excellent flame retarding properties, stability against weather, and maintainability of physical / mechanical properties as shown by maintaining the original flame retarding properties after long periods of outdoor exposure and hydrothermal dipping treatments.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

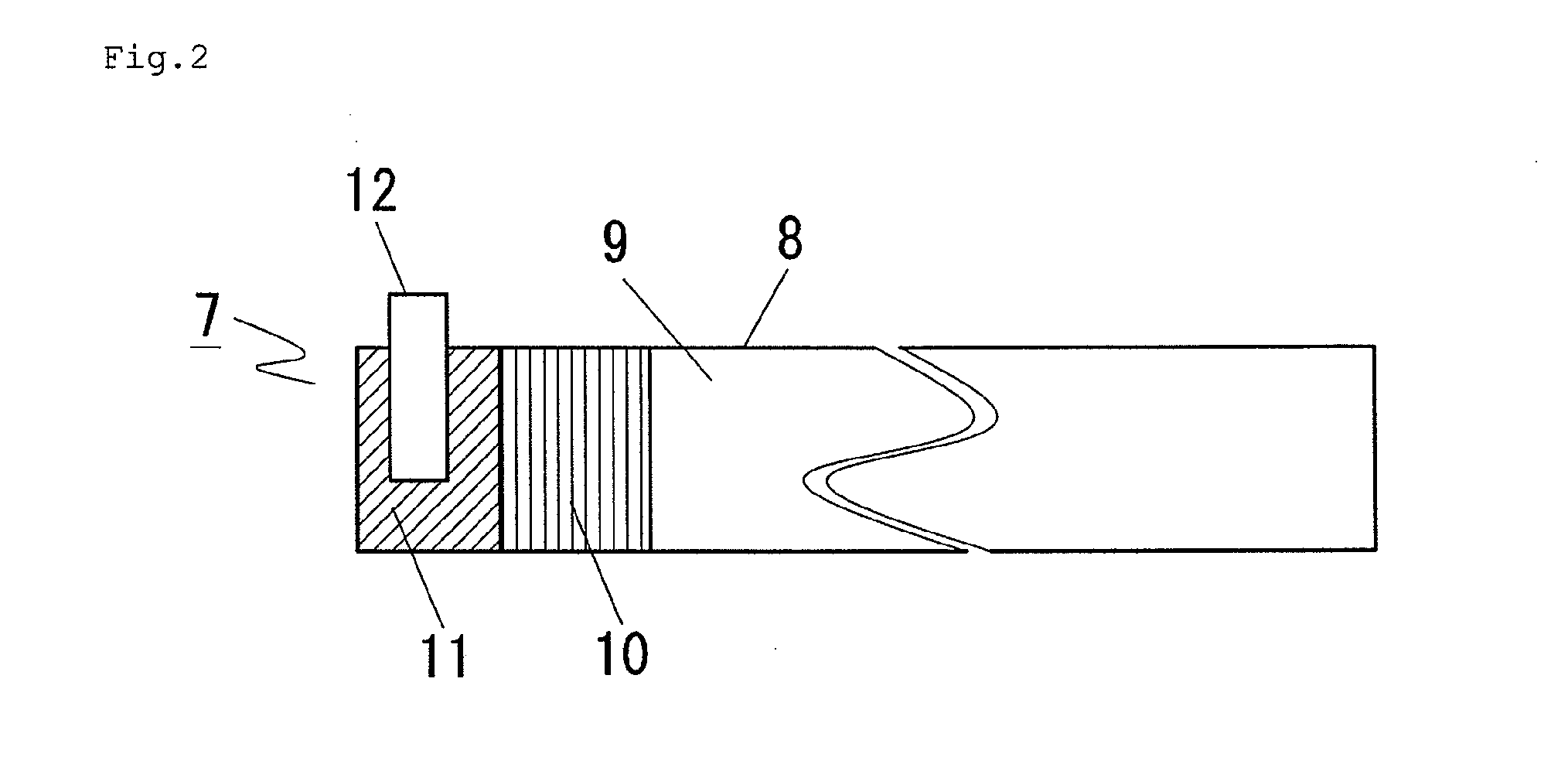

Insulated electric wire for automobile

ActiveUS20120279753A1Reduce amountImproving ASR recycling ratePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorBromine

The present invention relates to an insulated electric wire for an automobile containing a conductor and an insulating coating layer which coats the conductor, the insulating coating layer being formed of a non-crosslinkable resin composition containing 65 to 90 parts by weight of a polypropylene-based resin, 10 to 40 parts by weight of a metal hydrate, 20 to 50 parts by weight of a bromine-based flame retardant, 5 to 30 parts by weight of antimony trioxide, and 2 to 15 parts by weight of a maleic acid-modified resin in the ratio and further containing at least one of 3 to 10 parts by weight of a polyethylene resin and 2 to 10 parts by weight of an ethylene-based copolymer.

Owner:YAZAKI CORP

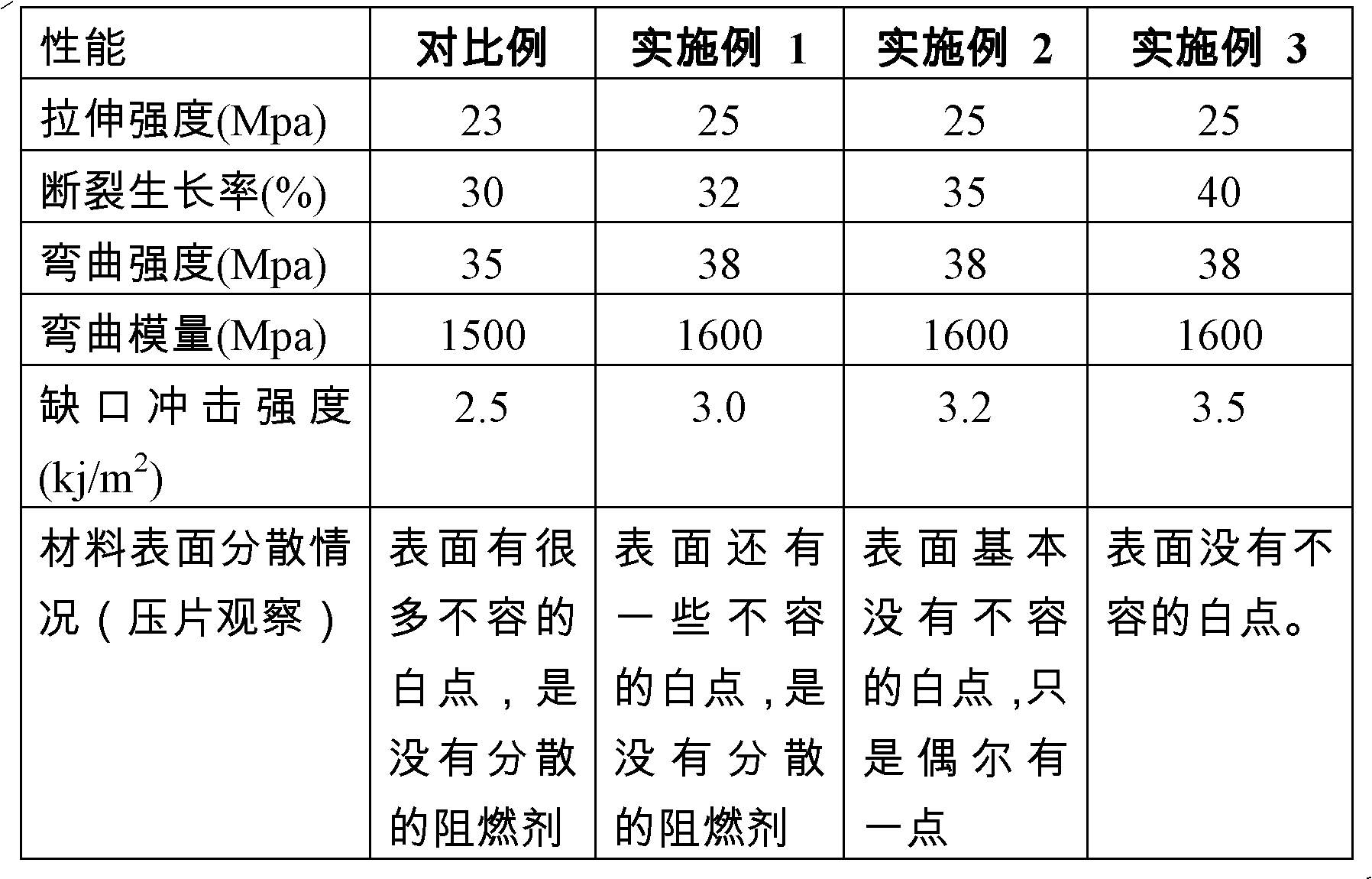

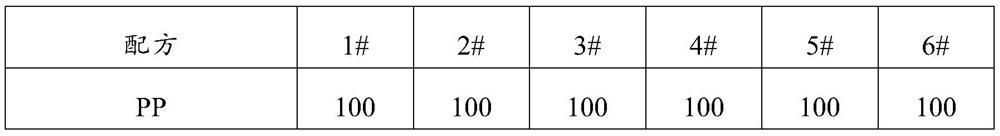

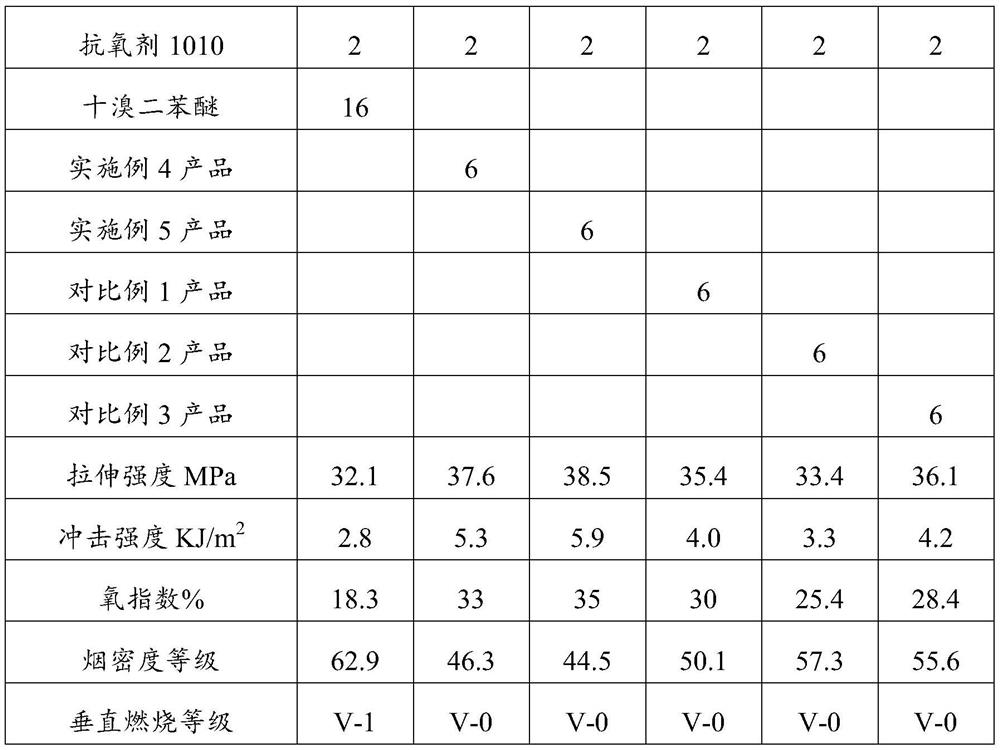

Dispersing method of halogen-free flame retardant polypropylene

The invention discloses a halogen-free flame retardant polypropylene composite which comprises the following components in parts by weight: 50-70 parts of polypropylene, 25-35 parts of halogen-free flame retardant, 1-10 parts of compatilizer and 1-10 parts of at least one dispersing agent selected from dispersing agent I, dispersing agent II and dispersing agent III, wherein the compatilizer is one or more than one polymer grafted with a polar monomer, a substrate of the polymer is one of or the mixture of polyethylene, polypropylene, EVA (ethylene-vinyl acetate) and ethylene-propylene-butadiene terpolymer, and the polar monomer is one or more than one of crylic acid, methacrylic acid and maleic anhydride; the dispersing agent I is ethylene double fatty acid amide and ethylene double fatty acid amide provided with a polar group; the dispersing agent II is high molecular weight alkyl ammonium salt copolymer; and the dispersing agent III is copolymer with an acid group. According to the halogen-free flame retardant polypropylene (PP) material disclosed by the invention, the compatibility of components is greatly improved.

Owner:FSPG HI TECH

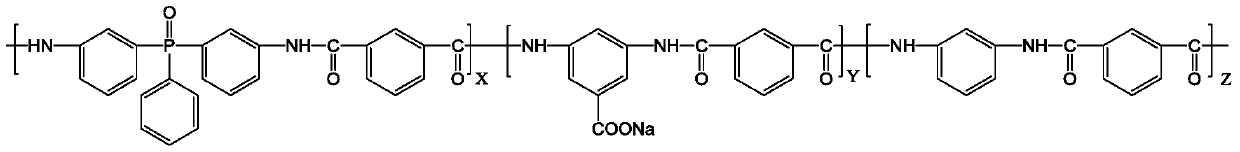

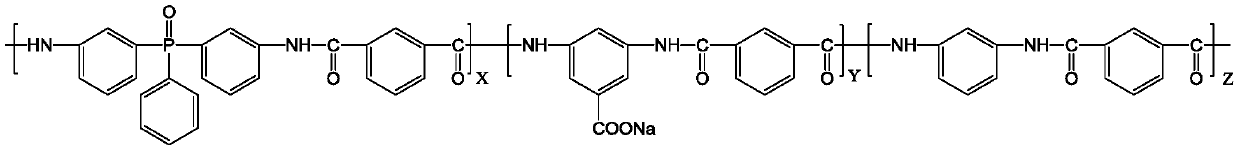

Dyeability modified meta-aramid fibers and preparation method therefor

InactiveCN110527082AIncrease capacityImprove dye uptake and color fastnessMonocomponent copolyamides artificial filamentWet spinning methodsSolubilityOxide

The invention discloses dyeability modified meta-aramid fibers and a preparation method therefor. According to the method, m-phthaloyl chloride, m-phenylenediamine, sodium 3,5-diaminobenzoate and bis(3-aminophenyl)phenylphosphorus oxide serve as monomers, a modified polymetaphenylene isophthamide spinning solution is prepared in an organic solvent by employing low-temperature polycondensation, andprepared fibers have good affinity and excellent flame retardance to cationic dyes; and carboxylic acid group containing 3,5-diaminobenzoic acid monomer is added during preparation and participates in copolymerization, and a carboxylic acid group is an anionic group and can be combined with the cationic dyes by ionic bonds so as to achieve dyeability of the cationic dyes. A spinning dope of the dyeability modified meta-aramid fibers prepared by the method has good solubility and spinnability, and prepared fibers maintain original high-temperature resistance and mechanical properties, have relatively high dye uptake in the cationic dyes and are sharp in color and good in light fastness.

Owner:YANTAI TAYHO ADVANCED MATERIALS

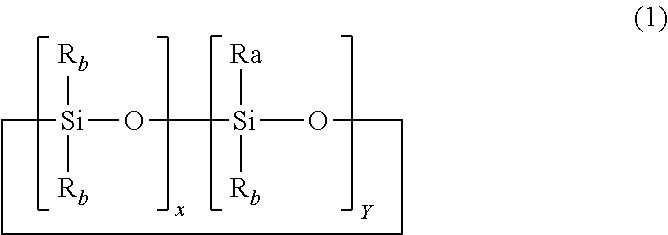

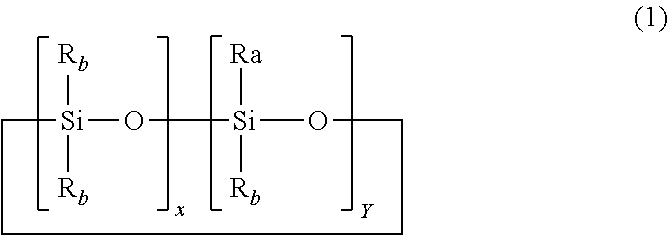

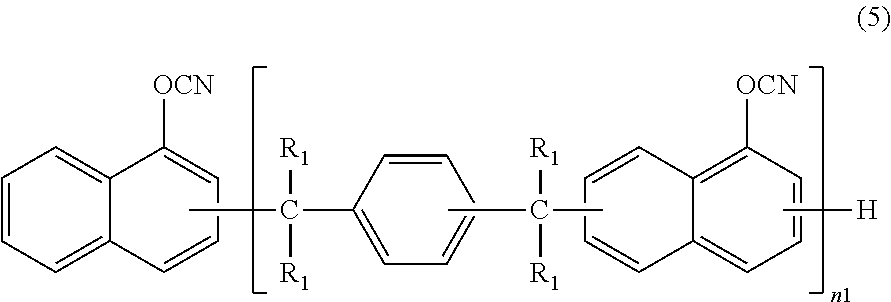

Resin composition, prepreg, laminate, and printed wiring board

ActiveUS9902851B2Improve heat resistanceReduction factorPrinted circuit aspectsSynthetic resin layered productsOrganic groupCyanate compound

A resin composition containing a cyclic epoxy-modified silicone compound (A) represented by formula (1), a cyanic acid ester compound (B) and / or a phenol resin (C) and an inorganic filler (D):wherein Ra each independently represent an organic group having an epoxy group; Rb each independently represent a substituted or unsubstituted monovalent hydrocarbon group; x represents an integer of 0 to 2; and y represents an integer of 1 to 6; and the siloxane unit marked with x and the siloxane unit marked with y are arranged mutually at random.

Owner:MITSUBISHI GAS CHEM CO INC

High impact blends of vinylidene fluoride-containing polymers

The invention relates to blends containing polymers of vinylidene fluoride, having low ductile-brittle transition temperatures and having excellent low temperature impact properties while maintaining the positive aspects of unmodified vinylidene fluoride-containing polymers. The blends of this invention are produced by adding a core-shell impact modifier (CSIM) comprised of a polysiloxane core and a shell compatible with vinylidene fluoride-containing polymer. The blends are further characterized by the presence of a heterogeneous copolymer composition comprised of two or more distinct phases and / or at least one flame and smoke suppressant. The preparation of these new blends can be done by conventional thermoplastic compounding techniques such as twin screw compounding; alternatively, the CSIM can be introduced earlier, such as in the latex. The unique properties of the new blends make them useful in end-use applications where those properties provide performance advantages, such as in wires & cables and in oil and gas applications.

Owner:ARKEMA INC

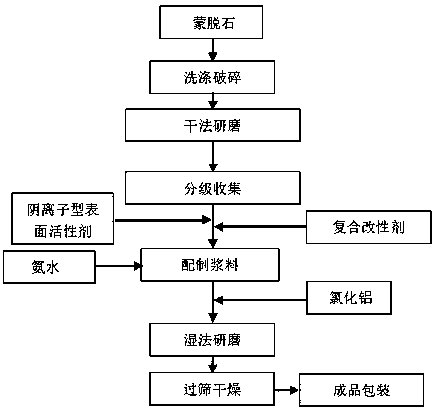

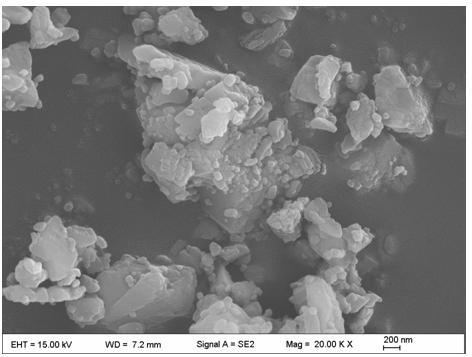

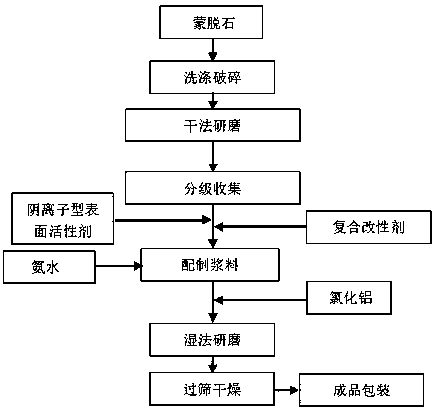

Preparation method of montmorillonite modified nano aluminum hydroxide composite inorganic flame retardant

The invention discloses a preparation method of a montmorillonite modified nano aluminum hydroxide composite inorganic flame retardant. The composite inorganic flame retardant is prepared from anionicmontmorillonite and nano aluminum hydroxide, wherein the equivalent diameter of nano aluminum hydroxide particles is 5-30 nm, and the equivalent diameter of the anionic montmorillonite is 0.5-2 microns. The method comprises the following steps: (1) preparation of the anionic montmorillonite; and (2) preparation of the nano aluminum hydroxide. According to the invention, the flame-retardant effectof aluminum hydroxide is maintained, and meanwhile, flame retardancy, heat resistance, reinforcing performance and gas-heat blocking of montmorillonite are utilized, so that the carbon-forming effectin a combustion process of the high-molecular material is promoted, and flame retardancy of the high-molecular material is better improved. The using amount of aluminum hydroxide is reduced, and meanwhile, the comprehensive mechanical property of the high-molecular material is improved, so that great significance is achieved for development of flame-retardant applications of aluminum hydroxide.

Owner:JIANGXI GUANGYUAN CHEM

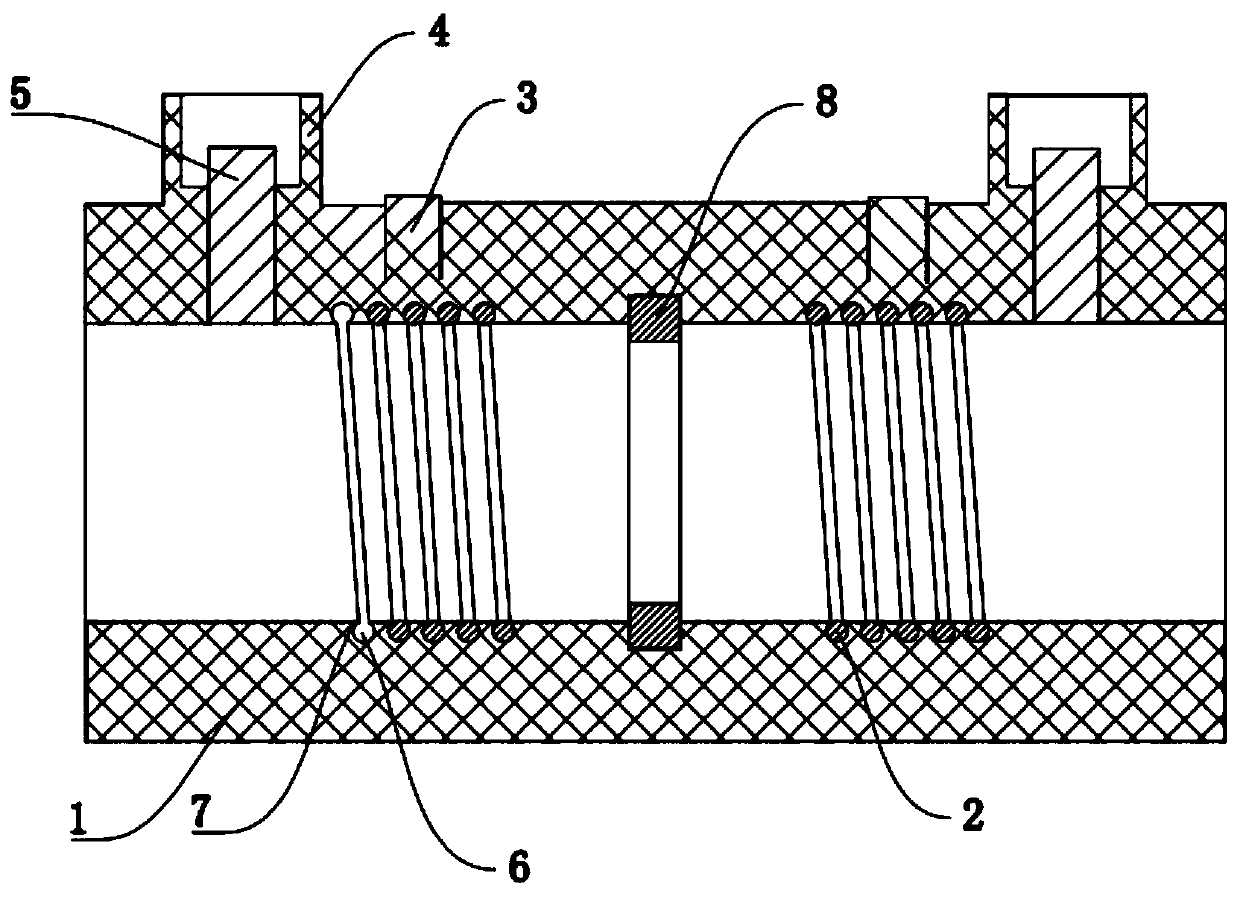

Exposed post-wire distribution type electric welding pipe fitting

InactiveCN110078991AHigh strengthImprove heat resistancePipe connection arrangementsMulliteHigh pressure

An exposed post-wire distribution type electric welding pipe fitting comprises a pipe body, electric heating wires arranged on the inner wall of the pipe body as well as observation holes and terminals which are exposed out of the pipe body and located at two ends of the pipe body, binding posts are arranged in the terminals and connected with the electric heating wires, non-closed wire embeddinggrooves are axially formed in the pipe body, and the electric heating wires are clamped in the wire embedding grooves. The pipe fitting is prepared from raw materials in parts by weight as follows: 90-120 parts of a PE100 grade raw material, 30-45 parts of PE high-pressure reclaimed material, 2-4 parts of an antioxidant, 1.5-3 parts of a dispersant, 5-10 parts of mullite powder, 3-10 parts of glass beads, 10-25 parts of EPDM (ethylene-propylene-diene monomer) rubber, 10-15 parts of modified diatomite, 20-35 parts of a heat stabilizer, 20-30 parts of a heat-resistant modifier, 0.5-1.5 parts ofEVA wax, 4-6 parts of dicumyl peroxide, 0.02-0.2 parts of a crosslinking agent TAIC, 2-3 parts of full-vulcanized superfine powder nitrile rubber, 0.5-1.5 parts of full-vulcanized superfine powder natural rubber, 5-10 parts of a halogen-free flame retardant and 1-5 parts of a colorant.

Owner:NINGBO HENGYUAN PRECISION VALVES TECH

Sericite-based steel structure fireproof coating material

The invention relates to a sericite-based fireproof coating for steel structures. The raw materials include the following main components in parts by mass: 15-25 parts of sericite, 15-30 parts of metal hydroxide, 5-12 parts of ethanol, calcium carbonate 7‑10 parts, 15‑25 parts of talcum powder, 6‑12 parts of silane, 6‑12 parts of siloxane, 5‑8 parts of glass sand, and 5‑8 parts of resin. The present invention uses sericite and metal hydroxide as a composite combination, so that the fire-resistant coating can not only have flame-retardant properties, but also maintain fire-resistant, flame-resistant and flame-retardant capabilities, and can effectively protect surrounding flammable materials.

Owner:江阴市尤乐防火阻燃材料有限公司

Dexsil 300-based fireproof coating

InactiveCN107513329AFlame retardantMaintain flame resistanceFireproof paintsEpoxy resin coatingsFireproofingEther

The invention relates to a fire-retardant coating based on polycarborane methylsiloxane, the raw material of which comprises the following main components in parts by mass: 15-25 parts of bis(2,3-epoxycyclopentyl) ether resin, 15-30 parts of metal hydroxide, 5-12 parts of ethanol, 7-10 parts of calcium carbonate, 15-25 parts of talc, 6-12 parts of polycarborane methylsiloxane, 5-8 parts of glass sand, 5-8 parts of resin. The present invention uses bis(2,3-epoxycyclopentyl) ether resin and metal hydroxide as a composite combination, and then adds polycarborane methyl siloxane, so that the fireproof coating has flame retardant properties and also It can maintain fire resistance such as flame resistance, flame resistance and flame retardancy, and can effectively protect surrounding flammable materials.

Owner:江阴市尤乐防火阻燃材料有限公司

Composite antimony trioxide flame retardant and preparation method thereof

The invention discloses a composite antimony trioxide flame retardant, belonging to the technical field of flame retardants. The omposite antimony trioxide flame retardant disclosed by the invention is prepared from the following raw materials in parts by weight: 40-60 parts of surface-modified antimony trioxide, 10-30 parts of silane modified halloysite nanotubes, 20-30 parts of phosphate amine salt, 2-3 parts of a coupling agent and 3-5 parts of an organic copper salt heat stabilizer, wherein the phosphate amine salt is formed by polymerizing pentaerythritol, phosphorus pentoxide and isobutyramide, and a mass ratio of the pentaerythritol to the phosphorus pentoxide to the isobutyramide is (1.5-2.5): 1: (1.8-3.6). The components of the composite antimony trioxide flame retardant provided by the invention have very good compatibility; and the composite antimony trioxide flame retardant has excellent interface bonding force with a plastic material, is uniformly dispersed, allows a plastic product using the composite antimony trioxide flame retardant to have excellent flame retardance and smoke suppression performance, and improves the mechanical properties of the plastic product.

Owner:HUNAN LOUDI HUAXING ANTIMONY IND

Flame retardant composition, flame retardant fiber and fabric formed using the same, and method for their production

InactiveUS20170283989A1Maintain flame retardancyProvide stretch propertyFireproof paintsMonocomponent polyurethanes artificial filamentYarnFire retardant

A flame retardant composition containing a phosphorous containing ammonium salt, a crosslinker, and water is provided, and its application to yarn or fabric to provide a flame retardant yarn or fabric. In a preferred embodiment, the yarn or fabric is made from a polyurethane elastomer, such as a spandex. A method to prepare the flame retardant composition and apply it to the fiber or yarn is also provided.

Owner:SUPREME CORQ

Cellulose acetate butyrate based fireproof paint for steel structures

The invention relates to a steel structure fireproof coating based on cellulose acetate butyrate, the raw materials of which contain the following main components in parts by mass: 15-25 parts of cellulose acetate butyrate, 15-30 parts of metal hydroxide, 5 parts of ethanol ‑12 parts, 7‑10 parts of calcium carbonate, 15‑25 parts of talcum powder, 6‑12 parts of silane, 6‑12 parts of siloxane, 5‑8 parts of glass sand, and 5‑8 parts of resin. The invention uses cellulose acetate butyrate and metal hydroxide as a composite combination, so that the fireproof coating can not only have flame retardant properties, but also maintain fire resistance, flame resistance and flame retardancy, and can effectively protect surrounding flammable materials.

Owner:江阴市尤乐防火阻燃材料有限公司

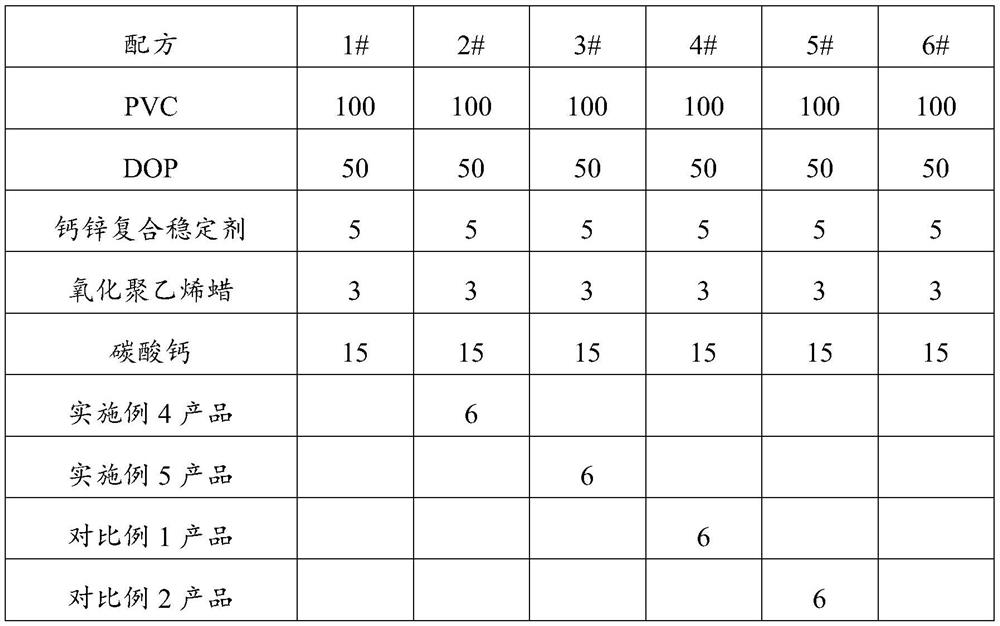

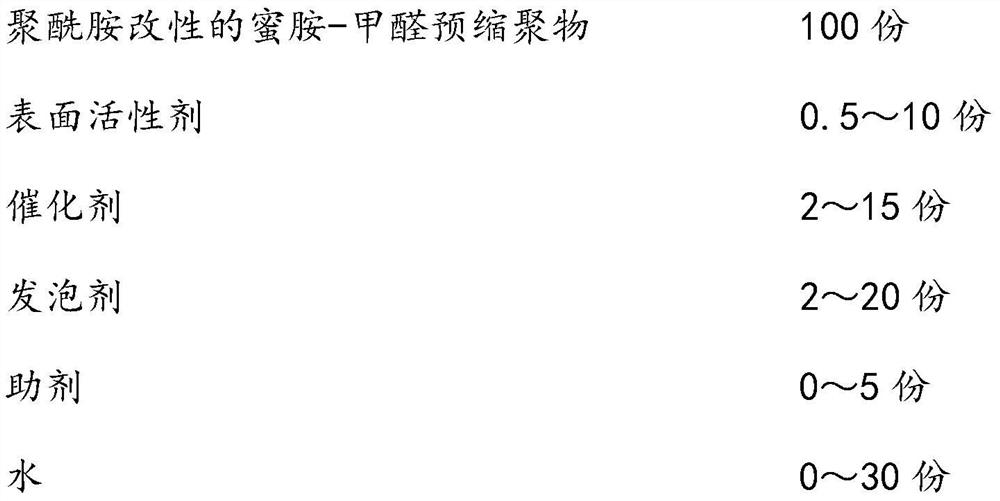

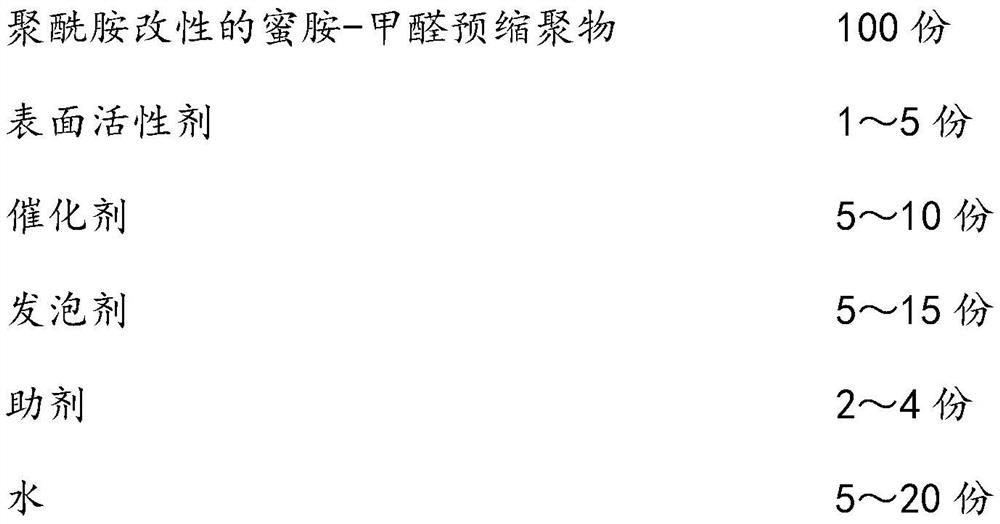

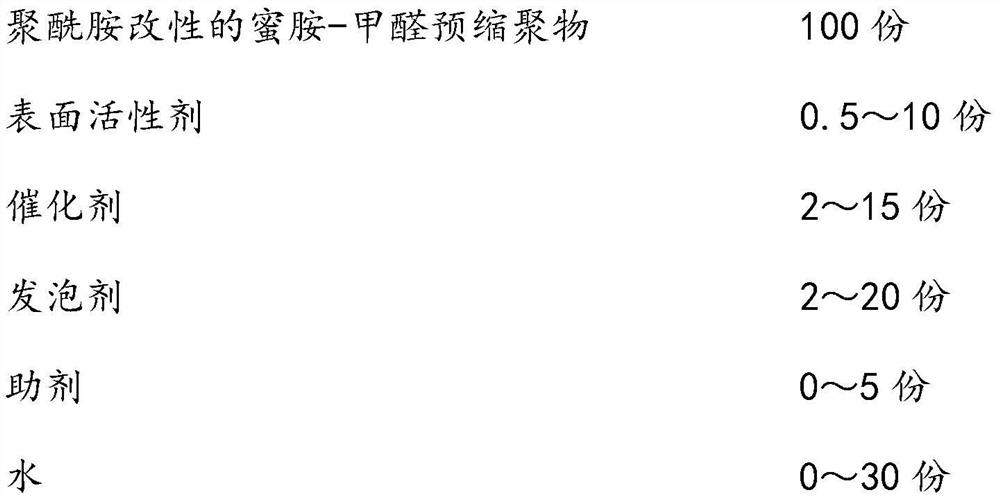

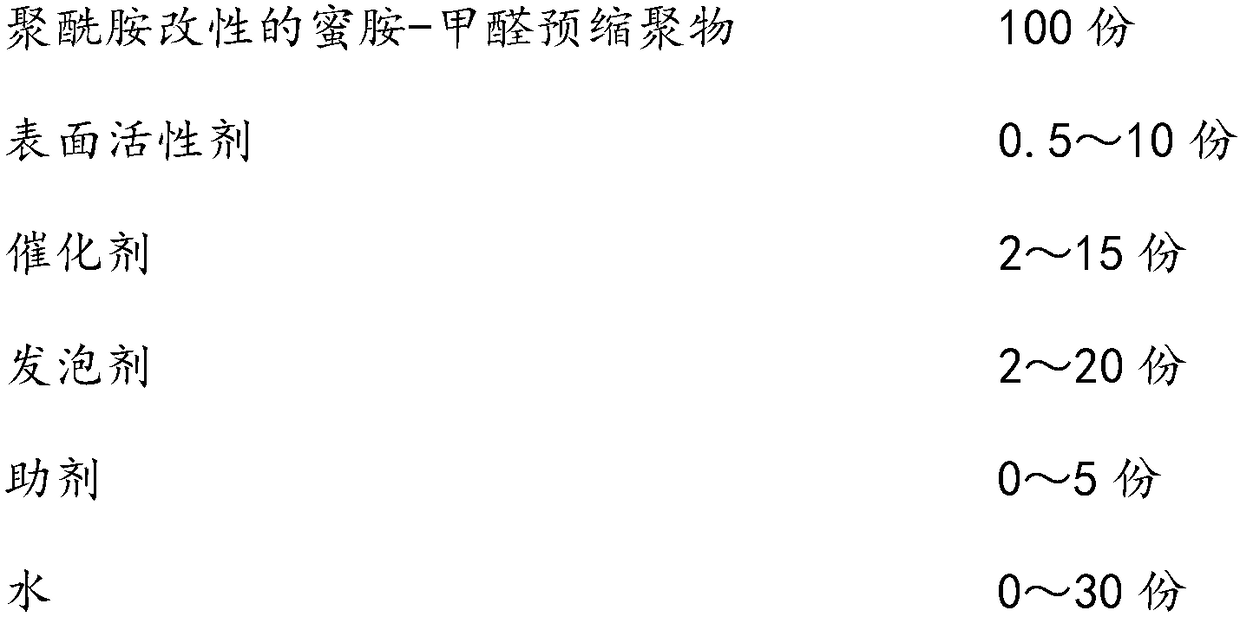

Polyamide-modified melamine-formaldehyde precondensate, foam material and preparation method

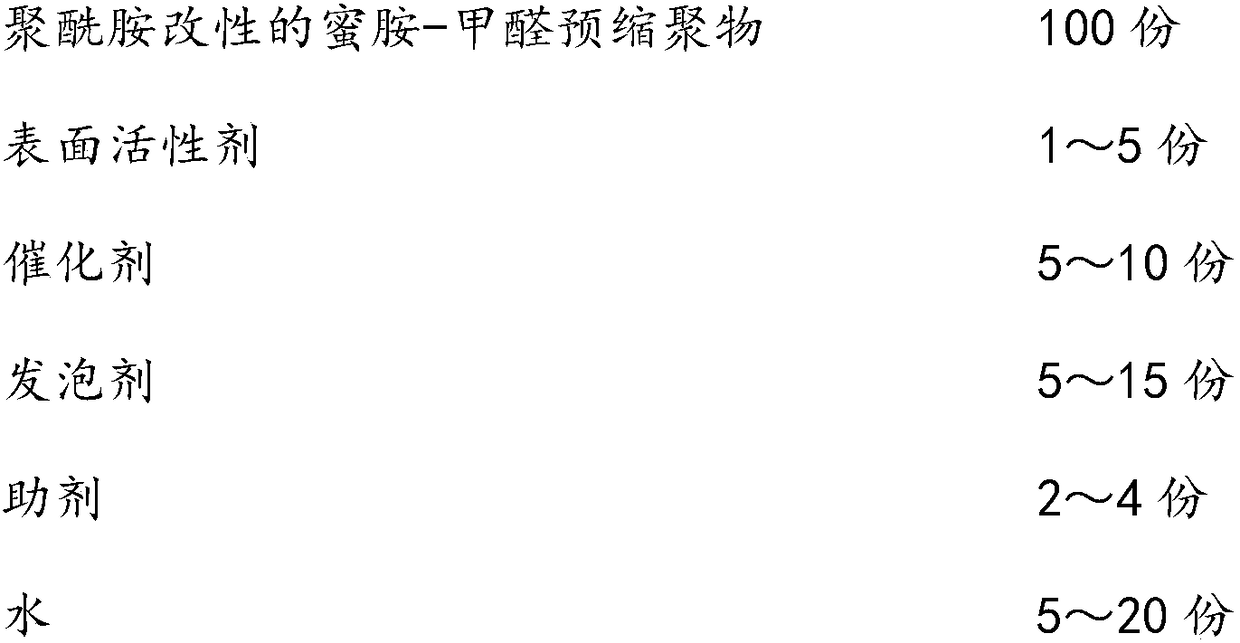

The invention provides a polyamide-modified melamine-formaldehyde precondensate, which belongs to the technical field of melamine-formaldehyde foam materials. The precondensed polymer is prepared by adjusting the pH value of the paraformaldehyde solution and then adding melamine, polyamide and modifier, monitoring the reaction process at the cloud point, stopping heating and cooling down rapidly after reaching the corresponding cloud point. The present invention also provides a polyamide-modified melamine-formaldehyde foam material, comprising 100 parts of polyamide-modified melamine-formaldehyde precondensate, 0.5-10 parts of surfactant, 2-15 parts of catalyst, and foaming 2-20 parts of agent, 0-5 parts of auxiliary agent and 0-30 parts of water. The invention uses polyamide to modify the melamine-formaldehyde foam material, which not only maintains the flame retardancy and thermal stability of the material, but also improves the tear toughness of the melamine-formaldehyde foam. The modification of the melamine-formaldehyde resin polycondensate by polyamide can improve the fluidity of the melamine-formaldehyde resin precondensate and reduce the difficulty of industrial production.

Owner:成都美讷敏新材料科技有限公司

Electric wire and cable fire retardant coating based on lithium nitride

The invention relates to a fireproof coating for electric wires and cables based on lithium lithium nitride. The raw materials include the following main components in parts by mass: 15-25 parts of ethylene acrylic acid copolymer, 15-30 parts of metal hydroxide, and three lithium nitride 12‑18 parts, 5‑12 parts of ethanol, 7‑10 parts of calcium carbonate, 15‑25 parts of talcum powder, 6‑12 parts of silane, 6‑12 parts of siloxane, 5‑8 parts of glass sand, 5‑8 parts of resin share. In the present invention, ethylene acrylic acid copolymer and metal hydroxide are used as a compound combination, and lithium nitride is added to make the fire retardant coating not only have flame retardant properties, but also maintain fire resistance, flame resistance and flame resistance, etc., and can effectively Protect surrounding flammable materials.

Owner:江阴市尤乐防火阻燃材料有限公司

Silicon nitride-based electric wire and cable fireproof coating

The invention relates to a silicon nitride-based fireproof coating for wires and cables. The raw materials include the following main components in parts by mass: 15-25 parts of ethylene acrylic acid copolymer, 15-30 parts of metal hydroxide, and 12-30 parts of silicon nitride. 18 parts, 5-12 parts of ethanol, 7-10 parts of calcium carbonate, 15-25 parts of talcum powder, 6-12 parts of silane, 6-12 parts of siloxane, 5-8 parts of glass sand, and 5-8 parts of resin. In the present invention, ethylene acrylic acid copolymer and metal hydroxide are used as a compound combination, and silicon nitride is added to make the fire retardant coating not only have flame retardant properties, but also maintain fire resistance, flame resistance and fire resistance, and can effectively protect Surrounded by flammable materials.

Owner:江阴市尤乐防火阻燃材料有限公司

Fireproof paint based on bis(3,4-epoxy-6-methylcyclohexylmethyl) adipate

InactiveCN107541139AFlame retardantFlame retardant property maintenanceFireproof paintsPolyether coatingsEpoxyEther

The invention relates to a fireproof coating based on bis(3,4-epoxy-6-methylcyclohexylmethyl)adipate, the raw material of which contains the following main components in parts by mass: bis(2,3- Epoxycyclopentyl) ether resin 15-25 parts, metal hydroxide 15-30 parts, ethanol 5-12 parts, calcium carbonate 7-10 parts, talcum powder 15-25 parts, bis(3,4-epoxy ‑6‑methylcyclohexylmethyl) adipate 6‑12 parts, glass sand 5‑8 parts, resin 5‑8 parts. The present invention uses bis(2,3-epoxycyclopentyl) ether resin and metal hydroxide as a composite combination, and then adds bis(3,4-epoxy-6-methylcyclohexylmethyl) adipate , so that in addition to being flame retardant, the fire retardant coating can also maintain fire resistance, flame resistance and flame retardancy, and can effectively protect the surrounding flammable materials.

Owner:江阴市尤乐防火阻燃材料有限公司

Ethylene-maleic acid copolymer based indoor fireproof paint

The present invention relates to a kind of indoor fireproof paint based on ethylene maleic acid copolymer, and its raw material comprises the main components of following mass parts: ethylene maleic acid copolymer 15-25 parts, metal hydroxide 15-30 parts, ethanol 5‑12 parts, 7‑10 parts of calcium carbonate, 15‑25 parts of talcum powder, 6‑12 parts of silane, 6‑12 parts of siloxane, 5‑8 parts of glass sand, and 5‑8 parts of resin. The invention uses ethylene-maleic acid copolymer and metal hydroxide as a composite combination, so that the fire-resistant coating can not only have flame-retardant properties, but also maintain fire-resistant, flame-resistant and flame-retardant capabilities, and can effectively protect surrounding flammable materials. .

Owner:江阴市尤乐防火阻燃材料有限公司

Anti-aging ppo-pps plastic alloy

The invention discloses an aging-resistant PPO-PPS plastic alloy, which is composed of the following components in weight part: 100 parts of PPO, 40-60 parts of PPS, 4-8 parts of compatibilizer and 0.5-1.5 parts of age resister. The aging-resistant PPO-PPS plastic alloy disclosed by the invention is an alloy material with excellent overall performances, mostly retains the advantages of PPS in respects of mechanical property, thermal tolerance, flame retardance and the like, and integrates excellent electrical performances of PPO. The aging-resistant PPO-PPS plastic alloy is suitable for fields of electric appliances such as thermotolerant breaker frameworks and electric appliance connectors.

Owner:浙江丞达新材料科技有限公司

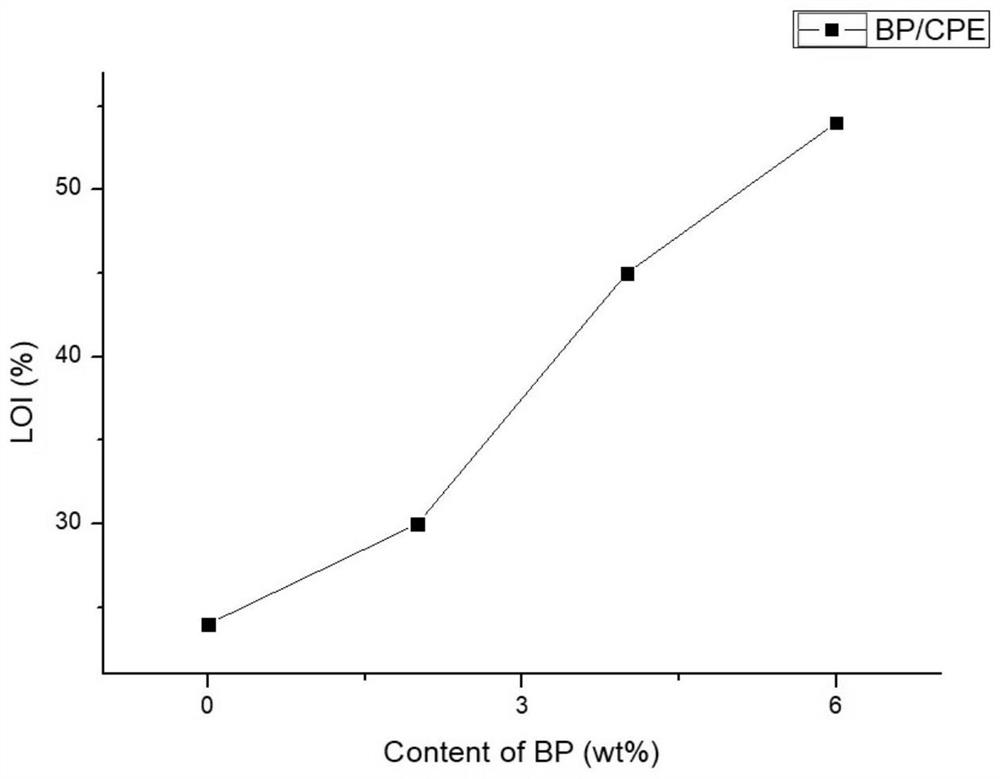

Chlorinated polyethylene composition containing black phosphorus (alkene) and application of composition

PendingCN112159566AGood mechanical propertiesImprove mechanical propertiesPolymer sciencePlasticizer

The invention discloses a chlorinated polyethylene composition containing black phosphorus (alkene) and application of the composition. The chlorinated polyethylene composition comprises the followingraw materials in parts by weight: 10-90 parts of chlorinated polyethylene; 0.1 to 20 parts of black phosphorus (alkene); 0.1 to 20 parts of a plasticizer; 0.1 to 10 parts of a stabilizing agent; 0-15parts of a cross-linking agent; 0-20 parts of a flame retardant; and 0.01-30 parts of filler. The chlorinated polyethylene composition containing black phosphorus (alkene) has a good flame retardanteffect, and can prevent flame combustion and inhibit smoldering; and the mechanical property of the composition is stronger than that of a chlorinated polyethylene matrix material. The chlorinated polyethylene composition containing black phosphorus (alkene) can be added into PVC, CPVC, ABS, PS, PA and other plastics to improve the impact property and flame retardancy, and can also be used in NBR,EPDM, natural rubber and other materials.

Owner:山东祥生新材料科技股份有限公司

Colored polyester concentric sheath-core composite fiber and method for producing the same

ActiveCN104532399BGuaranteed chemical stabilityMaintain gas barrier propertiesMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterFiber

Owner:SHANGHAI DEFULUN CHEM FIBER

Weaving paper spray flame retardant

InactiveCN108797203AHigh heat resistanceImprove cooling effectPaper coatingPaper/cardboardFiberPolyethylene glycol

The invention mainly relates to the technical field of weaving article processing, and discloses a weaving paper spray flame retardant which is prepared from silicone modified phenolic resin, modifiedhigh density polyethylene, sodium silicate, sodium selenite, magnesium hydroxide, nano-graphene fibers, phytic acid and polyethylene glycol. The weaving paper spray flame retardant is green, healthy,safe and environmentally friendly, the heat resistance of paper can be increased, heat dissipation of the paper is accelerated, the carbonization time of the paper is prolonged, paper water absorption and toxic gas generation are avoided, the structures of the paper and a woven product are kept complete, and loss generated by combustion is avoided. The silicone modified phenolic resin is rapidlyheated and molten, slow heating and stirring are continued after the magnesium hydroxide is added, melt polymerization of the silicone modified phenolic resin and the magnesium hydroxide is promoted,the flexibility and flame resistance of the silicone modified phenolic resin are improved, excessive paper hardness caused by the flame retardant is avoided, and folding and weaving performances of the paper are kept.

Owner:阜南县猛发工艺品有限公司

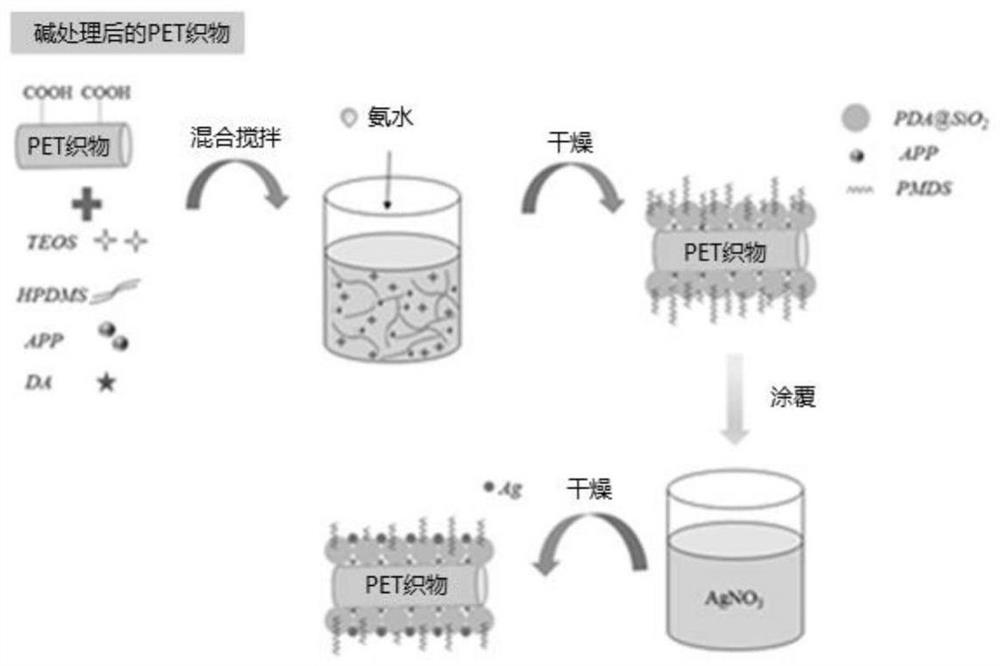

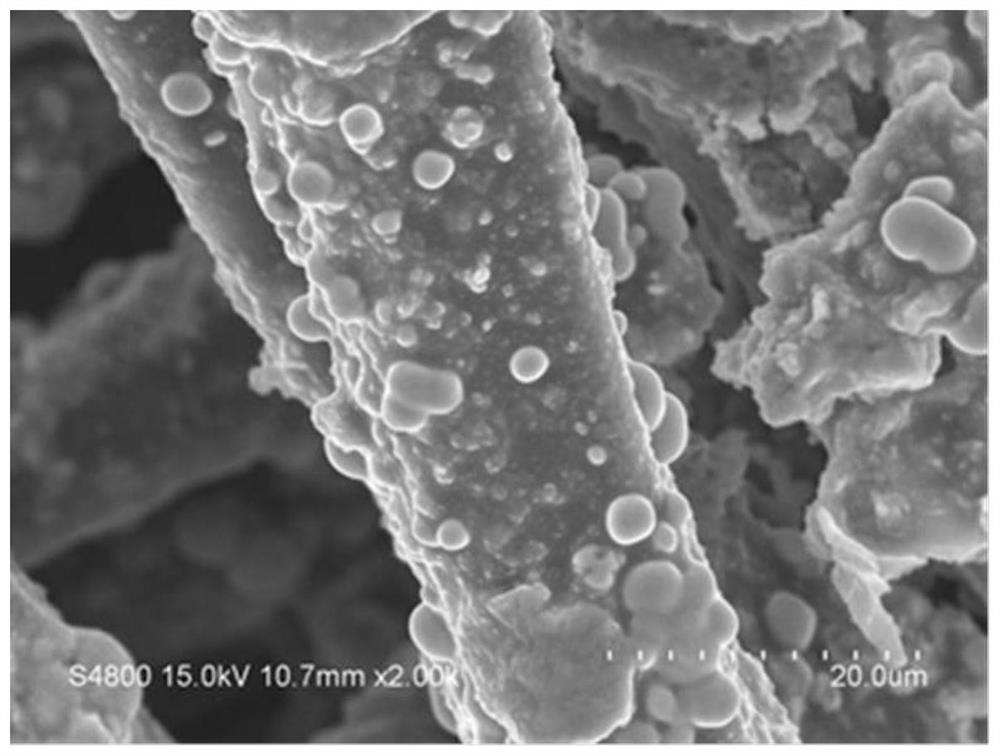

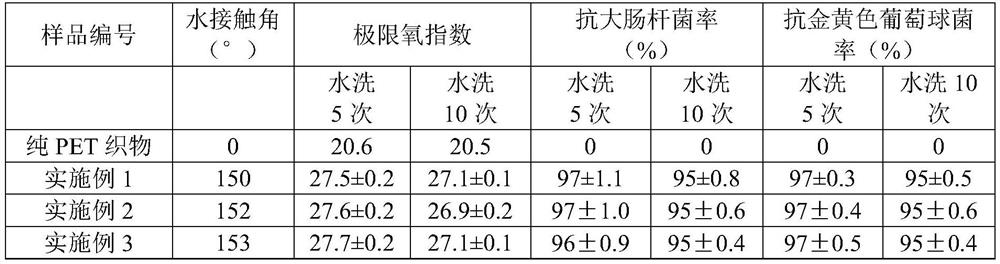

Modified fabric as well as preparation method and application thereof

PendingCN114717840AImprove flame retardant performanceExcellent superhydrophobicityBiochemical fibre treatmentHeat resistant fibresAnti bacteriaSilver particles

The invention discloses a modified fabric as well as a preparation method and application thereof. The method comprises the following steps: (1) ammonium polyphosphate coating, (2) PDMS (Polydimethylsiloxane)-SiO2 coating and (3) polydopamine coating are performed on the fabric; wherein the steps (1)-(3) are respectively carried out, or at least two steps are simultaneously carried out; the step (1) is not performed after the step (2). The modified fabric is obtained by adopting the preparation method. According to the invention, the synergistic effect of ammonium polyphosphate and SiO2 enhances the hydrophobicity and flame retardance of the PET fabric; the preparation method is simple and low in energy consumption; furthermore, the nano-silver particles are attached to the fabric through the reduction activity of the polydopamine; the fabric is endowed with flame retardance, antibacterial property, hydrophobicity and washing fastness. The modified fabric can be applied to the fields of outdoor articles, indoor decoration and fire-fighting articles.

Owner:EAST CHINA UNIV OF SCI & TECH

Polyamide modified melamine-formaldehyde prepolycondensate and foam material, and preparation methods thereof

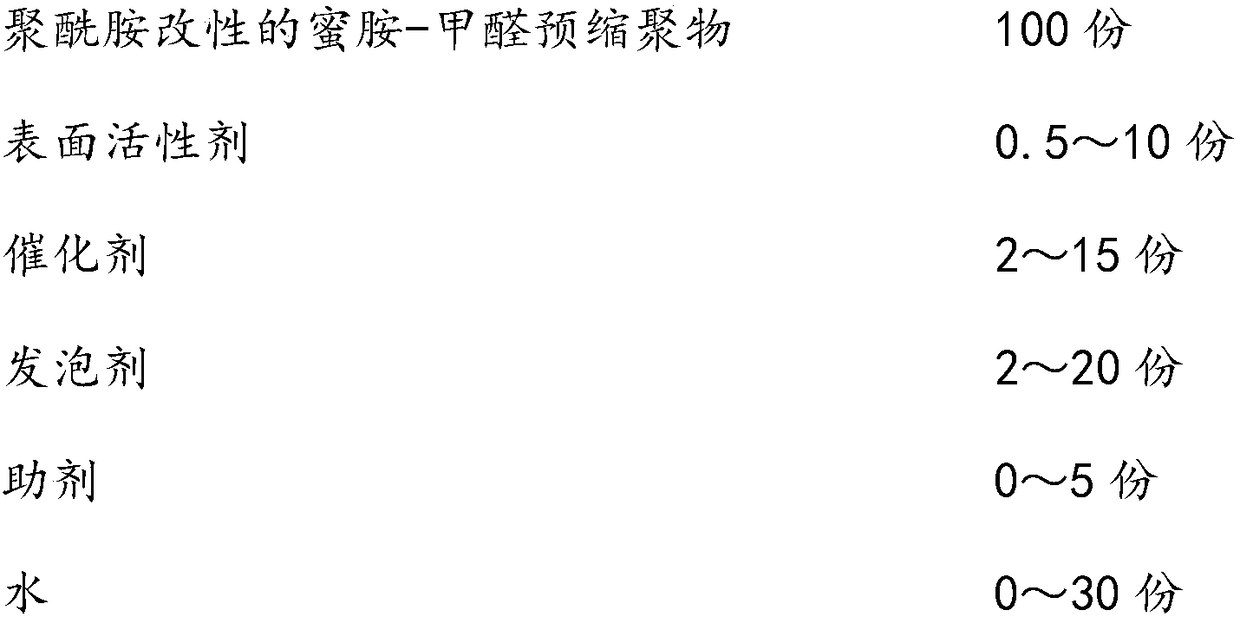

The invention provides a polyamide modified melamine-formaldehyde prepolycondensate, and belongs to the technical field of melamine-formaldehyde foam materials. The prepolycondensate is prepared through a method comprising the following steps: adjusting the pH value of a paraformaldehyde solution, heating the paraformaldehyde solution, adding melamine, polyamide and a modifier, performing a cloudpoint monitoring reaction progress, and performing heating stopping and rapid cooling after a corresponding cloud point is reached. The invention also provides a polyamide modified melamine-formaldehyde foam material. The foam material comprises 100 parts of the polyamide modified melamine-formaldehyde prepolycondensate, 0.5-10 parts of a surfactant, 2-15 parts of a catalyst, 2-20 parts of a foaming agent, 0-5 parts of an assistant and 0-30 parts of water. A melamine-formaldehyde foam material is modified with polyamide, so the flame retardancy and the thermal stability of the material are kept, and the tear toughness of the melamine-formaldehyde foam is improved. Modification of the melamine-formaldehyde resin polycondensate with polyamide can improve the fluidity of the melamine-formaldehyde resin prepolycondensate and reduce the difficulty of industrial production.

Owner:成都美讷敏新材料科技有限公司

Rapidly-formed halogen-free flame-retardant PA6 composite material and preparation method thereof

InactiveCN112745664AMaintain physical propertiesMaintain flame retardancyAntioxidantInjection moulding

The invention relates to a rapidly-formed halogen-free flame-retardant PA6 composite material and a preparation method thereof. The rapidly-formed halogen-free flame-retardant PA6 composite material comprises the following raw materials in percentage by mass: 65-80% of PA6 resin; 15-25% of a phosphorus-nitrogen composite flame retardant; 3-5% of a synergistic flame retardant; 0.5-2% of a nucleating agent; 0.5 to 1% of an antioxidant; and 1-2% of a lubricant. The prepared rapid prototyping halogen-free flame-retardant PA6 composite material does not contain halogen, meets the green and environment-friendly requirements, has the characteristics of rapid prototyping, shortening of the injection molding period and the like, is especially suitable for injection molding of thin-wall plastic products, effectively shortens the molding period during injection molding of the material, and improves the production efficiency. Meanwhile, the physical property and the flame retardant property of the material are kept.

Owner:扬州集飞新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com