Preparation method of montmorillonite modified nano aluminum hydroxide composite inorganic flame retardant

A technology of nano-aluminum hydroxide and inorganic flame retardant, which is applied in the field of fine chemicals, can solve the problems of low flame retardant efficiency, large amount of addition, and poor combustion charcoal performance, so as to improve comprehensive mechanical properties, improve flame retardant performance, and reduce The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

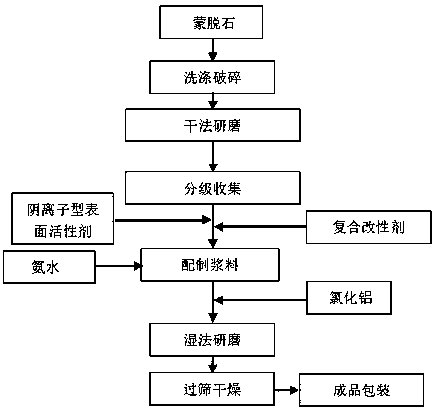

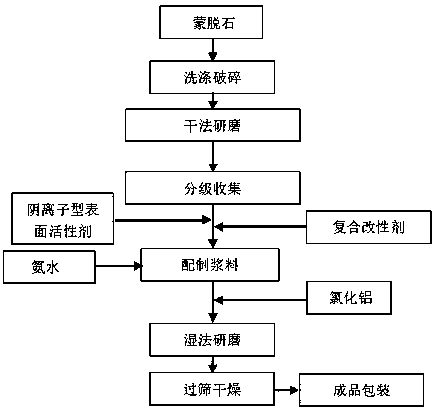

[0024] In this embodiment, a method for preparing a montmorillonite-modified nano-aluminum hydroxide composite inorganic flame retardant, the steps are as follows:

[0025] (1) Preparation of anionic montmorillonite:

[0026] Add montmorillonite powder into water, disperse and strip it by ultrasonic vibration, raise the temperature to 40°C, add γ-aminopropylmethyldimethoxysilane and dodeca Alkyl benzyl dimethyl ammonium chloride composite modifier, wherein the mass ratio of γ-aminopropyl methyl dimethoxysilane and dodecyl benzyl dimethyl ammonium chloride is 1:1, and then Adding sodium dodecylsulfonate anionic surfactant with a mass ratio of 1:80 to montmorillonite, mechanical stirring and grinding and ultrasonic oscillation for 12h, then adding dropwise anionic surfactant with a mass ratio of 1:100 to montmorillonite Ammonia, and react for 6 hours to obtain an anionic montmorillonite solution with an equivalent diameter of 0.5-2 μm.

[0027] (2) Preparation of nano aluminum...

Embodiment 2

[0032] In this embodiment, a method for preparing a montmorillonite-modified nano-aluminum hydroxide composite inorganic flame retardant, the steps are as follows:

[0033] (1) Preparation of anionic montmorillonite:

[0034] Add montmorillonite powder into water, disperse and strip it by ultrasonic vibration, raise the temperature to 60°C, add γ-aminopropylmethyldimethoxysilane and dodeca Alkyl benzyl dimethyl ammonium chloride composite modifier, wherein the mass ratio of γ-aminopropyl methyl dimethoxysilane and dodecyl benzyl dimethyl ammonium chloride is 1:1, and then Adding sodium dodecylsulfonate anionic surfactant with a mass ratio of 1:90 to montmorillonite, mechanical agitation, grinding and ultrasonic oscillation for 24 hours, then adding dropwise anionic surfactant with a mass ratio of 1:300 to montmorillonite Ammonia, and react for 8 hours to obtain an anionic montmorillonite solution with an equivalent diameter of 0.5-2 μm.

[0035] (2) Preparation of nano alumi...

Embodiment 3

[0040] In this embodiment, a method for preparing a montmorillonite-modified nano-aluminum hydroxide composite inorganic flame retardant, the steps are as follows:

[0041] (1) Preparation of anionic montmorillonite:

[0042] Add montmorillonite powder into water, disperse and strip it by ultrasonic vibration method, raise the temperature to 80°C, add γ-aminopropylmethyldimethoxysilane and dodeca Alkyl benzyl dimethyl ammonium chloride composite modifier, wherein the mass ratio of γ-aminopropyl methyl dimethoxysilane and dodecyl benzyl dimethyl ammonium chloride is 1:1, and then Adding sodium dodecylsulfonate anionic surfactant with a mass ratio of 1:100 to montmorillonite, mechanical agitation, grinding and ultrasonic oscillation for 48h, then adding dropwise anionic surfactant with a mass ratio of 1:400 to montmorillonite Ammonia, and react for 10 hours to obtain an anionic montmorillonite solution with an equivalent diameter of 0.5-2 μm.

[0043] (2) Preparation of nano a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com