Colored polyester concentric sheath-core composite fiber and method for producing the same

A composite fiber and colored polyethylene naphthalate technology, which is applied in the direction of conjugated synthetic polymer artificial filament, fiber treatment, melt spinning, etc., can solve the problems of difficult dyeing and fiber formation, and reduce the The effect of cost of use and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

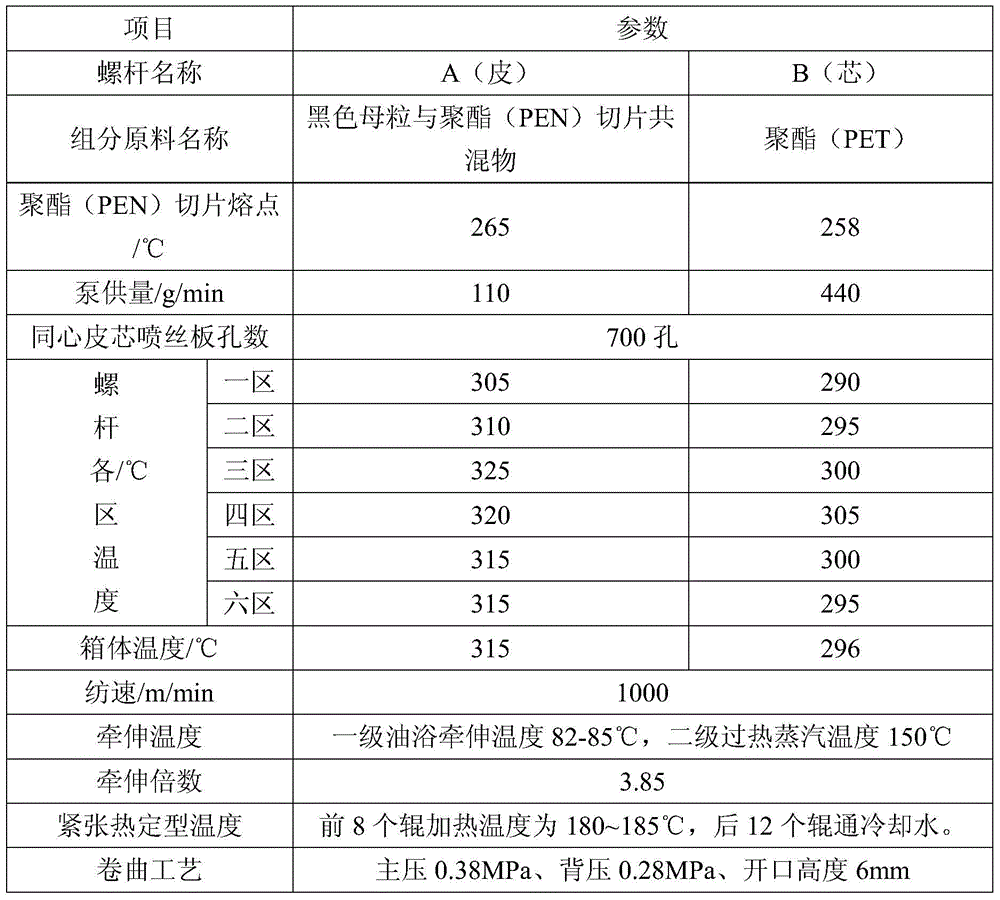

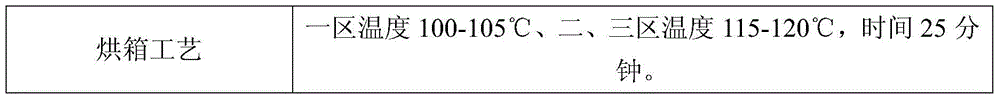

Embodiment 1

[0037] Black polyester PEN / PET concentric sheath-core fiber with a production line density of 2.50dtex.

[0038] Leather component preparation: the polyester (PEN) slices are pre-crystallized in a high-temperature fluidized bed at 185-210°C for 2.5-3 hours. Then add the high-temperature-resistant black masterbatch with a color content of 25% to the pre-crystallized polyester (PEN) chips at a ratio of 10% by weight, and carry out drum vacuum blending and drying. The drum heating temperature is 132°C. Drying time 10-10.5 hours.

[0039] Preparation of core components: Put polyester (PET) chips into a drum dryer for vacuum drying, cool for half an hour after feeding, and then directly raise the temperature to 132°C for 10 hours of drying.

[0040] Using LFH105 composite spinning equipment, the skin and core components dried by their respective systems are melted and extruded through their respective screws, and enter the spinneret assembly through their respective pipelines and ...

Embodiment 2

[0047] Green polyester PEN / PET concentric sheath-core composite fiber with a production line density of 5.56dtex.

[0048] Leather component preparation: the polyester (PEN) slices are pre-crystallized in a high-temperature fluidized bed at 185-210°C for 2.5-3 hours. Add the high-temperature-resistant green masterbatch with a color content of 30% to the pre-crystallized polyester (PEN) chips at a ratio of 6% by weight, carry out drum vacuum blending and drying, and the drum heating temperature directly rises to 132°C, drying time 10-10.5 hours.

[0049] Preparation of core components: Put polyester (PET) chips into a drum dryer for vacuum drying, cool for half an hour after feeding, and then directly raise the temperature to 132°C for 10 hours of drying.

[0050] Using the composite spinning equipment of our factory, the sheath and core components dried by their respective systems are melted and extruded through their respective screws, and enter the spinneret components thro...

Embodiment 3

[0057] Brown polyester PEN / PET concentric sheath-core composite fiber with a production line density of 4.44dtex.

[0058] Leather component preparation: pre-crystallize polyester (PEN) slices in a high-temperature fluidized bed at 185-210°C for 2.5-3 hours, and then add high-temperature-resistant brown masterbatches with a color content of 25% to 10% by weight The ratio is added to the pre-crystallized polyester (PEN) chips, and the drum is vacuum blended and dried. The temperature of the drum is directly raised to 132 ° C, and the drying time is 10-10.5 hours.

[0059] Preparation of core components: Put polyester (PET) chips into a drum dryer for vacuum drying, cool for half an hour after feeding, and then directly raise the temperature to 132°C for 10 hours of drying.

[0060] Using the existing composite spinning equipment, the skin and core components dried by their respective systems are melted and extruded through their respective screws, and enter the spinneret assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com