Sorbent for mutual separation of MA/RE in high-level waste and preparation thereof

A high-level radioactive waste and adsorbent technology, applied in silicon compounds, radioactive purification, other chemical processes, etc., can solve the safety concerns of post-processing cycles, low performance such as acid resistance and radiation resistance, and chemical instability, etc. The chemical stability of the solvent, ensuring the safety of the post-processing cycle, and the effect of good identification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

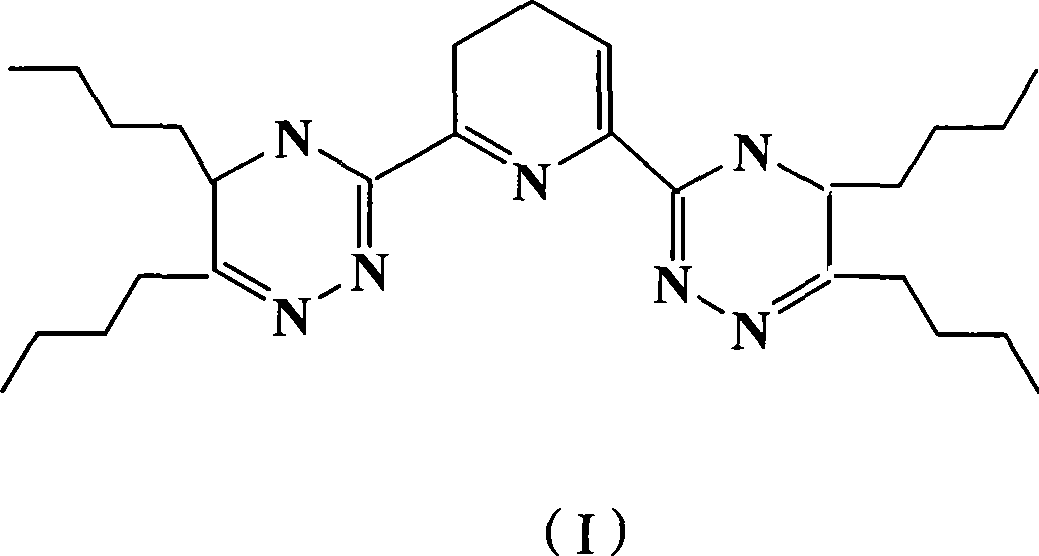

[0028] The preparation of embodiment 1 adsorbent

[0029] Dissolve 100 grams of 2,6-bis-(5,6-di-n-butyl-1,2,4-triazin-3-yl)-pyridine in 1000 mL of dichloromethane and mix well; add 300 grams of coating polymer macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 2

[0030] The preparation of embodiment 2 adsorbent

[0031] Dissolve 100 grams of 2,6-bis-(5,6-di-n-butyl-1,2,4-triazin-3-yl)-pyridine in 1500 mL of dichloromethane and mix well; add 600 grams of coating polymerization macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 3

[0032] Embodiment 3 preparation of adsorbent

[0033] Dissolve 100 grams of 2,6-bis-(5,6-di-n-butyl-1,2,4-triazin-3-yl)-pyridine in 3000 mL of dichloromethane and mix well; add 1500 grams of coating polymer macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com