Modified fabric as well as preparation method and application thereof

A fabric modification technology, applied in the field of modified fabrics and its preparation, can solve the problem that PET fabrics cannot have excellent water resistance and flame retardancy at the same time, and achieve enhanced superhydrophobicity, simple preparation process, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

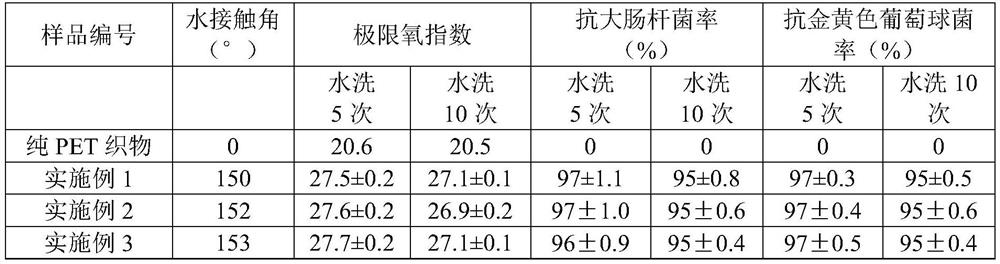

Embodiment 1

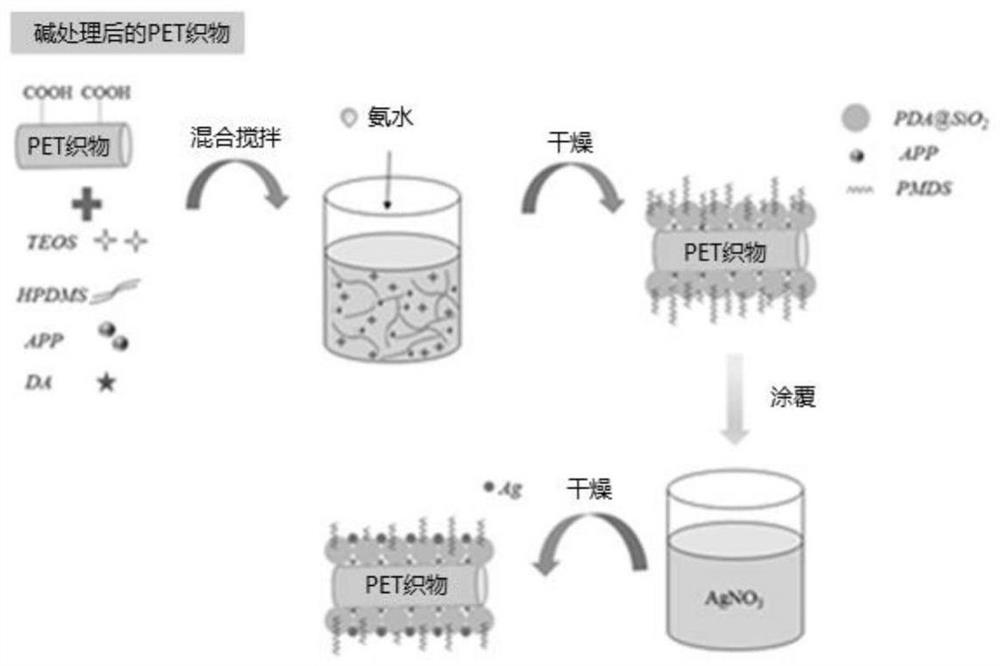

[0104] The 5cm*5cm PET fabric was mixed with 1M NaOH aqueous solution, treated at 90°C for 30min, and dried at 60°C for use.

[0105] Alkali-treated PET fabric was mixed with ethanol (100ml), ammonium polyphosphate (APP) (4g), tetraethoxysilane (TEOS) (4g), hydroxyl terminated polydimethylsiloxane (HPDMS) ( 4g) and a suspension of dopamine hydrochloride (DA) (0.1g), stir for 30min, add ammonia water to adjust the pH to 9, react at 30°C for 8h, take out the fabric and wash with deionized water, at 60°C Under drying, the fabric-(APP-PDMS-SiO 2 -PDA).

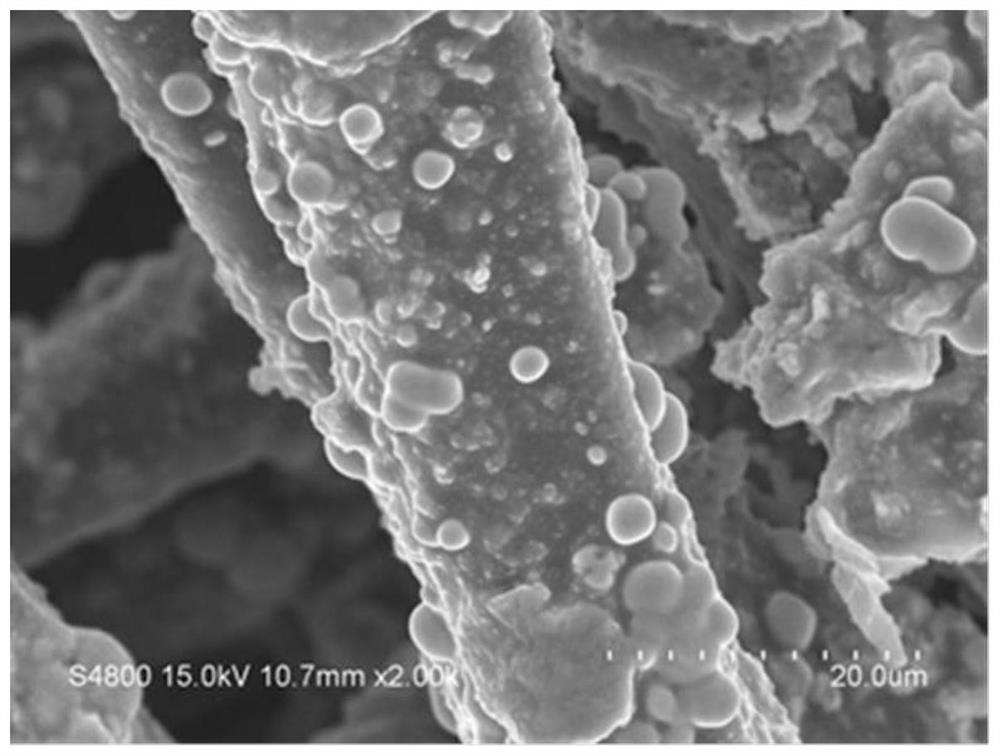

[0106] The fabric-(APP-PDMS-SiO 2 -PDA) with 10g / L AgNO 3 The aqueous solutions were mixed and treated at a mass ratio of 1:20 at 30 °C for 7 h. After taking out the fabric, it was washed with deionized water and dried at 60 °C to obtain a fabric-(APP-PDMS-SiO 2 -PDA-Ag), namely modified PET fabric, the SEM image of this modified PET fabric is as figure 2 shown.

Embodiment 2

[0108] The 5cm*5cm PET fabric was mixed with 1M NaOH aqueous solution, treated at 90°C for 30min, and dried at 60°C for use.

[0109] Alkali-treated PET fabric was mixed with ethanol (110 ml), ammonium polyphosphate (APP) (4.5 g), tetraethoxysilane (TEOS) (4.5 g), hydroxyl terminated polydimethylsiloxane (HPDMS) (4.5g) and a suspension of dopamine hydrochloride (DA) (0.1g) were mixed, and after stirring for 30min, ammonia water was added to adjust the pH to 9, and the reaction was carried out at 30°C for 8h. Dry at 60°C to obtain fabric-(APP-PDMS-SiO 2 -PDA).

[0110] The fabric-(APP-PDMS-SiO 2 -PDA) with 10g / L AgNO 3 The aqueous solutions were mixed and treated at a mass ratio of 1:20 at 30 °C for 7 h. After taking out the fabric, it was washed with deionized water and dried at 60 °C to obtain a fabric-(APP-PDMS-SiO 2 -PDA-Ag), ie modified PET fabric.

Embodiment 3

[0112] The 5cm*5cm PET fabric was mixed with 1M NaOH aqueous solution, treated at 90°C for 30min, and dried at 60°C for use.

[0113] Alkali-treated PET fabric was mixed with ethanol (150ml), ammonium polyphosphate (APP) (5g), tetraethoxysilane (TEOS) (5g), hydroxyl terminated polydimethylsiloxane (HPDMS) (5g) ) and the suspension of dopamine hydrochloride (DA) (0.15g), stir for 30min, add ammonia water to adjust the pH to 9, react at 30°C for 8h, take out the fabric and wash with deionized water, at 60°C Drying to obtain fabric-(APP-PDMS-SiO 2 -PDA).

[0114] The fabric-(APP-PDMS-SiO2 -PDA) with 10g / L AgNO 3 The aqueous solutions were mixed and treated at a mass ratio of 1:20 at 30 °C for 7 h. After taking out the fabric, it was washed with deionized water and dried at 60 °C to obtain a fabric-(APP-PDMS-SiO 2 -PDA-Ag), ie modified PET fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com