Exposed post-wire distribution type electric welding pipe fitting

A technology for electrofusion pipe fittings and wire cloth, which is applied in the direction of pipes/pipe joints/pipe fittings, pipeline connection layout, mechanical equipment, etc. The effect of increased distribution density, enhanced binding force, and increased fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

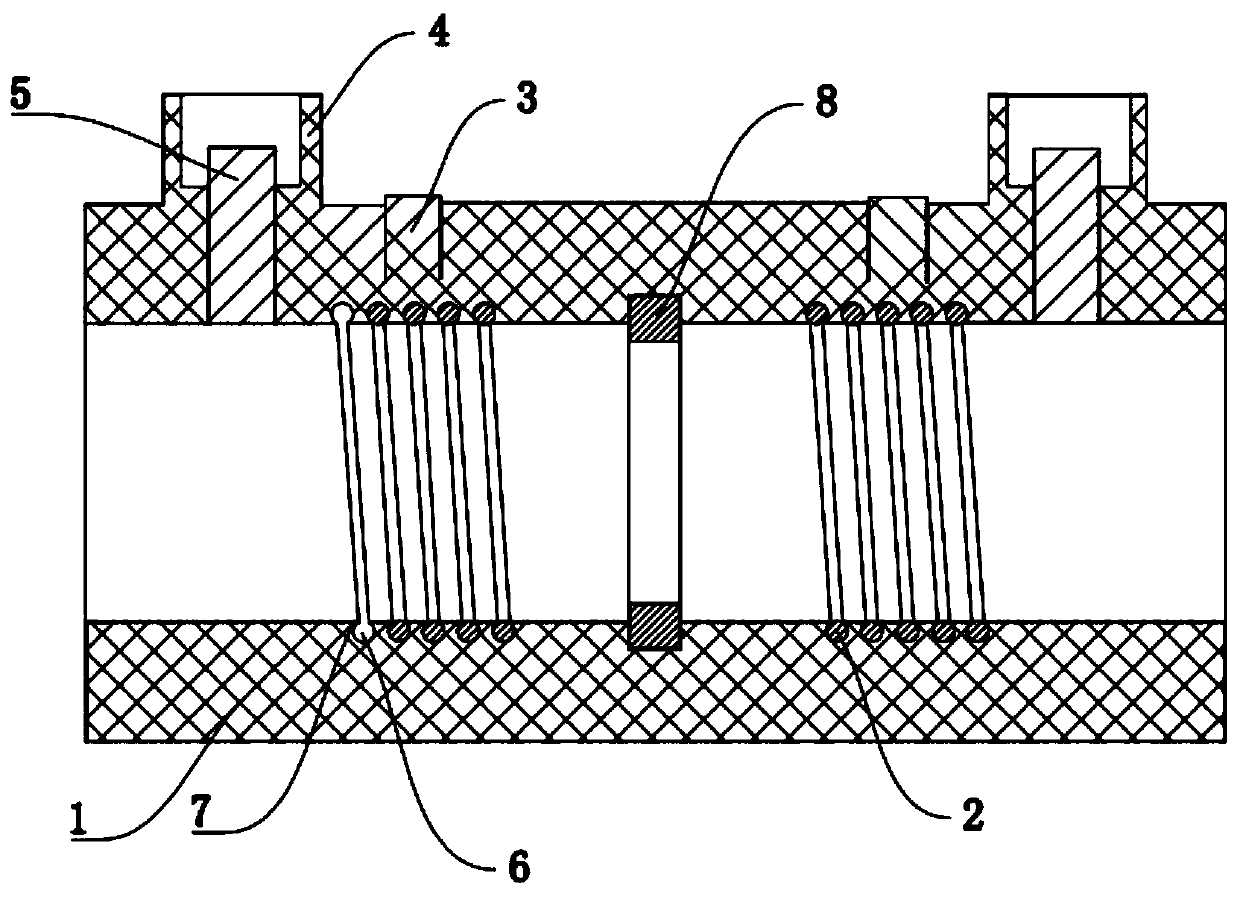

[0029] see figure 1 , a bare cloth wire electrofusion pipe fitting, comprising a pipe body 1, a heating wire 2 arranged on the inner wall of the pipe body 1, an observation hole 3 exposed from the pipe body 1 and located at both ends of the pipe body 1, and a terminal 4, each electrofusion Both ends of the pipe are provided with observation holes 3 and terminal 4, the terminal 4 is provided with a terminal 5, the terminal 5 is connected to the heating wire 2, and the pipe body 1 is provided with a non-conductor along the axial direction. A closed wire embedding groove 6, the heating wire 2 is clamped in the wire embedding groove 6, and a ring groove is opened in the inner middle part of the tube body 1, and the limit ring 8 is clamped in the ring groove.

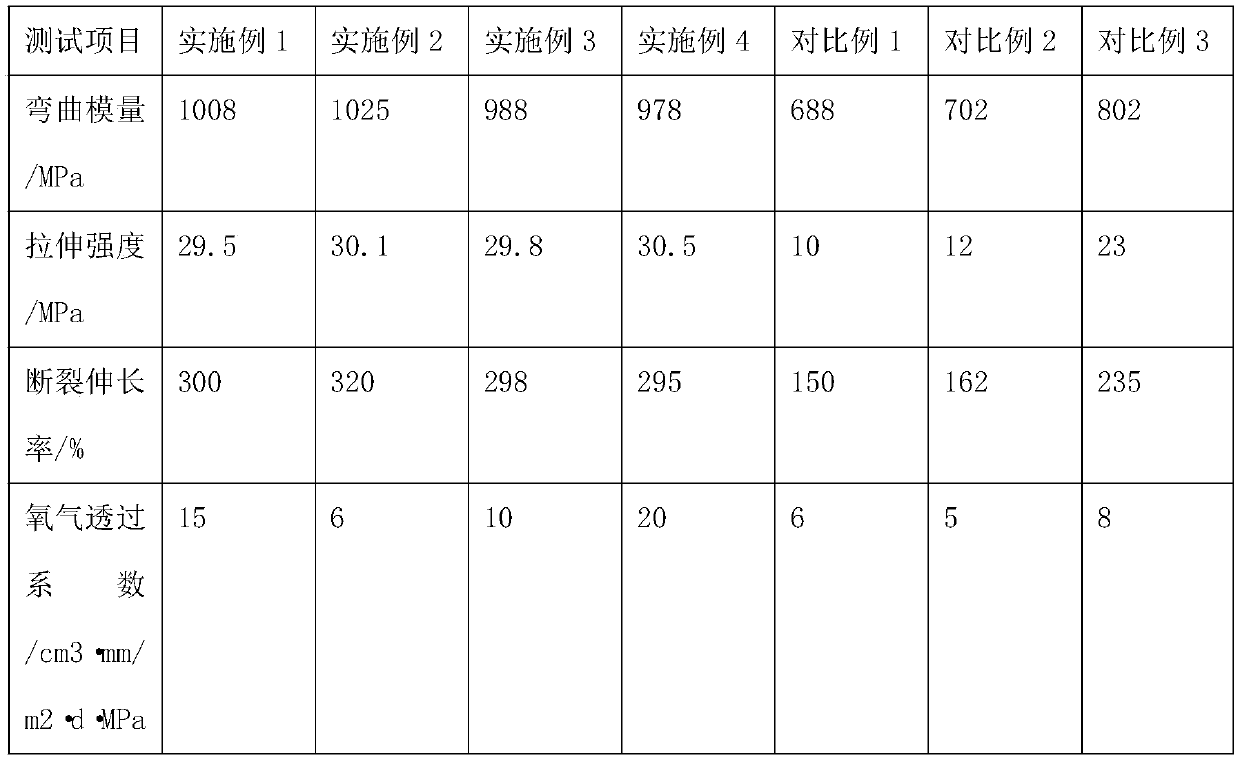

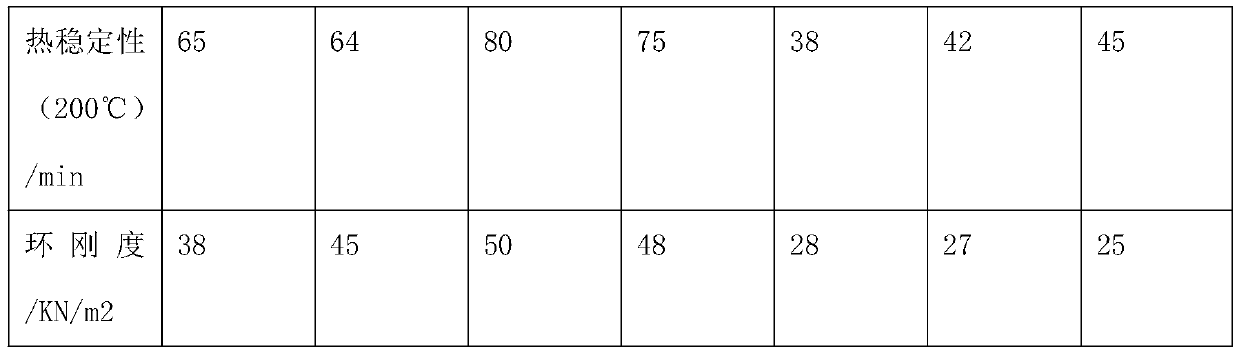

[0030] Among them, the pipe body 1 is mainly made of the following raw materials in parts by weight: 90 parts of PE100 grade raw materials, 30 parts of PE high-pressure recycled materials, 2 parts of antioxidant diphenylamin...

Embodiment 2

[0036] see figure 1 , a bare cloth wire electrofusion pipe fitting, comprising a pipe body 1, a heating wire 2 arranged on the inner wall of the pipe body 1, an observation hole 3 exposed from the pipe body 1 and located at both ends of the pipe body 1, and a terminal 4, each electrofusion Both ends of the pipe are provided with observation holes 3 and terminal 4, the terminal 4 is provided with a terminal 5, the terminal 5 is connected with the heating wire 2, and the pipe body 1 is provided with a non-conductor along the axial direction. A closed wire embedding groove 6, the heating wire 2 is clamped in the wire embedding groove 6, and a ring groove is opened in the inner middle part of the tube body 1, and the limit ring 8 is clamped in the ring groove.

[0037]Wherein, the pipe body 1 is mainly made of the following raw materials in parts by weight: 120 parts of PE100 grade raw materials, 45 parts of PE high-pressure recycled materials, 4 parts of antioxidant p-phenylenedi...

Embodiment 3

[0043] see figure 1 , a bare cloth wire electrofusion pipe fitting, comprising a pipe body 1, a heating wire 2 arranged on the inner wall of the pipe body 1, an observation hole 3 exposed from the pipe body 1 and located at both ends of the pipe body 1, and a terminal 4, each electrofusion Both ends of the pipe are provided with observation holes 3 and terminal 4, the terminal 4 is provided with a terminal 5, the terminal 5 is connected to the heating wire 2, and the pipe body 1 is provided with a non-conductor along the axial direction. A closed wire embedding groove 6, the heating wire 2 is clamped in the wire embedding groove 6, and a ring groove is opened in the inner middle part of the tube body 1, and the limit ring 8 is clamped in the ring groove.

[0044] Wherein, the pipe body 1 is mainly made of the following raw materials in parts by weight: 100 parts of PE100 grade raw materials, 35 parts of PE high-pressure recycled materials, 3 parts of antioxidant dihydroquinoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com