Composite antimony trioxide flame retardant and preparation method thereof

An antimony trioxide and flame retardant technology, applied in the field of flame retardants, can solve the problems affecting the use effect of polymer products, poor compatibility of polymer matrix, general mechanical properties of polymers, etc. The effect of improving compatibility, improving mechanical properties and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

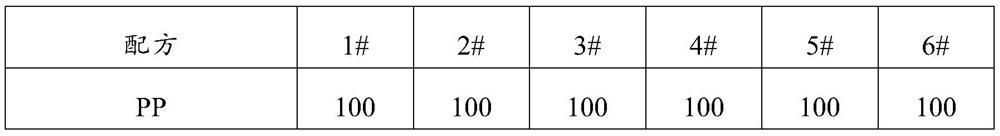

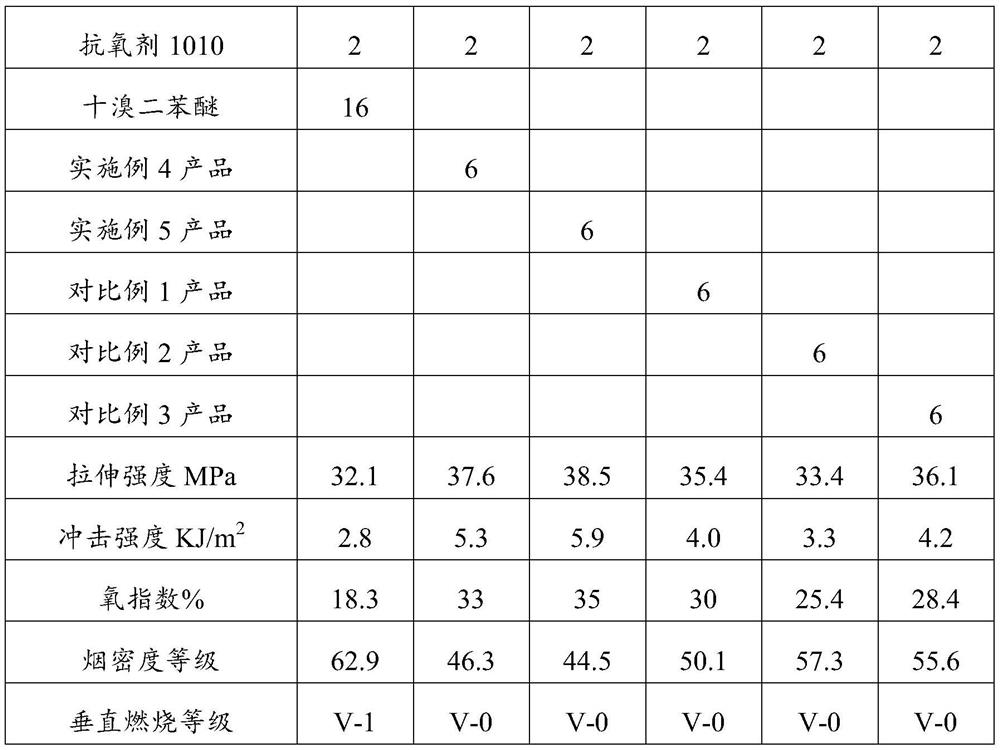

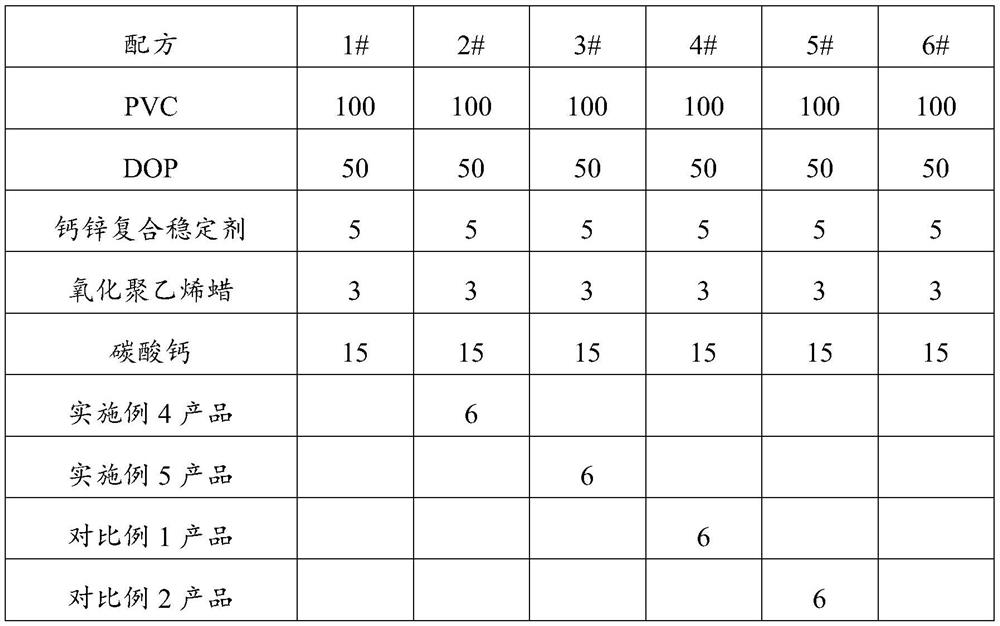

Examples

Embodiment 1

[0027] A preparation method of a composite antimony trioxide flame retardant is as follows: add 40 parts of surface-modified antimony trioxide to 60 parts of ethanol and mix evenly, then add 30 parts of phosphate amine salt, heat up to 50-60 °C, Stir for 30 minutes, then add 2 parts of titanate coupling agent and 5 parts of organic copper salt heat stabilizer, raise the temperature to 90-100°C and stir for 1 hour, then cool down to 60°C, add 30 parts of silane-modified halloysite nanotubes, Stir for 30 minutes, cool to room temperature, and grind to prepare a composite antimony trioxide flame retardant.

[0028]The phosphate ester amine salt is polymerized from pentaerythritol, phosphorus pentoxide and isobutyramide. The preparation method is: add 150g of pentaerythritol to 100g of ethanol and mix evenly, then add 100g of phosphorus pentoxide and stir at 50°C After 30 minutes, ethanol was distilled under pressure at room temperature to remove ethanol, and then 180 g of isobuty...

Embodiment 2

[0032] A preparation method of a composite antimony trioxide flame retardant is as follows: add 60 parts of surface-modified antimony trioxide to 120 parts of ethanol and mix evenly, then add 30 parts of phosphate ester amine salt, heat up to 50-60°C, Stir for 30 minutes, then add 3 parts of aluminate coupling agent and 3 parts of organic copper salt heat stabilizer, heat up to 90-100°C and stir for 1 hour, then cool down to 60°C, add 10 parts of silane-modified halloysite nanotubes, Stir for 30 minutes, cool to room temperature, and grind to prepare a composite antimony trioxide flame retardant.

[0033] The phosphate ester amine salt is polymerized from pentaerythritol, phosphorus pentoxide and isobutyramide. The preparation method is: add 250g of pentaerythritol to 180g of ethanol and mix evenly, then add 100g of phosphorus pentoxide and stir at 50°C After 30 minutes, ethanol was distilled under pressure at room temperature to remove ethanol, and then 360 g of isobutyramide...

Embodiment 3

[0037] A preparation method of a composite antimony trioxide flame retardant is as follows: add 50 parts of surface-modified antimony trioxide to 80 parts of ethanol and mix evenly, then add 30 parts of phosphate ester amine salt, heat up to 50-60°C, Stir for 30 minutes, then add 2.4 parts of aluminate coupling agent and 3.5 parts of organic copper salt heat stabilizer, heat up to 90-100°C and stir for 1 hour, then cool down to 60°C, add 20 parts of silane-modified halloysite nanotubes, Stir for 30 minutes, cool to room temperature, and grind to prepare a composite antimony trioxide flame retardant.

[0038] The above amine phosphate salt is polymerized from pentaerythritol, phosphorus pentoxide and isobutyramide. The preparation method is: add 220g of pentaerythritol to 190g of ethanol and mix evenly, then add 100g of phosphorus pentoxide and stir at 50°C After 30 minutes, ethanol was distilled under pressure at room temperature to remove ethanol, then 280 g of isobutyramide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com