Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180results about How to "Low dimensional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of PTFE (polytetrafluoroethylene) copper-clad plate with high elastic modulus

InactiveCN102166852ALow dielectric constantLow elastic modulusGlass/slag layered productsMetal layered productsGlass fiberPolymer science

The invention provides a preparation method of a PTFE (polytetrafluoroethylene) copper-clad plate with a high elastic modulus, which comprises the following steps of: preparing copper foil and glass fiber cloth with a low dielectric constant, and preparing a fluororesin mixture; soaking the glass fiber cloth with the prepared fluororesin mixture, transferring the soaked glass fiber cloth into a baking oven for baking and drying, and repeating the steps to enable the glass fiber cloth to be soaked, baked and dried many times, thereby obtaining soaking pieces the resin content of which is about 60-70%; and superposing the soaking pieces, coating the copper foil on two sides, and laminating to obtain the PTFE copper-clad plate. The baking and drying process comprises three stages, wherein the temperature of the baking oven in the first stage is 50-100 DEG C, the temperature of the baking oven in the second stage is 200-320 DEG C, and the temperature of the baking oven in the third stage is 380-400 DEG C. The plate prepared by the method provided by the invention not only has a lower dielectric constant but also has a higher elastic modulus, and the plate has the advantages of consistent internal structure and good dimensional stability.

Owner:GUANGDONG SHENGYI SCI TECH

Polyether-type urethane acrylate UV-cured adhesive and preparation method thereof

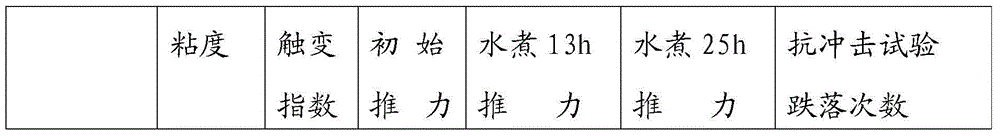

ActiveCN104531041AGood flexibilityExcellent heat and humidity resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveShock resistance

The invention belongs to the technical field of adhesives and relates to a polyether-type urethane acrylate UV-cured adhesive and a preparation method thereof. The polyether-type urethane acrylate UV-cured adhesive comprises, by weight, 20-70 parts of polyether-type urethane acrylate, 10-40 parts of auxiliary resin, 5-20 parts of ethylene-acrylate rubber, 5-40 parts of an acrylate monomer, 5-35 parts of isobornyl acrylate, 1-7 parts of a photoinitiator, 1-5 parts of fumed silica and 0.5-2 parts of a silane coupling agent. Through use of the polyether-type urethane acrylate, auxiliary resin, ethylene-acrylate rubber and acrylate monomer, the polyether-type urethane acrylate UV-cured adhesive has excellent long-term high temperature resistance, low temperature resistance, high temperature and high humidity resistance, excellent shock resistance and a low cost and can be prepared by simple processes.

Owner:信泰永合(烟台)新材料有限公司

Aluminium titanate-mullite-corundum sagger as well as preparation method and application thereof

The invention provides an aluminium titanate-mullite-corundum sagger as well as a preparation method and an application thereof and relates to the technical field of refractory materials. The aluminium titanate-mullite-corundum sagger mainly adopts aluminium titanate, mullite with specific grain size, corundum powder with specific grain size, titanium dioxide, alumina, magnesia powder and yellow dextrin as raw materials, and has the advantages of long service life and low use cost; besides, the raw materials are widely sourced and low in cost; the preparation method of the aluminium titanate-mullite-corundum sagger adopts simple technological steps, processing is simple and convenient, and the sagger has the advantages of low cost, high performance cost ratio and long service life. When the aluminium titanate-mullite-corundum sagger is applied to production of a lithium-ion battery cathode material, the production cost of ceramics can be effectively reduced due to the fact that the aluminium titanate-mullite-corundum sagger has the advantages of low cost, high performance cost ratio and long service life.

Owner:ZHEJIANG UNIV

Bio-based, insulating foam

There is disclosed a bio-based polyurethane foam useful as rigid insulation in which the reactant portion of the B side is composed of a transesterified and hydroxylated derivative of vegetable oil, preferably soy and or linseed oil; water and minor amounts of catalysts and surfactant. The vegetable oil is obtained by reacting the oil with a bio-based, multifunctional hydroxyl compound such as glycerol, sorbitol, or fructose. The A and B sides are admixed in weight proportions of 20 to 60 parts organic polyisocyanate (A side) and 80 to 40 parts polyol (B side) per 100 parts of finished insulation. Preferably a tin catalyst and an alkyl diethylene diamine cocatalyst are used to minimize cure time of the foam insulation.

Owner:NIEMANN LANCE K

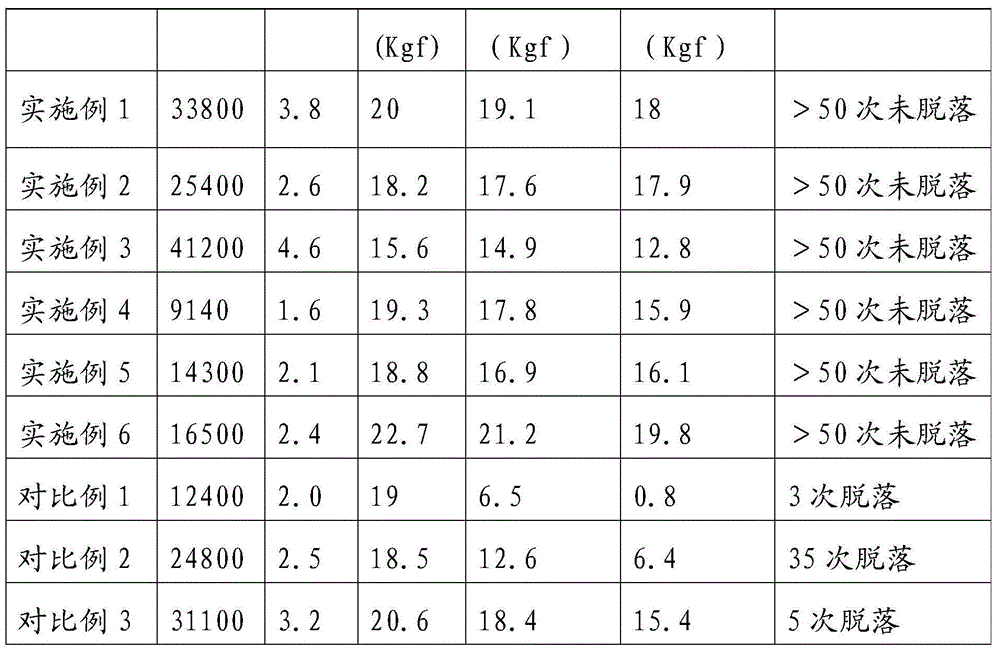

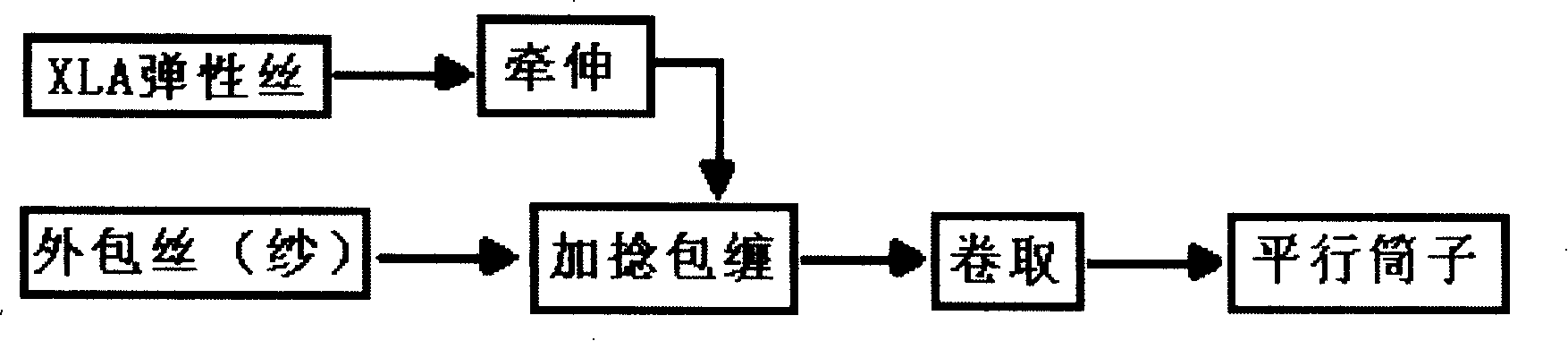

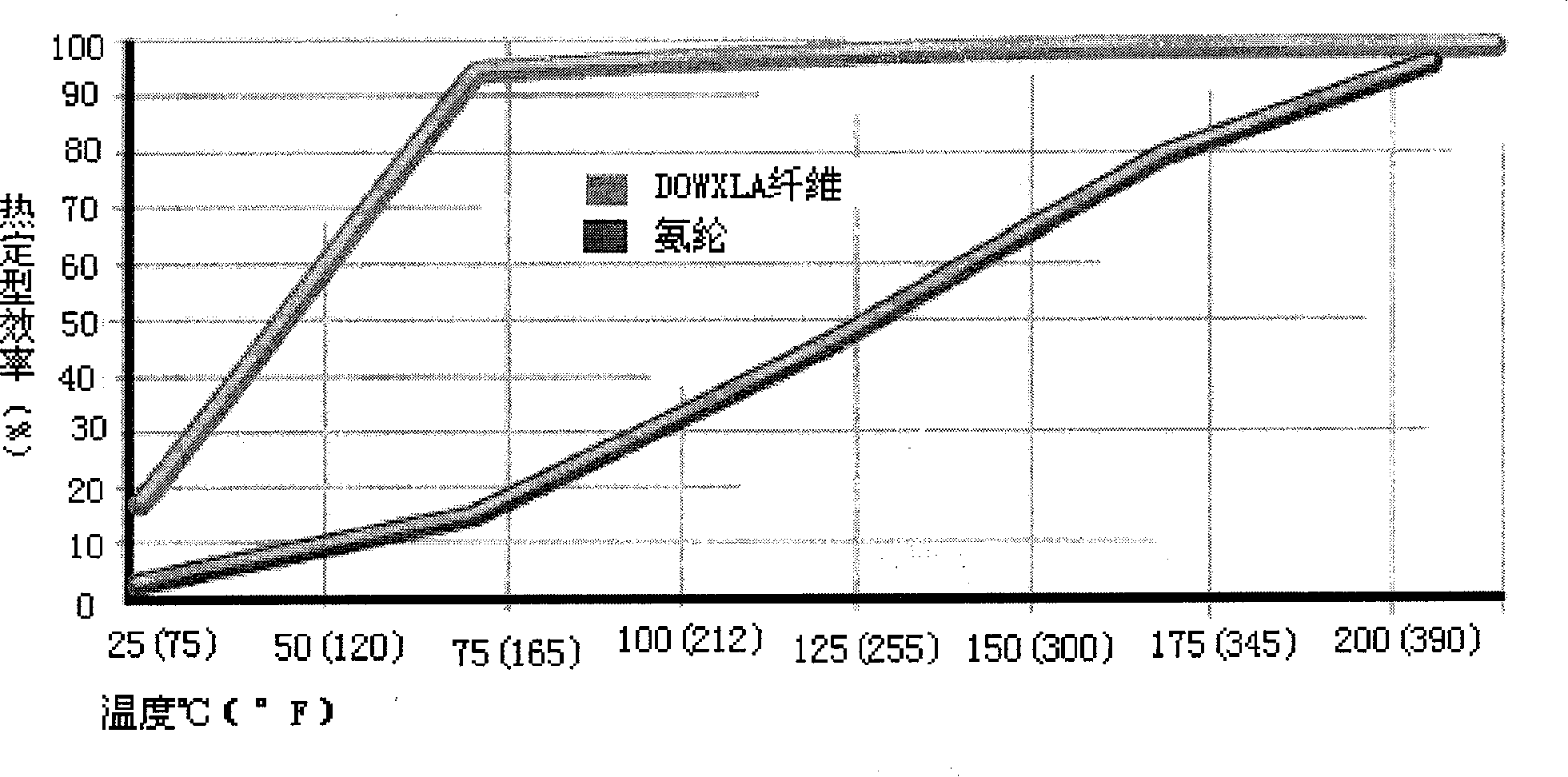

Manufacturing process for low-temperature shaped elastic coating yarn

InactiveCN101200825AImprove physicsGood chemical propertiesHeating/cooling textile fabricsYarnYarnPolyolefin

The invention discloses a low temperature setting elastic coating wire manufacturing process, in particular relates to a coating manufacturing process which implements the low temperature setting on polyolefin elastic filament fiber. The technological process of the invention is mainly divided into four parts of elastic wire feeding, tensile covering, relaxation coiling and the last lower temperature setting of textile. In every process step, specific process conditions are selected. Especially when the low temperature setting condition is selected, such as 60 or 70 DEG C, the setting of the elastic long fiber textile can be realized. At the same time, proper traction force, traction multiple, coating twist, winding speed, etc. are matched in the coating wire manufacturing process. The invention has the advantage that wearing fabrics with high quality can be produced under the effective energy saving condition. Fabric strength, heat setting property, etc. are well guaranteed. And the operation is more convenient. The invention can be widely applied to the preparation process of various high-grade fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

Preparation method of silica sol surface modified straw wood-plastic composite material

The invention discloses a preparation method of a silica sol surface modified straw wood-plastic composite material. The preparation method includes crushing and drying crop straws to obtain straw powders, using silica sol to soak the straw powders, drying the straw powders to obtain surface modified straw powders, mixing the surface modified straw powders, recycled plastics and other processing auxiliaries at a high speed, and then performing extrusion and granulation to obtain granules of the silica sol surface modified straw wood-plastic composite material. The prepared silica sol surface modified straw wood-plastic composite material is lower in water absorption rate and higher in strength, modulus, size stability and antiflaming performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Ammonia-free phenolic molding compound and its preparation method

The invention discloses an ammonia-free phenolic molding compound and its preparation method. The compound is composed of the following raw materials: 100 parts of phenolic resin, 30-50 parts of kaolin, 140-180 parts of glass fiber, 3-8 parts of eleaostearic acid, 10-20 parts of nitrile-butadiene rubber, and optionally a small amount of a curing accelerator, a pigment and other auxiliary agents. The preparation method consists of: mixing the above components uniformly and conducting heating melting, kneading, mixing and crushing, thus obtaining the ammonia-free phenolic molding compound in irregular particles. The ammonia-free phenolic molding compound prepared by the invention has good heat resistance, high mechanical strength, low molding shrinkage, and dimensional stability, and also has no ammonia gas release during production and compression molding, thus being environment-friendly.

Owner:WUXI CHUANGDA ELECTRONICS

Polyurethane-compounded cement-based expanded-perlite heat preservation plate and preparing method thereof

InactiveCN106116328AIncrease productivityGood dimensional stabilityCeramicwarePolyurethane adhesiveWeather resistance

The invention discloses a polyurethane-compounded cement-based expanded-perlite heat preservation plate and a preparing method thereof. The polyurethane composite cement-based expanded-perlite heat preservation plate is prepared from 50-100 parts of expanded perlite, 40-90 parts of cement, 5-10 parts of two-component polyurethane adhesive, 0.1-0.5 part of coupling agent, 0.1-0.25 part of fiber, 0.1-0.5 part of reusable dispersion emulsion powder, 40-90 parts of water, 0.5-2 parts of early strength agent and 0.1-0.5 part of water reducing agent. According to the polyurethane-compounded cement-based expanded-perlite heat preservation plate and the preparing method thereof, cement mortar is modified through polyurethane, polyurethane resin and the cement are evenly dispersed into the expanded perlite, hydration of the cement and solidification of polyurethane are carried out at the same time, and the mutually-filled whole structure is formed; the expanded perlite and the polyurethane cement-based composite are combined, and the polyurethane composite cement-based expanded-perlite heat preservation plate is prepared in a compression-molding mode; the defects of the expanded perlite are effectively overcome, and meanwhile the advantages and the like of the water resistance and heat preservation performance of the polyurethane material, the low heat conductivity of the expanded perlite, the high weather resistance of concrete and the liker are used.

Owner:ANHUI MINGYUAN NEW BUILDING MATERIAL TECH CO LTD

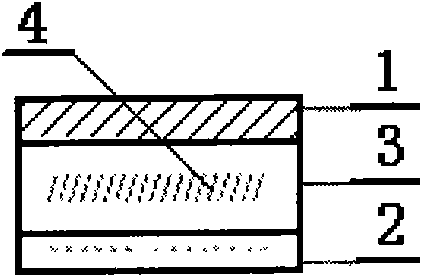

Support for Magnetic Recording Medium, and Magnetic Recording Medium

ActiveUS20090297888A1Good dimensional stabilityLittle unlikelyMagnetic materials for record carriersBase layers for recording layersPolyesterSurface resistivity

A magnetic recording medium substrate has a polyester film having metallic oxide-containing layers (layers M) formed on both the surfaces, one layer on each surface, the layers M having a thickness of 50 to 200 nm each, characterized in that the magnetic recording medium substrate has a total light transmittance of 0 to 75% and a surface resistivity of 1×102 to 1×1013Ω on each surface.

Owner:TORAY IND INC

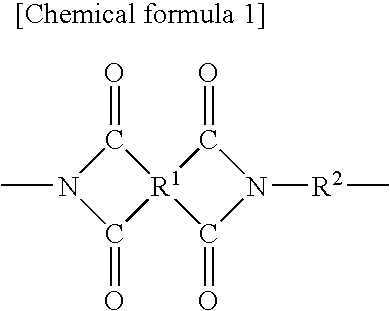

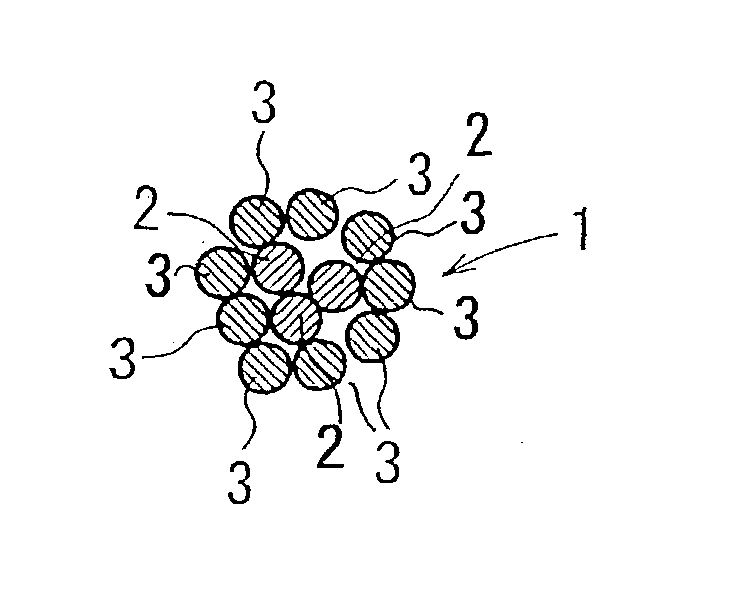

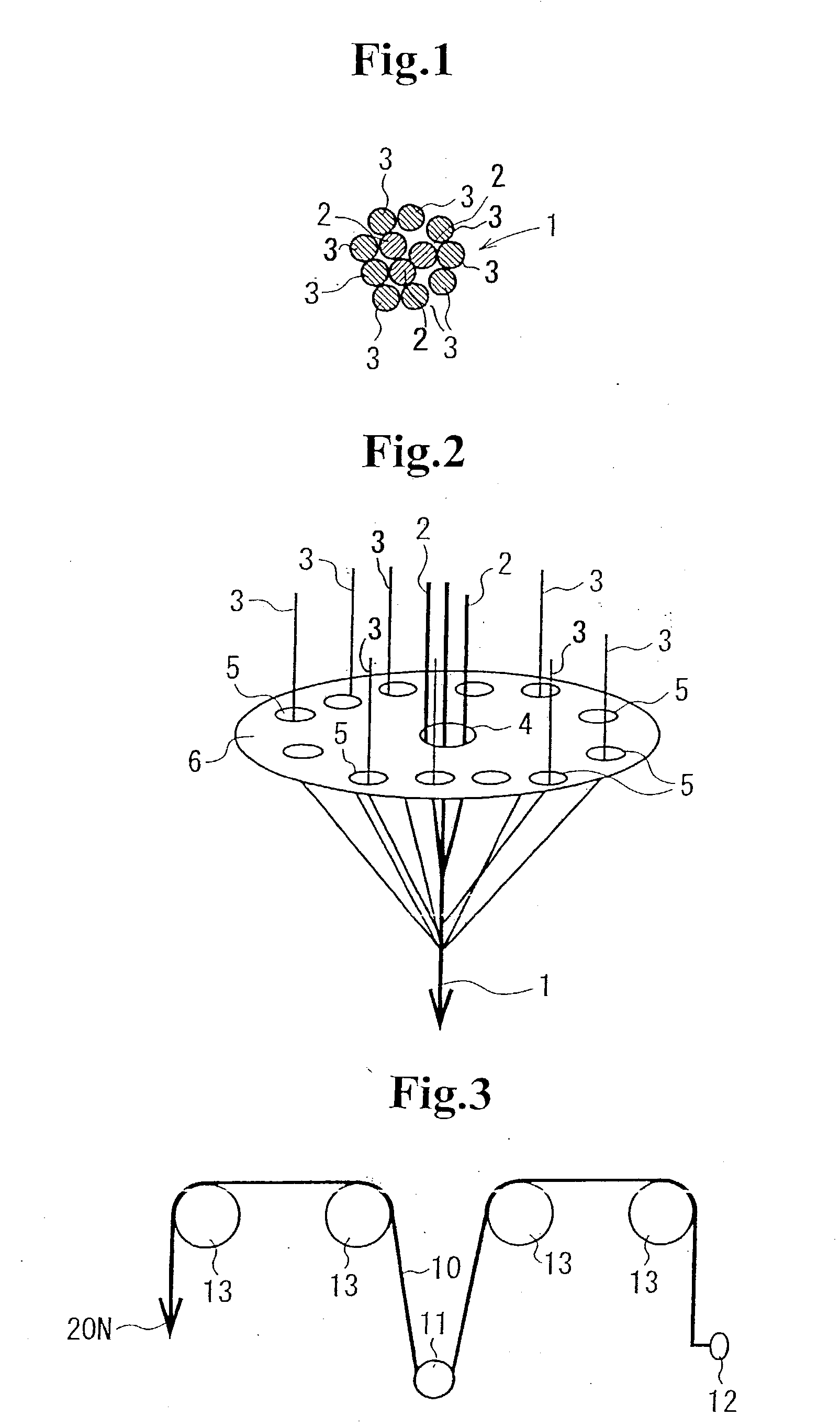

Hybrid cord and rubber product

InactiveUS20030175490A1Good dimensional stabilityReduce resistanceFibre typesSynthetic resin layered productsGlass fiberAramides

There is provided a hybrid cord having excellent dimensional stability and flexing resistance for use in a reinforcement of rubber, and a rubber product reinforced with the hybrid cord. The hybrid cord 1 has glass fiber strands 2 disposed at its center, and aramid fiber strands 3 disposed therearound. Glass fiber filaments applied with RFL treatment are bound to form the strands. A plurality of the strands are primarily twisted at a twisting rate of 1 to 10 turns / 25 mm. Aramid fiber filaments applied with RFL treatment are bound to form the strands. A plurality of the strands are primarily twisted at a twisting rate of 1 to 10 turns / 25 mm. The glass fiber strands 2 primarily twisted are disposed at a center, and the aramid fiber strands 3 are properly twisted in an opposite direction to the primary twist. The cord is overcoated to form a rubber coat.

Owner:NIPPON SHEET GLASS CO LTD

Entire-water polyurethane rigid foam, and preparation method and application thereof

The invention relates to an entire-water polyurethane rigid foam, and a preparation method and an application thereof. The entire-water polyurethane rigid foam comprises a first polyether polyol as araw material, the functionality of the first polyether polyol is 3-8, the hydroxyl value of the first polyether polyol is 50-400 mgKOH / g, and the viscosity of the first polyether polyol is 200-3500 mPa.s. The polyether polyol with proper functionality, molecular weight, hydroxyl value and viscosity is selected, and when the raw material is used for producing rigid foam, the foam has a better isocyanate index and a small foam density, the problem of foam shrinkage is avoided in the foaming process, the foam has good dimensional stability, and the viscosity of the system is effectively reduced in an all-water system without a physical foaming agent.

Owner:上海抚佳精细化工有限公司

High-performance synthetic rubber asphalt waterproof coiled material

ActiveCN102031833AImprove tensile propertiesGood flexibilityRoof covering using flexible materialsBuilding insulationsPolyesterWater leakage

The invention relates to a high-performance synthetic rubber asphalt waterproof coiled material with good high and low temperature resistance, high bonding strength, good air permeability, high surface tensile strength and capability of meeting the long-term water leakage-proof use requirement in a 'composite waterproof system'. The coiled material consists of an upper coverage layer, a lower coverage layer and a middle waterproof layer, wherein the upper coverage layer is made of polyethylene polypropylene fibers, a polyethylene film or a metal aluminum foil; the lower coverage layer is made of needled polyester non-woven fabric; and the middle waterproof layer is made of modified asphalt glue layer prepared from modified asphalt glue. The performance of the coiled material is improved by organically and comprehensively utilizing special functional materials, multiple macromolecules and inorganic materials, the waterproof performance of the coiled material is greatly improved, the cost of the coiled material is effectively reduced, the service life of the coiled material is reliably guaranteed, and the coiled material used with non-curing glue can make a substantial contribution to construction of a complete composite waterproof system, so the coiled material has obvious technical advancement and strong practicability.

Owner:上海北新月皇新材料集团有限公司 +1

Flexible metal laminate sheet

ActiveCN104220251ALow dielectric constantLow heat resistanceDielectric materialsCoatingsPolymer resinPolymer chemistry

The present invention relates to a flexible metal laminate sheet comprising a polymer resin layer including a polyimide resin having a specific structure and a fluorine-based resin. More fluorine-based resin is distributed on the inside of the polymer resin layer than at the surface of the polymer resin layer.

Owner:GUANGDONG SHENGYI SCI TECH

Ultrahigh-strength high-toughness multistep isothermal bainite steel and preparation method thereof

The invention relates to an ultrahigh-strength high-toughness multistep isothermal bainite steel and a preparation method thereof. The technical scheme of the invention is as follows: a hot-rolled steel billet is austenitized 0.2-5.0 hours at a temperature of 850-1100 DEG C firstly, and then the steel billet is subjected to bainite multistep isothermal transformation, so that an ultrahigh-strength high-toughness multistep isothermal bainite steel is obtained. The multistep isothermal transformation is implemented through the following steps: 1, carrying out heat preservation 0.2-3.0 hours in an isothermal medium at a temperature of 250-450 DEG C; 2, carrying out heat preservation 2-50 hours in the isothermal medium at a temperature of 220-350 DEG C; 3, carrying out heat preservation 24-240 hours in the isothermal medium at a temperature of 180-250 DEG C; and 4, carrying out heat preservation 50-360 hours in the isothermal medium at a temperature of 150-220 DEG C, and cooling the obtained product to room temperature, wherein the multistep refers to step 1 to step 2, or step 1 to step 3, or step 1 to step 4. The bainite steel prepared by using the method disclosed by the invention has the characteristics of high hardness, high strength, high toughness, good volume stability and fine microstructure.

Owner:WUHAN UNIV OF SCI & TECH

Corrosion resistant metal coating for gear box inner surface

ActiveCN106498291AStable austenite phaseImprove hardenabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCorrosion resistantMetal coating

The invention discloses a corrosion resistant metal coating for a gear box inner surface. The corrosion resistant metal coating comprises the following components by mass percentage: 0.03-0.05% of C, 0.45-0.48% of Mn, 12.76-12.79% of Cr, 6.12-6.15% of Ni, 0.16-0.18% of Mg, 0.22-0.25% of Mo, 0.27-0.29% of Co, 0.26-0.28% of V, 0.22-0.24% of Ti, 0.21-0.23% of Na, 0.12-0.15% of Ga, 0.32-0.35% of Eu, 0.12-0.14% of Lu, 0.62-0.68% of La, and the balance Fe.

Owner:南京创贝高速传动机械有限公司

Wear-resistant high-impact-resistance nylon composite material, and preparation method and application thereof

The invention relates to a wear-resistant high-impact-resistance nylon composite material which comprises the following components in parts by weight: 20-80 parts of nylon resin, 10-50 parts of fiber material, 10-40 parts of anti-wear agents, 0.1-2 parts of surface treating agent perfluoropolyether, 0.1-1.0 part of lubricant and 0.1-0.6 part of antioxidant. The preparation method comprises the following steps: uniformly mixing different types of anti-wear agents at medium speed; heating to 90-100 DEG C, adding the perfluoropolyether, and uniformly mixing at high speed; adding the nylon resin, lubricant and antioxidant, and continuing mixing uniformly; and carrying out melt blending extrusion, drawing, cooling, and granulation on the obtained mixture and fiber material through a double screw extruder, thereby obtaining the wear-resistant high-impact-resistance nylon composite material. The wear-resistant high-impact-resistance nylon composite material has the advantages of low friction factor, favorable wear resistance, high mechanical strength, favorable heat resistance, excellent toughness, excellent impact resistance, low mold shrinkage rate, favorable dimensional stability, favorable flowability and high processability.

Owner:株洲时代工程塑料实业有限公司

Flame retardants which contain phosphorus, and flame-retardant thermoplastic molding compositions

InactiveUS7019056B2Low dimensional stabilityGood dimensional stabilityNanostructure manufacturePhosphorus organic compoundsFire retardantToughness

An oligophosphate of general formula is disclosed. The oligophosphate is suitable as a flame retardant for thermoplastic molding compositions that exhibit a good flame-retardant effect, improved dimensional stability under the effect of heat, a good level of toughness and excellent flowability.

Owner:COVESTRO DEUTSCHLAND AG

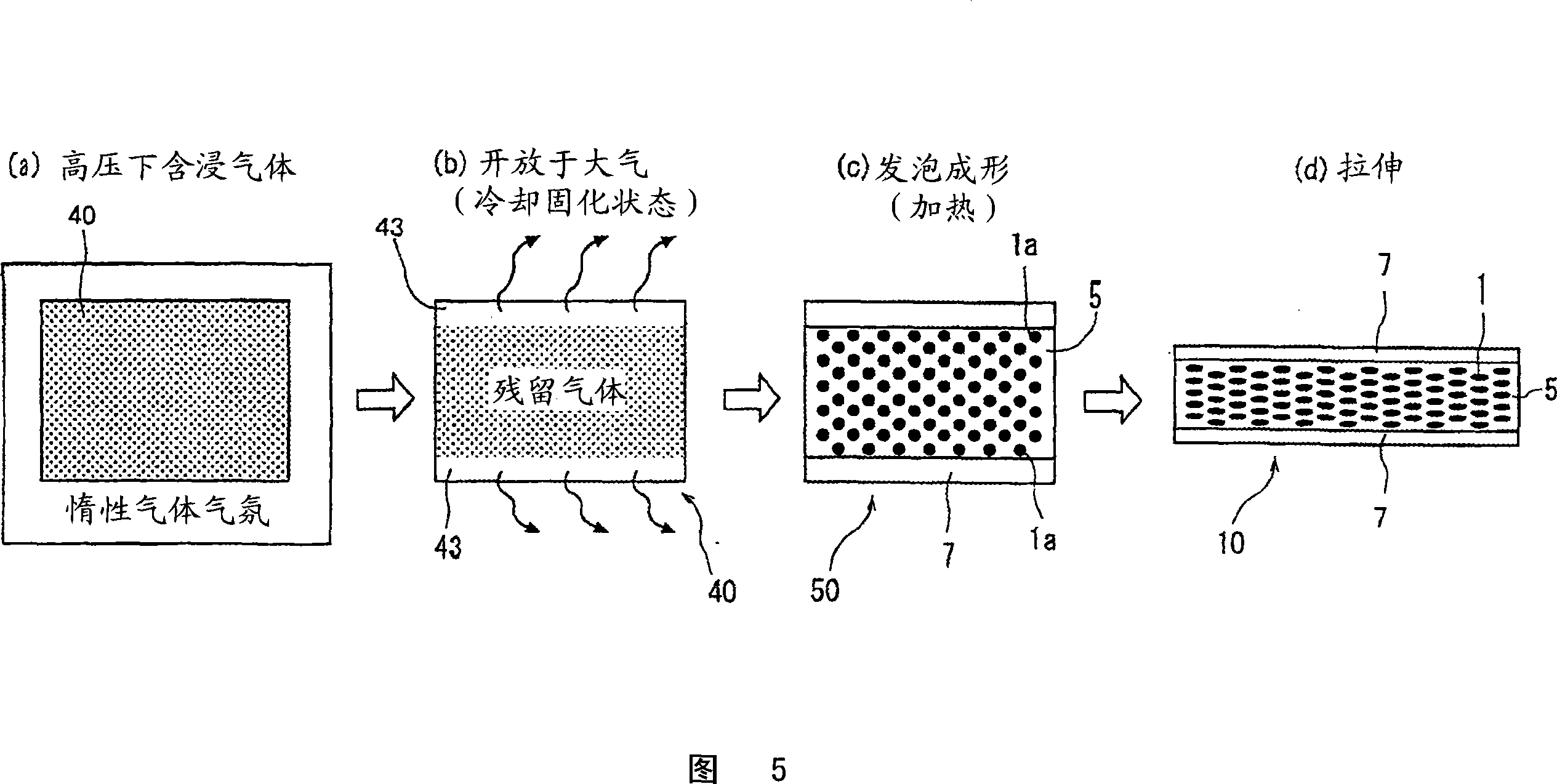

Plastic container having pearl-like appearance and process for producing the same

This invention provides a plastic container characterized in that an expanded layer comprising expanded cells having a flat shape with an average major axis of not more than 400 [mu]m and an average aspect ratio (L / t) of not less than 6 as viewed in cross section of the container wall along the maximum stretch direction, which are oriented in the stretch direction and are distributed so as to be superimposed on top of each other in the thickness-wise direction, is formed within the container wall. In this container, expanded cells having a flat shape are distributed so as to orient in a given direction and, thus, has light shielding properties and has a pearl-like appearance, that is, has a very high commercial value. Further, since any colorant is not contained, the suitability for recycling is also excellent.

Owner:TOYO SEIKAN KAISHA LTD

Corrosion-resistant metal coating used for outer surface of gear box

ActiveCN106498290AImprove corrosion resistanceImprove antistatic performanceNon-macromolecular adhesive additivesFilm/foil adhesivesMetal coatingCorrosion resistant

The invention discloses a corrosion-resistant metal coating used for the outer surface of a gear box. The corrosion-resistant metal coating comprises, by mass, 0.06%-0.08% of C, 0.15%-0.18% of Mn, 10.76%-10.79% of Cr, 2.12%-2.15% of Ni, 0.13%-0.15% of Mg, 0.21%-0.23% of Mo, 0.25%-0.27% of Co, 0.06%-0.08% of V, 0.42%-0.44% of Ti, 0.22%-0.25% of Na, 0.17%-0.19% of Ga, 0.22%-0.25% of Ce, 0.16%-0.18% of Nd, 0.32%-0.38% of La and the balance Fe.

Owner:南京创贝高速传动机械有限公司

Herringbone surface decorative material and manufacturing method thereof

ActiveUS20180029407A1Easy to manufactureQuick installationCovering/liningsDecorative surface effectsBiomedical engineeringBoundary line

Owner:FLOORING IND LTD

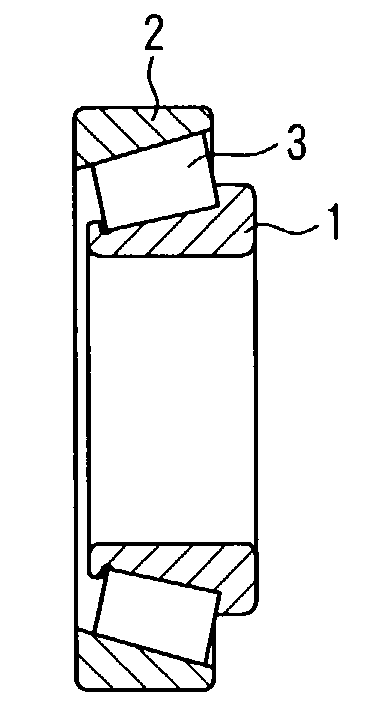

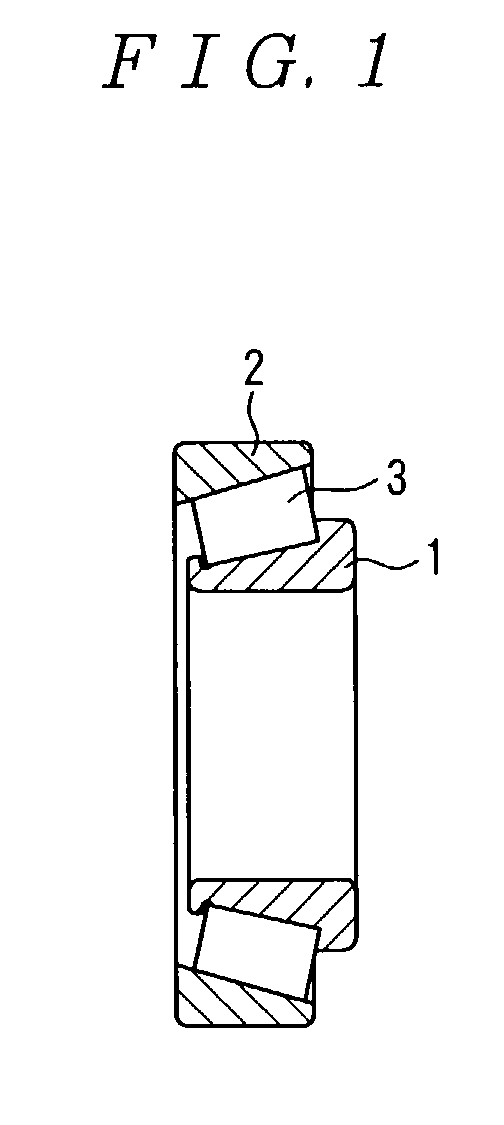

Rolling bearing

InactiveUS20030123770A1Low dimensional stabilityAvoid excessRoller bearingsBall bearingsLubricationNitrogen

A rolling bearing intended for longer life by improving seizure resistance and wear resistance in the circumstance with slip contact or in the circumstance where lubricant tends to be exhausted, which is manufactured by applying carburization or carbonitridation to an Si-added material to disperse and precipitate carbides or carbonitrides containing Si or Si-X (X=one or more of Mn, Mo, and Cr) thereby improving the seizure resistance and the wear resistance by the self-lubrication effect thereof, the size of the carbides or carbonitrides being preferably 10 mum or less for preventing flaking, and the area ratio for the carbides or carbonitrides being preferably 1.0-30% for obtaining sufficient self-lubrication effect.

Owner:NSK LTD

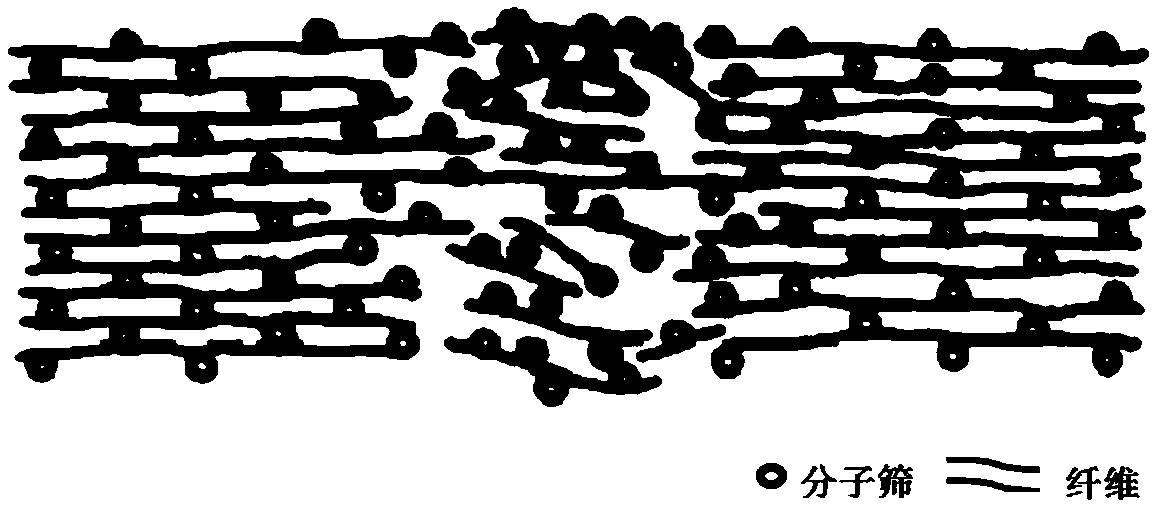

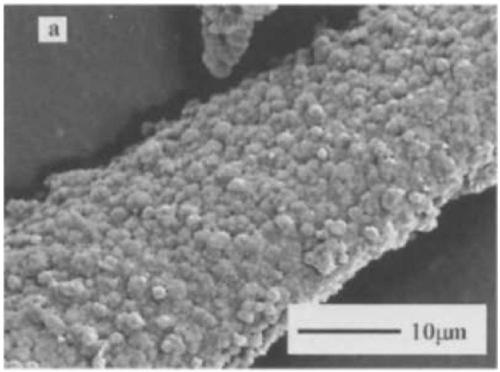

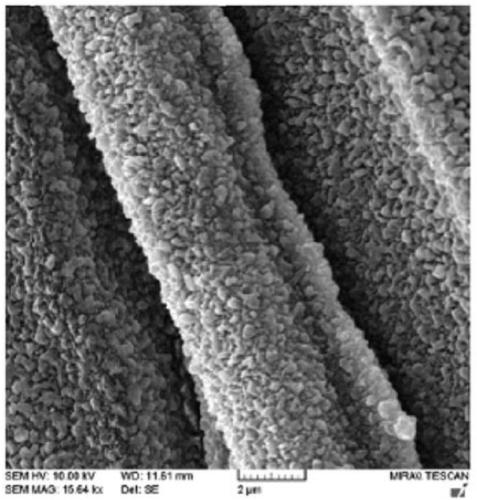

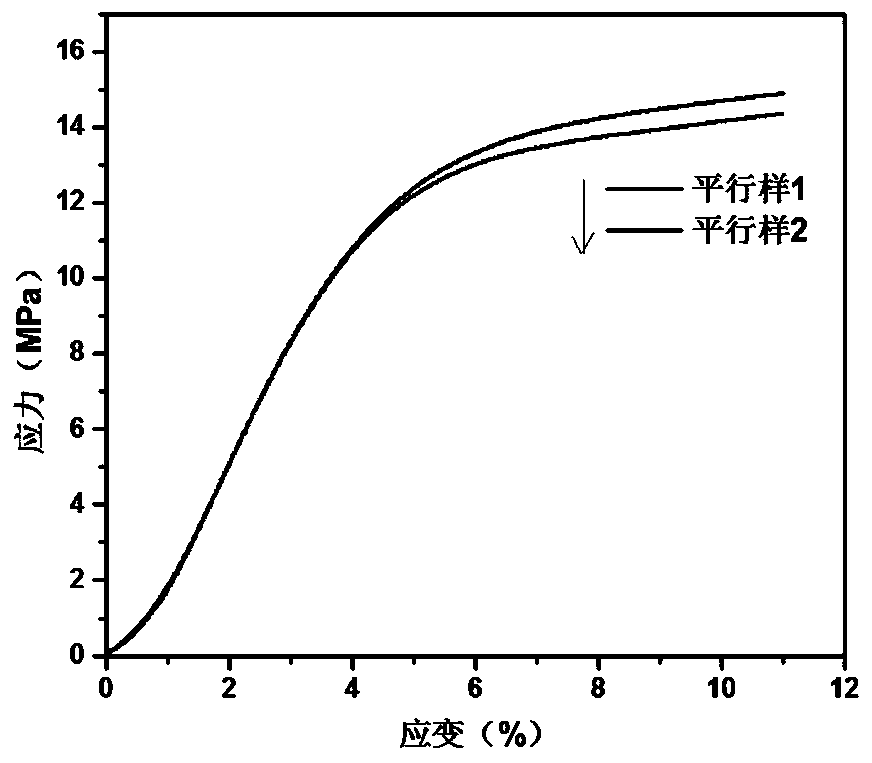

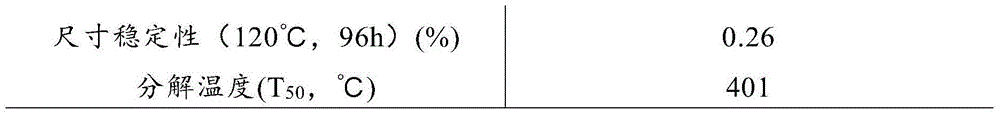

Molecular sieve/fiber composite material and preparation method therefor

ActiveCN109851858ASolve the clogging defectHigh strengthSuture equipmentsSurgical adhesivesMolecular sieveChemical physics

The invention provides a molecular sieve / fiber composite material. The molecular sieve / fiber composite material comprises molecular sieves and fibers, wherein the molecular sieves are distributed on surfaces of the fibers and are in contact with the surfaces of the fibers directly, the particle size D90 of the molecular sieves is 0.01 to 50 microns, and the particle size D50 of the molecular sieves is 0.005 to 30 microns; and the molecular sieves are uniformly distributed on the surfaces of the fibers. The invention further provides a preparation method for the molecular sieve / fiber compositematerial and various uses of the molecular sieve / fiber composite material. According to the molecular sieve / fiber composite material, the preparation method therefor and various uses of the molecularsieve / fiber composite material, the problem of molecular sieve / fiber composite materials that molecular sieves are gathered on surfaces of fibers is solved for the first time, the molecular sieve / fiber composite material prepared is bran-new and has relatively high strength, elasticity restorability and dimensional stability, and thus, the composite material is firm and durable. The molecular sieve / fiber composite material provided by the invention is simple in structure, low in cost, high in stability, high in performance repeatability and high in practical efficiency and can be applied to the fields of arresting bleeding, facial beautification, deodorization, sterilization, water purification, air purification and antiradiation.

Owner:杭州沸创生命科技股份有限公司

Transparent drop-out fuse

ActiveCN102054638AImprove performanceImprove creep resistanceProtective switch operating/release mechanismsTungstenEngineering

The invention discloses a transparent fuse. The fuse comprises an upper base plate, an insulator upper hardware fitting, an insulator, a mounting plate, an insulator lower hardware fitting, a lower base plate, a lower tension disc, a fusion tube lower copper cap, a fusion tube lower hardware fitting, a fusion tube, a fuse, a fusion tube upper hardware fitting, a pressure relief cap, a static contact plate, a spring and an upper tension disc, wherein the mounting plate is arranged in the middle of the insulator; a fusion tube outer sleeve is sleeved on the fusion tube, and the lower end of thefusion tube is sleeved and fixed in the fusion tube lower hardware fitting, and the upper end of the fusion tube is sleeved and fixed in the fusion tube upper hardware fitting with a hook. The transparent fuse is characterized in that a transparent umbrella is sleeved on the insulator; the transparent fusion tube outer sleeve is sleeved on the fusion tube; 0 to 4 slotted holes are arranged in themiddle section of the fusion tube; tungsten-copper is welded on the fusion tube upper copper cap; and tungsten-copper contacts are welded at the bottom of the pressure relief cap. The fuse can be used for quickly and visually detecting and determining whether the fuse is fused or not, so that the transparent fuse can be repaired in time to ensure safe operation of the transmission circuit. The fuse has low production cost, high standard degree, high product quality, high mechanical strength and long service lie, and can meet the requirement on high, medium and low voltage circuit fuses.

Owner:蔡彭博

Optical plate, display device having the optical plate, and method of manufacturing the optical plate

InactiveUS20090180053A1Low dimensional stabilityComplicated to manufacturePrismsOptical articlesVitrificationSurface layer

An optical plate includes a core layer and a surface layer. The surface layer is disposed on at least one surface of the core layer and includes a plurality of prism patterns. The core layer and the surface layer have different glass transition temperatures.

Owner:SAMSUNG DISPLAY CO LTD

Lightweight and high-strength high-molecular material and preparation method thereof

The invention provides a lightweight and high-strength high-molecular material and a preparation method thereof. The preparation system of the material comprises a continuous phase and a dispersion phase; and the continuous phase comprises a gelling agent and an oil phase reactant, and does not include n-octyltriethoxysiloxane, wherein the oil phase reactant is one or more of styrene, methyl methacrylate, an epoxy resin prepolymer and a polyurethane prepolymer. N-octylsiloxane is avoided, so 95% or more of the prepared material is a closed-cell structure, the water absorption rate is small, the heat insulation performance is good, and the mechanical properties and the heat insulation performance of the material are improved.

Owner:SHAANXI NORMAL UNIV

Preparation method of rigid foam flame-retardant polyether polyol for all-water foaming

The invention belongs to the technical field of polyurethane synthesis, and in particular relates to a preparation method of a rigid foam flame-retardant polyether polyol for all-water foaming. The preparation method uses sucrose, a low-molecular-weight polyol, a halogenated alcohol, phenolic resin, and oil as initiators, and uses an alkali metal salt as a catalyst, and a section of propylene oxide is introduced for carrying out a reaction; and after the reaction is completed, a mixture of propylene oxide and ethylene oxide is introduced for carrying out a mixed polymerization reaction, and acrude ether is purified by post-treatment to obtain a finished product. The technological process is simple in operation, the obtained rigid foam flame-retardant polyether product for all-water foaming has low viscosity and good compatibility with water, a polyurethane foam plastic product prepared from the polyether product has relatively narrow density distribution, relatively high strength, good dimensional stability and bonding strength, and relatively low thermal conductivity, has certain flame-retardant effects, and is especially suitable for all-water foamed thermal insulation pipes andother thermal insulation fields.

Owner:BEFAR GROUP CO LTD +1

High and low temperature resistant PPR (Polypropylene Random) pipe with aluminum metal effect

The invention relates to a high and low temperature resistant PPR (Polypropylene Random) pipe with an aluminum metal effect. The PPR pipe is prepared from the following components in parts by weight:100 parts of PPR, 10 to 25 parts of aluminite powder, 8 to 18 parts of dispersing agent, 3 to 8 parts of soft-core hard-shell type core-shell copolymer, 5 to 10 parts of butadiene styrene rubber, 5 to10 parts of carbon fiber, 3 to 8 parts of aciform wollastonite fiber, 1 to 3 parts of coupling agent, and 1.5 to 3 parts of antioxygen. The PPR pipe provided by the invention has a uniform aluminum metal effect, good low-temperature toughness and good heat resistance.

Owner:江西陈氏科技集团股份有限公司

Machining process for thin-wall aluminum volute

The invention discloses a machining process for a thin-wall aluminum volute. The machining process comprises the following steps: 1) selecting a rough machining reference; 2) machining a reference surface and a thread hole; 3) installing a base fixture; 4) roughly machining a hole, an end surface and the thread hole; 5) carrying out heat treatment; 6) finely milling the end surface; and 7) finelyboring an inner hole. The machining process disclosed by the invention is definite in reference, convenient to clamp, and high in machining efficiency and dimensional stability, only needs vertical machining centre equipment, and is especially applicable to machining for the thin-wall aluminum volute.

Owner:SHIJIAZHUANG KINGSTON BEARING TECH

Polyamide resin and preparation method thereof and polyamide material prepared from same

ActiveCN106188534AAdequate thermal stabilityImprove thermo-oxidative stabilityPolyamideGlass transition

The invention discloses polyamide resin and a preparation method thereof and a polyamide material prepared from the same. The polyamide resin is prepared from fluorine-containing aromatic dicarboxylic acid or a mixture of the fluorine-containing aromatic dicarboxylic acid and conventional aromatic diacid and one or more of diamine containing an alicyclic structure. The polyamide resin and other auxiliaries are mixed through a double-screw extruder technology to prepare the polyamide material. The prepared resin and material have good transparency, and the visible light transmittances of resin and material sheets of 1 mm both exceed 90%; meanwhile, the resin and material have excellent heat resistance, thermal-oxidation stability and low water absorption property, the glass-transition temperature of the resin and the glass-transition temperature of the material are both larger than 200 DEG C, good optical property and chemical property still can be kept after long-time usage at 150 DEG C, and the polyamide material can serve as a transparent material suitable for being used under higher temperature occasions.

Owner:WANHUA CHEM GRP CO LTD

Rigid polyurethane foam and preparation method thereof

The invention discloses a rigid polyurethane foam and a preparation method thereof. The preparation method of the rigid polyurethane foam comprises the following steps: premixing 100 parts by weight of hyperbranched polyurethane polyol with 1-10 parts by weight of foam stabilizer, adding 100-250 parts by weight of organic isocyanate or modified isocyanate to the pre-mixture and then curing at 30-100 DEG C for 12 hours to 3 days, thus obtaining the rigid polyurethane foam, wherein the hyperbranched polyurethane polyol is prepared by use of the following steps: reacting a polyhydroxylated compound with a diisocyanate monomer to obtain a first-generation hyperbranched prepolymer; on the basis of the isocyanate group content of the first generation hyperbranched prepolymer, adding the polyhydroxylated compound again and reacting to obtain the hyperbranched polyurethane polyol. The rigid polyurethane foam prepared by use of the method is high in strength, good in temperature resistance, good in dimensional stability and low in heat conductivity coefficient, and can be applied to the fields of thermal insulation, gap filling and supporting, wood-imitation materials and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com