Lightweight and high-strength high-molecular material and preparation method thereof

A polymer material and high-strength technology, applied in the field of lightweight materials, can solve the problems of affecting mechanical properties, dimensional stability and stability of mechanical properties, and limited mechanical properties of materials, so as to achieve uniform pore distribution and simple and green preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

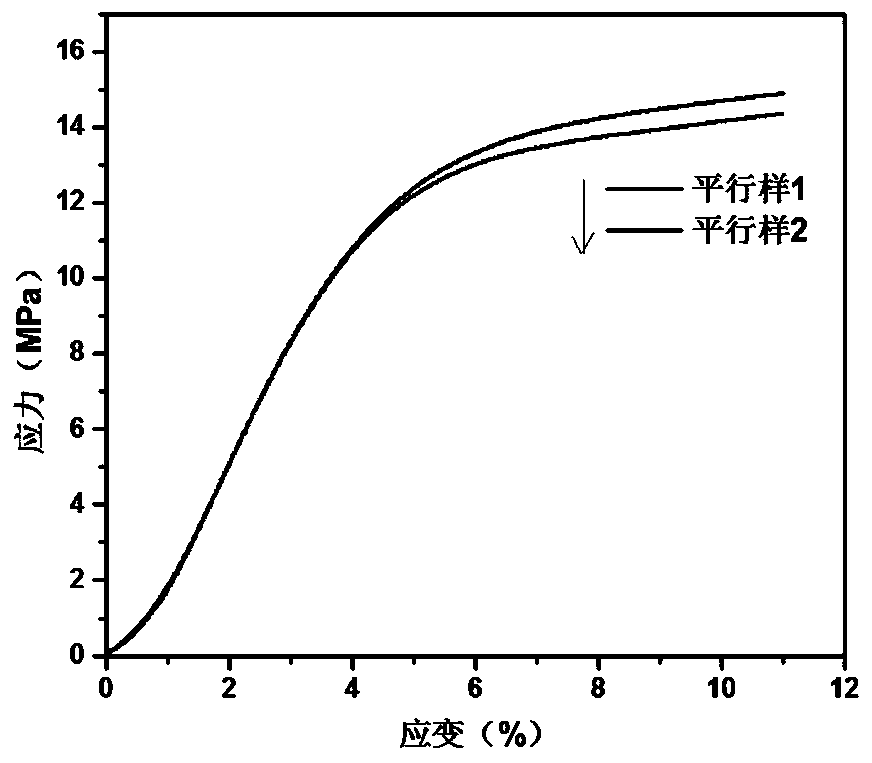

Examples

preparation example Construction

[0050] Its preparation method comprises the following steps:

[0051] 1. Preparation of soft template

[0052] Under normal temperature and pressure, add a certain amount of gelling agent, oil phase reactive monomer, oil phase crosslinking agent and initiator into a suitable container, stir and shake evenly, and then add the dispersed phase to emulsify to form a uniform, fine, inverted No runny gel lotion. Wherein the volume ratio of continuous phase and dispersed phase is (8.5~1.5):(1.5~8.5);

[0053] Alternatively, add the gelling agent, oil phase prepolymer and curing agent into a suitable container, stir and oscillate evenly, and then add the dispersed phase for emulsification to form a uniform, delicate, inverted and non-flowing gel emulsion. Wherein the volume ratio of continuous phase and dispersed phase is (8.5~1.5):(1.5~8.5);

[0054] Alternatively, add the gelling agent, oil phase reactant, oil phase crosslinking agent, initiator and curing agent into a suitable c...

Embodiment 1

[0058] Add 2.75 mg of dicholesterol derivatives, 550 μL of styrene, 27.5 μL of tripropenyl isocyanurate, 82.5 μL of hexanediol diacrylate and 2.75 mg of azobisisobutyronitrile into the test tube, shake evenly on a shaker, Add 3740 μL of water and oscillate on a vortex shaker to form a uniform, inverted and non-flowing milky white gel emulsion system. Seal the test tube opening with the gel emulsion system, react in a water bath at 30°C for 12 hours, and warm at 60°C. Dry in an oven for 24 hours to obtain a density of 0.15±0.01g / cm 3 of lightweight polystyrene. The compression strength of this lightweight polystyrene is 3MPa, the compression modulus is 75MPa, the flexural strength is 3.5MPa, the flexural modulus is 130MPa, and the shear strength is 2.3 MPa.

Embodiment 2

[0060] Add 220 mg of sodium lauryl sulfate, 550 μL of styrene, 55 μL of methyl methacrylate, 18.2 μL of pentaerythritol tetraacrylate, 60.5 μL of tripropenyl isocyanurate, and 12.1 mg of azobisisobutyronitrile into the test tube. Shake evenly on the oscillator, add 5245 μL of sodium bicarbonate aqueous solution with a pH value of 10 and shake on the vortex shaker to form a uniform milky white gel emulsion system that is inverted and does not flow, and seal the test tube mouth with the gel emulsion system , reacted in a water bath at 60°C for 6h, dried in a warm oven at 50°C for 24h, and obtained a density of 0.15±0.01g / cm 3 A lightweight polystyrene-methyl methacrylate copolymer. The compressive strength of this lightweight high-strength material is 2.7MPa, the compressive modulus is 58MPa, the flexural strength is 3.4MPa, the flexural modulus is 130MPa, and the shear strength is 2.3MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com