Flexible metal laminate sheet

A flexible metal and laminate technology, applied in the direction of metal layered products, coatings, layered products, etc., can solve the problems of poor adhesion strength, inability to apply flexible copper foil, copper foil line peeling, etc., to achieve the difference Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

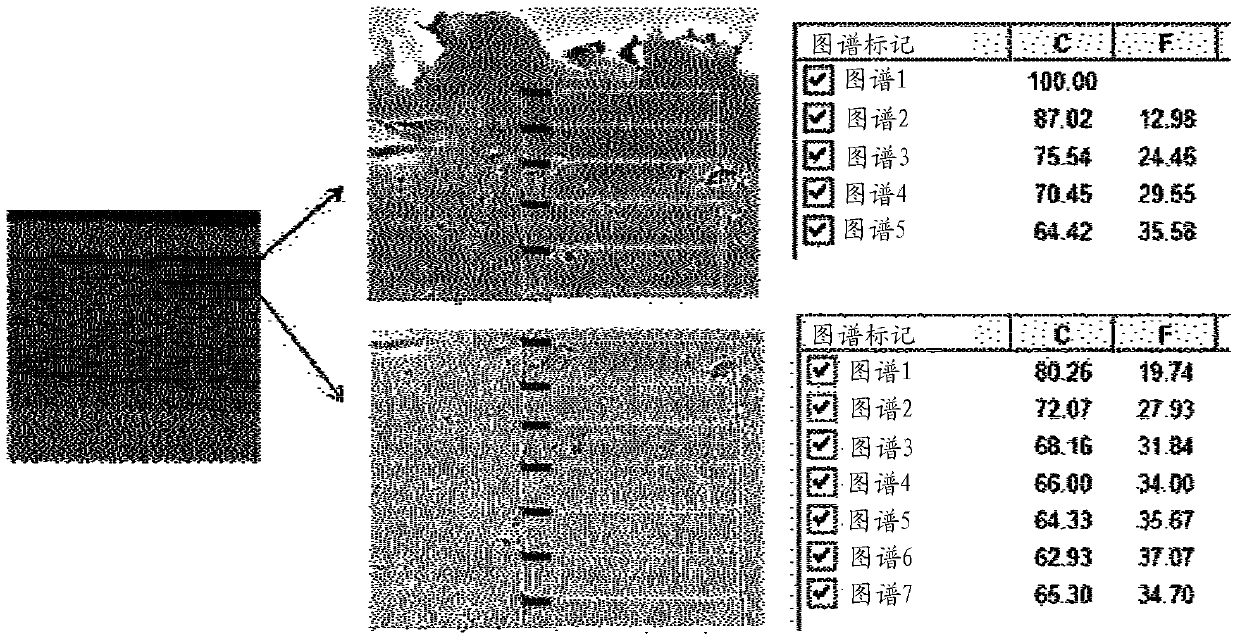

Image

Examples

preparation Embodiment 1

[0112] Preparation Example 1: Preparation of Polyamic Acid Solution (P1) Containing Fluororesin

[0113] Fill a 1 L polyethylene (PE) bottle with nitrogen gas and add 765 g of dimethylacetamide (DMAc), 219 g of polytetrafluoroethylene (PTFE) fine powder (particle size: 0.1 μm to 2.0 μm), 10.95 After g of polyester-based polymer [acid value: 26 mg KOH / g, alkali equivalent: 1200] as a dispersant and 765 g of beads with a diameter of 2 mm, the resulting mixture was stirred in a high-speed ball mill to disperse PTFE. In a 500mL round bottom flask, put 80g of the solution dispersed with PTFE, 107g of dimethylacetamide, 1.852g of 3,4,3',4'-biphenyltetracarboxylic dianhydride, 12.355g pyromellitic dianhydride, 5.453g of 2,2'-dimethyl-4,4'-diaminobiphenyl, 12.340g of 2,2'-bis(trifluoromethyl)-4,4' - After diaminobiphenyl, the mixture was stirred with a stirrer, and reacted at 50° C. for 10 hours while blowing nitrogen gas thereinto, to obtain a polyamic acid solution (P1) having a ...

preparation Embodiment 2

[0114] Preparation Example 2: Preparation of Polyamic Acid Solution (P2) Containing Fluororesin

[0115] Fill a 1 L polyethylene (PE) bottle with nitrogen gas and add 765 g of dimethylacetamide (DMAc), 219 g of polytetrafluoroethylene (PTFE) fine powder (particle size: 0.1 μm to 2.0 μm), 10.95 After g of polyester-based polymer [acid value: 26 mg KOH / g, alkali equivalent: 1200] as a dispersant and 765 g of beads with a diameter of 2 mm, the resulting mixture was stirred in a high-speed ball mill to disperse PTFE. In a 500mL round bottom flask, put 73g of the solution dispersed with the PTFE, 115g of dimethylacetamide, 11.609g of pyromellitic dianhydride, 17.391g of 2,2'-bis(trifluoroform base)-4,4'-diaminobiphenyl, the mixture was stirred with a stirrer, and reacted at 50° C. for 10 hours while blowing nitrogen thereinto, to obtain a polyamic acid solution having a viscosity of about 100,000 cps (P2).

preparation Embodiment 3

[0116] Preparation Example 3: Preparation of Polyamic Acid Solution (P3) Containing Fluororesin

[0117] Fill a 1 L polyethylene (PE) bottle with nitrogen gas and add 765 g of dimethylacetamide (DMAc), 219 g of polytetrafluoroethylene (PTFE) fine powder (particle size: 0.1 μm to 2.0 μm), 10.95 After g of polyester-based polymer [density (20° C.): 1.13 g / ml] as a dispersant and 765 g of beads with a diameter of 2 mm, the resulting mixture was stirred in a high-speed ball mill to disperse PTFE.

[0118] In a 500mL round bottom flask, put 80g of the solution dispersed with the PTFE, 107g of dimethylacetamide, 13.937g of pyromellitic dianhydride, 5.536g of 2,2'-dimethyl-4 , 4'-diaminobiphenyl (m-TB-HG), 12.527 g of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl, the mixture was stirred with a stirrer, And reacted at 50° C. for 10 hours while blowing nitrogen gas thereinto, to obtain a polyamic acid solution (P3) having a viscosity of about 20,000 cps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com