Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Low defect content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene dispersing agent, preparation method thereof and preparation method of graphene

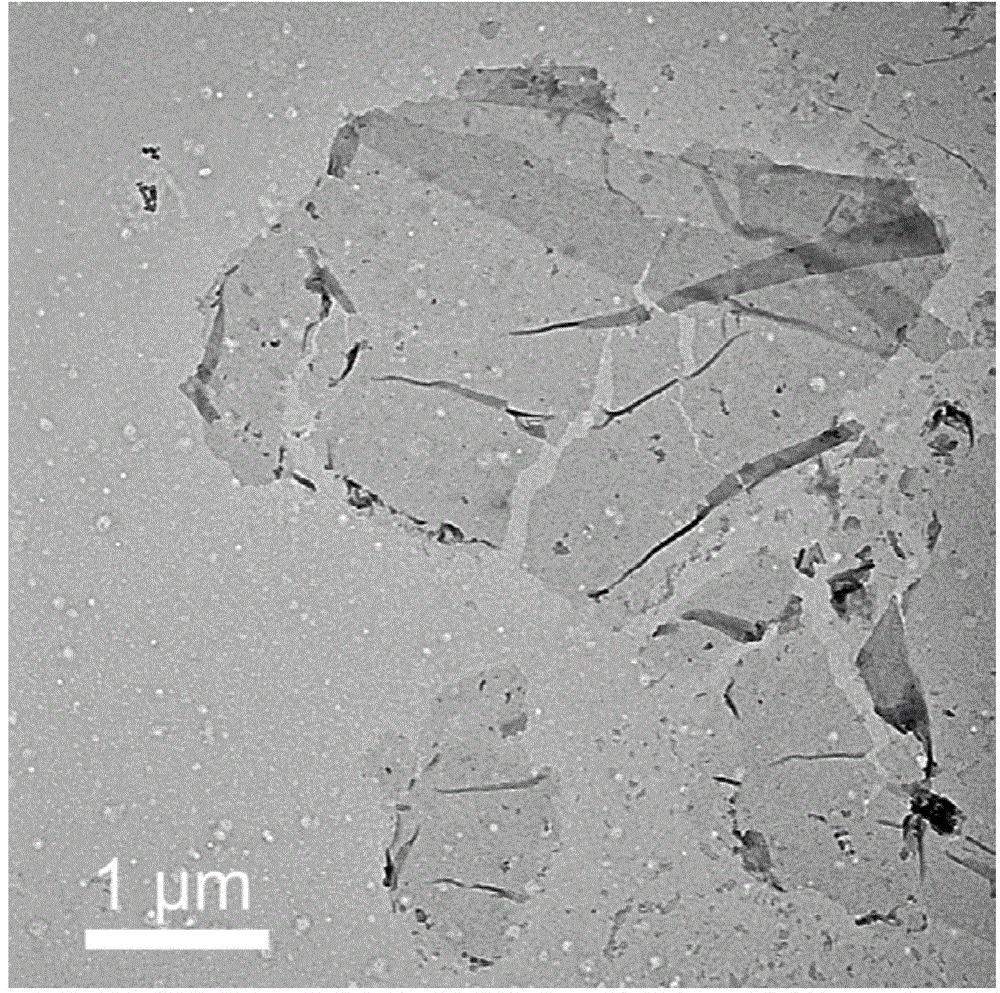

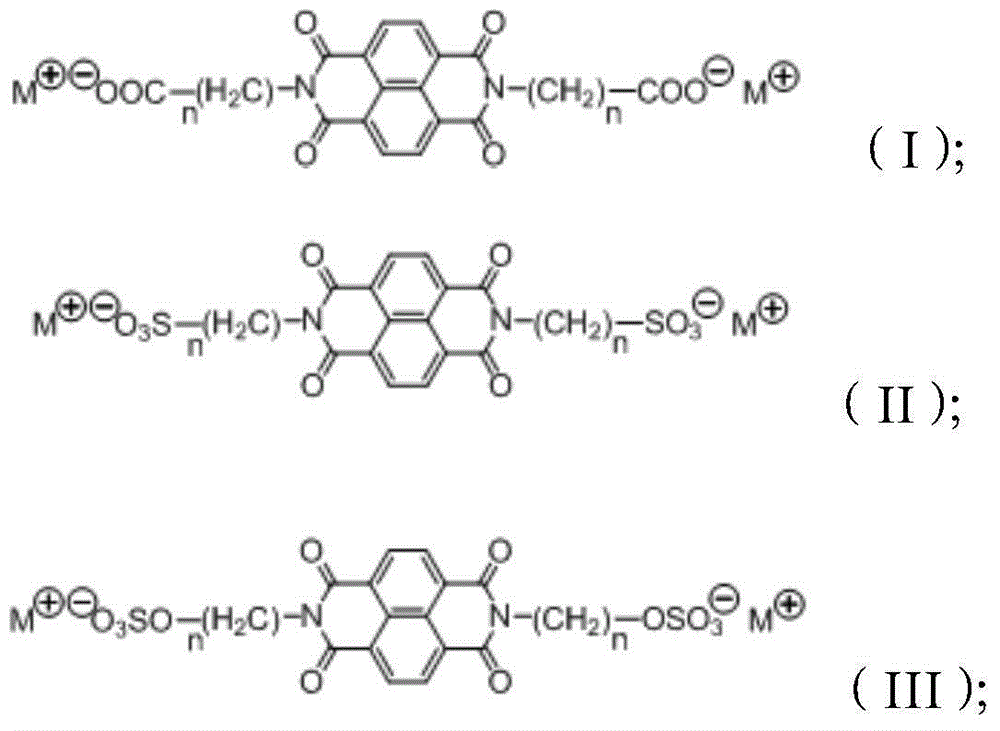

ActiveCN103623741AGood dispersionAttractiveOrganic chemistryTransportation and packagingSolubilityWater soluble

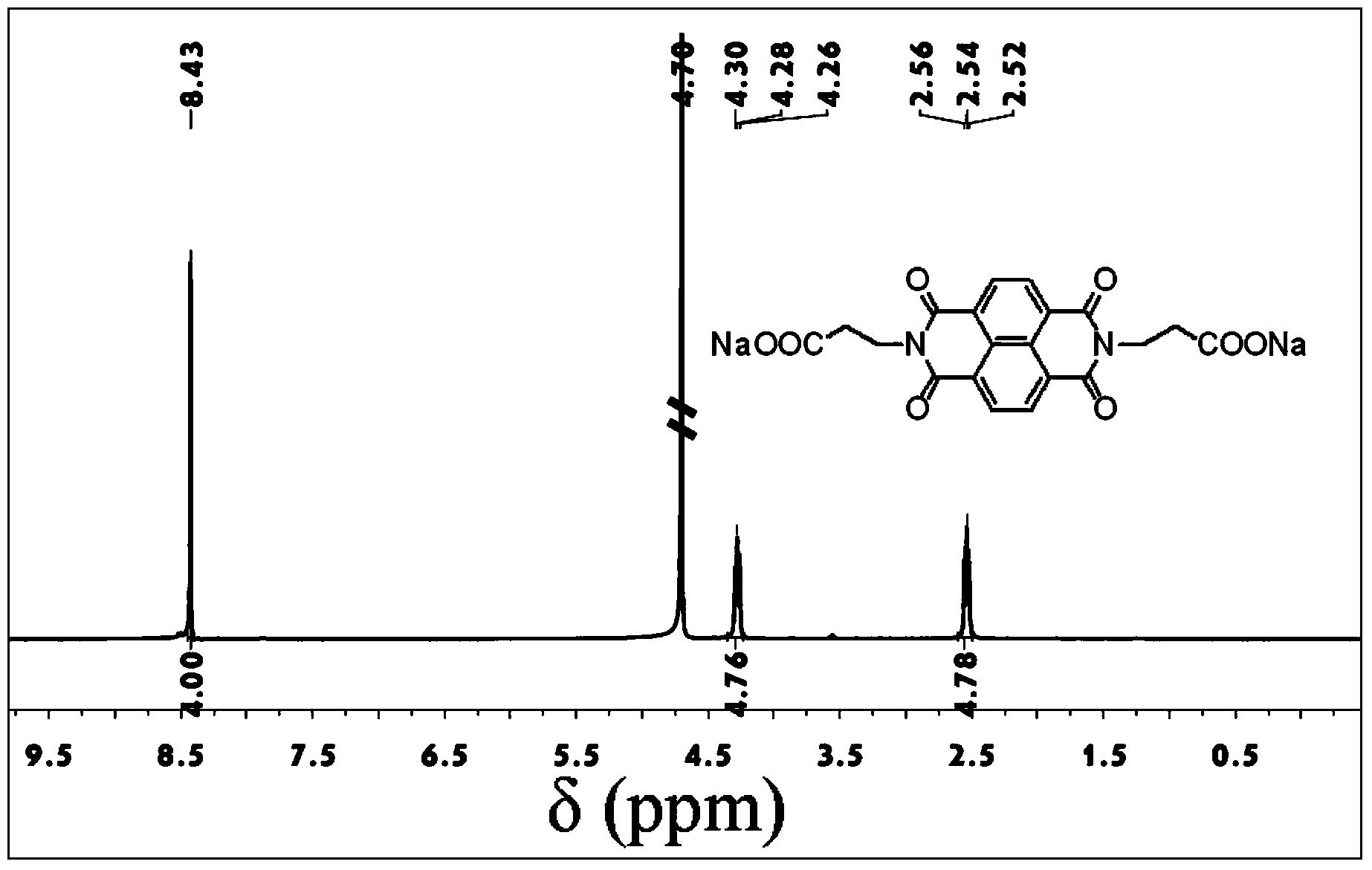

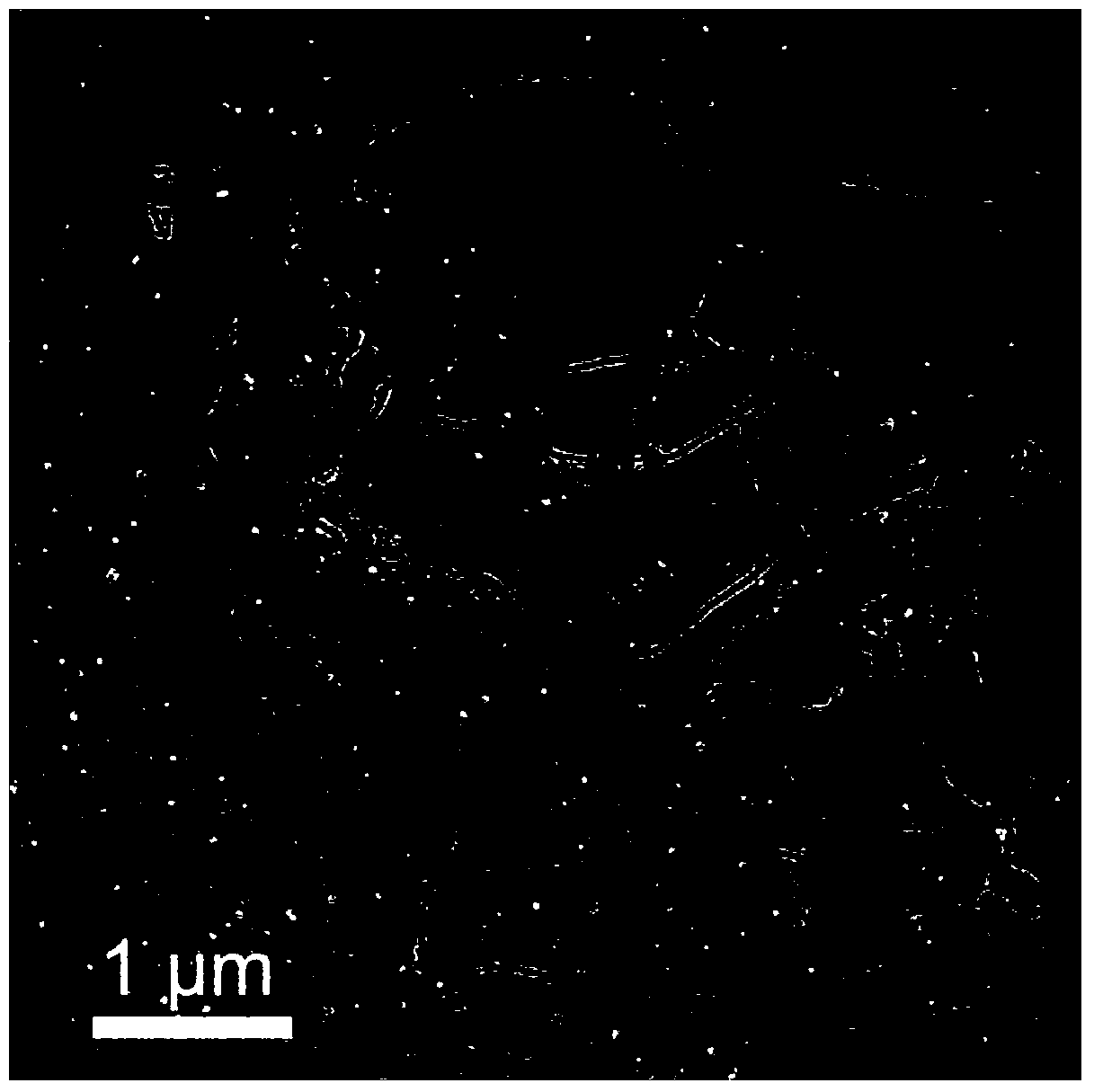

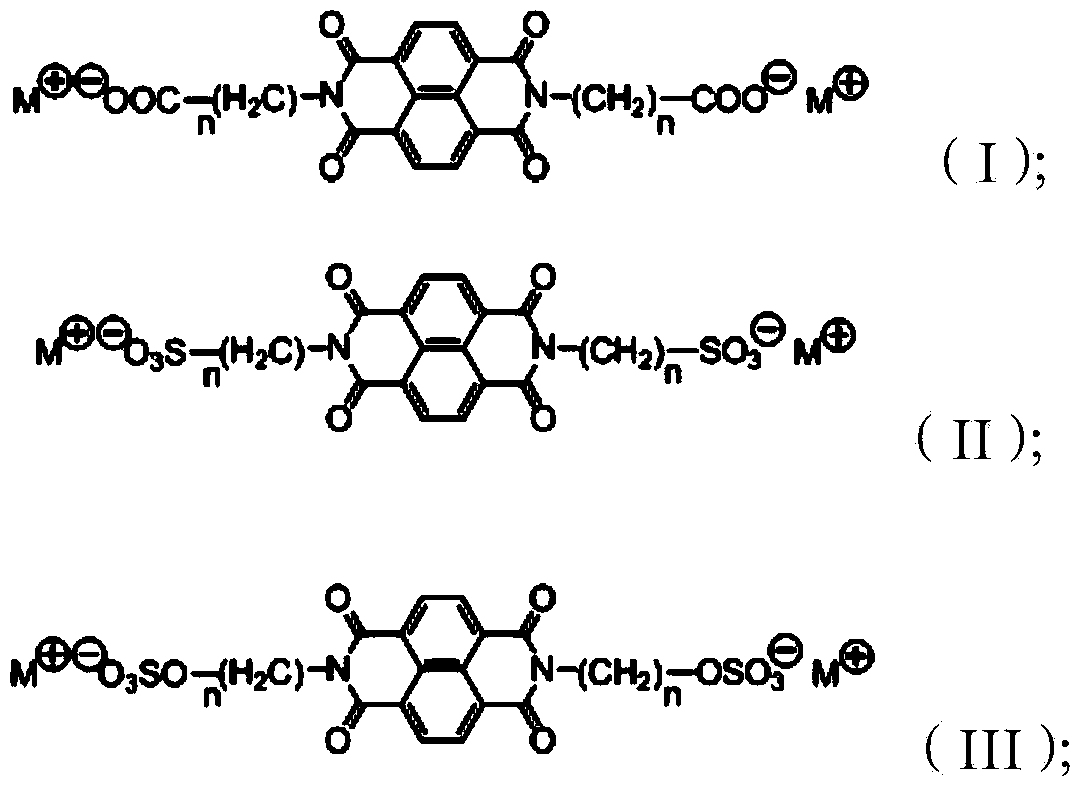

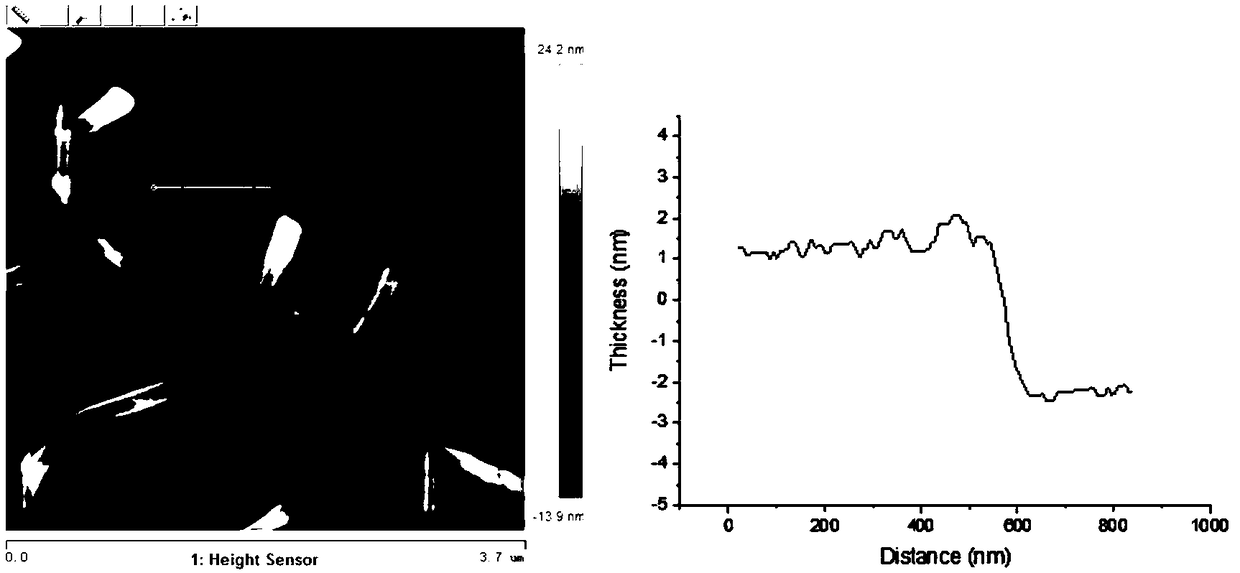

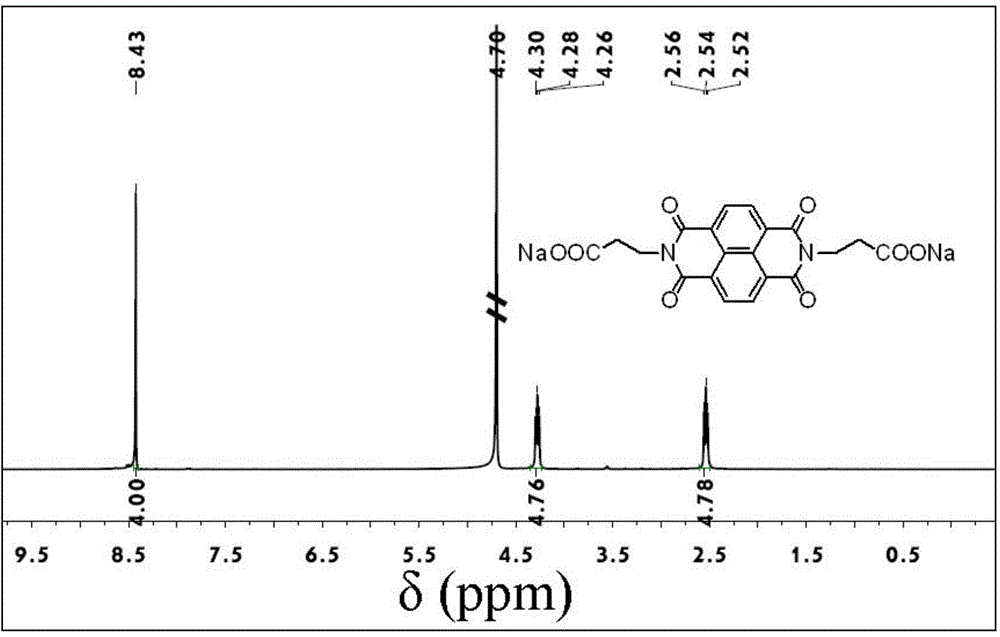

The invention provides a graphene dispersing agent as shown in a formula (I), a formula (II) or a formula (III) in the Specification. The graphene dispersing agent consists of a naphthalene tetracarboxylic acid bisimide unit, an anion group and an alkyl chain. Firstly, the naphthalene tetracarboxylic acid bisimide unit and graphene have strong attraction to each other, so that the whole molecules can be combined with the graphene; secondly, the anion group has excellent water solubility, so that the combined object of the molecules and the graphene can be fully dispersed in water; moreover, the alkyl chain can be used for separating the naphthalene tetracarboxylic acid bisimide unit from the anion group, so that the naphthalene tetracarboxylic acid bisimide unit and the anion group can act independently. Therefore, through the combination of the naphthalene tetracarboxylic acid bisimide unit, the anion group and the alkyl chain, the graphene dispersing agent provided by the invention has excellent graphene dispersing capability; the graphene prepared by using the graphene dispersing agent and adopting an ultrasonic method is not subjected to the oxidation-reduction process, so that the flaw content is low, and the preparation cost is low.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

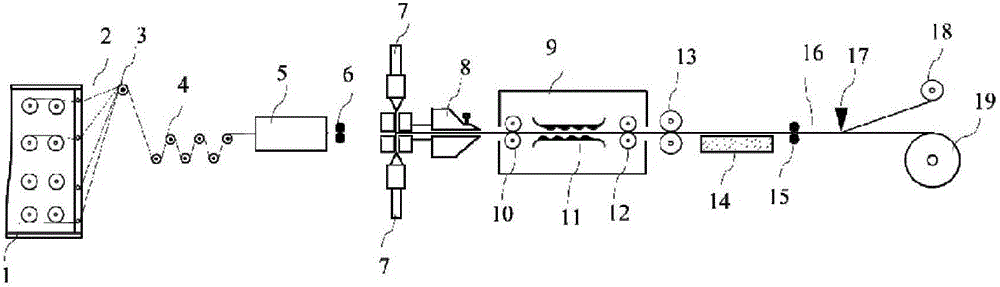

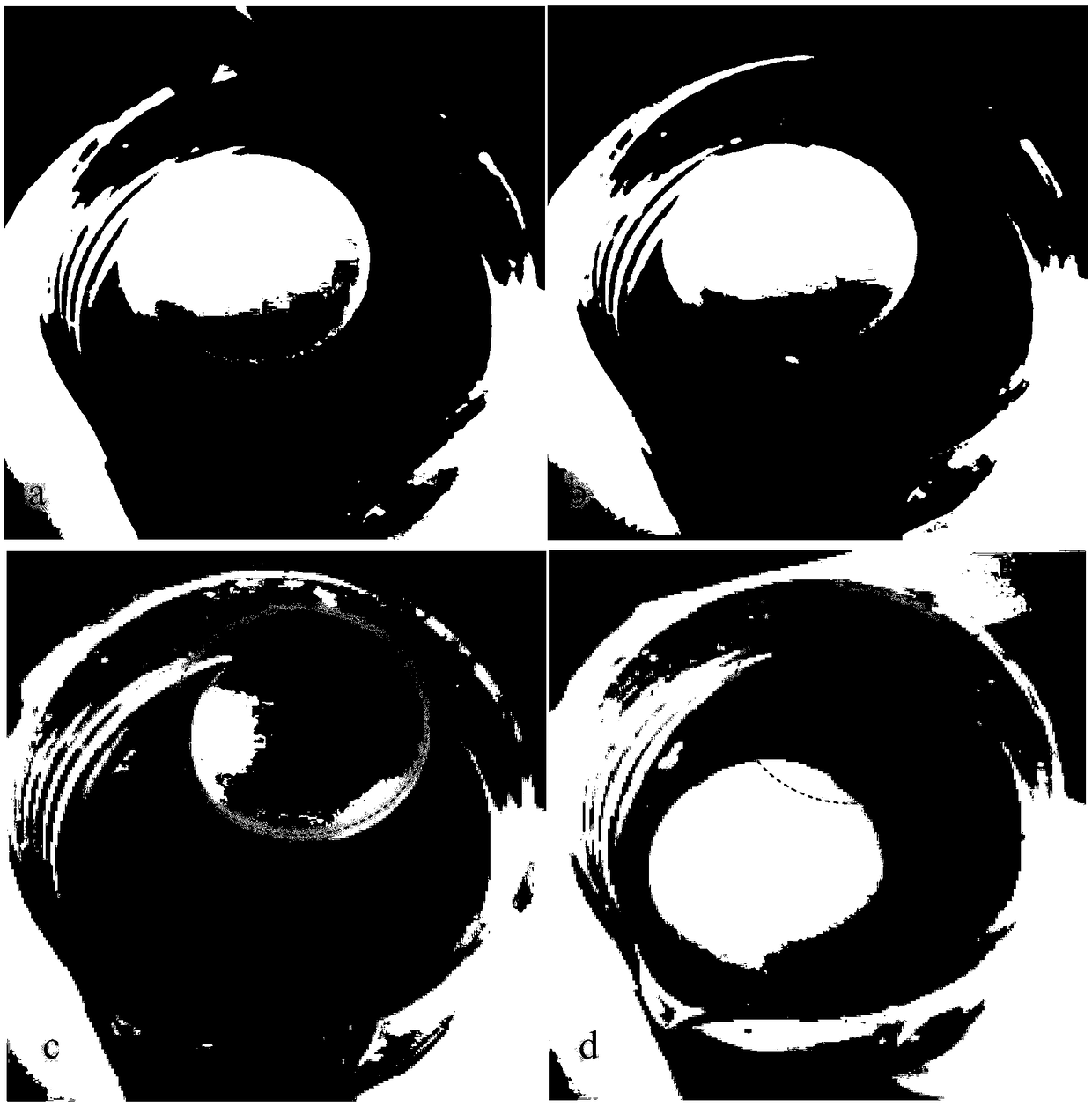

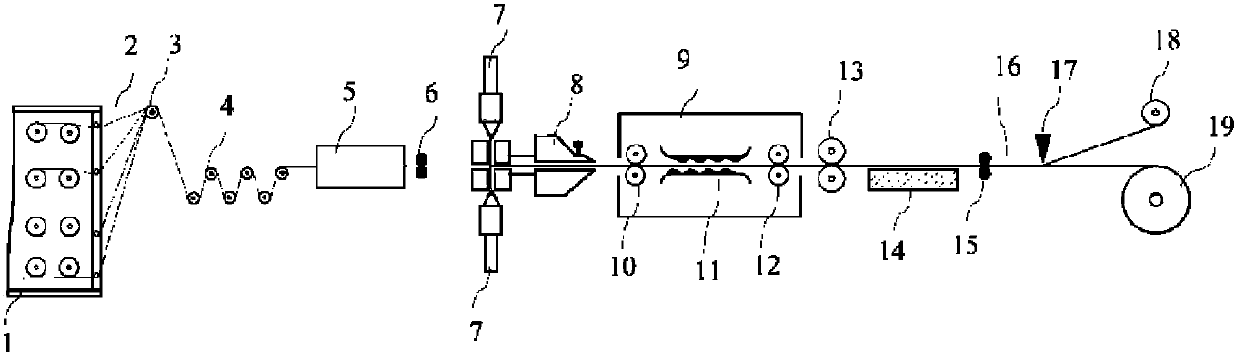

Ultrathin continuous fiber reinforced thermoplastic resin prepreg and preparation method thereof

The invention discloses a preparation method of a continuous fiber reinforced thermoplastic resin prepreg. The method comprises the steps of: (1) thinning continuous fiber; and (2) impregnating the thinned fiber prepared in step (1) with thermoplastic resin melt. The method provided by the invention particularly can realize impregnation of fiber in high temperature and high viscosity PEEK resin so as to obtain high performance continuous fiber reinforced thermoplastic prepreg.

Owner:BEIHANG UNIV

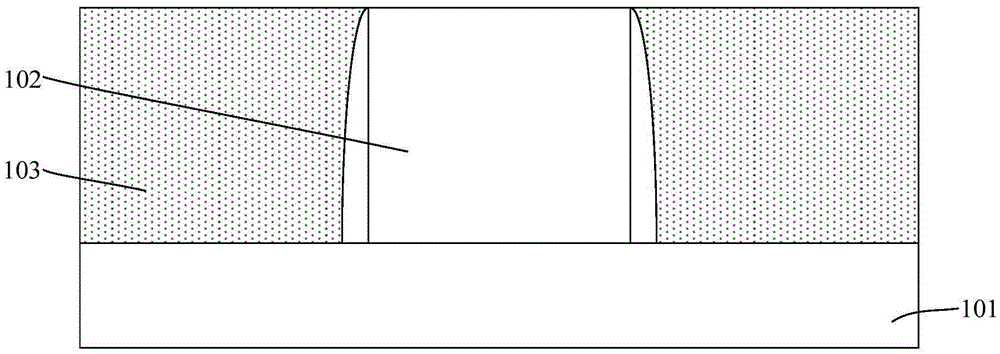

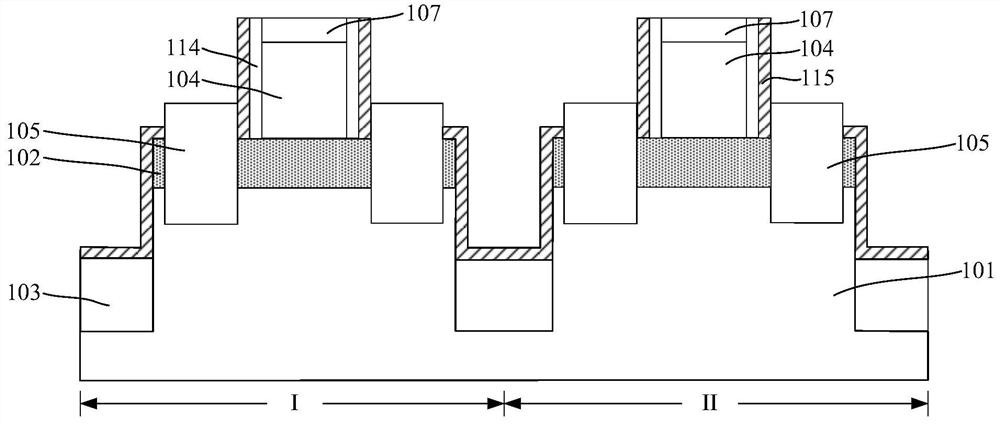

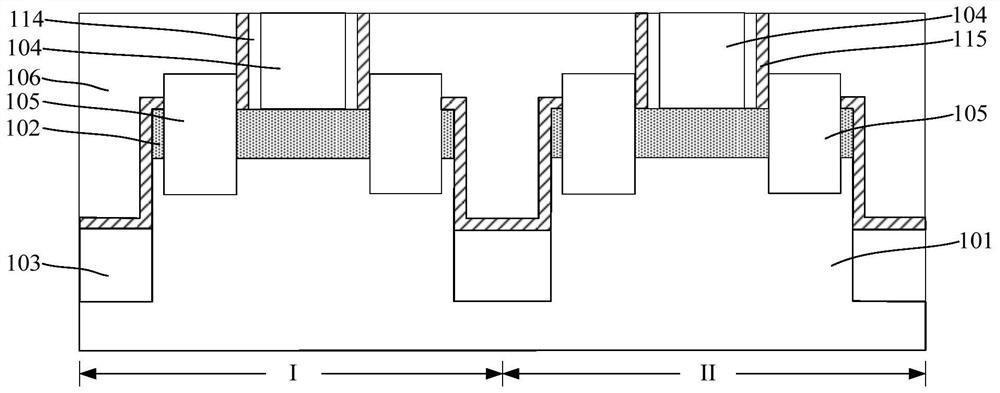

Forming method of semiconductor structure

ActiveCN106653605AImprove electrical performanceModerate electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureElectrical performance

A forming method of a semiconductor structure includes the following steps: providing a substrate; forming a high k gate medium layer on the surface of the substrate; forming a sacrificial layer on the surface of the high k gate medium layer; conducting defect passivation annealing on the high k gate medium layer, wherein the defect passivation annealing is carried out in an atmosphere lacking defect passivation ions, and the defect passivation ions enter the high k gate medium layer via the sacrificial layer during the defect passivation annealing process; removing the sacrificial layer; and forming a gate electrode layer on the surface of the high k gate medium layer. According to the method, a problem of dielectric relaxation of the high k gate medium layer is overcome, the density of the high k gate medium layer and the density of an interfacial layer are increased, and thus the electrical performance of a semiconductor structure formed by the method is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for preparing fine denier strong viscose fibers

ActiveCN108677273AReduce manufacturing costImprove the pressing effectArtificial filament washing/dryingArtificial filaments from viscoseSulfonateAfter treatment

Owner:赛得利(福建)纤维有限公司

Clean high-white viscose fiber preparation method

ActiveCN108588880AImprove the pressing effectImprove qualityMonocomponent cellulose artificial filamentNonwoven fabricDissolving pulp

The invention relates to the technical field of chemical fiber processing, in particular to a clean high-white viscose fiber preparation method which includes the steps: performing meal mixing on softwood dissolving pulp and hardwood dissolving pulp according to a certain proportion, soaking, squeezing and crushing mixture to obtain alkali cellulose, oxidizing, degrading and yellowing the alkali cellulose to obtain sulphonic acid ester solution; performing filtering, defoaming and ripening to obtain viscose stoste, uniformly mixing the viscose stoste and matting agent dispersion liquid, conveying mixture into a spinning machine, and coagulating the mixture to regenerate nascent fibers; converging the nascent fibers into long tows by a godet and a two-bath groove, and enabling the long tows to sequentially enter a drawing machine, a nap groove and a desizing machine to obtain the clean high-white viscose fiber. The prepared clean high-white viscose fiber is low in defect content and less in residual sulfur content and can be used for the fields such as non-woven fabrics and medical sanitation materials, and used pulp raw materials are completely from native woods and have natural,safe, reproducible and environment-friendly advantages. The clean high-white viscose fiber is simple to prepare and low in cost, and the market competitiveness of the viscose fiber can be improved.

Owner:赛得利(福建)纤维有限公司

Anti-carbonization concrete tubular pile and preparation method therefor

The invention discloses an anti-carbonization concrete tubular pile and a preparation method therefor. The anti-carbonization concrete tubular pile consists of the following raw materials in parts by weight: 10-16 parts of light calcium carbonate, 1-2 parts of wool grease, 0.7-2 parts of sodium lauroyl sarcosine, 20-30 parts of potassium feldspar powder, 3-4 parts of n-methyl pyrrolidone, 500-640 parts of ordinary silicate cement, 300-400 parts of yellow ground, 200-300 parts of gravels, 7-14 parts of a polycarboxylate water reducer, 0.1-0.2 part of dibenzoyl peroxide, 5-6 parts of maleic anhydride, 2-3 parts of polyethylene glycol monoethylether, 0.7-2 parts of sp-80, 50-70 parts of waste rubber powder, 0.1-0.2 part of triethylamine, 16-20 parts of polyethylene wax and 2-4 parts of polyvinyl butyral. The anti-carbonization concrete tubular pile can reduce quantity of harmful holes and defects in a concrete structure, reduces alkalinity of hydration products and promotes low-strength hydration products to transform into high-strength hydration products.

Owner:安徽三环管业有限公司

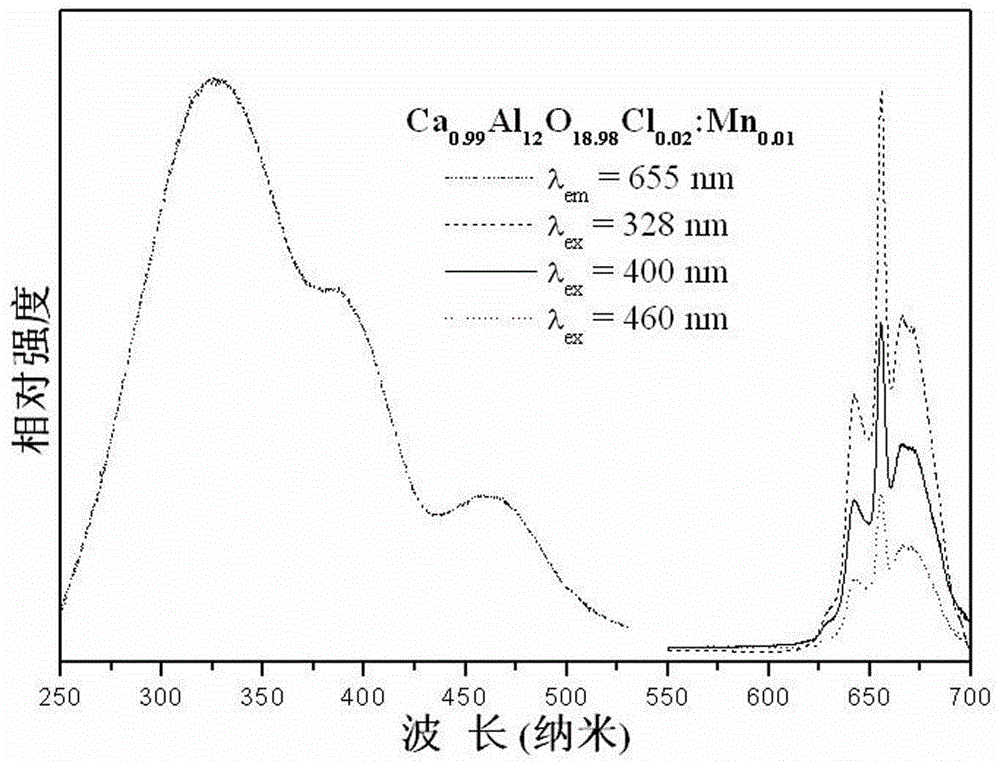

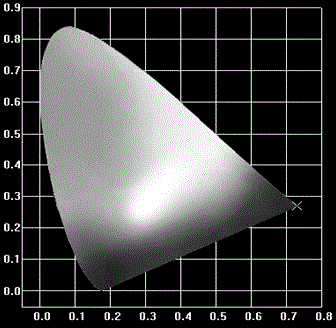

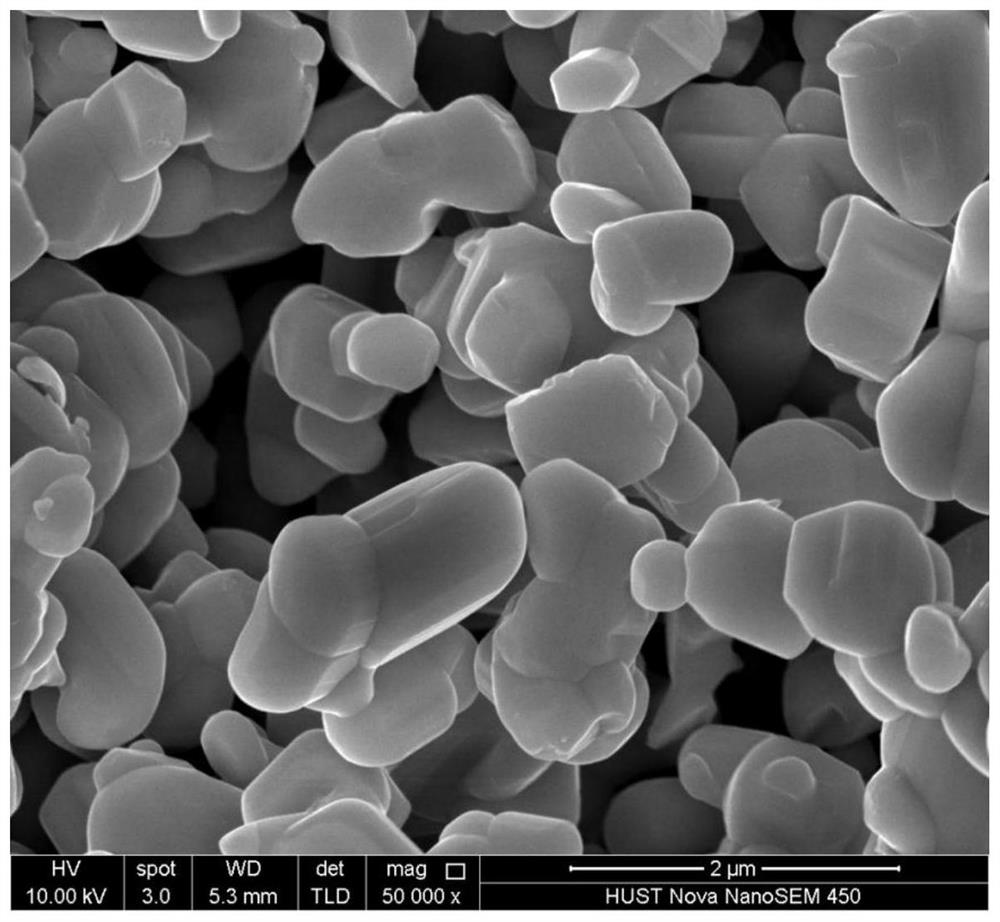

Aluminate red phosphor activated by manganese ion and preparation method thereof

The invention provides an aluminate red phosphor activated by manganese ion and a preparation method thereof. A feature chemical general formula of the red phosphor is that M1-xAl12O19-2xA2x: Mnx, wherein M is at least one type of Mg, Ca, Sr or Ba, A is C1 or F and 0<x<=0.1. The preparation method comprises the steps: oxide of the Mg, the Ca, the Sr, the Ba or the Mn or relative salt, aluminum oxide, halide containing Cl iron and F iron are accurately weighed according to a ratio of the general formula, evenly mixed with a fluxing agent, sintered for 1 hour to 2 hours at the temperature of 600 DEG C-800 DEG C and then sintered for 4 hours to 10 hours at the temperature of 1500 DEG C-1630 DEG C. The powder obtained after sintering is smashed, washed, screened, water-powder-separated and dried so that the aluminate red phosphor activated by the manganese ion is obtained. The red phosphor is capable of emitting red light rays of 620 nm-700 nm under action of light of 250 nm-500 nm and has the advantages that in the range from ultraviolet to a visible region, absorption is performed by a board band, emitting is performed by a narrow band and color purity is high. The red phosphor is suitable for ultraviolet and a blue ray light emitting diode (LED) chip.

Owner:GUANGDONG INST OF RARE METALS

TiNb2O7 material with preferential growth of (010) crystal face and preparation method and application of TiNb2O7 material

ActiveCN113206240AImproved magnification performanceLow defect contentCell electrodesSecondary cellsChemical physicsLithium-ion battery

The invention belongs to the technical field of lithium ion battery materials, and particularly relates to a TiNb2O7 material with preferential growth of a (010) crystal face and a preparation method and application of the TiNb2O7 material. The preparation method comprises the following steps: (1) dispersing a niobium source and a titanium source into a solvent, performing uniform mixing, performing drying, and removing the solvent to obtain a precursor; (2) performing heat treatment on the precursor in an oxygen-containing atmosphere to obtain an intermediate; (3) cooling the intermediate to a tempering temperature according to a set cooling rate, and then performing natural cooling to room temperature to obtain the TiNb2O7 material with preferential growth of the (010) crystal face. The TiNb2O7 material prepared by the method preferentially grows along the (010) crystal face, the migration distance of lithium ions is short, the lithium ions can rapidly migrate along the crystallographic direction, and the TiNb2O7 material has high specific capacity, excellent rate capability and small specific surface area; and when the material is used as a negative electrode of a lithium ion battery, high electrode compaction density and volume energy density can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

Sodium-ion battery positive electrode material, preparation method thereof and sodium-ion battery

ActiveCN111547742ALow costIncrease productionIron cyanidesCell electrodesElectrical batteryElectrically conductive

The invention discloses a sodium ion battery positive electrode material, a preparation method thereof and a sodium ion battery; the preparation method comprises the following steps: step 1, uniformlymixing reactants comprising sodium ferrocyanide, organic weak acid and a complexing agent to obtain a solution A; and 2, subjecting the solution A to heat preservation for 8-16 h at the temperature of 80-160 DEG C, cooling, washing a product, and drying. Under the condition that the prepared sodium-ion battery positive electrode material is not coated with any conductive material, the first discharge capacity of the prepared battery is 117.8 mAg <-1 > under the current density of 1A g <-1 >, the capacity retention rate of the prepared battery reaches up to 88.9% after 200 times of charge-discharge cycles, and the electrochemical performance of the prepared battery is very excellent.

Owner:浙江钠创新能源有限公司

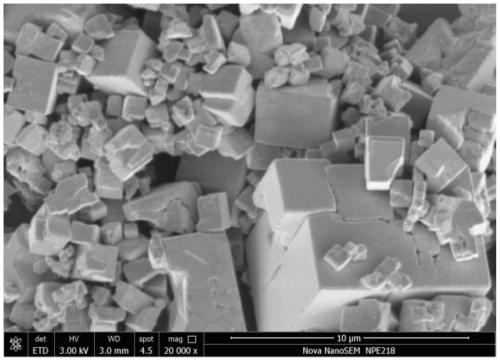

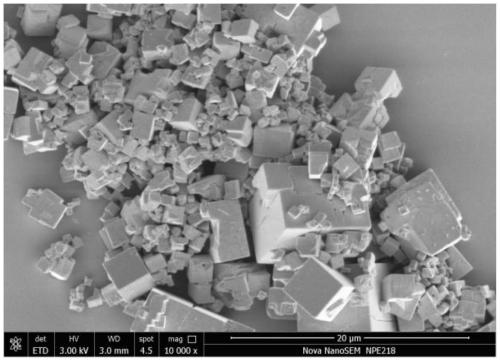

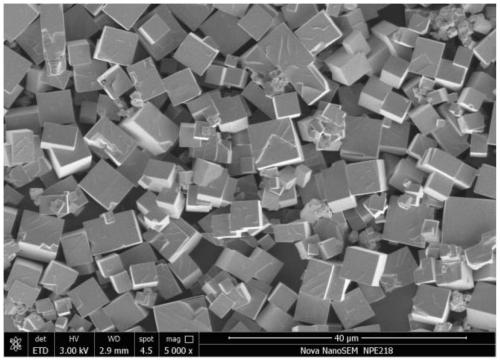

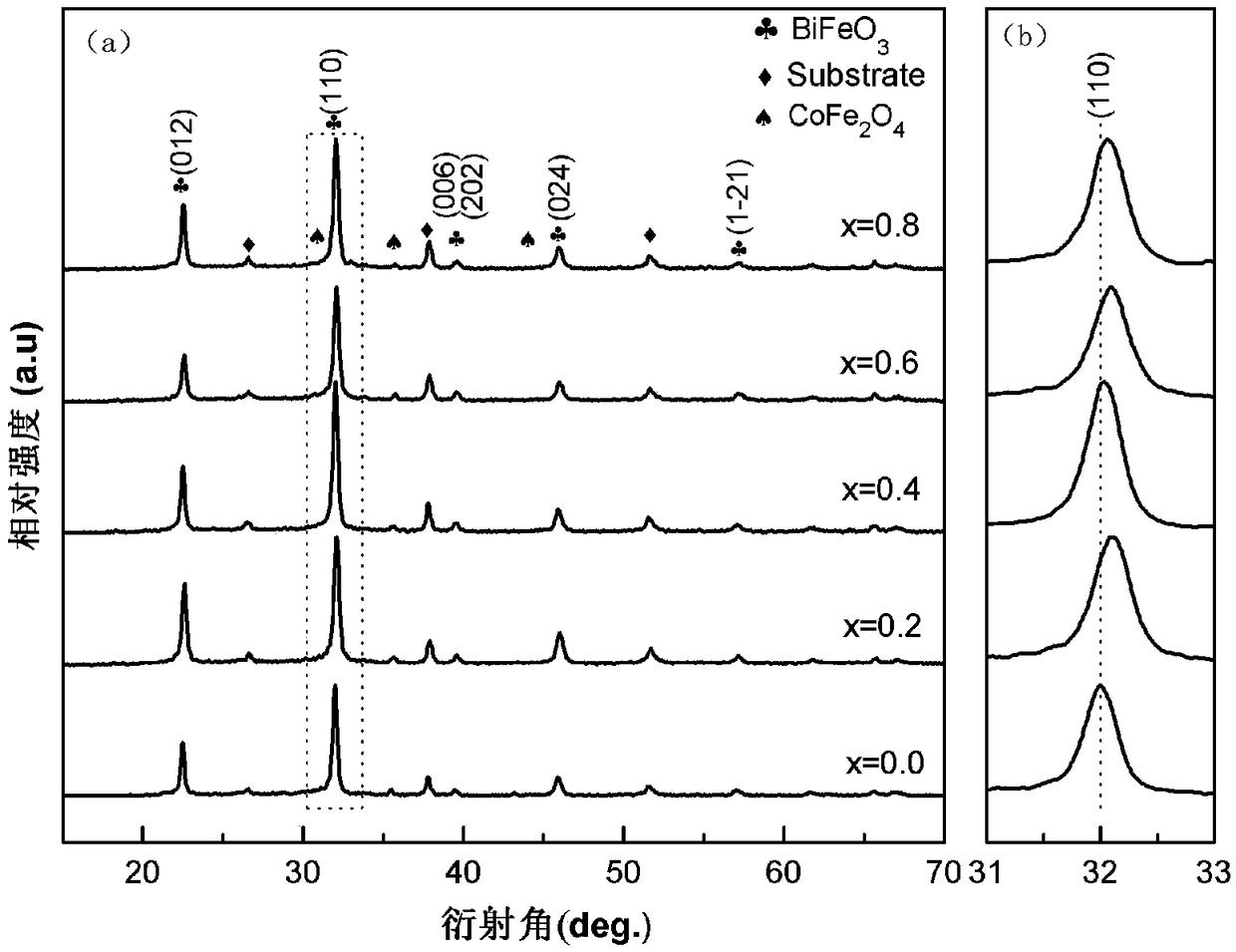

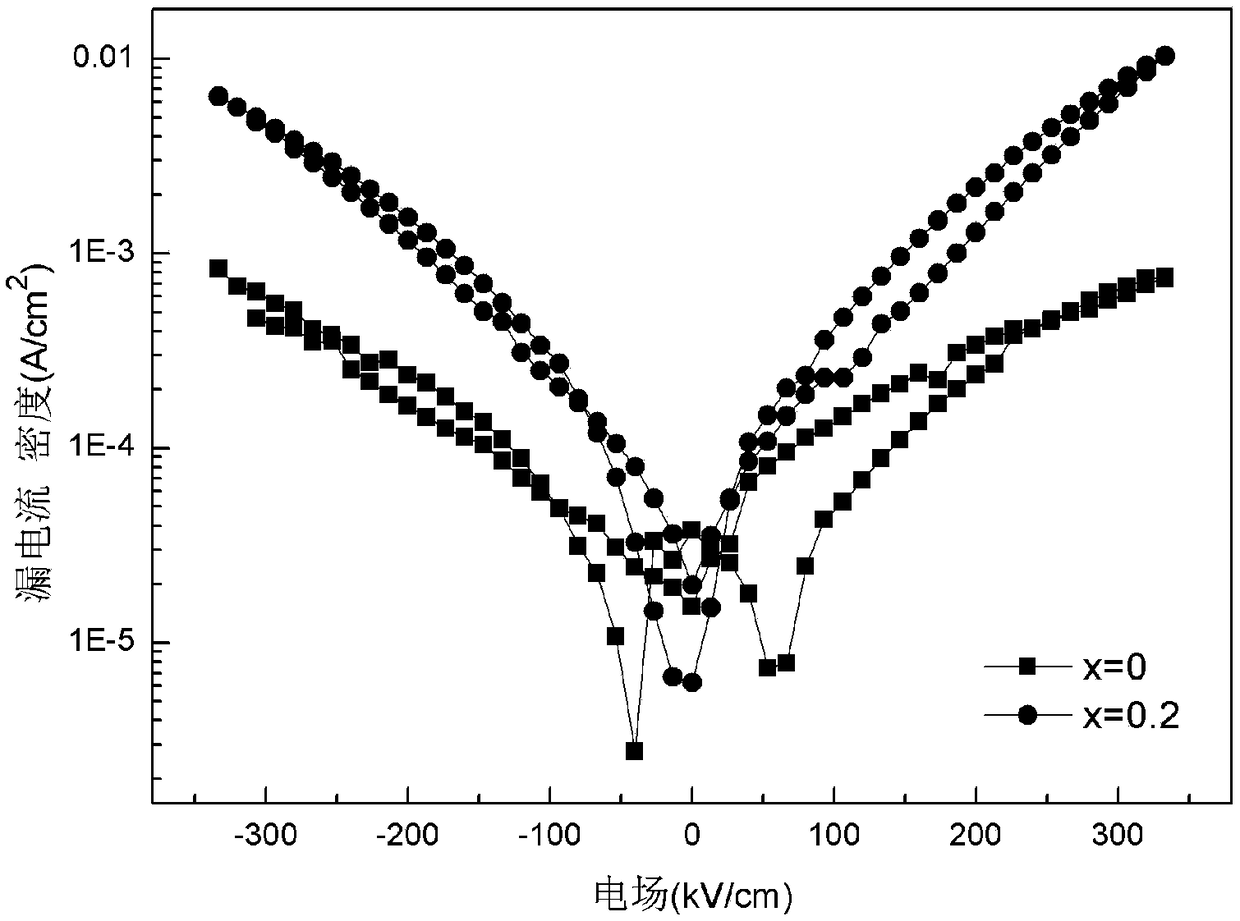

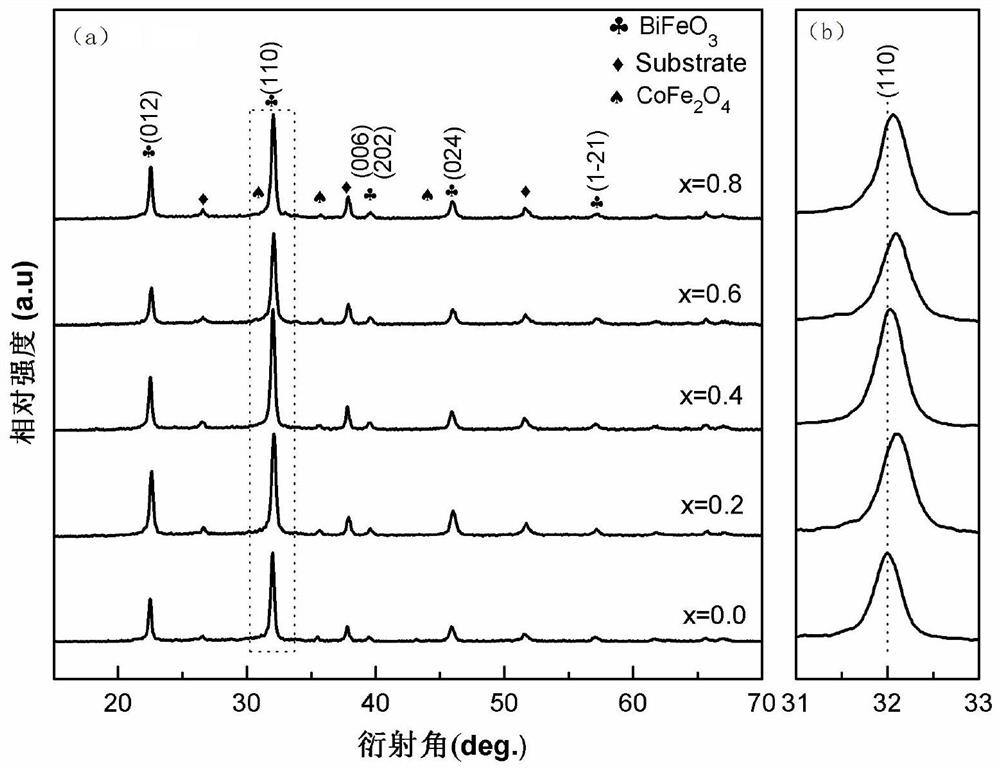

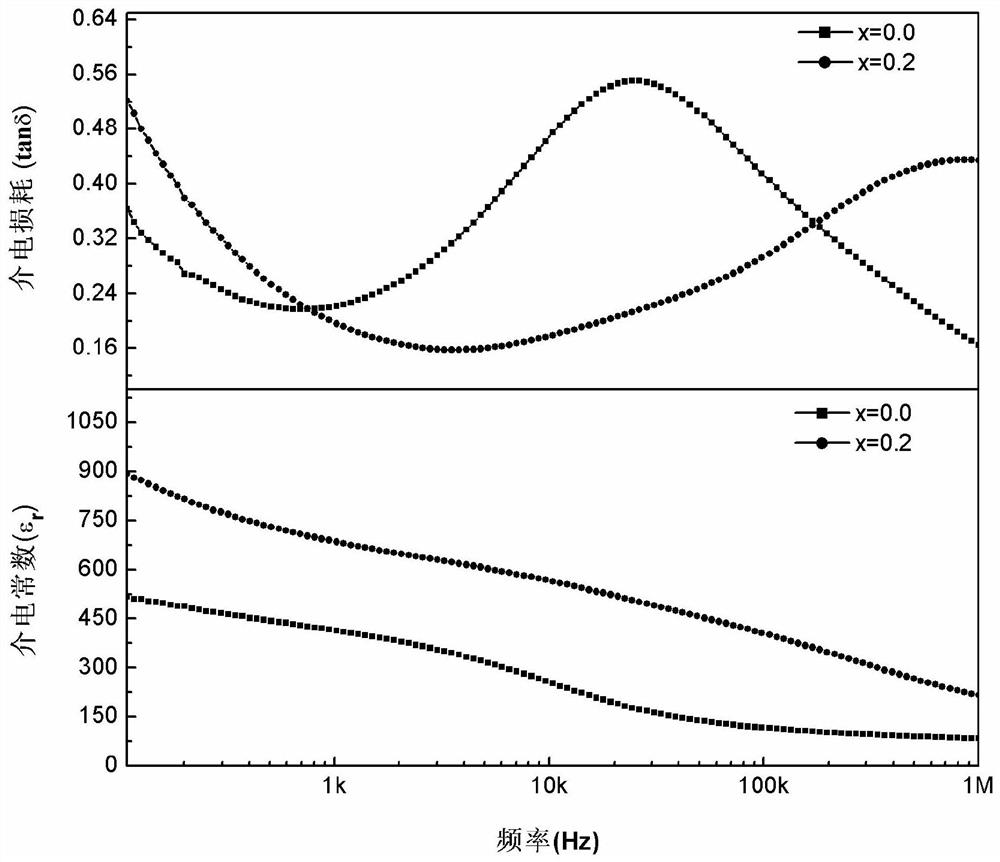

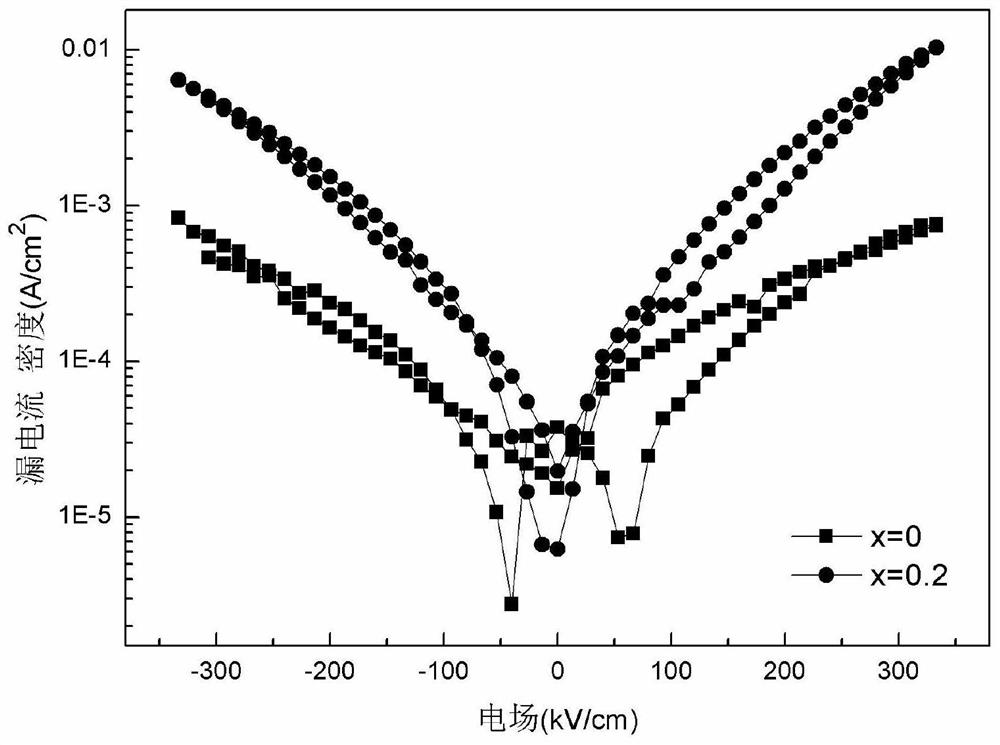

BLSFMC/CMFO film with resistance switch effect and preparation method thereof

ActiveCN109111127AImprove multiferroic performanceReduce leakage current densityComposite filmSpace group

The invention provides a BLSFMC / CMFO film with a resistance switch effect and a preparation method thereof. The BLSFMC / CMFO film comprises an upper layer film and a bottom layer film which are composited together; a chemical formula of the bottom layer film is Co1-xMnxFe2O4, the bottom layer film is a distorted cubic inverse spinel structure, and a space group is Fd3m; and a chemical formula of the upper layer film is Bi0.79La0.19Sr0.03Fe0.94Mn0.04Co0.0203, the upper layer film is a distorted rhombohedral perovskite structure, and a space group is R3c, wherein x is equal to 0 to 0.8. The BLSFMC / CMFO film is prepared by adopting a sol-gel method and a layer-by-layer annealing process. By virtue of the doping for the BiFeO3 film, the ferroelectric performance is improved; and the BiFeO3 filmis composited with a CoFe2O4 magnetic layer, so that the resistance switch effect of the ferroelectric polarization-regulated ferroelectric / ferromagnetic composite film can be realized.

Owner:SHAANXI UNIV OF SCI & TECH

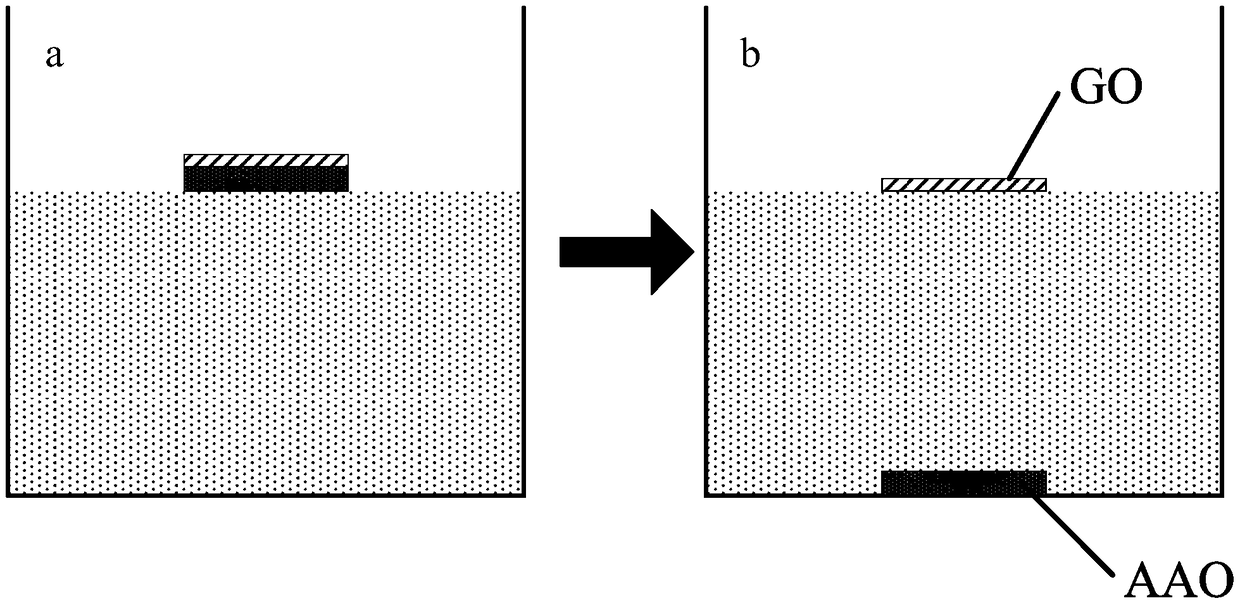

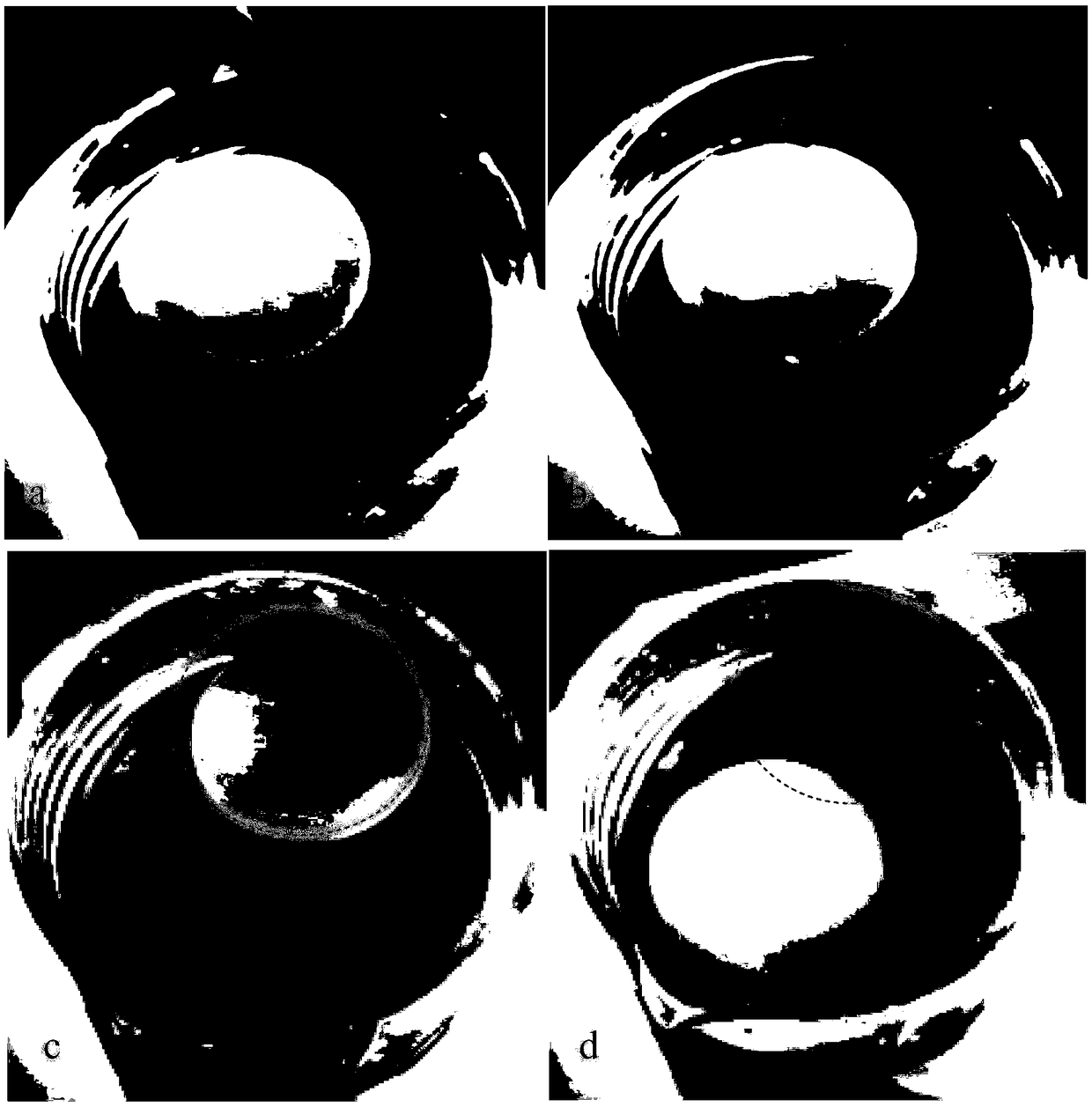

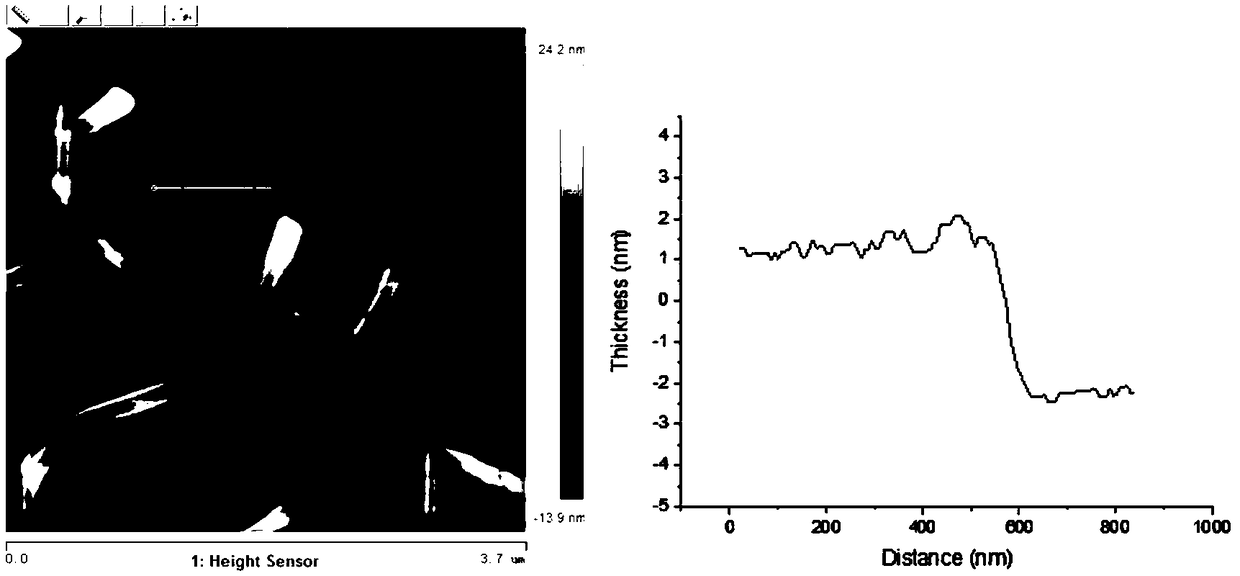

A graphene-based thin film solar cell

ActiveCN109036851AGuaranteed uniformityHigh light transmittanceMaterial nanotechnologyLight-sensitive devicesDefective grapheneFiltration

The invention discloses a graphene-based thin film solar cell, comprising a transparent electrode, wherein the transparent electrode is a graphene film, and the thickness is not more than 20 nm. The thin film is prepared by a suction filtration method to ensure the uniformity of the thin film and the stability of the device. A water transfer method is used to control the thickness of the graphenefilm at a nanometer level, and the transmittance of the film is improved. During the transfer process, micro-wrinkles are introduced to increase the contact area between the film and the photosensitive layer. After high temperature treatment, the graphene defects are few and the film strength is high, which can withstand the stress change in the process of repeated folding of the flexible electrode. The whole process is simple, green and easy to operate. The thin film serves as a photoanode, a counter electrode and the like; and in contrast, graphene has higher electron mobility and no heavy metal pollution problem exists, the cost is reduced and the light conversion efficiency is improved.

Owner:ZHEJIANG UNIV

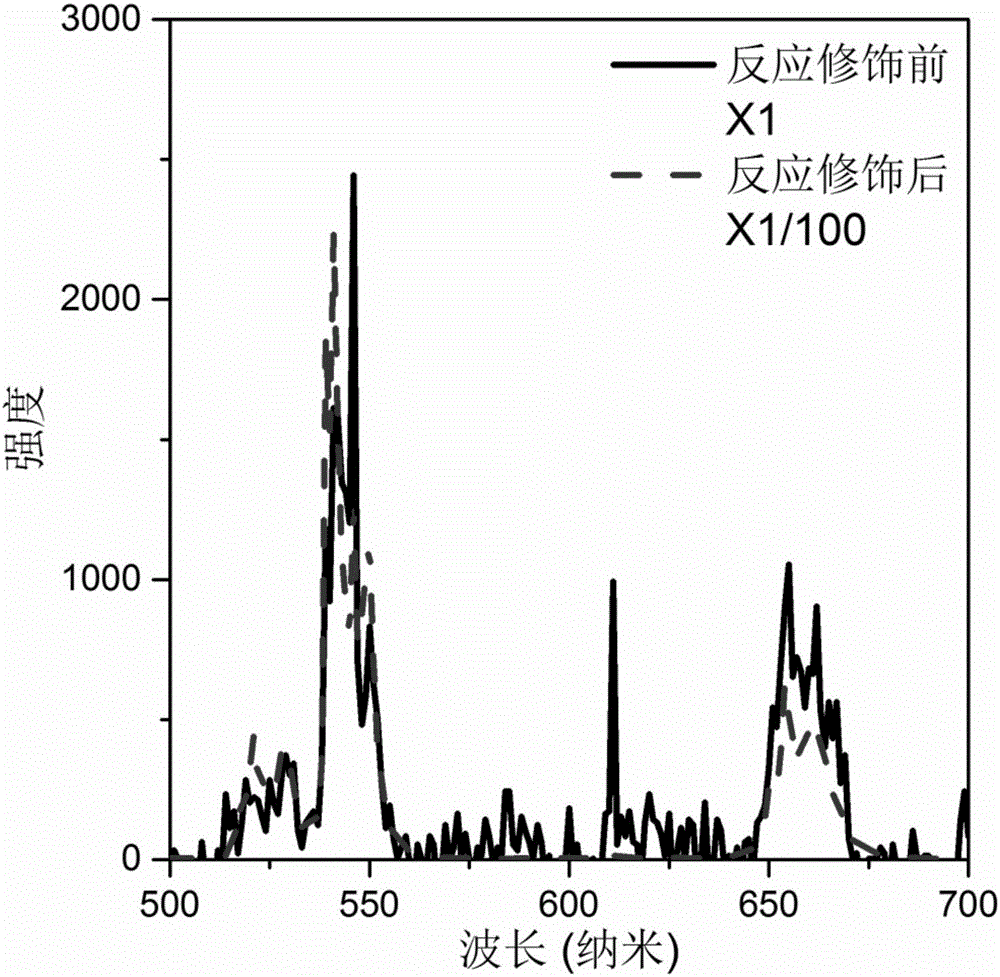

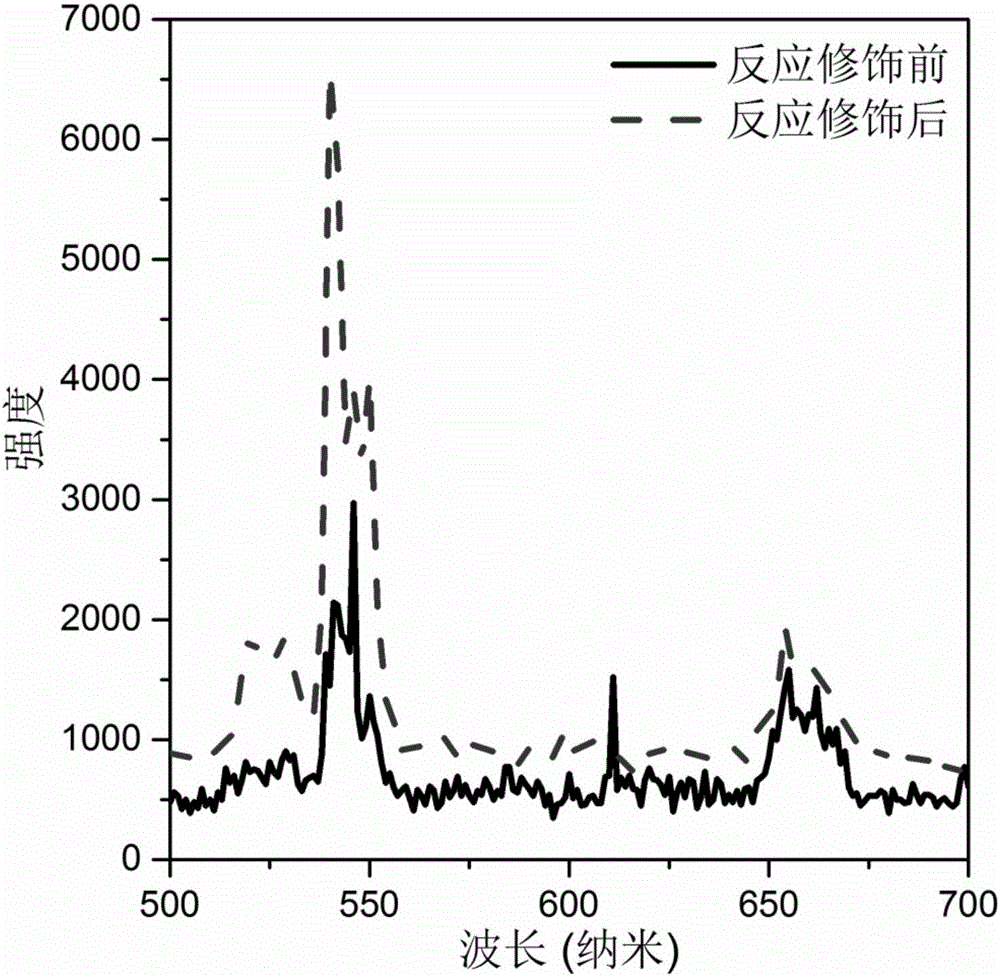

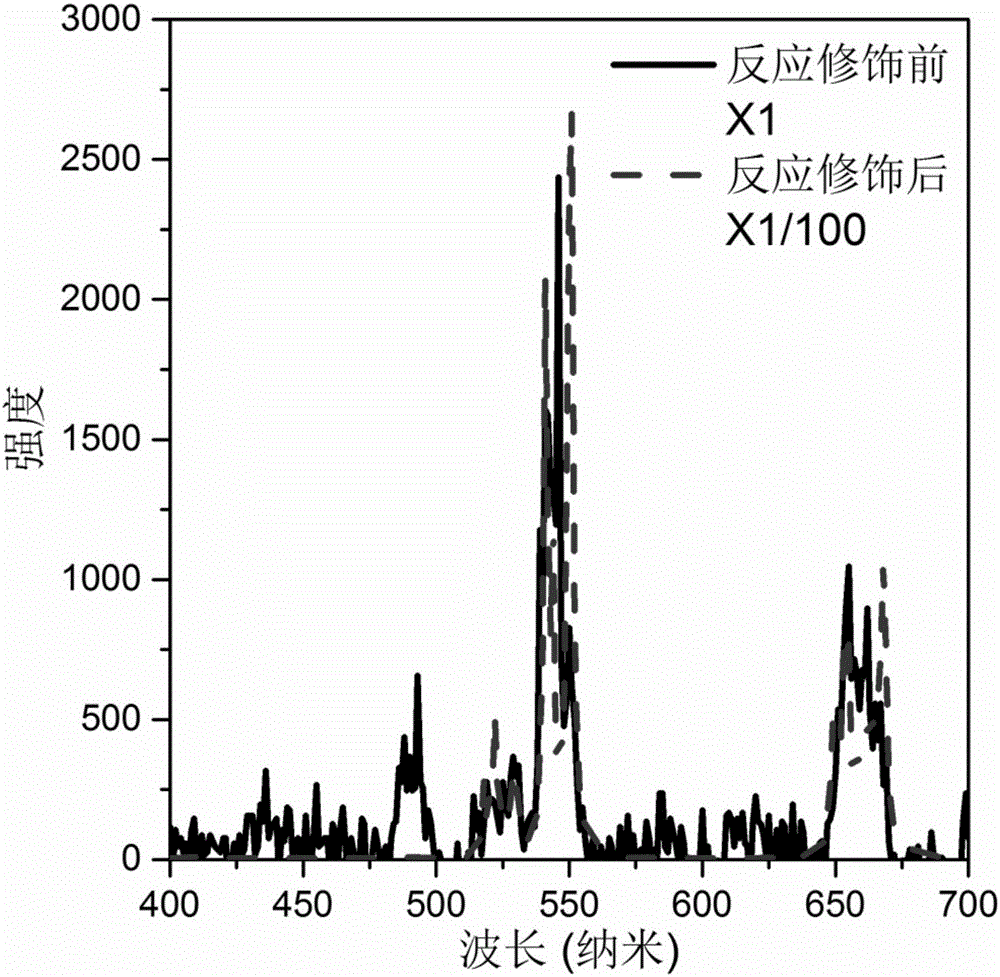

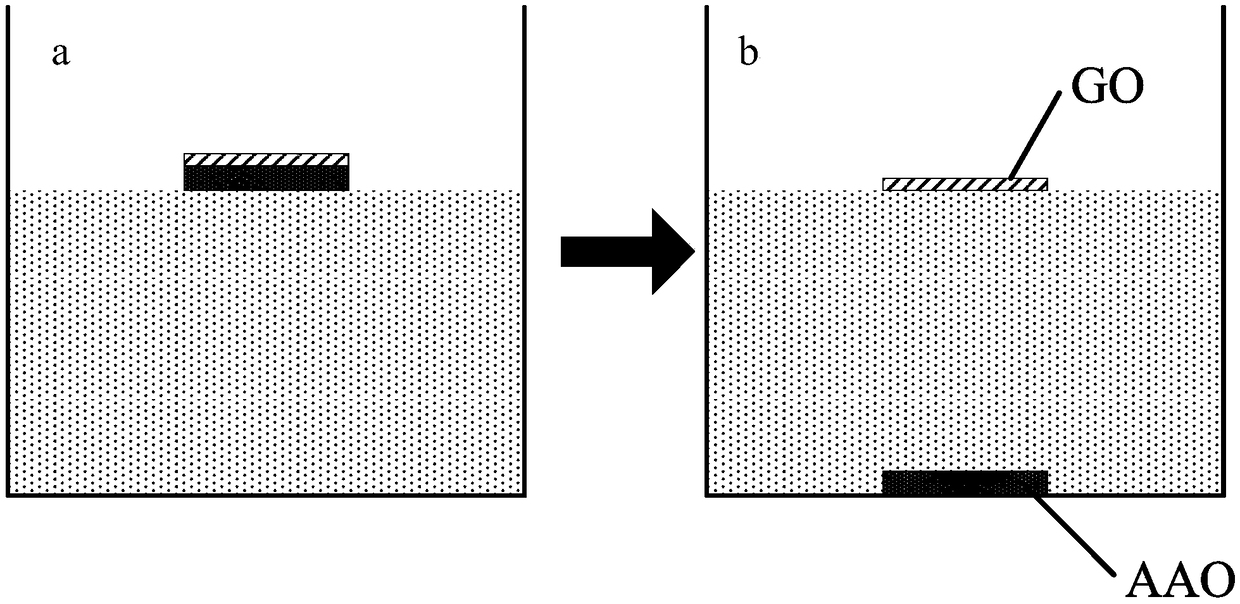

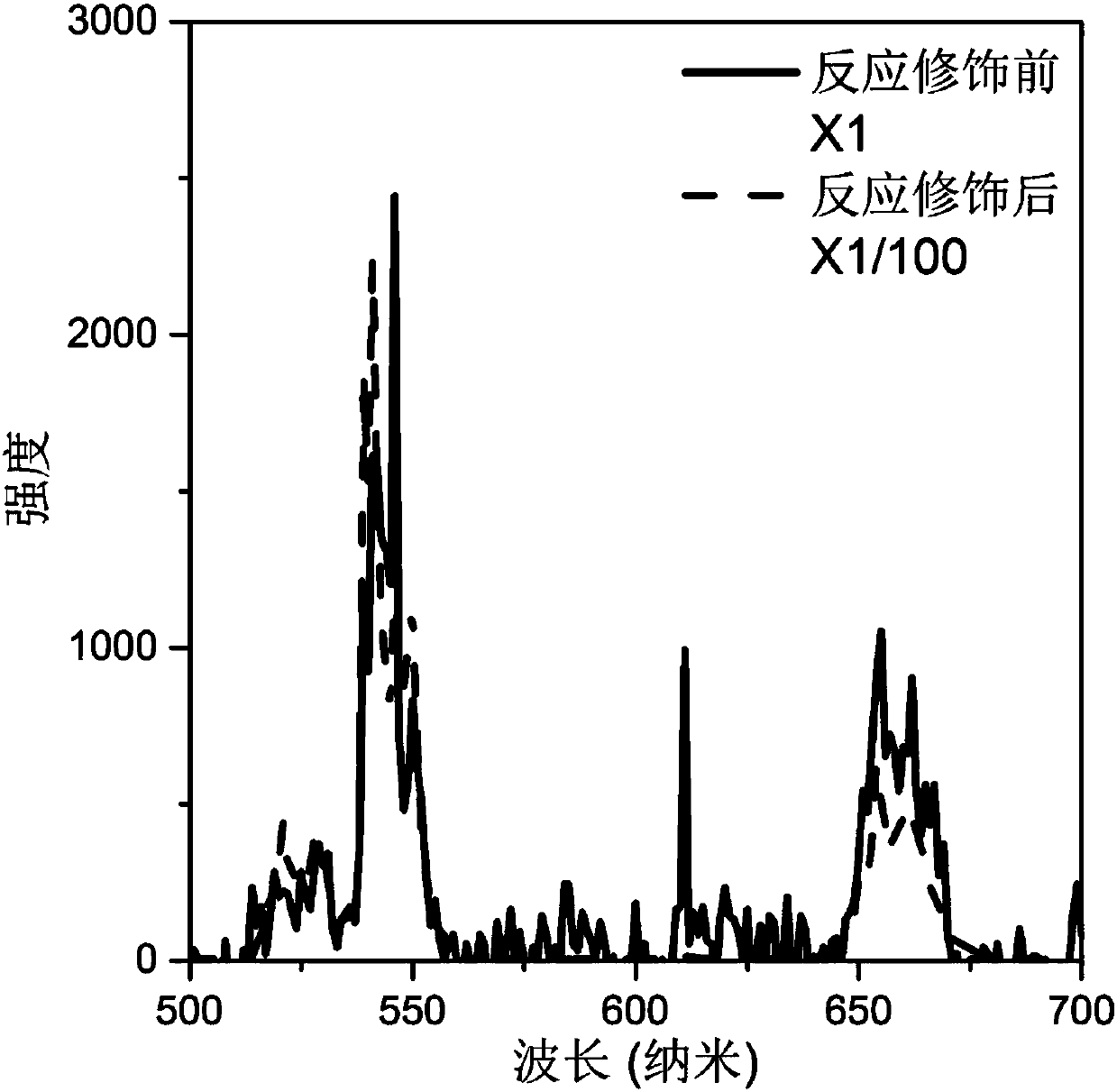

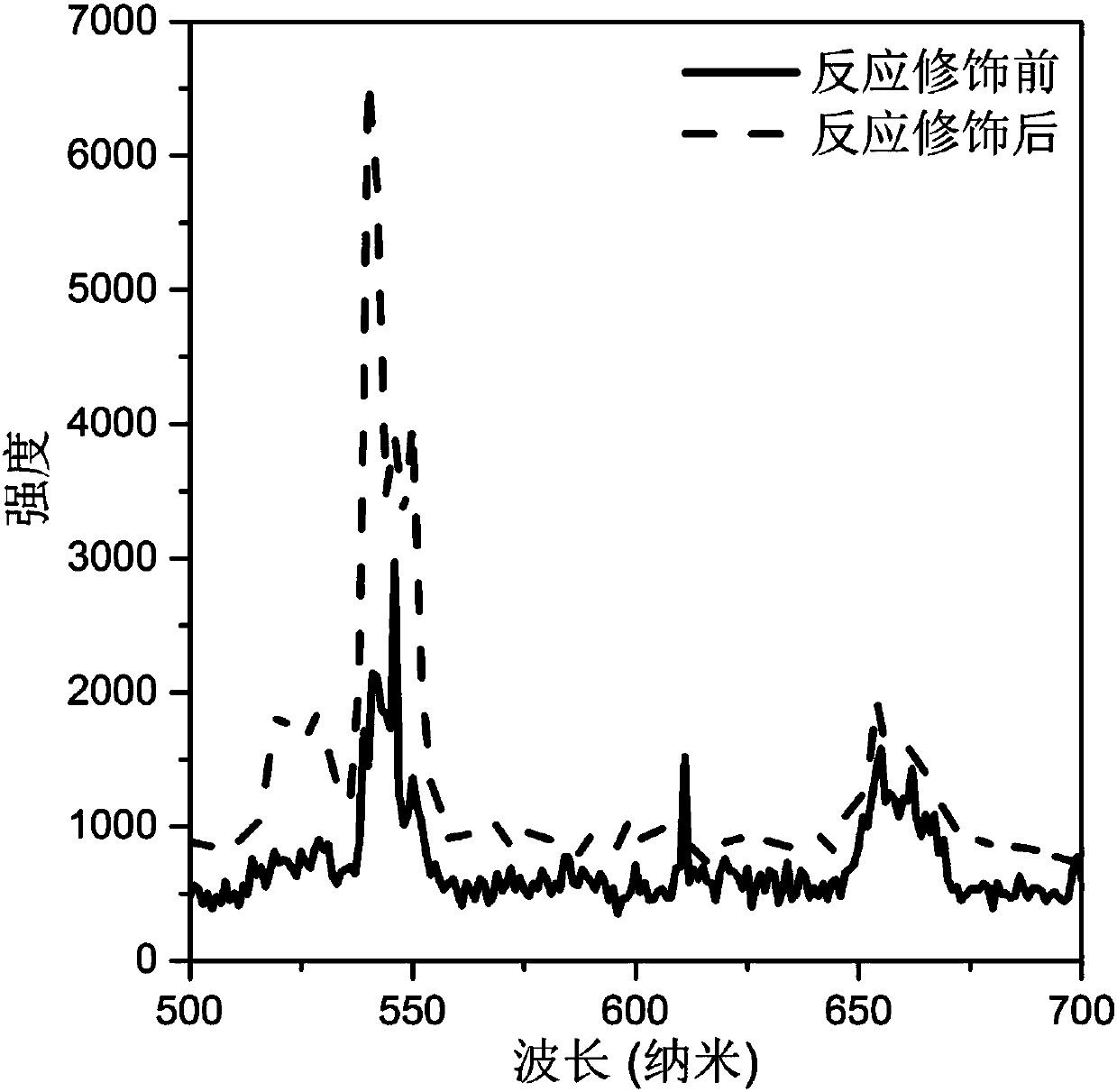

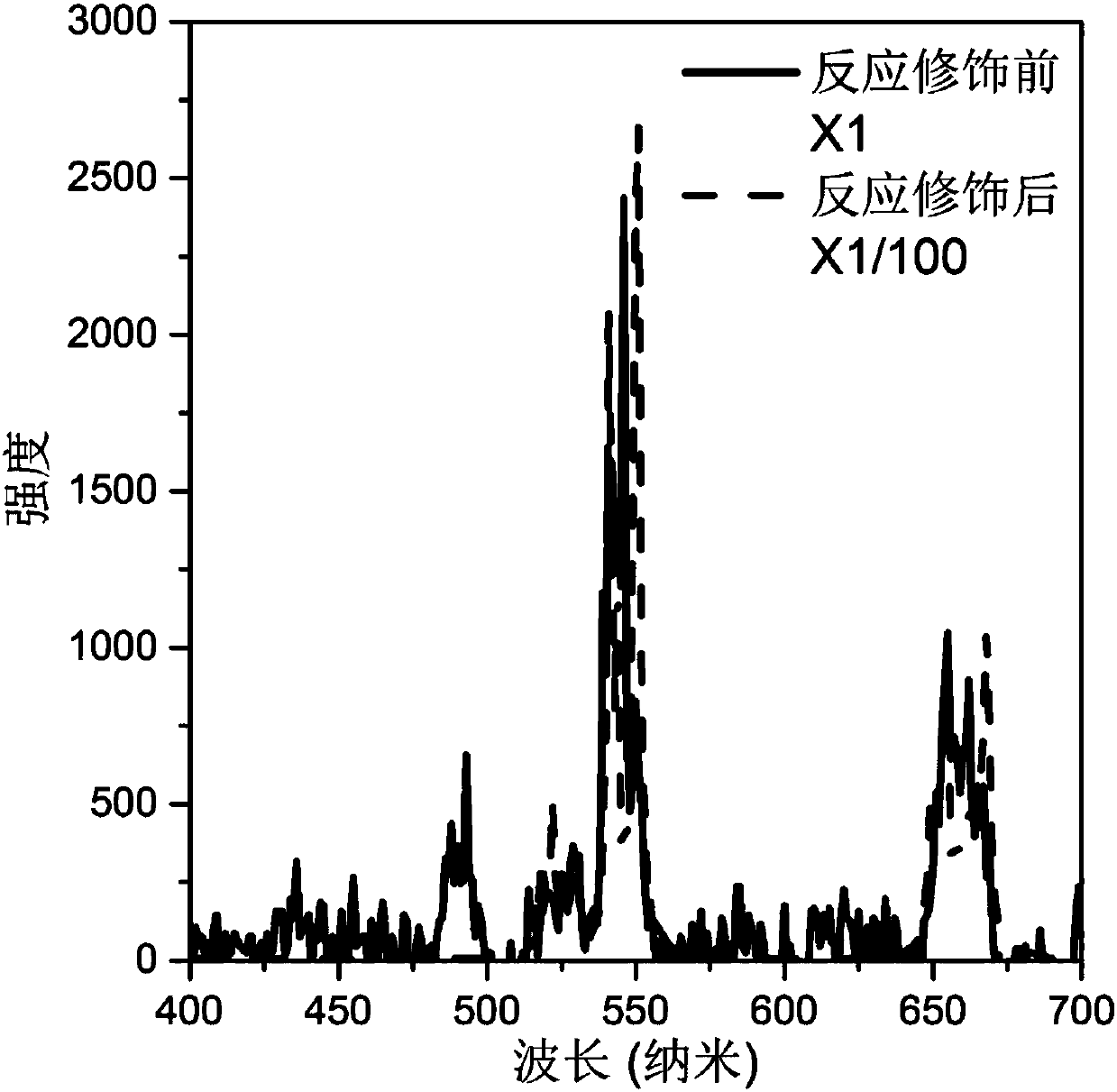

Method for improving up-conversion luminescence intensity of rare earth ion doped inorganic fluoride

ActiveCN105885844ALow defect contentUp-conversion emission enhancementLuminescent compositionsUpconversion luminescenceQuantum efficiency

The invention discloses a method for improving up-conversion luminescence intensity of rare earth ion doped inorganic fluoride. According to the method, pre-synthesized rare earth doped inorganic fluoride is mixed with a solution containing alkali metal cations and fluoride ions, an obtained mixture is subjected to a sufficient reaction at a high temperature, the alkali metal cations and the fluoride ions added to the solution all participate in material modification, luminescence quenching centers in the inorganic fluoride can be reduced, and the up-conversion luminescence intensity and the quantum efficiency of the rare earth ion doped inorganic fluoride can be improved greatly.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Low-cost fly ash concrete pile, and preparation method therefor

The present invention discloses a low-cost fly ash concrete pile. The pile consists of the following raw materials in parts by weight: 5-6 parts of maleic anhydride,40-50 parts of fly ash, 1.5-3 parts of Butyl-p-hydroxybenzoate, 0.1-0.2 parts of diazolidinyl urea, 0.1-0.3 parts of two thioglycolic acid dimethyl diisooctyl tin, 0.2-0.4 parts of polysorbate 80, 4-7 parts of kynar, 500-640 parts of ordinary Portland cement, 300-400 parts of yellow sand, 200-300 parts of crushed stone, 7-15 parts of polycarboxylate superplasticizer, 16-20 parts of polyethylene wax, 0.1-0.2 parts of dibenzoyl peroxide, 2-3 parts of polyethylene glycol monomethyl ether, 0.7-2 parts of sp-80, and 50-70 parts of waste rubber powder. The pile of the invention, with fly ash being used as a filler, is low in cost, good in surface resistance, high in strength, strong in impermeability, and superior in overall performance.

Owner:安徽三环管业有限公司

Silicon-based solar cell

ActiveCN109037370AGuaranteed uniformityHigh light transmittanceMaterial nanotechnologyFinal product manufactureWrinkle skinDefective graphene

The invention discloses a silicon-based solar cell, comprising a transparent electrode, wherein the transparent electrode is a graphene film, and the thickness is not more than 20nm. The thin film isprepared by a suction filtration method, so as to ensure the uniformity of the thin film and the stability of the device. A water transfer method is used to control the thickness of the graphene filmat a nanometer level, and the transmittance of the film is improved. During the transfer process, micro-wrinkles are introduced to increase the contact area between the film and the photosensitive layer. After high temperature treatment, the graphene defects are few and the film strength is high, which can withstand the stress change in the process of repeated folding of the flexible electrode. The whole process is simple, green and easy to operate. Comparatively speaking, the graphene film has high electron mobility and relatively low light transmittance, and the solar energy absorbance of silicon is increased by continuous reflection, and the electron holes generated by the graphene film can be separated under the action of a built-in electric field, so as to improve the light conversionefficiency.

Owner:ZHEJIANG UNIV

Carbon-silicon reinforced concrete tubular pile and production method thereof

InactiveCN106116371AImprove non-polarityImprove compatibilitySolid waste managementStructural systemCarbon dioxide

The present invention discloses a carbon-silicon reinforced concrete tubular pile; since ethoxylated rubber fiber is doped, inner pore structure of concrete can be effectively improved and mass closed pores can be formed so as to prevent capillary pores from forming a continuous through meshed structural system, an 'anti-carbonization belt' is formed, inhibition on carbon dioxide invasion is further enhanced, and it is also additionally possible to reduce harmful pores and defects in the concrete structure, reduce alkality of hydrates and promote the conversion of low-strength hydrates to high-strength hydrates.

Owner:ANHUI XINRUN NEW MATERIALS

Concrete pipe pile and preparation method thereof

InactiveCN105016682AImprove hydrophilicityHigh strengthSolid waste managementFiberPolyethylene glycol

The invention discloses a concrete pipe pile which is prepared from the following raw materials in parts by weight: 500-640 parts of common silicate cement, 300-400 parts of yellow sand, 200-300 parts of gravels, 14-20 parts of aluminum phosphate, 7-15 parts of a poly carboxylic acid water reducing agent, 16-20 parts of polyethylene wax, 0.1-0.2 part of dibenzoyl peroxide, 5-6 parts of maleic anhydride, 2-3 parts of methoxy polyethylene glycol, 4-7 parts of ethyecellulose, 0.7-2 parts of sp-80, 50-70 parts of waste rubber powder and 0.1-0.2 part of triethylamine. According to the concrete pipe pile disclosed by the invention, by doping the ethoxylated rubber fiber, the inner pore structure of the concrete can be effectively improved to form a lot of closed pores to prevent pores from forming a continuous penetrating netty structure system so as to play a role of further enhancing inhibition of invasion of carbon dioxide. In addition, the content of harmful pores and defects in the concrete structure can be further reduced, the alkalinity of hydration products is reduced, and the low-strength hydration products are promoted to be converted into high-strength hydration products.

Owner:安徽三环管业有限公司

A kind of ultra-thin continuous fiber reinforced thermoplastic resin prepreg and preparation method thereof

The invention discloses a preparation method of a continuous fiber reinforced thermoplastic resin prepreg. The method comprises the steps of: (1) thinning continuous fiber; and (2) impregnating the thinned fiber prepared in step (1) with thermoplastic resin melt. The method provided by the invention particularly can realize impregnation of fiber in high temperature and high viscosity PEEK resin so as to obtain high performance continuous fiber reinforced thermoplastic prepreg.

Owner:BEIHANG UNIV

Nano-filler concrete tubular pile and preparation method therefor

The invention discloses a nano-filler concrete tubular pile. According to the nano-filler concrete tubular pile, through doping ethoxylated rubber fibers, the internal pore structure of concrete can be effectively improved, and a large number of closed pores are formed, so that capillary pores are prevented from forming a continuous and perforated meshed structural system, an anti-carbonization zone is formed, and a further reinforcing effect on inhibition of intrusion of carbon dioxide is exerted; in addition, the nano-filler concrete tubular pile has the advantages that the content of harmful pores and defects in a concrete structure can be reduced, the alkalinity of hydration products is lowered, and the transformation of low-strength hydration products to high-strength hydration products is prompted.

Owner:ANHUI XINRUN NEW MATERIALS

Bauxite and brucite concrete tubular pipe and preparation method therefor

InactiveCN105060818AImprove hydrophilicityHigh strengthSolid waste managementPolyethylene glycolWaste rubber

The invention discloses a bauxite and brucite concrete tubular pipe which is prepared from the raw materials in parts by weight: 2-3 parts of dinonyl barium naphthalenesulfonate, 13-20 parts of bauxite, 1-2 parts of calcium phosphate, 0.1-0.2 part of sodium thiosulfate, 3-7 parts of brucite amianthine, 7-10 parts of n-methyl pyrrolidinone, 500-640 parts of common silicate cement, 300-400 parts of yellow sand, 200-300 parts of gravels, 7-15 parts of a polycarboxylic acid based superplasticizer, 16-20 parts of polyethylene wax, 0.1-0.2 part of dibenzoyl peroxide, 5-6 parts of maleic anhydride, 2-3 parts of polyethylene glycol monomethyl ether, 4-7 parts of ethyecellulose, 0.7-2 parts of sp-80 and 50-70 parts of waste rubber powder. By doping ethoxylated rubber fiber, the inner pore structure of the concrete can be effectively improved to form a lot of close pores so as to prevent capillary pores from forming a continuous cut-through netty structural system, thereby forming an anti-carbonizing zone which plays a reinforcing effect in inhibiting invasion of carbon dioxide.

Owner:六安市永发新型建材有限责任公司

Composite fiber reinforced concrete pile and preparation method therefor

InactiveCN105036643AImprove hydrophilicityHigh strengthSolid waste managementPolyethylene glycolWaste rubber

The present invention discloses a composite fiber reinforced concrete pile. The pile consists of the following materials in parts by weight: 2-3 parts of flax fiber,2-4 parts of alum powder, 0.8-2 parts of triethanolamine oleic soap, 3-5 parts of polystyrene fiber, 1-2 parts of ammonium metaborate, 4-6 parts of n- methylpyrrolidone, 500-640 parts of ordinary Portland cement, 300-400 parts of yellow sand, 200-300 parts of crushed stone, 7-14 parts of a polycarboxylate superplasticizer, 0.1-0.2 parts of benzoyl peroxide, 5-6 parts of maleic anhydride, 2-3 parts of polyethylene glycol monomethyl ether, 0.7-2 parts of sp-80, 50-70 parts of waste rubber powder, 0.1-0.2 parts of triethylamine, and 16-20 parts of polyethylene wax. The composite fiber reinforced concrete pile of the invention is high in strength and good in resistance to corrosion caused by sulfate.

Owner:安徽三环管业有限公司

Graphene dispersing agent, preparation method thereof and preparation method of graphene

ActiveCN103623741BGood dispersionAttractiveOrganic chemistryTransportation and packagingImideGraphene

The invention provides a graphene dispersing agent as shown in a formula (I), a formula (II) or a formula (III) in the Specification. The graphene dispersing agent consists of a naphthalene tetracarboxylic acid bisimide unit, an anion group and an alkyl chain. Firstly, the naphthalene tetracarboxylic acid bisimide unit and graphene have strong attraction to each other, so that the whole molecules can be combined with the graphene; secondly, the anion group has excellent water solubility, so that the combined object of the molecules and the graphene can be fully dispersed in water; moreover, the alkyl chain can be used for separating the naphthalene tetracarboxylic acid bisimide unit from the anion group, so that the naphthalene tetracarboxylic acid bisimide unit and the anion group can act independently. Therefore, through the combination of the naphthalene tetracarboxylic acid bisimide unit, the anion group and the alkyl chain, the graphene dispersing agent provided by the invention has excellent graphene dispersing capability; the graphene prepared by using the graphene dispersing agent and adopting an ultrasonic method is not subjected to the oxidation-reduction process, so that the flaw content is low, and the preparation cost is low.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Method for Improving Rare Earth Ion Doped Inorganic Fluoride Upconversion Luminescence Intensity

ActiveCN105885844BLow defect contentUp-conversion emission enhancementLuminescent compositionsUpconversion luminescenceQuantum efficiency

The invention discloses a method for improving up-conversion luminescence intensity of rare earth ion doped inorganic fluoride. According to the method, pre-synthesized rare earth doped inorganic fluoride is mixed with a solution containing alkali metal cations and fluoride ions, an obtained mixture is subjected to a sufficient reaction at a high temperature, the alkali metal cations and the fluoride ions added to the solution all participate in material modification, luminescence quenching centers in the inorganic fluoride can be reduced, and the up-conversion luminescence intensity and the quantum efficiency of the rare earth ion doped inorganic fluoride can be improved greatly.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

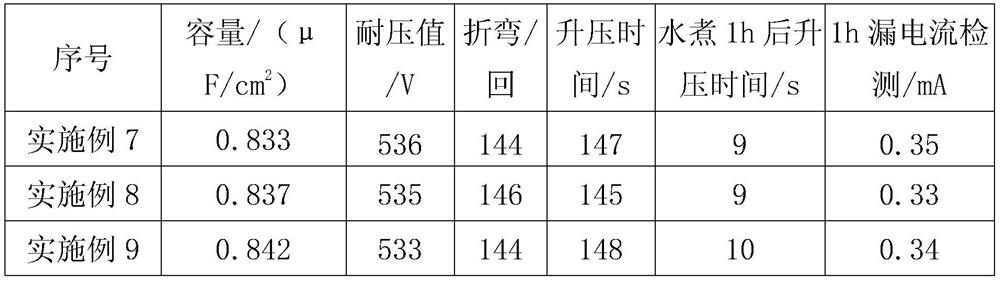

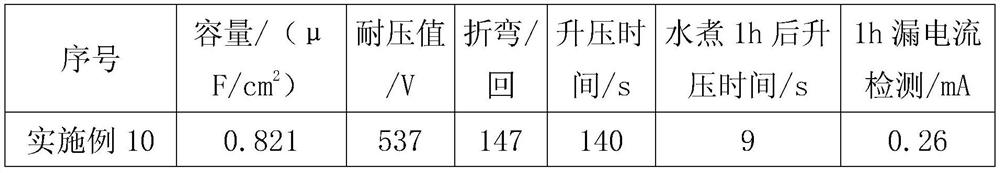

Six-stage formation process of high-stability high-voltage anode foil

ActiveCN112117130AImproves hydration resistanceReduce leakageElectrolytic capacitorsO-Phosphoric AcidPhysical chemistry

The invention relates to a six-stage formation process of a high-stability high-voltage anode foil. The invention discloses a six-stage formation process of a high-stability high-voltage anode foil. The six-stage formation process comprises the following steps: (1), performing pretreatment; (2), performing primary formation; (3), performing secondary formation; (4), performing monobutyl phosphatetreating 1; (5), performing third-stage formation; (6), performing fourth-stage formation; (7), carrying out sheet burning treatment 1; (8), performing phosphoric acid treatment 1; (9), performing five-stage formation; (10), performing' six-stage formation; (11), performing phosphoric acid treatment 2; (12), repairing the rear end 1; (13), performing phosphoric acid treatment 3; (14), repairing the rear end 2; (15). carrying out sheet burning treatment 2; (16), repairing the rear end 3; and (17), performing post-treatment. The six-stage formation process of the high-stability high-voltage anode foil is simple in process and easy to operate, the high-stability high-voltage anode foil can be produced in batches, and the produced anode foil has the multiple advantages of being high in capacity, low in electric leakage, high in bending and high in hydration resistance.

Owner:XINJIANG JOINWORLD CO LTD +1

Semiconductor device and method of forming the same

ActiveCN108257849BImprove electrical performanceReduce germanium contentSemiconductor/solid-state device manufacturingSemiconductor devicesReduction treatmentDevice material

The present invention provides a semiconductor device and a formation method thereof. The formation method comprises the steps of: providing a base, wherein the base comprises a substrate and a germanium-silicon layer located on the substrate; performing oxidation treatment of the germanium-silicon layer, and forming an oxygen-containing germanium-silicon layer on the germanium-silicon layer; performing reduction treatment of the surface of the germanium-silicon layer, and reducing the germanium content in the oxygen-containing germanium-silicon layer; after the reduction treatment, forming ahigh k-gate medium layer on the oxygen-containing germanium-silicon layer; and forming a metal gate on the high k-gate medium layer. The semiconductor device and the formation method thereof improve the interface performances between a germanium-silicon channel region and the high k-gate medium layer and improve the quality of the formed high k-gate medium layer so as to improve the electrical properties of the formed semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

High friction uplift-resistant concrete tubular pile and preparation method thereof

The present invention discloses a high friction uplift-resistant concrete tubular pile. According to the present invention, with doping of the ethoxylated rubber, the internal pore structure of concrete can be effectively improved and a large number of closed pores are formed, such that the capillary pores can be prevented from formation of the continuous and penetrating network structure system, the anti-carbonation zone can be formed, and the further enhancement effect is provided for the inhibition of the intrusion of carbon dioxide; and the contents of the harmful pores and the defects in the concrete structure can be effectively reduced, the alkality of the hydration product is reduced, and the conversion of the low strength hydration product to the high strength hydration product is promoted.

Owner:六安市永发新型建材有限责任公司

A kind of blsfmc/cmfo thin film with resistive switching effect and preparation method thereof

ActiveCN109111127BImprove multiferroic performanceReduce leakage current densityPerovskite (structure)Resistive switching

The invention provides a BLSFMC / CMFO film with a resistance switching effect and a preparation method thereof, comprising an upper film and a bottom film compounded together; the chemical formula of the bottom film is Co 1‑ x mn x Fe 2 o 4 , which is a twisted cubic inverse spinel structure, the space group is Fd3m; the chemical formula of the upper layer is Bi 0.79 La 0.18 Sr 0.03 Fe 0.94 mn 0.04 co 0.02 o 3 , which is a distorted rhombohedral perovskite structure, space group R3c; wherein, x=0˜0.8. It is prepared by sol-gel method and layer-by-layer annealing process. The present invention through the BiFeO 3 Doping the thin film improves the ferroelectric properties, by doping BiFeO 3 Thin film composite CoFe 2 o 4 The magnetic layer realizes the resistive switching effect of the ferroelectric / ferromagnetic composite thin film regulated by ferroelectric polarization.

Owner:SHAANXI UNIV OF SCI & TECH

Modified fiber concrete tubular pile and preparation method thereof

InactiveCN106186912AImprove hydrophilicityHigh strengthShaping reinforcementsFiberPolyethylene glycol

The invention discloses a modified fiber concrete tubular pile. The modified fiber concrete tubular pile comprises, by weight, 0.1-0.2 parts of dimethylolpropionic acid, 7-10 parts of n-methylpyrrolidone, 10-20 parts of bone black, 500-640 parts of ordinary portland cement, 300-400 parts of yellow sand, 200-300 parts of broken stone, 7-15 parts of a polycarboxylic acid water reducer, 16-20 parts of polyethylene wax, 0.1-0.2 parts of dibenzoyl peroxide, 5-6 parts of maleic anhydride, 2-3 parts of methoxy polyethylene glycol, 4-7 parts of ethyl cellulose, 0.7-2 parts of sp-80, 50-70 parts of waste and old rubber powder, 0.1-0.2 parts of triethylamine and 2-3 parts of an IPDI trimer. The modified fiber concrete tubular pile further improves carbon dioxide intrusion inhibition, reduces harmful aperture and defect contents of a concrete structure, reduces hydration product alkalescence and promotes conversion of a low strength hydration product into a high strength hydration product.

Owner:ANHUI XINRUN NEW MATERIALS

A Six-Stage Formation Process of High Stability High Voltage Anode Foil

ActiveCN112117130BImproves hydration resistanceReduce leakageElectrolytic capacitorsHydration reactionO-Phosphoric Acid

The invention is a six-stage chemical formation process of high-stability high-voltage anode foil. A six-stage chemical formation process for high-voltage high-voltage anode foils with high stability, including: (1) pretreatment; (2) primary chemical formation; (3) secondary chemical formation; (4) monobutyl phosphate treatment 1; (6) Four-stage chemical formation; (7) Sintered sheet treatment 1; (8) Phosphoric acid treatment 1; (9) Five-stage chemical formation; (10) Six-stage chemical formation; (11) Phosphoric acid treatment 2; (12) After (13) phosphoric acid treatment 3; (14) back-end repair 2; (15) burn-in treatment 2; (16) back-end repair 3; (17) post-treatment. The six-stage formation process of a high-stability high-voltage anode foil described in the present invention has a simple process and is easy to operate, and can produce high-stability high-voltage anode foil in batches, and the anode foil produced has high capacity, low leakage, and high bending And the multiple advantages of strong hydration resistance.

Owner:XINJIANG JOINWORLD CO LTD +1

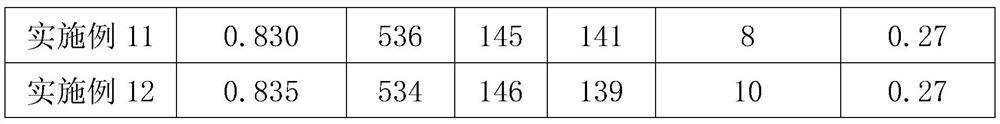

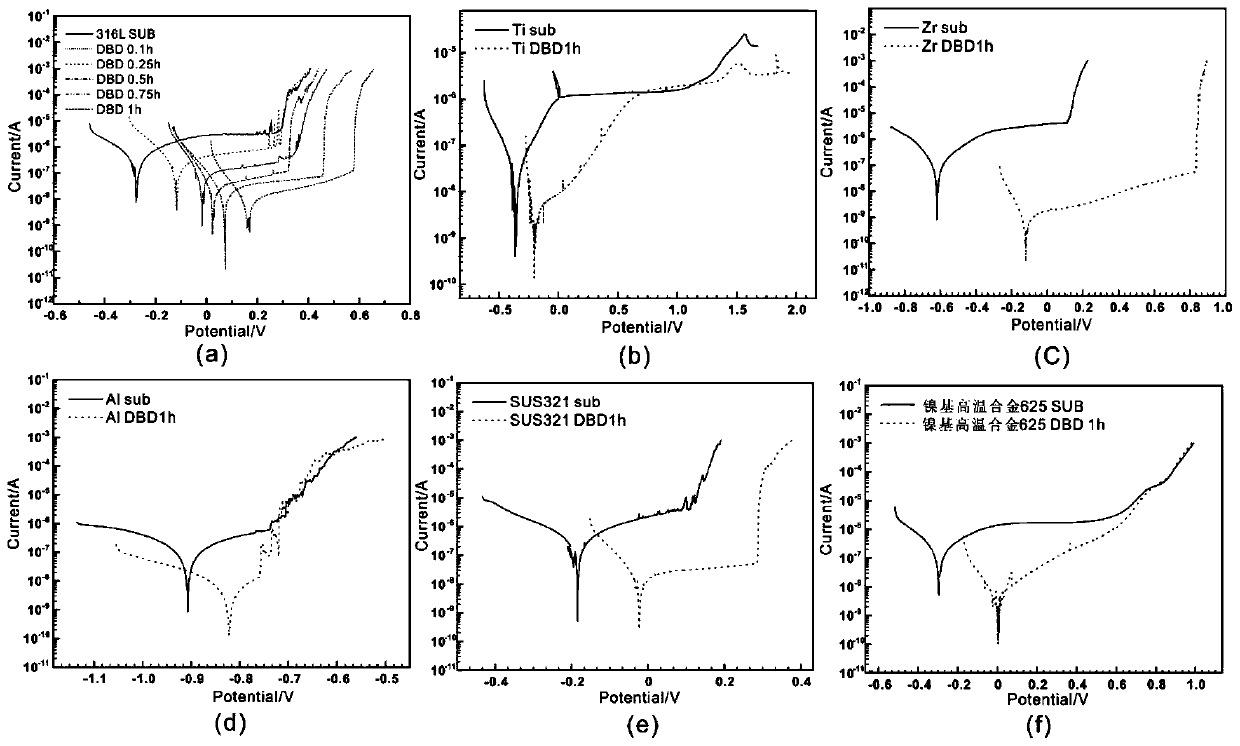

Treatment method for modifying metal passivation film through dielectric barrier discharge

InactiveCN111455309AAccelerated corrosionImprove high temperature resistanceSolid state diffusion coatingThin metalDielectric plate

The invention discloses a treatment method for modifying a metal passivation film through dielectric barrier discharge. The method comprises the following steps of firstly, polishing metal to be treated, and carrying out ultrasonic vibration washing in absolute ethyl alcohol and acetone separately to obtain a vibration washing sample; secondly, drying the vibration washing sample, and storing thevibration washing sample in a vacuum environment for later use; and finally, preheating a double-dielectric barrier discharge instrument, setting device parameters, then placing a standby sample to betreated between dielectric plates, carrying out frequency modulation until stable current output is achieved, after dielectric barrier discharge treatment is completed, turning off a power supply, taking out the treated sample, and obtaining a thickened passivation film on the surface of the treated sample. The method is low in cost, easy to operate, efficient and suitable for various metals andalloys, the corrosion resistance and high-temperature oxidation resistance of the modified passivation film are greatly improved, a new thought and means can be provided for metal surface protection,and application and development of metal materials and ultrathin metal oxide film layers can be greatly promoted.

Owner:XI AN JIAOTONG UNIV

Aluminate red phosphor activated by manganese ion and preparation method thereof

The invention provides an aluminate red phosphor activated by manganese ion and a preparation method thereof. A feature chemical general formula of the red phosphor is that M1-xAl12O19-2xA2x: Mnx, wherein M is at least one type of Mg, Ca, Sr or Ba, A is C1 or F and 0<x<=0.1. The preparation method comprises the steps: oxide of the Mg, the Ca, the Sr, the Ba or the Mn or relative salt, aluminum oxide, halide containing Cl iron and F iron are accurately weighed according to a ratio of the general formula, evenly mixed with a fluxing agent, sintered for 1 hour to 2 hours at the temperature of 600 DEG C-800 DEG C and then sintered for 4 hours to 10 hours at the temperature of 1500 DEG C-1630 DEG C. The powder obtained after sintering is smashed, washed, screened, water-powder-separated and dried so that the aluminate red phosphor activated by the manganese ion is obtained. The red phosphor is capable of emitting red light rays of 620 nm-700 nm under action of light of 250 nm-500 nm and has the advantages that in the range from ultraviolet to a visible region, absorption is performed by a board band, emitting is performed by a narrow band and color purity is high. The red phosphor is suitable for ultraviolet and a blue ray light emitting diode (LED) chip.

Owner:GUANGDONG INST OF RARE METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com