A kind of ultra-thin continuous fiber reinforced thermoplastic resin prepreg and preparation method thereof

A thermoplastic resin and enhanced thermoplastic technology, applied in the direction of coating, can solve the problems of difficult to achieve high temperature resistance and high viscosity, large deformation of prepreg, environmental pollution, etc., to reduce defects and facilitate infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059]By adjusting the extruded amount of the thermoplastic high-temperature melt extruded by the extruder docked with the impregnated die and the distance between the exits of the impregnated die, the raw materials and feed ratios used to prepare the continuous carbon fiber reinforced thermoplastic prepreg are controlled as follows:

[0060] Continuous carbon fiber (Toray T700SC, 12K continuous carbon fiber) 50wt%,

[0061] Polyetheretherketone resin (melt index at 380°C is 85g / 10min) 50wt%;

[0062] The preparation process includes the following steps:

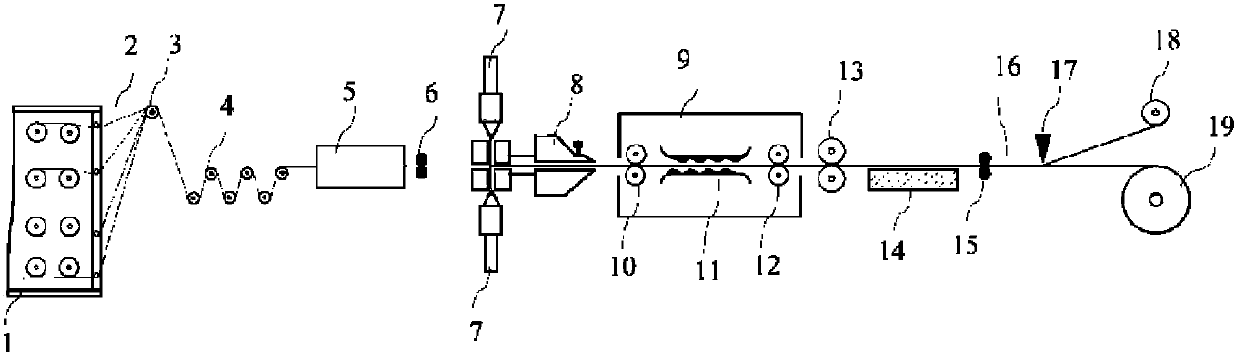

[0063] First, the continuous carbon fiber yarn 2 is placed on the creel 1, and the continuous carbon fiber yarn 2 is drawn to the needle-shaped yarn guide device 3 under the action of the rubber pulling roller 6, so that the continuous carbon fiber yarn 2 is evenly arranged; the evenly arranged continuous carbon fiber yarn 2 Pass through the fiber thickness adjustment device 4 to adjust the thickness of the carbon fiber yar...

Embodiment 2

[0079] The extrusion rate of the thermoplastic high-temperature melt extruded by the extruder docked with the impregnation die and the outlet distance of the impregnation die are controlled to prepare the continuous carbon fiber reinforced thermoplastic prepreg raw material and the feed ratio as follows:

[0080] Continuous carbon fiber (Toray T700SC, 12K continuous carbon fiber) 50wt%,

[0081] Polyetheretherketone resin (melt index at 380°C is 85g / 10min) 50wt%;

[0082] The preparation process includes the following steps:

[0083]First, the continuous carbon fiber yarn 2 is placed on the creel 1, and the continuous carbon fiber yarn 2 is drawn to the needle-shaped yarn guide device 3 under the action of the rubber pulling roller 6, so that the continuous carbon fiber yarn 2 is evenly arranged; the evenly arranged continuous carbon fiber yarn 2 Pass through the fiber thickness adjustment device 4 to adjust the thickness of the carbon fiber yarn to about 40 μm and the width ...

Embodiment 3

[0088] The extrusion rate of the thermoplastic high-temperature melt extruded by the extruder docked with the impregnation die and the outlet distance of the impregnation die are controlled to prepare the continuous carbon fiber reinforced thermoplastic prepreg raw material and the feed ratio as follows:

[0089] Continuous carbon fiber (Toray T700SC, 12K continuous carbon fiber) 50wt%,

[0090] Polyetheretherketone resin (melt index at 380°C is 85g / 10min) 50wt%;

[0091] The preparation process includes the following steps:

[0092] First, the continuous carbon fiber yarn 2 is placed on the creel 1, and the continuous carbon fiber yarn 2 is drawn to the needle-shaped yarn guide device 3 under the action of the rubber pulling roller 6, so that the continuous carbon fiber yarn 2 is evenly arranged; the evenly arranged continuous carbon fiber yarn 2 Pass through the fiber thickness adjustment device 4 to adjust the thickness of the carbon fiber yarn to about 30 μm and the width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com