A kind of blsfmc/cmfo thin film with resistive switching effect and preparation method thereof

A technology of resistive switch and thin film, applied in the field of BLSFMC/CMFO thin film and its preparation, can solve the problems of difficult to meet strong magnetoelectric coupling, difficult to obtain, high residual polarization value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The BLSFMC / Co 1-x mn x Fe 2 o 4 The preparation method of composite film, comprises the following steps:

[0036] Step 1: Add Co(NO 3 ) 2 ·6H 2 O, C 4 h 6 MnO 4 4H 2 O and Fe(NO 3 ) 3 9H 2 O is (1-x) in molar ratio: x: 2 is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride, stirs evenly, obtains Co 1-x mn x Fe 2 o 4 Precursor;

[0037] Step 2: Coating Co on the FTO / Glass substrate by spin coating method 1-x mn x Fe 2 o 4 Precursor, get Co 1- x mn x Fe 2 o 4 Wet film, the wet film is baked at 195-200°C to obtain a dry film after uniform glue, and then annealed at 550-600°C to obtain crystalline Co 1-x mn x Fe 2 o 4 film;

[0038] Step 3: To be crystalline Co 1-x mn x Fe 2 o 4 After natural cooling of the film, the crystalline Co 1-x mn x Fe 2 o 4 Repeat step 2 on the film to reach the desired thickness, that is, to obtain Co 1-x mn x Fe 2 o 4 film;

[0039] Step 4: Bi(NO 3 ) 3 ·5H 2 O, La(NO...

Embodiment 1

[0051] Step 1, Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 1:2, and stirred evenly for 2 hours to obtain CoFe 2 o 4 Precursor, CoFe 2 o 4 The concentration of metal ions in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0052] Step 2, spin coating CoFe on FTO / Glass substrate by spin coating method 2 o 4 Precursor solution, the homogenization speed is 4000r / min, the homogenization time is 15s, and the CoFe 2 o 4 Wet film, bake the wet film at 200°C for 8 minutes to obtain a dry film, and then anneal at 600°C for 30 minutes to obtain crystalline CoFe 2 o 4 film;

[0053] Step 3, to be crystalline CoFe 2 o 4 After natural cooling of the film, the crystalline CoFe 2 o 4 Repeat step 2 on the film to achieve the desired thickness, that is, to obtain CoFe 2 o 4 film;

[0054] Step 4, th...

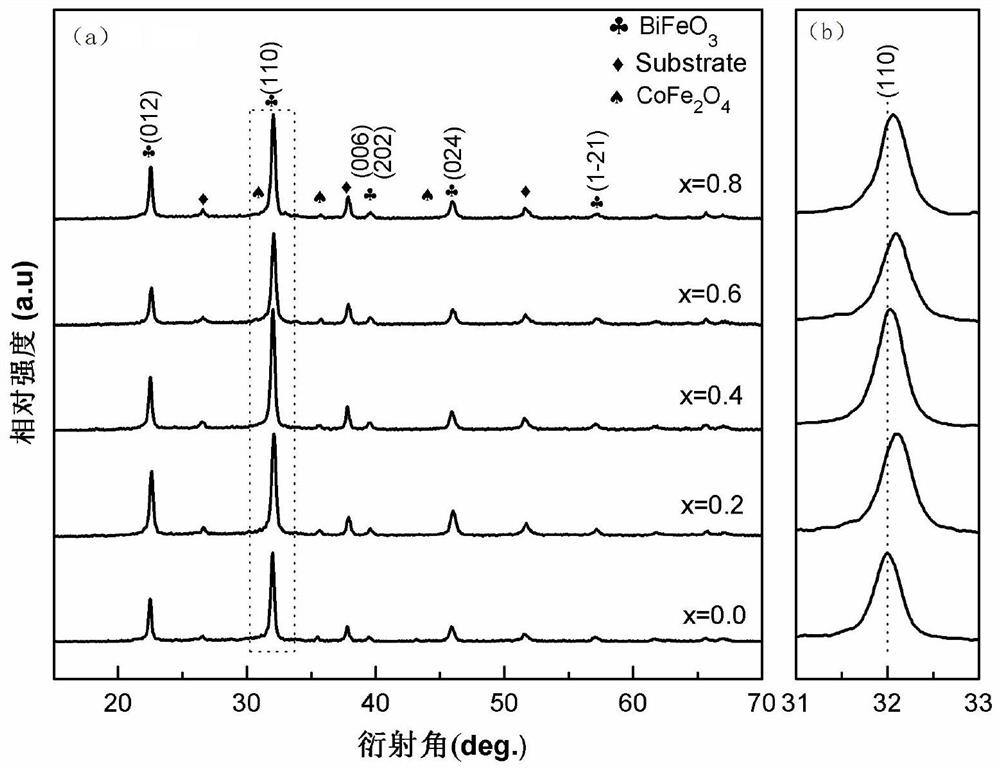

Embodiment 2

[0058] Step 1, Co(NO 3 ) 2 ·6H 2 O, C 4 h 6 MnO 4 4H 2 O and Fe(NO 3 ) 3 9H2 O is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride with a molar ratio of 0.8:0.2:2, and stirred evenly for 2h to obtain Co 0.8 mn 0.2 Fe 2 o 4 Precursor, Co 0.8 mn 0.2 Fe 2 o 4 The concentration of metal ions in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0059] Step 2, Spin Coating Co on FTO / Glass Substrate by Spin Coating 0.8 mn 0.2 Fe 2 o 4 Precursor solution, the homogenization speed is 4000r / min, the homogenization time is 15s, and the Co 0.8 mn 0.2 Fe 2 o 4 Wet film, bake the wet film at 200°C for 8 minutes to obtain a dry film, and then anneal at 600°C for 30 minutes to obtain crystalline Co 0.8 mn 0.2 Fe 2 o 4 film;

[0060] Step 3, to be crystalline Co 0.8 mn 0.2 Fe 2 o 4 After natural cooling of the film, the crystalline Co 0.8 mn 0.2 Fe 2 o 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com