Silicon-based solar cell

A solar cell and silicon-based technology, applied in the field of solar cells, can solve the problems of single-layer graphene with many transfer defects, few-layer graphene with small area, and not suitable for mass production, so as to facilitate electron transmission and improve light transmittance , the effect of less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

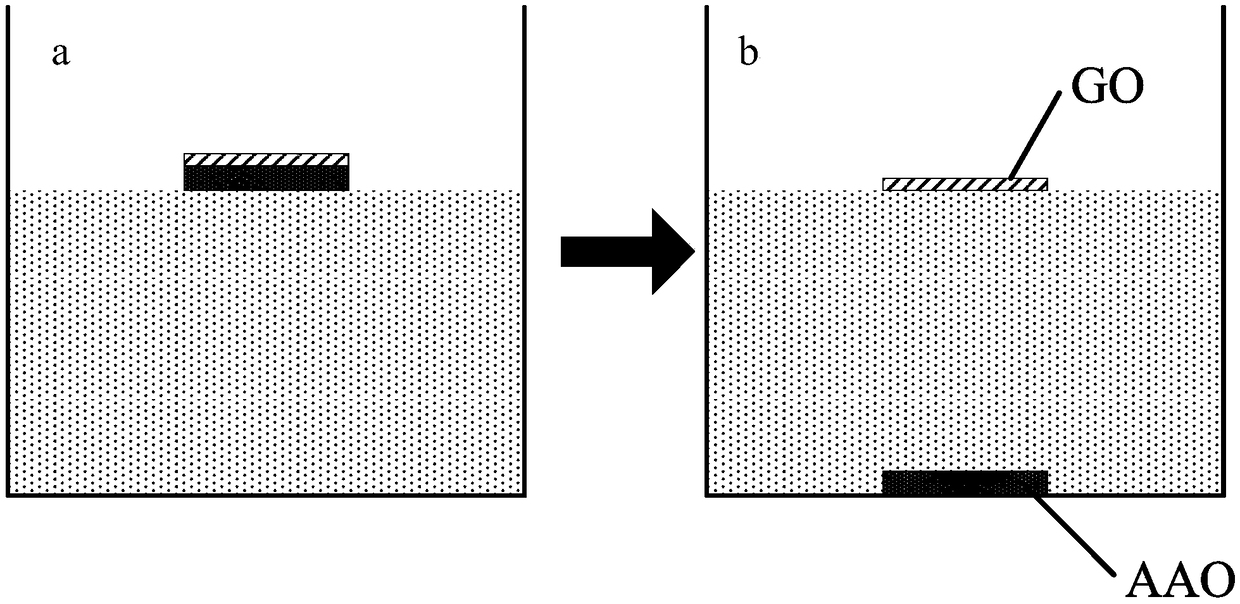

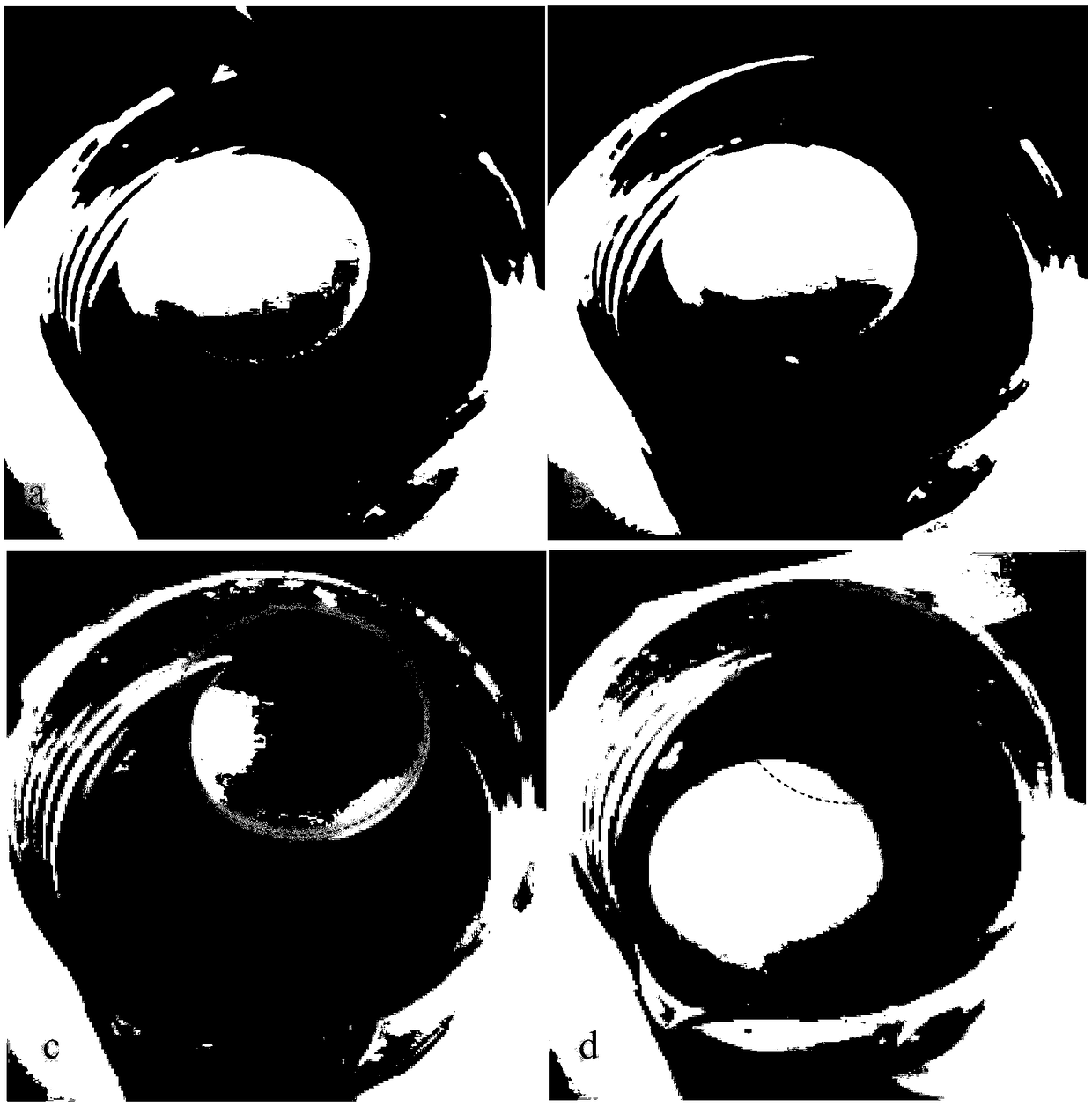

[0023] Such as figure 1 As shown, by controlling the concentration of the graphene solution, an ultra-thin graphene oxide film is obtained by suction filtration on the AAO base membrane by suction filtration; , placed on the water surface with the graphene membrane facing up, such as figure 1 a and 2a; press the AAO basement membrane, as figure 2 b, AAO basement membrane begins to sink, as figure 2 c, Finally, the AAO basement membrane sinks to the bottom of the cup, and the graphene membrane (inside the dotted circle) floats on the water surface, as shown in figure 1 b and 2d.

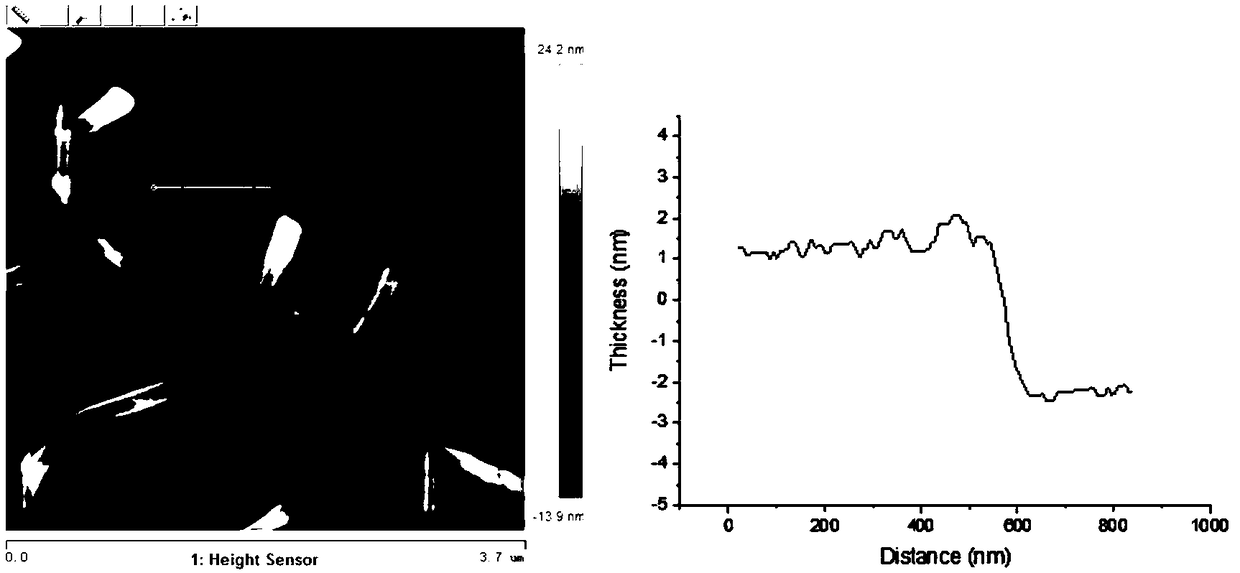

[0024] Use a silicon chip to pick up the graphene film floating on the water surface from bottom to top, so that the graphene film is tiled on the surface of the substrate, evaporate the water in the graphene oxide film at room temperature for 30 minutes, and measure the water content of the graphene oxide film as 54wt%; the graphene oxide film after the evaporation treatment is freeze-dried, an...

Embodiment 2

[0028] By controlling the concentration of the graphene solution, the ultra-thin reduced graphene oxide film is obtained by suction filtration at the AAO base membrane by suction filtration; Place the graphene membrane facing upwards, place it on the water surface, press the edge of the AAO basement membrane, the AAO basement membrane begins to sink, and finally, the AAO basement membrane sinks to the bottom of the cup, the graphene membrane floats on the water surface, and the graphene membrane is successfully peeled off.

[0029] Use a silicon chip to pick up the graphene film floating on the water surface from bottom to top, so that the graphene film is tiled on the surface of the substrate, evaporate the water in the graphene oxide film at room temperature for 30 minutes, and measure the water content of the graphene oxide film as 67wt%; The graphene oxide film after the evaporation treatment is freeze-dried, and the graphene oxide film is detached from the silicon wafer su...

Embodiment 3

[0033] By controlling the concentration of the graphene solution, the ultra-thin reduced graphene oxide film is obtained by suction filtration at the AAO base membrane by suction filtration; Place the graphene membrane facing upwards, place it on the water surface, press the edge of the AAO basement membrane, the AAO basement membrane begins to sink, and finally, the AAO basement membrane sinks to the bottom of the cup, the graphene membrane floats on the water surface, and the graphene membrane is successfully peeled off.

[0034] Use a silicon chip to pick up the graphene film floating on the water surface from bottom to top, so that the graphene film is tiled on the surface of the substrate, evaporate the water in the graphene oxide film at room temperature for 30 minutes, and measure the water content of the graphene oxide film as 75wt%; the graphene oxide film after the evaporation treatment is freeze-dried, and the graphene oxide film is detached from the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com