Method for improving up-conversion luminescence intensity of rare earth ion doped inorganic fluoride

A rare earth ion, luminous intensity technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of complex operation and high cost, and achieve the effect of reducing defect content, low cost, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 of the method of the present invention includes the following steps:

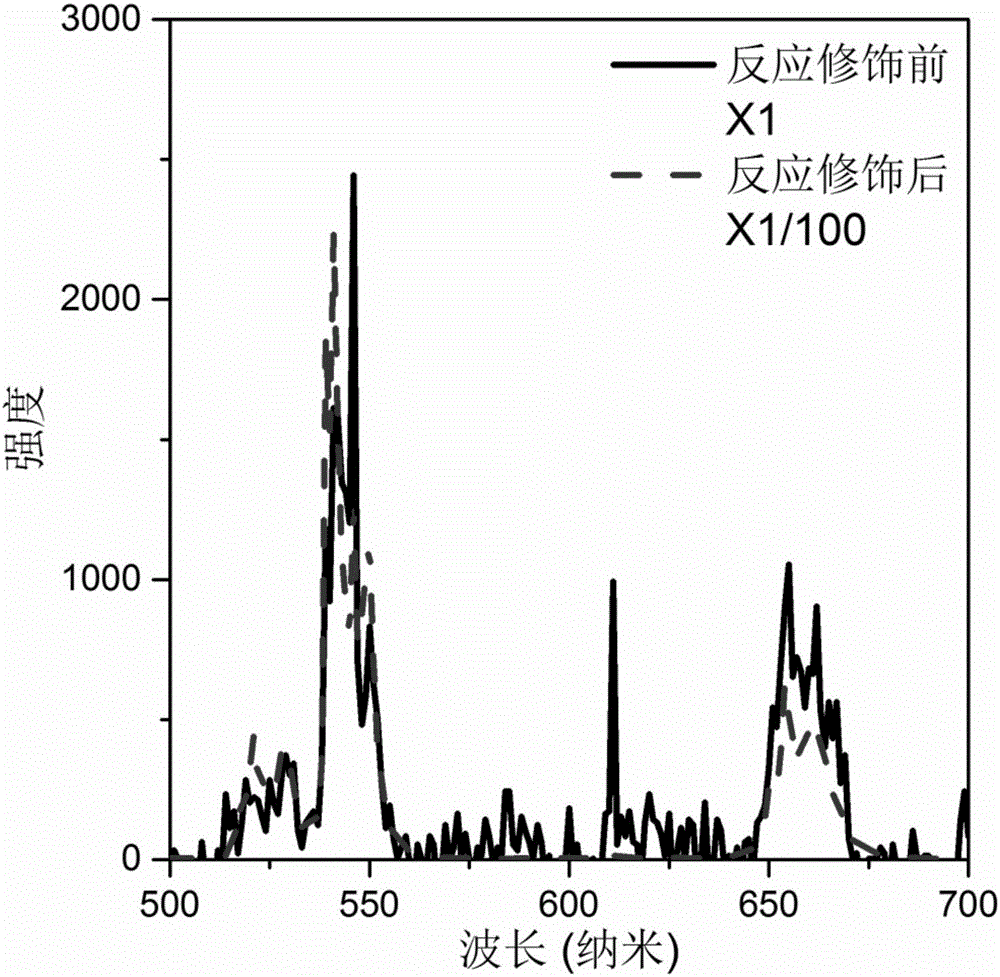

[0024] (1) Hydrothermal synthesis of β-NaYF using sodium citrate as rare earth ion complexing agent 4 : 20mol% Yb 3+ ,2mol% Er 3+ Fluoride powder crystals. Measure 2.6ml Y(NO 3 ) 3 Solution, 2.0ml Yb(NO 3 ) 3 Solution, 0.4ml of Er(NO 3 ) 3 The solution, 10ml of aqueous solution, 0.5882g of sodium citrate dihydrate were mixed and stirred for 30min. Then 15ml of NaF aqueous solution containing 0.5249g was added to this solution, mixed and stirred for 15min. Finally, the mixed solution was transferred to a 50ml polytetrafluoroethylene bottle, put into a stainless steel autoclave, sealed, heated to 180°C, and kept for 24h. It is naturally cooled to room temperature, and the synthesized crystal is obtained by centrifugation, the size is about 2.5 μm, and it has a hexagonal disk shape. Dry in a drying oven at 80°C for 12 hours, set aside. Weigh 0.0902g of the synthesized rare earth doped fluor...

Embodiment 2

[0029] Embodiment 2 of the method of the present invention includes the following steps:

[0030] (1) Select the β-NaYF synthesized in Example 1 4 : 20mol% Yb 3+ ,2mol% Er 3+ The fluoride powder crystal was used as the modified object, weighing 0.4806 g. Select NaF and NH 4 HF 2 As a carrier of alkali metal cations and fluoride ions, weighing 0.1105g of NaF, NH 4 HF 2 0.2744g.

[0031] (2) Measure 4.0ml of H 2 O, added to the solid mixture, mixed and stirred for 5 min.

[0032] (3) Transfer the mixed system to a 25ml polytetrafluoroethylene bottle, put it into a stainless steel autoclave, seal, heat to 200°C, and react for 24 hours.

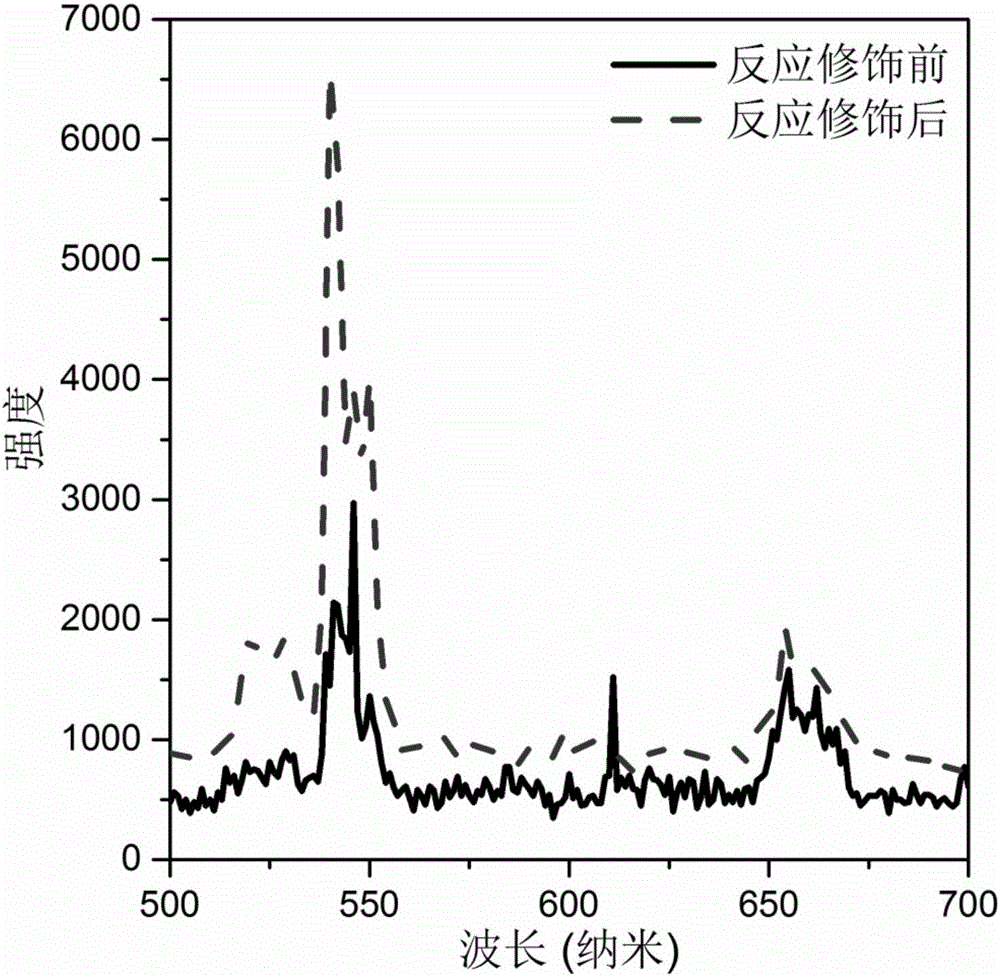

[0033] (4) After the reaction is completed, it is naturally cooled to room temperature, washed with water by centrifugation, and dried at 60° C. to obtain modified rare earth ion-doped inorganic fluoride. The luminescence spectrum of the synthesized crystal under 980nm laser excitation before and after the modification reaction is shown in figure 2 Sh...

Embodiment 3

[0035] Embodiment 3 of the method of the present invention includes the following steps:

[0036] (1) Select the β-NaYF synthesized in Example 1 4 : 20mol% Yb 3+ ,2mol% Er 3+ The fluoride powder crystal was used as the modified object, weighing 0.1605g. Select LiF as the carrier of alkali metal cation and fluoride ion, and weigh 0.1541g.

[0037] (2) Measure 1.6ml of H 2 O, added to the solid mixture, mixed and stirred for 5 min.

[0038] (3) Transfer the mixed system to a 25ml polytetrafluoroethylene bottle, put it into a stainless steel autoclave, seal, heat to 220°C, and react for 16h.

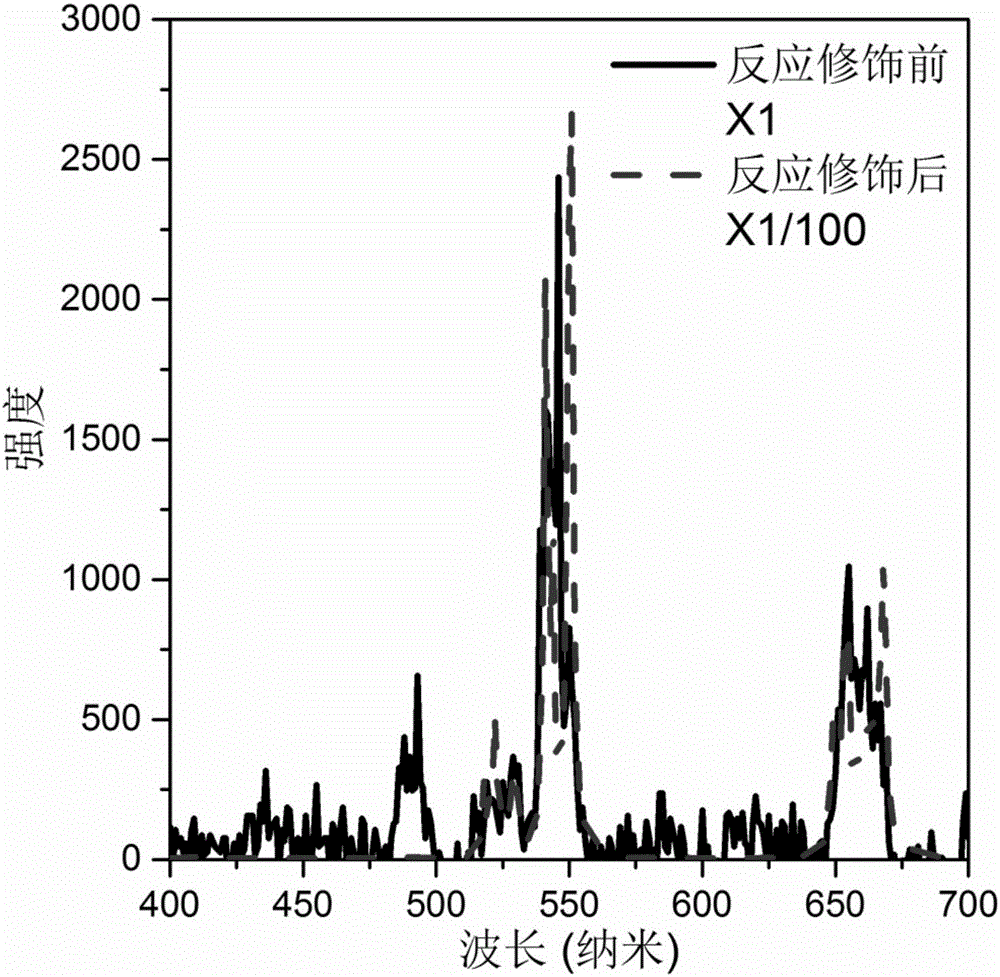

[0039] (4) After the reaction is completed, it is naturally cooled to room temperature, washed with water by centrifugation, and dried at 60° C. to obtain modified rare earth ion-doped inorganic fluoride. The luminescence spectrum of the synthesized crystal under 980nm laser excitation before and after the modification reaction is shown in image 3 Show in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com